Abstract

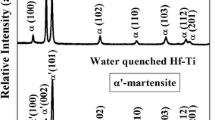

The degradation of reprocessing materials to nitric acid corrosion in aqueous spent fuel nuclear reprocessing plants is an unwanted and serious issue. The PUREX (Plutonium URanium EXtraction) process employs head-end treatment of chemical or mechanical decladding followed by the dissolution of spent fuel in different nitric acid concentrations (1–14 M HNO3), feed clarification, and chemical conditions of the solution for solvent extraction. These construction materials demand a high integrity and resistance to corrosion for components like fuel dissolvers, evaporators, waste storage tanks, piping, etc. The materials most commonly used for spent reprocessing plants are austenitic grades of type 304L stainless steels (SS), with restricted trace elements of C, B, Si, P, S, Mo, etc., and AISI type 300 series of stabilized grade, Si-based nitric acid grade SS, along with small quantities of refractory metals like titanium and zirconium alloys. Alternatively, aluminium alloys, Ni, Ti and Zr-based bulk metallic glasses alloys, and recently, oxide dispersion strengthened steels have also been investigated. Similarly, the material degradation due to tribocorrosion, i.e., the synergistic interactions between wear and corrosion of reprocessing materials of type 304L SS, Ti-grade 2, Zr-702 and Zircaloy-4 materials in the nitric acid medium are also briefly addressed. In the nuclear reprocessing environment, the tribocorrosion phenomena are encountered in a continuous rotary dissolver, solvent extraction apparatus, moving parts, and also some frictional or moving components are subjected to scratches or wear- or flow-induced vibrations in a nitric acid medium. Despite its practical importance, little basic research has been devoted to understanding the synergistic mechanism involved in a tribocorrosion system of materials used in nuclear reprocessing plants. Finally, the corrosion acceleration process and factors affecting the structural materials specific to the reprocessing environments in the nitric acid environment are presented. It is essential that providing an understanding of the corrosion degradation processes and its mechanism of structural materials will be useful in minimizing the nitric acid corrosion of reprocessing materials.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kamachi Mudali U (2017) Materials for hostile corrosive environments.In: Tyagi AK, Banerjee S (eds) Materials under extreme conditions - recent trends and future prospects. Elsevier, pp 91–128

Kamachi Mudali U (2013) Austenitic stainless steels for back end of nuclear fuel cycle. Adv Mat Res 794:530–538

Raj B, Kamachi Mudali U (2006) Materials development and corrosion problems in nuclear fuel reprocessing plants. Prog Nucl Energy 48:283–380

U. Kamachi Mudali, R.K Dayal and J.B Gnanamoorthy, Corrosion studies on materials of construction for spent nuclear fuel reprocessing plant equipment, Journal of Nuclear Materials 203 (1993) pp. 73–82.

Whillock GOH, Worthington SE (2010) Corrosion in nitric acid. In: Richardson TJA, Cottis BRA, Lindsay R, Lyon S, Scantlebury DJD, Stott H, Graham M (eds) Shreir’s corrosion, vol 2. Amsterdam, Elsevier Ltd, pp 1250–1269

Schillmoller CM (1999) Select the best alloys to resist nitric acid. Chem Eng Prog 95:65–69

Ahluwalia HS, Corrosion by nitric acid, ASM handbook. In: SD Cramer, BS Covino Jr (eds) Corrosion: environments and industries, vol 13C, pp 668–673

Herbst RS, Baron P, Nilsson M (2011) Standard and advanced separation: PUREX processes for nuclear fuel reprocessing. In: Advanced separation techniques for nuclear fuel reprocessing and radioactive waste treatment, pp 141–175

Fauvet P, Balbaud F, Robin R, Tran Q-T, Mugnier A, Espinoux D (2008) Corrosion mechanisms of austenitic stainless steels in nitric media used in reprocessing plants. J Nucl Mater 375:552–564

Yamamota T, Tsukui S, Okamoto S, Nagai T, Takeuchi M, Takeda S, Tanaka Y (1998) Gamma-ray irradiation effects on corrosion rates of stainless steel in boiling nitric acid containing ionic additives. J Nucl Sci Technol 35:353–356

Ueno F, Kato C, Motooka T, Ichikawa S and Yamamota M (2008) Corrosion Phenomenon of Stainless Steel in Boiling Nitric Acid Solution Using Large-Scale Mock-Up of Reduced Pressurized Evaporator. J Nucl Sci Technol 45(10):1091–1097

Kato C (2020) Corrosion in nuclear fuel reprocessing plants: corrosion in boiling nitric acid. In: Konings RJM, Stoller RE (eds) Comprehensive nuclear materials, 2nd edn, vol 4. Elsevier, pp 528–563

