Abstract

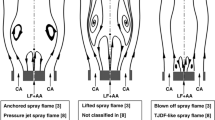

Holographic interferometry has been applied to the study of concentration and temperature distribution in transient vaporizing non-burning and burning fuel sprays in a quiescent bomb. Semi-theoretical relations have been obtained in this chapter to describe the axial and radial variations of concentration in the vaporizing non-burning spray and to evaluate the penetration of sprays and air entrainment in the free and wall jet regions of non-burning and burning sprays. The movement of the “tail” of the spray in the post-injection period is studied. The data is presented for species concentration and temperature profiles within the burning spray. The equations form the basis for building the phenomenological models of ignition delay, emissions, and heat release rate in the next chapters.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- A f :

-

= 0.5 (experimental), the proportionality constant of Ricou-Spalding relation of the ratio of air entrainment rate to fuel injection rate with the ratio of axial distance to equivalence diameter of the nozzle hole whereas proposed by Spalding was 0.32 (−)

- A w :

-

similar to the Af proposed by Ricou and Spalding for free spray, a constant for spray along the wall, 0.95 (−)

- C :

-

concentration (−)

- C f :

-

concentration of fuel (−)

- \(C_{f_{\max } }\) :

-

concentration with axial distance, x (−)

- C R,L. :

-

refers to the mixture fraction at rich limit combustion (−)

- d e :

-

orifice equivalent diameter and for the non-burning jet is defined as do ╳ [density of injected fuel/density of air in Bomb]1/2 (m)

- de :

-

equivalent diameter of the nozzle hole (m)

- H :

-

distance from the nozzle hole to the plate on which the spray impinges at a right angle (normally) (m)

- K b :

-

combined Gladstone-Dale constant for burned products (m3/kg)

- m :

-

mass entrained (kg)

- \(m_a^{\prime} {\text{and }}m_o^{\prime}\) :

-

rate of air mass entrained into the jet, and the rate of mass flow of the jet fluid through the orifice respectively (kg/s)

- M b :

-

average molecular weight of the products of combustion at the rich limit (kg/kmol)

- M f :

-

molecular weight of fuel (kg/kmol)

- n :

-

refractive index (−)

- p :

-

pressure (Pa)

- r :

-

radius at any x position from the nozzle hole (m)

- R 0.5 :

-

radius at which the concentration has half its maximum value (m)

- r 0.5 :

-

radius at which concentration of fuel drops 50%, used for non-dimensionalizing r (m)

- S :

-

penetration along the wall (m)

- s :

-

distance of the wall jet from the point of impingement (m)

- t :

-

time (s)

- T :

-

temperature (K)

- t imp :

-

time after jet impingement (s)

- t inj :

-

injection period (s)

- U j :

-

velocity of fuel at the nozzle hole (m/s)

- w :

-

radius of the free jet at x = H (m)

- x :

-

axial distance in the free spray along the centre line of the nozzle hole from the nozzle hole (m)

- x o :

-

distance from the orifice beyond which \(C_{f_{\max } }\) with the axial position is decaying (m)

- y :

-

distance perpendicular to the impingement plate (m)

- y :

-

height of wall jet (m)

- y :

-

height in the free spray at a radial distance of s from the point of impingement (m)

- y 0.5 :

-

height at which concentration of fuel drops 50%, used for non-dimensionalizing y (m)

- z :

-

constant of proportionality in equation (4–7) =0.75

- δ :

-

location of the virtual source inside the nozzle at δ/de = 2.3 (m)

- \(\theta_{{\text{cone}}} /2\) :

-

half jet angle, tan(cone angle/2) = 0.22 (°)

- ρ a :

-

density of air (kg/m3)

- ρ f :

-

density of fuel (kg/m3)

- Φ:

-

mixture fraction (−)

- \(\infty\) :

-

surroundings

- r :

-

considered a point in the jet

- f :

-

fuel vapour

- a :

-

air

- f :

-

free jet

- f :

-

fuel

- imp:

-

impingement time

- inj:

-

end of injection

- max:

-

maximum of the variation, for example, of the concentration profile of fuel over a section at an axial distance x or distance along the wall, s

- r :

-

any point in burning spray

- w :

-

wall jet

- . :

-

rate with respect to time

- ’:

-

rate with respect to time

References

Aoyagi Y et al (1980) A gas sampling study on the formation process of soot and NO in a DI engine. SAE 800254

