Abstract

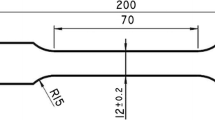

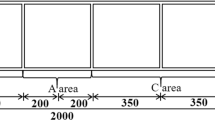

Increasing requirements on energy efficiency and saving of resources, e.g. in the automotive industry, require the application of concepts of lightweight design. These concepts are based on design optimizations and the usage of high performance materials e.g. high stress steels. Caused by design optimizations, the stress level of materials, in particular at crash conditions, is increasing to nonlinear plastic ranges. To use the entire potential of high performance materials the knowledge about the behavior of these materials, especially in the nonlinear plastic range at crash conditions, is absolutely necessary. However, in order to lift the entire load potential of high stress steels, the latest material models are necessary. Therefore, the identification of specific material parameters e.g. strain rate sensitivity at compression load, is indispensable. This leads to the development of a test rig to extract even those needed specific material parameters. After defining boundary conditions for the test specimen geometry a general concept study took place to identify an optimized test rig concept. Next to the geometrical boundary conditions of the test specimen also the conditions for the test procedure itself have been defined. One main weakness of usual compression tests at high strain rate levels is the impact on the specimen surface (usually caused by falling weights) as it may cause deviations in the test results due to surface hardening. Furthermore, the idea to keep the plastic strain rate constant in the plastic strain range has to be implemented. These main tasks have been solved by developing a hydro mechanic cam shaft test rig with a special developed cam geometry. It allows compression of the specimen at different continuously variable strain rate levels without impact on the specimen at compression initiation and constant strain rate at every chosen strain rate level in the plastic range of the material. After manufacturing and assembling the test rig, a compression test was performed and compared to an existing material model of the tested material with good concordance. These results showed that this concept of the hydro mechanical cam shaft test rig is a relatively simple possibility to get information on material behavior at different strain rates and high deformation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Biermann H, Krüger L (2015) Moderne Methoden der Werkstoffprüfung. Wiley-VCH, Freiberg

Steward M (1974) Constant true strain rate compression: the cam plastometer. Can Metall Q 13(3):503–509

Merklein M (2006) Charakterisierung von Blechwerkstoffen für den Leichtbau. Meisenbach, Bamberg

Acknowledgments

The authors gratefully appreciate the technical support from our project partners Edwin Till and Christian Walch from the company Voestalpine, steel division in Linz. The technical support by Peter Mayrl is gratefully acknowledged. Particular thanks are due to Erich Humer for his support in design and testing the developed devices. This work has been supported by the Austrian COMET-K2 programme of the Linz Center of Mechatronics (LCM), and was funded by the Austrian federal government and the federal state of Upper Austria.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Grillenberger, M., Schagerl, M. (2017). Extended Characterization of the Hardening and Failure Behavior of Advanced High Strength Steels at Dynamic Compression Load. In: Öchsner, A., Altenbach, H. (eds) Properties and Characterization of Modern Materials . Advanced Structured Materials, vol 33. Springer, Singapore. https://doi.org/10.1007/978-981-10-1602-8_14

Download citation

DOI: https://doi.org/10.1007/978-981-10-1602-8_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-1601-1

Online ISBN: 978-981-10-1602-8

eBook Packages: EngineeringEngineering (R0)