Abstract

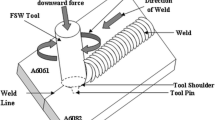

The paper focuses on the processing of FSW and to have the position of conditions to improve the efficiency for welding of the materials to improve the strength. The research has taken place innovative manner for different input process parameters for significance taken place by studying and understanding of a lot of literature survey for different speeds and tool angles. The position of the tool takes a major role in the designing of the tooltip to have the particular position to weld today’s scenario of the investigations. The experimental design and microstructural investigations were planned with the help of the Taguchi method. The responses are calculated based on experimental work to get the position of the optimal welding process of the technology to help the society satisfying environmental conditions. The responses are calculated and carried on the optimization techniques of multiple responses applicable and helpful for this method. It is quite possible to optimize the optimal conditions for the output responses more than one. So, this method is very helpful and proved to be very effective in finding the multiple responses which can yield the optimal results.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Markopoulos, A.P., Habrat, W., Galanis, N.I., Karkalos, N.E.: Modelling and optimization of machining with the use of statistical methods and soft computing, Springer International Publishing Switzerland 2016. In: Davim, J.P. (ed.) Design of Experiments in Production Engineering, Management and Industrial Engineering. https://doi.org/10.1007/978-3-319-23838-8_2

Fallahi, A.A., Shokuhfar, A., Ostovari Moghaddam, A., Abdolahzadeh, A.: Analysis of SiC nano-powder effects on friction stir welding of dissimilar Al-Mg alloy to A316L stainless steel. J. Manuf. Process. 30, 418–430 (2017)

Tara, J., Mustapha, S., Fakir, M.A., Herb, M., Wang, H., Ayoub, G., Hamade, R.: Application of ultrasonic waves towards the inspection of similar and dissimilar friction stir welded joints. J. Mater. Process. Technol. https://doi.org/10.1016/j.jmatprotec.2018.01.006

Morgan, R., Thirumalaisamy, N.: Experimental and numerical analysis of friction stir welded dissimilar copper and bronze plates. Mater. Today: Proc. 5, 803–809 (2018)

KepiGangwar, M.: Ramulu, frictionstir, welding of titaniumalloys. Jade (2017). https://doi.org/10.1016/j.matdes.2017.12.033

Moradi, M., Aval, H.J., Jamaati, R., Amirkhanlo, S., Ji, S.: Microstructure and texture evolution of friction stir welded dissimilar aluminum alloys: AA2024 and AA6061. J. Manuf. Process. 32, 1–10 (2018)

Abandon, H.K., Jashnani, H.R., Payday, M.: Effect ofprecipitation hardening heat treatment on mechanical and microstructure features of dissimilar friction stir welded AA2024-T6 and AA6061-T6 alloys. J. Manuf. Process. 31, 214–220 (2018)

Hajideh, M.R., Farahani, M., Ramezani, N.M.:Reinforced dissimilar friction stir weld of polypropylene to acrylonitrile butadiene styrene with copper nanopowder. J. Manuf. Process. 32, 445–454 (2018)

Fey, X., Ye, Y., Jin, L., Wang, H., Live, S.: Special welding parameters study on Cu/Al joint in laser-heated friction stir welding. J. Mater. Process. Technol. https://doi.org/10.1016/j.jmatprotec.2018.02.004

Zhou, L., Zhang, R.X., Hu, X.Y., Guo, N., Zhao, H.H., Huang, Y.X.: Effects of a rotation speed of assisted shoulder on microstructure and mechanical properties of 6061–T6 aluminum alloy by dual-rotation friction stir welding. Int. J. Adv. Manuf. Technol. 100, 199–208 (2019)

Liu, F.J., Fu, L., Chen, H.Y.: Microstructure evolution and fracture behavior of friction stir welded 6061–T6 thin plate joints under high rotational speed. Sci. Technol. Weld Join 23(4), 1–12 (2017)

Zhu, J., Jiang, W., Li, G., Guan, F., Yu, Y., Fan, Z.: Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. J. Mater. Process. Tech. 283, 116699 (2020). https://doi.org/10.1016/j.jmatprotec.2020.116699

Veysel, E, Sezer, Ç, Oguzhan, S.: Investigation of the microstructure of aluminum-based composite material obtained by mechanical alloying. Met. Mater. Int. 139 (2020). https://doi.org/10.1007/s12540-019-00583-x

Erturun, V., Sahin, O.: Investigation of microstructural evolution in ball-milling of SiC reinforced aluminum matrix composites. Powder Metall. Met. Ceram. 57(11–12), 687–696 (2019)

Sadooghi, A., Rahmani, K.: Experimental study on mechanical and tribology behaviors of Mg–SiC nano/micro composite produced by friction stir process. J. Mech. Sci. Technol. 35, 1121–1127 (2021). https://doi.org/10.1007/s12206-021-0225-9

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Shaik, B., Gowd, G.H., Prasad, B.D., Ali, P.S. (2022). Investigations on Microstructures by Using Friction Stir Processing. In: Reddy, A.N.R., Marla, D., Favorskaya, M.N., Satapathy, S.C. (eds) Intelligent Manufacturing and Energy Sustainability. Smart Innovation, Systems and Technologies, vol 265. Springer, Singapore. https://doi.org/10.1007/978-981-16-6482-3_53

Download citation

DOI: https://doi.org/10.1007/978-981-16-6482-3_53

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6481-6

Online ISBN: 978-981-16-6482-3

eBook Packages: EngineeringEngineering (R0)