Beer JM, Chigier NA (1972) Combustion aerodynamics. Applied Science Publishers

Benajes J, Molina S, Garcia JM, Riesco JM (2004) The effect of swirl on combustion and exhaust emissions. J Auto Eng IMechE 218

Bradshaw P, Cebeci T, Whitelaw JH (1981) Engineering calculations for turbulence flow. Academic Press

Bremhorst K, Watson RD (1981) Velocity field and entrainment of a pulse cored jet. J Fluid Eng Trans ASME 103

Chigier NA, Apak G (1975) Interaction of multiple turbulent diffusion flames. Combust Sci Technol 10:219–231

Chigier NA, Strokin V (1974) Mixing processes in a turbulent diffusion flame. Combust Sci Technol 9:111–118

Chiu WS (1973) The experimental set up for basic diesel, spray mixing and combustion studies. Cummins Tech Report doc 3534

Dec JE, Westbrook C (1999) Diesel combustion: an integrated view combining laser diagnostics, chemical kinetics and empirical validation. SAE 1999-01-0509

Dent JC (1971) Basis for comparison of various experimental methods for studying penetration. SAE Trans 710571

Dent JC (1980) Potential applications of holographic interferometry to engine combustion. Combustion modeling in reciprocating engines. Plenum, New York

Dent JC, Keightley JD, DeBoer CD (1977) Application of interferometry to air-fuel measurements. SAE Paper No. 770825

Guruz AG, Guruz HK, Osuwan S, Steward RF Aerodynamics of a confined burning jet. Combust Sci Technol 9:103–110

Hartel H (1962) Stromongsorgange beim Freien Huberstrahler Luftfahrtechnik, 8

Heywood JB (2018) Internal combustion engine fundamentals. McGraw-Hill Education

Hiroyasu H, Arai M, Nakanishi K (1980) Soot formation and oxidation in diesel engines. SAE 800252

Yoshihiro H, Kiyomi N, Takayuki F, Minaji I, Kiyoshi F, Ichiro S (2002) The cause of exhaust smoke and its reduction methods in an HSDI diesel engine under high speed and high load conditions. SAE Transactions, pp 2064–2074, 2002-01-1160

Kurtz EM, Foster DE (2004) Identifying a critical time for mixing in a direct injection diesel engine through the study of increased in-cylinder mixing and its effect on emissions through the study of increased in-cylinder mixing and its effects on emissions. Int J Eng Res IMechE 5(3)

Lakshminarayanan PA, Dent JC (1983) Interferometric studies of vapourising and combusting sprays. SAE 830244

Lyu MS, Shin BS (2002) Study of nozzle characteristics on the performance of a small-bore high-speed D. I. engine. Int J Eng Res IMechE 3

Martin MK, Heywood JB (1977) Approximate relationship for the thermodynamic properties of hydrocarbon-air combustion products. Combus Sci Technol

Matsui Y, Kamimoto T, Matsuoka S (1982) Formation and oxidation processes of soot particulates in a D. I diesel engine—an experimental study via the two-colour method. SAE paper 820464

Rajaratnam N (1976) Turbulent jets. Elsevier

Ricou FP, Spalding DB (1961) Measurement of entrainment by axisymmetrical turbulent jets. J Fluid Mech 11:21–23

De Risi A, Donabeo T, Laforgia D (2005) An innovative methodology to improve the design and the performance of direct injection diesel engine. Int. J. Eng. Res. IMechE 5(5)

De Risi A, Manieri D, Laforgia D (1999) A theoretical investigation on the effects of combustion chamber geometry and engine speed on soot and NOx emissions. ASME-ICE, Paper No. 99-ICE-207, vol 33-1

Shahed SM, Chiu WS, Lyn WT (1975) A mathematical model of diesel combustion. Proc IMechE C94/75

Spalding DB (1979) Combustion and mass transfer. Cox and Wyna Ltd., London

Steward FR, Guruz AG (1977) Aerodynamics of a confined jet with variable density. Combust Sci Technol 16:20–45

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Lakshminarayanan, P.A., Aghav, Y.V. (2022). Turbulent Structure of the Diesel Spray. In: Modelling Diesel Combustion. Mechanical Engineering Series. Springer, Singapore. https://doi.org/10.1007/978-981-16-6742-8_4

Download citation

DOI: https://doi.org/10.1007/978-981-16-6742-8_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6741-1

Online ISBN: 978-981-16-6742-8

eBook Packages: EngineeringEngineering (R0)