Abstract

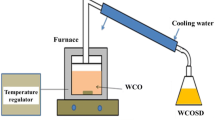

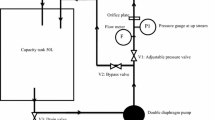

While electric and hybrid vehicles do act as credible replacement option for diesel engines, reality is that they will not replace it anytime soon. This leaves consumers with no choice but to prefer a diesel car over the other options. In addition, diesel engines are notorious for the emissions they emit which cause damage to health and the environment. This calls for urgency of action on emissions of diesel engine till the other viable options become better. Another major problem is the shortage of conventional fuels, especially diesel. In the present work, biodiesel derived from waste cooking oil has been employed as fuel along with ethanol (which serves as an oxygenated additive) and is considered for investigation. A Kirloskar made TV2 diesel engine has been employed to conduct the experiment at varied load. In this experiment, diesel has been considered as baseline reading, and two other fuels, that is biodiesel and biodiesel+ ethanol, have been considered for comparison purpose. The engine has been run from 0 to 100% load using the three fuels and the results have been evaluated, tabulated and plotted on graphs for discussion. From the results, it is revealed that the brake thermal efficiency (BTE) is increased by nearly 10% and brake-specific fuel consumption (BSFC) has reduced by 12%, thus showing that the performance of the engine is improved. The emissions of carbon monoxide (CO), nitrogen oxide (NOx) and particulate matter (PM) have significantly reduced; especially NOx has reduced by nearly 30%. There is also improvement of combustion with the heat release rate (HRR) increasing by nearly 15% and introduction of ignition delay. Exhaust gas recirculation (EGR) has also been used. EGR provides the best results when used as an after exhaust treatment system and is detrimental to NOx formation which is the most notorious emissions from a diesel engine and the results gotten from it were promising. Thus by employing this additive, the emissions are decreased without penalizing the performance and combustion characteristics.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

M. Chhetri, A.B. Watts, K.C. Islam, M. Rafiqul, Waste cooking oil as an alternate feedstock for biodiesel production. https://doi.org/10.3390/en1010003

S. Ahmed, M.H. Hassan, M.A. Kalam, S.A. Rahman, M.J. Abedin, A. Shahir, An experimental investigation of biodiesel production, characterization, engine performance, emission and noise of Brassica juncea methyl ester and its blends. J. Cleaner Prod. 79, 74–81 (2014)

British Petroleum Statistical Review of World Energy June 2007 [Online]. www.bp.com/statisticalreview. Accessed Feb 2020

G. Santori, G.D. Nicola, M. Moglie, F. Polonara, A review analyzing the industrial biodiesel production practice starting from vegetable oil refining. Appl. Energy 92, 109–132 (2012)

E.G. Giakoumis, A statistical investigation of biodiesel effects on regulated exhaust emissions during transient cycles. Appl. Energy 98, 273–291 (2012)

M.K. Lam, K.T. Lee, Renewable and sustainable bioenergies production from palm oil mill effluent [POME]: win-win strategies toward better environmental protection. Biotechnol. Adv. 29, 124–141 (2011)

M. Atapour, H.R. Kariminia, Characterization and transesterification of Iranian bitter almond oil for biodiesel production. Appl. Energy 88(7), 2377–2381 (2011)

M.G. Kulkarni, A.K. Dalai, Waste cooking oils: an economical source for biodiesel: a review. Ind. Eng. Chem. Res. 45, 2901–2913 (2006)

D. Phillips, Implications of imported used cooking oil [UCO] as a biodiesel feedstock (NNFC York, UK)

C. Calderón, G. Gauthier, J.M. Jossart, Bioenergy Europe Pellet Report 2018. European Pellet Council [Online]. https://epc.bioenergyeurope.org/bioenergy-europe-pellet-report-2018/. Accessed Feb 2019

S.K. Hoekman, A. Broch, C. Robbins, E. Ceniceros, M. Natarajan, Review of biodiesel composition, properties, and specifications. Renew. Sustain. Energy Rev. 16, 143–169 (2012)

S. Sivalakshmi, T. Balusamy, Effect of biodiesel and its blends with diethyl ether on the combustion, performance and emissions from a diesel engine. Fuel 106, 106–110 (2013)