Ningshen S, Sakairi M (2015) Corrosion degradation of AISI type 304L stainless steel for application in nuclear reprocessing plant. J Solid State Electrochem 19:3533–3542

Ningshen S, Kamachi Mudali U, Ramya S, Raj B (2011) Corrosion behavior of AISI type 304L stainless steel in nitric acid media containing oxidizing species. Corros Sci 53 (1):64–70

Ningshen S, Kamachi Mudali U, Raj B (2009) Assessment of corrosion performance of nitric acid grade stainless steels exposed to nitric acid environments. Corros Sci 51:322–329

Decours J, Decugis J-C, Demay R, Pelras M, Turluer G (1987) Austenitic stainless steels: Assessment of progress in materials performance for reprocessing applications. IAEA-TECDOC-421, pp 117–127

Kiuchi K, Kato T, Motooka H, Hamada S (1999)Technological problems and counter-measures on equipment materials for reprocessing of high burnup fuels. International Atomic Energy Agency, Vienna (Austria); 333 p; ISSN 1011-4289; Jul 2002; pp 210–215; Technical committee meeting on technical and economic limits to fuel burnup extension; San Carlos de Bariloche (Argentina); 15–19 Nov 1999; 16 refs, IAEA-TECDOC-1299

Furuya T, Kawafuku U, Satoh H, Shimogori K, Aoshim A, Takeda S (1991) A Corrosion Testing Method for Titanium in Nitric Acid Environments. ISIJ Int 31(2):189–193

Kamachi Mudali U, Raju VR, Dayal RK (1998) Corrosion of advanced materials in liquid, condensate and vapour phase of nitric acid environments. In: Proceedings of eighth nation congress on corrosion control. Kochi: National Corrosion Council of India, pp 7.3.1–7.3.8

Corrosion resistance of titanium - Titanium Metals Corporation TIMET Report, 1997 Titanium Hearth Technologies, Inc.Pennsylvania, USA

Priya R, Kumar A, Kaliraj K, Vijayalakshmi S, Ningshen S, Philip J, Raju S, Albert SK, Nitric acid test of titanium dissolver material (Ti-Gr2), Report No: IGCAR/MMG/CSTD/2020/388

Ravi Shankar A, Kamachi Mudali U (2013) Refractory metal coatings on titanium to improve corrosion resistance in nitric acid medium. Surf Coat Technol 235:155–164

Ningshen S, Sakairi M, Suzuki K, Okuno O (2015) Corrosion performance and surface analysis of Ti-Ni-Pd-Ru-Cr alloy in nitric acid solution. Corros Sci 91:120–128

Furuya T, Satoh H, Shimogori K, Aoshima A, Takeda S (1984) Corrosion resistance of zirconium and titanium alloy in HNO3 solutions. In: Fuel reprocess, waste manage. Proceedings of the American Nuclear Society International Topical Meeting, vol 1, pp 249–258

Kato C, Ishijima Y, Ueno F, Yamamoto M (2016) The effect of crystal textures on the anodic oxidization of zirconium in a boiling nitric acid solution. J Nucl Sci Technol 53:1371–1379

Auchapt P, Patarin L, Tarnero M (1984) Proc, The International Meeting on Fuel Reprocessing and Waste Management (RECOD’84), vo1 II, p 2, American Nuclear Society, La Grange Park, 1984, ASM, La Grange Park, IL

Nagano H, Kajimura H, Yamanaka K (1995) Corrosion resistance of zirconium and zirconium-titanium alloy in hot nitric acid. Mater Sci Eng, A 198:127–134

Yau T (1986) Zirconium for nitric acid solutions. In: Young C, Durham J (eds) Industrial applications of titanium and zirconium: fourth volume. West Conshohocken, PA zirconium could be attacked, ASTM International, pp 57–68

Chauve H, Decour J, Demay R, Pelras M, Simonne J, Turluer G (1987) Zirconium use for large process components, Materials Reliability in the Back End of the Nuclear Fuel Cycle, IAEA, Vienna. IAEA-TECDOC-421

Tonpe S, Saibaba N, Jayaraj RN, Ravi Shankar A, Kamachi Mudali U, Raj B (2011) Process development for fabrication of Zircaloy–4 dissolver assembly for reprocessing of spent nuclear fuel. Energy Procedia 7:459–467

Jayaraj J, Thyagarajan K, Mallika C, Kamachi Mudali U (2015) Corrosion behaviour of zirconium, titanium and their alloys in simulated dissolver solution of fast breeder reactor spent nuclear fuel using Zircaloy-4 mock-up dissolver vessel. Nucl Technol 191:38–70

Kamachi Mudali U, Ravishankar A, Natarajan R, Saibaba N, Raj B (2013) Applications of zirconium alloys for reprocessing plant components. Nucl Technol 182:349–357

