Abstract

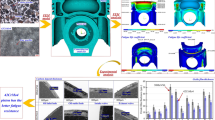

The Study of this research is to carry out how the Hypereutectic alloys can be used as a piston material rather than commonly used alloys of Aluminium, Cast Iron, AlSiC, Al2O3, etc. We carried out Structural and Steady Thermal Analysis on ANSYS to determine the properties of AlSi17Cu5MgNi (Hypereutectic alloy) which exhibits high performance durability, toughness and can be used in high performing engines, where the piston undergoes continuous dynamic loads and high stresses. Though this piston has not comparison in strong, but hypereutectic pistons are made as an ideal choice of selection for the engine producing power between 600HP to 700HP based on the application of use. In further technological developments, the new material of is made by the composition of aluminium i.e. the formation of meatal matrix composite on the basis of aluminium and production is done with the help of power metallurgy. Some other constituents are added to reduce the weight such as carbon and magnesium. The current research on piston material like cast and forged aluminium alloys provides better potential for optimization and plays a vital role in upcoming years.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Piątkowskia, J., Wieszałab, R.: Tribological properties of AlSi17Cu5Mg alloy modified with CuPMaster alloy with various speeds of friction, vol. 16 (2015). ISSN 1897-3310

Piątkowski, J., Kamiński, P.: Crystallization of AlSi17Cu5Mg alloy after time-thermal treatment, vol. 15 (2014). ISSN 1897-3310

Bhandari, V.B.: Design of Machine Elements Paperback, 3rd edn (2010)

Broutman, L.J., Chandrashekhara, K., Agarwal, B.D.: Analysis and Performance of Fiber Composites, 3rd edn. Paperback (2012)

Krishnan, S.B., Vallavi, M.S.A., Arunkumar, M., Haripraveen, A.: Design and analysis of an IC engine piston using composite material. Eur. J. Adv. Eng. Technol. 4(3), 209–215 (2017)

Shehanaz, M., Shankariah, G.: Design and Analysis of Piston Using Composite Material, vol. 6 (2017). ISSN 2319-8753

John, A., Mathew, J.T., Malhotra, V., Dixit, N.: Design and analysis of piston with SiC material. Int. J. Innovative Res. Sci. Technol. 1(12), 578–590 (2015). ISSN 2349-6010

Karl-Heinz, Z.G.: Microstructure and Wear of Materials (Tribology) (1987)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jog, S., Anthony, K., Bhoinkar, M., Kadam, K., Patil, M.M. (2020). Modelling and Analysis of IC Engine Piston with Composite Material (AlSi17Cu5MgNi). In: Gunjan, V., Singh, S., Duc-Tan, T., Rincon Aponte, G., Kumar, A. (eds) ICRRM 2019 – System Reliability, Quality Control, Safety, Maintenance and Management. ICRRM 2019. Springer, Singapore. https://doi.org/10.1007/978-981-13-8507-0_25

Download citation

DOI: https://doi.org/10.1007/978-981-13-8507-0_25

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-8506-3

Online ISBN: 978-981-13-8507-0

eBook Packages: EngineeringEngineering (R0)