A.R. Patil, S.G. Taji, Effect of oxygenated fuel diethyl malonate additive on diesel engine performance and emission. J. Mech. Civil Eng. 7, 58–62

N. Marek, J. Evanoff, Pre-commercialization of E-diesel fuels in off-road applications, in Proceedings of A&WMA 2002; Annual Conference, paper No. 42740

M. Duernholz, H. Endres, Exhaust-gas recirculation. A measure to reduce exhaust emissions of DI diesel engines, International Congress and Exposition (February 24, 1992))

G.H. Abd-Alla, Using exhaust gas recirculation in internal combustion engines: a review. Energy Convers. Manag. 43, 1027–1042 (2002)

A. Lobo, Influence of zinc oxide on direct injection ci engine fueled with waste cooking oil biodiesel (2019). https://doi.org/10.17148/iarjset.2019.61106

A. Kakoee, Y. Bakhshan, S.M. Aval, A. Gharehghani, An improvement of a lean burning condition of natural gas/diesel RCCI engine with a pre-chamber by using hydrogen. Energ. Convers. Manag. 166, 489–499 (2018)

D.B. Hulwan, S.V. Joshi, Performance, emission and combustion characteristic of a multicylinder DI diesel engine running on diesel–ethanol–biodiesel blends of high ethanol content. Appl. Energy 88, 5042–5055 (2011)

N. Ladommatos, R. Balian, R. Horrocks, L. Cooper, The effect of exhaust gas recirculation on soot formation in a high-speed direct-injection diesel engine, SAE Technical Paper No. 960841

A. Bilgin, O. Durgun, Z. Sahin, The effects of diesel-ethanol blends on diesel engine performance. Energy Sources 24, 431–440 (2002)

H. Saleh, Effect of exhaust gas recirculation on diesel engine nitrogen oxide reduction operating with jojoba methyl ester. Renew Energy 34, 2178–2186 (2009)

D. Qi, M. Leick, Y. Liu, C.-F. Lee, Effect of EGR and injection timing on combustion and emission characteristics of split injection strategy DI-diesel engine fueled with biodiesel. Fuel 90, 1884–1891 (2011)

K. Cheenkachorn, B. Fungtammasan, Biodiesel as an additive for diesohol. Int. J. Green Energy 6, 57–72 (2009)

K. Murlidharan, D. Vasudevan, Performance, emission and combustion characteristics of a variable compression ratio engine using methyl esters of waste cooking oil and diesel blends. Appl. Energy 88, 3959–3968 (2011). https://doi.org/10.1016/j.apenergy.2011.04.014

S. Puhan, R. Jegan, K. Balasubbramanian, G. Nagarajan, Effect of injection pressure on performance, emission and combustion characteristics of high lino- lenic linseed oil methyl ester in a DI diesel engine. Renew. Energy 34, 1227e33 (2009)

N. Ladommatos, S. Abdelhalim, H. Zhao, Z. Hu, The effects of carbon dioxide in exhaust gas recirculation on diesel engine emissions. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 212, 25–42 (1998)

R.P. Wilson, E.B. Muir, F.A. Pellicciotti, Emissions study of a single-cylinder diesel engine, SAE Papers 740123 (1974)

M. Lapuerta, J.M. Herreros, L.L. Lyons, R. García-Contreras, Y. Briceño, Effect of the alcohol type used in the production of waste cooking oil biodiesel on diesel performance and emissions. Fuel (2008). https://doi.org/10.1016/j.fuel.2008.05.013

S. Gjirja, E. Olsson, A. Karistrom, Considerations on engine design and fuelling technique effects on qualitative combustion in alcohol diesel engines, SAE Technical Paper Series 982530

K. Schmidt, J.H. Van Gerpen, The effect of biodiesel fuel composition on diesel combustion and emissions, SAE paper 961086 (1996)

W.G. Wang, D.W. Lyons, N.N. Clark, M. Gautam, P.M. Norton, Emissions from nine heavy trucks fuelled by diesel and biodiesel blend without engine modification. Environ. Sci. Technol. 34(6), 933–939 (2000)

