Abstract

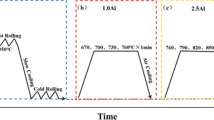

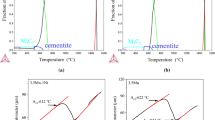

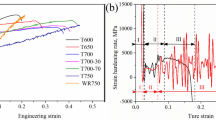

Medium manganese (Mn) steels are an important part of 3rd generation advanced high strength steels (AHSS) due to their ability of overcoming the so-called “strength-ductility trade-off” that was the limitation in the earlier developed 1st generation AHSS. Medium Mn steels have high strength-ductility combination owing to the ultrafine microstructure consisting of laths of martensite/ferrite along with a significant amount of interlath embedded austenite films. Austenite phase is stabilized in such steels via the austenite reverted transformation (ART) techniques or simply by the intercritical annealing (IA) treatment. In typical ART treatment, the sample with fully martensitic microstructure is held at an intercritical temperature, during which partitioning of alloying elements such as carbon, manganese (austenite stabilizers) occurs from the intercritical ferrite to the austenite phase, thus lowers the martensitic start (MS) temperature of the intercritical austenite phase and consequently increasing its thermal stability. Upon subsequent cooling to the room temperature, the microstructure retains sufficient austenite phase, owing to its increased stability. The retained austenite on deformation exhibits various strain hardening mechanism like transformation-induced plasticity (TRIP) and/or twinning-induced plasticity (TWIP) that eventually imparts high strength-ductility combination to medium Mn steels. It is imperative to achieve ideal mechanical stability of austenite during IA. Stability of the retained austenite phase is dependent on various factors such as intercritical annealing temperature, annealing time, grain morphology, initial microstructure etc. Among these, the IA temperature and time are the most important parameter with respect to the austenite phase stability. There are various other factors affecting the final properties of the steel, such as stacking fault energy and austenite grain size, which are known to be indirectly associated with the IA temperature and time. In the present study, the sensitiveness of the intercritical annealing temperature and time on microstructure and the ensuing mechanical properties of medium Mn steels is revealed. A correlation between the factors affecting the retained austenite stability and mechanical properties is established. The effect of stacking fault energy is also assessed. It is found that the mechanical properties of the medium Mn steels vary significantly with a variation in the intercritical annealing temperature and time.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Worldautosteel (2011) Future steel vehicle—final engineering report. http://Www.Autosteel.Org/Programs/Future%20steel%20vehicle.Aspx

Mishra G, Chandan AK, Kundu S (2017) Hot rolled and cold rolled medium manganese steel: mechanical properties and microstructure. Mater Sci Eng A 701:319–327. https://doi.org/10.1016/j.msea.2017.06.088

Chandan AK, Mishra G, Mahato B, Chowdhury SG, Kundu S, Chakraborty J (2019) Stacking fault energy of austenite phase in medium manganese steel. Metall Mater Trans A 50:4851–4866. https://doi.org/10.1007/s11661-019-05367-x

Chandan AK, Bansal GK, Kundu J, Chakraborty J, Chowdhury SG (2019) Effect of prior austenite grain size on the evolution of microstructure and mechanical properties of an intercritically annealed medium manganese steel. Mater Sci Eng A 768(138458). https://doi.org/10.1016/j.msea.2019.138458

Bansal GK, Madhukar DA, Chandan AK, Ashok K, Mandal GK, Srivastava, VC (2018) On the intercritical annealing parameters and ensuing mechanical properties of low-carbon medium-Mn steel. Mater Sci Eng A 733:246–256. https://doi.org/10.1016/j.msea.2018.07.055

Bansal GK, Rajinikanth V, Ghosh C, Srivastava VC, Kundu S, Chowdhury SG (2018) Microstructure–property correlation in low-Si steel processed through quenching and nonisothermal partitioning. Metall Mater Trans A 49:3501–3514. https://doi.org/10.1007/s11661-018-4677-1

Bansal GK, Junior LP, Ghosh C, Rajinikanth V, Tripathy S, Srivastava VC, Bhagat AN, Chowdhury SG (2020) Quench temperature-dependent phase transformations during nonisothermal partitioning. Metall Mater Trans A 51:3410–3424.https://doi.org/10.1007/s11661-020-05779-0

