Abstract

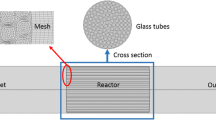

Photocatalysis produces strong oxidizing agents that can decompose organic compounds (VOCs) and kill microorganisms. One of the practical applications is air purification. The objective of this study is design optimization of a photocatalytic tubular honeycomb reactor for indoor air purification. A prototype photoreactor was fabricated and experimentally tested for the artificial-UV-assisted photocatalytic oxidation effect on gaseous nitric oxide (NO). It was found that more than 90% degradation of NO could be achieved in a single pass through the photoreactor. An empirical-correlation analysis was conducted to characterize the performance of the photoreactor with respect to the reactor dimensions, UV irradiance, and volumetric flow rate of treated air. Based on the empirical-correlation results, design optimization analysis of photocatalytic tubular honeycomb reactor was successfully accomplished.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

An empirical correlation study was conducted to determine the air purification performance of photocatalytic tubular

IAQMG (Indoor Air QualityManagement Group), Guidance Notes for the Management of Indoor Air Quality in Offices and Public Places, The Government of the Hong Kong Special Administrative Region, 2003.

OSH, Workplace Exposure Standards, Occupational Safety and Health Service, Department of Labour, Wellington, New Zealand, 2002.

15) NIOSH, NIOSH Pocket Guide to Chemical Hazards (NPG), NIOSH Publication No. 97-140, 3rd Printing, 2003.

Ringo C.W. Lam, Michael K.H. Leung, Dennis Y.C. Leung, Lilian L.P. Vrijmoed, W.C. Yam, S.P. Ng, Visible-light-assisted photocatalytic degradation of gaseous formaldehyde by parallel-plate reactor coated with Cr ion-implanted TiO2 thin film, Solar Energy Materials and Solar Cells, vol. 91, 2006, pp. 54–61.

Michael K.H. Leung, S.M. Tang, Ringo C.W. Lam, Dennis Y.C. Leung, W.C. Yam, S.P. Ng, and Lilian L.P. Vrijmoed, Parallel-plate solar photocatalytic reactor for air purification: semi-empirical correlation, modeling, and optimization, Solar Energy, vol. 80, 2006, pp. 949–955.

Ching, W.H., Leung, M., Leung, D.Y.C., Solar photocatalytic degradation of gaseous formaldehyde by sol-gel TiO2 thin film for enhancement of indoor air quality, Solar Energy, vol. 77, issue 2, 2004, pp. 129–135.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2008 Tsinghua University Press, Beijing and Springer-Verlag GmbH Berlin Heidelberg

About this paper

Cite this paper

Leung, M.K.H., Yiu, C.W. (2008). Design Optimization of Photocatalytic Glass Tubular Honeycomb Reactor for Air Purification. In: Goswami, D.Y., Zhao, Y. (eds) Proceedings of ISES World Congress 2007 (Vol. I – Vol. V). Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-75997-3_78

Download citation

DOI: https://doi.org/10.1007/978-3-540-75997-3_78

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-540-75996-6

Online ISBN: 978-3-540-75997-3

eBook Packages: EngineeringEngineering (R0)