Ukai S (2012) Oxide dispersion strengthened steels. Comp Nucl Mater 4:241–271

Ukai S, Fujiwara M (2002) Perspective of ODS alloys application in nuclear environments. J Nucl Mater 307–311:749–757

Ningshen S, Sakairi M, Sukuki K, Ukai S (2013) Corrosion resistance of 9–15% Cr ODS steels and its comparison with austenitic stainless steel. Adv Mat Res 794:575–582

Ningshen S, Sakairi M, Suzuki K, Ukai S (2014) The corrosion resistance and passive film compositions of 12% Cr and 15% Cr ODS steels in nitric acid media. Corros Sci 78:322–334

Ningshen S, Sakairi M, Suzuki K, Ukai S (2014) “The surface characterization and corrosion resistance of 11% Cr ferritic/martensitic and 9–15% Cr ODS steels for nuclear fuel reprocessing application. J Solid State Electrochem 18(2):411–425

Tanno T, Takeuchi M, Ohtsuka S, Kaito T (2017) Corrosion behavior of ODS steels with several chromium contents in hot nitric acid solutions. J Nucl Mater 494:219–226

Priya R, Ningshen S, Sakairi M, Ukai S (2020) Corrosion behaviour of Al-containing high Cr ferritic oxide dispersion strengthened steel in nitric acid environment. J Nucl Mater 534:Article: 152120

Johnson WL (1986) Thermodynamic and kinetic aspects of the crystal to glass transformation in metallic materials. Prog Mater Sci 30:81–134

U. Kamachi Mudali, S. Scudino, U. Kuhn, J. Eckert and A. Gebert, Polarisation behaviour of the Zr57Ti8Nb25Cu139Ni111Al75 alloy in different microstructural states in acid solutions, Scripta Mater., 50 (2004), pp. 1379–1384

Kamachi Mudali U, Scudino S, Kuhn U, Eckert J, Schultz L, Gebert A (2006) Corrosion behaviour of zirconium based bulk metallic glasses. Trans IIM 59:123–138

Padhy N, Ningshen S, Kamachi Mudali U (2010) Electrochemical and surface investigation of zirconium based metallic glass Zr59Ti3Cu20Al10Ni8 alloy in nitric acid and sodium chloride media. J Alloy Compd 503:50–56

Qin C, Asami K, Kimura H, Zhang W, Inoue A (2008) Surface characteristics of high corrosion resistant Ni–Nb–Zr–Ti–Ta glassy alloys for nuclear fuel reprocessing applications. Electrochemistry Communications 10:1408–1410

Qin C, Asami K, Kimura H, Zhang W, Inoue A (2009) Electrochemical and XPS studies of Ni-based metallic glasses in boiling nitric acid solutions. Electrochim Acta 54:1612–1617

Poddar C, Ningshen S, Jayaraj J (2020) Corrosion assessment of Ni60 Nb30Ta10 metallic glass and its partially crystallized alloy in concentrated nitric acid environment. J Alloy Compd 813:152172

Poddar C, Jayaraj J, Ningshen S, Kamachi Mudali U (2019) Effect of thermal oxidation on the oxide characteristic and corrosion behavior of Ni60Nb40 amorphous ribbon in nitric acid. Appl Surf Sci 479:430–439

Celis JP, Ponthiaux P, Wenger F (2006) Tribocorrosion of materials: Interplay between chemical, electrochemical and mechanical reactivity of surfaces. Wear 261:939–946

Mischler S (2008) Triboelectrochemical techniques and interpretation methods in tribocorrosion: A comparative evaluation. Tribology Int 41:573–583

Priya R, Ningshen S, Vasudevan M, Thyagarajan K, Mallika C, Kamachi Mudali U (2015) Wear and tribocorrosion behaviour of 304L stainless steel welds. Tribol Mater, Surf Interfaces 9:181–189

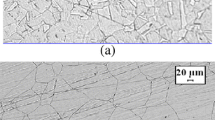

Priya R, Mallika C, Kamachi Mudali U (2014) Wear and tribocorrosion behaviour of 304L SS, Zr-702, Zircaloy-4 and Ti-grade2, Wear, 310, pp 90–100

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ningshen, S., Priya, R., Kamachi Mudali, U. (2022). Nitric Acid Corrosion Issues of Spent Fuel Nuclear Fuel Reprocessing Plants Materials. In: Kamachi Mudali, U., Subba Rao, T., Ningshen, S., G. Pillai, R., P. George, R., Sridhar, T.M. (eds) A Treatise on Corrosion Science, Engineering and Technology. Indian Institute of Metals Series. Springer, Singapore. https://doi.org/10.1007/978-981-16-9302-1_3

Download citation

DOI: https://doi.org/10.1007/978-981-16-9302-1_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9301-4

Online ISBN: 978-981-16-9302-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)