Abstract

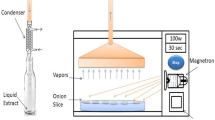

Hot air drying of ginger (Zingiber Officinale) samples (10 mm × 10 mm × 5 mm) having an initial moisture content of 84.89% (wet basis) were carried out at 60℃. Effect of treatment prior to drying was studied at different concentrations of calcium chloride (CaCl2) of 3, 3.5, 4, and 4.5 Mol per liter and compared with the samples dried without pretreatment. Also, process intermittency was applied with a pulse ratio of 1.5 by keeping the sample in vacuum or open atmosphere. During intermittent drying, the products were dried in hot air dryer for 40 min, followed by either vacuum drying or open-air drying at ambient conditions for 20 min. It was observed that calcium chloride with higher concentrations had a significant effect on the moisture extraction rate. Open-air intermittency exhibited better rehydration ability and lowest shrinkage ratio, which facilitated a higher drying rate during the falling rate period.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- \(m_{d}\) :

-

mass of dried sample (kg)

- \(m_{r}\) :

-

mass of rehydrated sample (kg)

- RH:

-

relative humidity (%)

- \(V_{d}\) :

-

volume of sample after drying (m3)

- \(V_{f}\) :

-

volume of sample before drying (m3)

- w/v:

-

weight per volume

References

FAOSTAT (2016) Food and Agricultural Organization (FAO) of United Nations, Rome

Beristain-Bauza SDC, Hernández-Carranza P, Cid-Pérez TS, Ávila-Sosa R, Ruiz-López II, Ochoa-Velasco CE (2019) Antimicrobial activity of ginger (Zingiber officinale) and its application in food products. Food Rev Intl 35(5):407–426

Peter KV (2001) Handbook of herbs and spices. CRC Press, Boca Raton, US

Rahman S (2007) Handbook of food preservation, 2nd edn. Taylor & Francis, Boca Raton

Majumdar AS (2004) Dehydration of products of biological origin. Enfield: Science Publishers, New Hampshire

Kudra T (2004) Energy aspects in drying. Drying Technol 22(5):917–932

Beedie M (1995) Energy saving–a question of quality? Dairy Industries International 60(12):27

Galanakis CM (2018) Sustainable food systems from agriculture to industry: improving production and processing. Academic Press, London

Kumar C, Karim MA, Joardder MUH (2014) Intermittent drying of food products: a critical review. J Food Eng 121:48–57

Deng LZ, Mujumdar AS, Zhang Q, Yang XH, Wang J, Zheng ZA, Gao ZJ, Xiao HW (2019) Chemical and physical pretreatments of fruits and vegetables: effects on drying characteristics and quality attributes—a comprehensive review. Crit Rev Food Sci Nutr 59(9):1408–1432

Gan H, Charters E, Driscoll R, Srzednicki G (2017) Effects of drying and blanching on the retention of bioactive compounds in ginger and turmeric. Horticulturae 3:13

Thuwapanichayanan R, Phowong C, Jaisut D, Štencl J (2014) Effects of pretreatments and drying temperatures on drying characteristics, antioxidant properties and color of ginger slice. Acta Universitatis Agriculturae et Silviculturae Mendelianae Brunensis 62(5):1125–1134

Deshmukh AW, Varma MN, Yoo CK, Wasewar KL (2013) Effect of ethyl oleate pretreatment on drying of ginger characteristics and mathematical modelling. J Chem 1–6

George JM, Sowbhagya HB, Rastogi NK (2018) Effect of high-pressure pretreatment on drying kinetics and oleoresin extraction from ginger. Drying Technol 36(9):1107–1116

Tang HCL, Mcfeeters RF (1983) Relationship among cell wall constituents, calcium and texture during cucumber fermentation and storage. J Food Sci 48(1):66–70

AOAC (2000) Official Methods of Analysis, 17th edn. The Association of Official Analytical Chemists, Gaithersburg, MD, US

Majumder P, Sinha A, Mishra L, Gupta R (2020) Prediction of moisture ratios (MRs) during fluidized bed drying of ginger (Zingiber officinale) cubes by using mathematical modelling and experimental validation. In: Biswal BB, Sarkar BK, Mahanta P (eds) Advances in mechanical engineering. Springer Nature, Singapore, pp 729–740

Ajani C, Curcio S, Dejchanchaiwong R, Tekasakul P (2019) Influence of shrinkage during natural rubber sheet drying: numerical modelling of heat and mass transfer. Appl Therm Eng 149:798–806

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1994) Densities, shrinkage and porosity of some vegetables during air drying. Drying Technol 12(7):1653–1666

Saengrayap R, Tansakul A, Mittal GS (2015) Effect of far-infrared radiation assisted microwave-vacuum drying on drying characteristics and quality of red chilli. J Food Sci Technol 52(5):2610–2621

Grewal JS, Alam MS (2014) Response surface optimization of fluidized bed-cum-microwave drying process for garlic slices (Allium Sativum L.). Int J Eng Res Appl 4(5):106–114

Benseddik A, Azzi A, Zidoune MN, Khanniche R, Besombes C (2019) Empirical and diffusion models of rehydration process of differently dried pumpkin slices. J Saudi Soc Agric Sci 18:401–410

Takougnadi E, Boroze TET, Azouma OY (2018) Development of an intermittent drying process of onion. Cogent Food Agric 4:1–15

Esturk O (2012) Intermittent and continuous microwave-convective air-drying characteristics of sage (Salvia officinalis) leaves. Food Bioprocess Technol 5:1664–1673

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Majumder, P., Sinha, A., Gupta, R., Mishra, L. (2022). Hot Air Drying Characteristics and Quality Analysis of Ginger (Zingiber Officinale): Effect of Pretreatment and Process Intermittency. In: Palanisamy, M., Natarajan, S.K., Jayaraj, S., Sivalingam, M. (eds) Innovations in Energy, Power and Thermal Engineering . Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-4489-4_19

Download citation

DOI: https://doi.org/10.1007/978-981-16-4489-4_19

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-4488-7

Online ISBN: 978-981-16-4489-4

eBook Packages: EngineeringEngineering (R0)