Bansal GK, Rajinikanth V, Ghosh C, Srivastava VC, Dutta M, Chowdhury SG (2020) Effect of cooling rate on the evolution of microstructure and mechanical properties of nonisothermally partitioned steels. Mater Sci Eng A 788, art no. 139614. https://doi.org/10.1016/j.msea.2020.139614

Bansal GK, Pradeep M, Ghosh C, Rajinikanth V, Srivastava VC, Bhagat AN, Kundu S (2019) Evolution of microstructure in a low-Si micro-alloyed steel processed through one-step quenching and partitioning. Metall Mater Trans A 50:547–555. https://doi.org/10.1007/s11661-018-5039-8

Lee Y-K, Han J (2015) Current opinion in medium manganese steel. Mater Sci Technol 31:843–856. https://doi.org/10.1179/1743284714Y.0000000722

Zackay VF, Parker ER, Fahr D, Busch R (1967) The enhancement of ductility in high-strength steels. ASM Trans Quart 60(2):252

Emmanuel DM, David KM, Speer JG, Matthew JM (2011) Austenite stabilization through manganese enrichment. Scripta Mater 64:185–188. https://doi.org/10.1016/j.scriptamat.2010.09.040

Andersson JO, Helander T, Hoglund L, Shi PF, Sundman B (2002) Thermo-Calc and DICTRA, computational tools for materials science. Calphad 26:273–312. https://doi.org/10.1016/S0364-5916(02)00037-8

Mahieu J, Maki J (2002) Phase transformation and mechanical properties of si-free CMnAl transformation induced plasticity-aided steel. Metall Mater Trans A 33:2573. https://doi.org/10.1007/s11661-002-0378-9

Koistinen DP, Marburger RE (1959) A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall 7:59–60. https://doi.org/10.1016/0001-6160(59)90170-1

Kim JK, Kim JH, Suh DW (2019) Partially-recrystallized ferrite grains and multiple plasticity enhancing mechanisms in a medium Mn steel. Mater Charact 15:109812.https://doi.org/10.1016/j.matchar.2019.109812

El-Danaf E, Kalidindi, Doherty SR (1999) Influence of grain size and stacking-fault energy on deformation twinning in fcc metals. Metall. Mater Trans A 30A:1223–33. https://doi.org/10.1007/s11661-999-0272-9

Curtze S, Kuokkala V (2010) Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater 58:5129–5141. https://doi.org/10.1016/j.actamat.2010.05.049

Allain S, Chateau JP, Bouaziz O, Migot S, Guelton N (2004) Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater Sci Eng A 387–389:158–162. https://doi.org/10.1016/j.msea.2004.01.059

Lee Y-K (2012) Microstructural evolution during plastic deformation of twinning-induced plasticity steels. Scripta Mater 66:1002–1006. https://doi.org/10.1016/j.scriptamat.2011.12.016

Sato K, Ichinose M, Hirotsu Y, Inoue Y (1989) Effects of deformation induced phase transformation and twinning on the mechanical properties of austenitic Fe–Mn–Al Alloys ISIJ Int 29:868–77. https://doi.org/10.2355/isijinternational.29.868

Cooman BCD, Kwon O, Chin K-G (2012) State-of-the-knowledge on TWIP steel. Mater Sci Technol 28:513–527. https://doi.org/10.1179/1743284711Y.0000000095

Xua HF, Zhaoa J, Cao WQ, Shi J, Wang CY, Wang C, Li J, Dong H (2012) Heat treatment effects on the microstructure and mechanical properties of a medium manganese steel (0.2C–5Mn). Mater Sci Eng A 532:435–442. https://doi.org/10.1016/j.msea.2011.11.009

Acknowledgements

The author AKC would like thank Md. Sameer Ansari for his contribution in performing the thermodynamic model calculation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Chandan, A.K., Bansal, G.K., Sahoo, B.K., Chakraborty, J. (2022). Medium Manganese Steel: Revealing the High Sensitivity of Microstructure and Mechanical Properties on Intercritical Annealing Temperature and Time. In: Kumari, R., Majumdar, J.D., Behera, A. (eds) Recent Advances in Manufacturing Processes. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-3686-8_18

Download citation

DOI: https://doi.org/10.1007/978-981-16-3686-8_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3685-1

Online ISBN: 978-981-16-3686-8

eBook Packages: EngineeringEngineering (R0)