A.L. Boehman, J. Song, M. Alam, Impact of biodiesel blending on diesel soot and the regeneration of particulate filters. Energy Fuels 19, 1857–1864 (2005)

M. Zheng, G.T. Reader, J.G. Hawley, Diesel engine exhaust gas recirculation—a review on advanced and novel concepts. Energy Convers. Manage. 45, 883–900 (2004)

D. Agarwal, S. Sinha, A. Kumar, Experimental investigation of control of NOx emissions in biodiesel-fueled compression ignition engine. https://doi.org/10.1016/j.renene.2005.12.003

M.J. Abedin, H.H. Masjuki, M.A. Kalam, A. Sanjid, S.M.A. Rahman, I.M.R. Fattah, Performance, emissions, and heat losses of palm and jatropha biodiesel blends in a diesel engine. Ind. Crops Prod. 59, 96–104 (2014)

A. Lobo, D.K. Ramesh, D.R. Chowdhury, M. Aditya, Experimental investigation on influence of additives on emissions, combustion and performance of diesel engine along with EGR fueled with waste cooking oil derived biodiesel. Int. J. Emer. Technol. 10(1), 01–03

V. Pradeep, R. Sharma, Use of HOT EGR for NOx control in a compression ignition engine fuelled with bio-diesel from Jatropha oil. Renew. Energy 32, 1136–1154 (2007)

E.W. De Menezes, R. Da Silva, R. Cataluna, R.J.C. Ortega, Effect of ethers and ether/ethanol additives on the physicochemical properties of diesel fuel and on engine tests. Fuel 85, 815–822 (2006)

B.S. Chauhan, N. Kumar, H.M. Cho, A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy 37(1), 616–622 (2012)

M. Gürü, A. Koca, Ö. Can, C. Cinar, F. Sahin, Biodiesel production from waste chicken fat based sources and evaluation with Mg based additive in a diesel engine. Renew. Energy 35, 637–643 (2010)

G. Knothe, A.C. Matheaus, T.W. Ryan, Cetane numbers of branched and straight chain fatty esters determined in an ignition quality tester. Fuel 82, 971–975 (2003)

M.J. Ramos, C.M. Fernandez, A. Casas, L. Rodriguez, A. Perez, Influence of fatty acid composition of raw materials on biodiesel properties. Bioresour. Technol. 100, 261–268 (2009)

M. Mittelbach, C. Remschmidt, Biodiesel the Comprehensive Handbook (Boersedruck Ges.m.b.H, Viena, 2004)

M. Lapuerta, J. Rodríguez-Fernández, E.F. De Mora, Correlation for the estimation of the cetane number of biodiesel fuels and implications on the iodine number. Energy Policy 37, 4337–4344 (2009)

D.Y. Chang, J.H. Van Gerpan, Fuel properties and engine performance for biodiesel prepared from modified feed stocks, SAE Paper 2005:2005–01–2200, https://doi.org/10.4271/971684

M.J. Murphy, J.D. Taylor, R.L. McCormick, Compendium of experimental cetane number data, NREL Report 2004: NREL/SR-540-36805

M.S. Graboski, J.R. Alvarez, R. McCormick, NOx solution for biodiesel, 2003:NREL/ SR-510-31465

G.A. Ban-Weiss, J.Y. Chen, B.A. Buchholz, R.W. Dibble, A numerical investigation into the anomalous slight NOx increase when burning biodiesel: a new [old] theory. Fuel Process. Technol. 88(7), 659–677 (2007)

N. Ladommatos, R. Balian, R. Cooper, The effect of exhaust gas recirculation on soot formation in a high-speed direct-injection diesel engine, SAE Technical Paper No. 960841

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Lobo, A., Ramesha, D.K. (2021). Experimental Investigation of Performance, Emission and Combustion Characteristics of Diesel Engine Using Waste Cooking Oil-Derived Biodiesel with Ethanol with Application of EGR. In: Ramesh, C.S., Ghosh, P., Natarajan, E. (eds) Recent Trends in Mechanical Engineering . Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-2086-7_1

Download citation

DOI: https://doi.org/10.1007/978-981-16-2086-7_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-2085-0

Online ISBN: 978-981-16-2086-7

eBook Packages: EngineeringEngineering (R0)