Abstract

The choice of solar collector type to employ and the number of chosen collectors to subsequently deploy, are important planning decisions, which can greatly influence the economic attractiveness of solar water heating systems. In this paper, a thermo-economic model is developed for the computation of a suitable metric that can aid in choosing the most cost-effective collector to use in a solar water heating system and to determine the optimal sizing of the solar water heater components once the choice collector has been picked. The energy-per-dollar comparison metric, calculated as the annual heat energy output of the collector in an average year, at the so-called “sweet-spot” size of the collector array, divided by the annualized life-cycle cost, based on warranty life and collector initial cost, was recommended as instructive for comparing cost-effectiveness of different solar collectors. For the determination of the sweet-spot size of collector to use in a particular solar water heating system, at which the energy-per-dollar is calculated, the Net Present Value of Solar Savings was used as the objective function to maximize. Ten (10) different models of liquid solar thermal collectors (5 flat plate and 5 evacuated tube type), which are rated by the Solar Ratings & Certification Corporation (SRCC), were ranked according to the energy-per-dollar criterion through the thermo-economic model described in this study. At the sweet-spot collector area for the solar water heating system, the corresponding volume of hot water storage tank and the optimal solar fraction are also simultaneously determined. The required hot water storage volume decreases as the deployed collector area increases while the solar fraction increases, with diminishing marginal increase, until it saturates at a value of unity. For the present case study where the required load temperature is 50 °C and the solar water heating system is located in central Zimbabwe (latitude 19° S and longitude 30° E), the selected collector model happened to be a flat-plate type, which achieved the highest energy-per-dollar score of 26.1 kWh/$. The optimal size of this collector model to deploy in the solar water heating system at the case-study location is 18 m2 per m3 of daily hot water demand; with a hot water storage volume of 900 l/m3; at an optimal solar fraction of 91%. Although the method of this paper was applied only for a solar water heating application of specified operating temperature, at a specified location, it can be applied equally well for any other solar water heating application and at any other location.

OCRID Researcher ID: E 4889-2018

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Energy-per-dollar

- Thermo-economic model

- Collector choice

- Optimal sizing

- Diminishing marginal returns

- SRCC-rated

1.1 Introduction

Worldwide, the heating of water to low and medium temperatures using solar thermal energy has gained popularity for many residential, commercial and industrial applications. This is because of the numerous favourable characteristics of solar water heating, which result in a large displacement of conventional energy sources in an economically and environmentally sustainable way. Solar thermal water heaters are a prudent option where, among other considerations, the cost of conventional energy for heating water is higher than $0.034/kWh; daily average solar irradiation is higher than 4.5 kWh/m2 and where energy security is important (e.g. where there is interruptible supply of conventional energy) [1]. In Zimbabwe, the price of electricity is $0.11/kWh for domestic customers consuming 50–300 kWh/month and from $0.04/kWh (off-peak) to $0.13/kWh (peak period), for time-of-use customers [2]. Solar radiation is abundant (an annual average of 5.6–7 kWh/day) and ubiquitously distributed over the country [3]. Electricity, which is the conventional energy for heating water, is in short supply, with frequent load-shedding [4] events and reliance on importation of the commodity. With this scenario, it is not surprising that the Zimbabwe Government has recently launched the National Solar Water Heater Program [5], where water heating by electric geysers will be substituted by solar thermal water heating systems. This policy initiative is perceived to have many favourable outcomes including the reduction in national electricity consumption, improvement of consumer economics as well as a significant contribution to mitigating environmental degradation. A challenge that exists, however, is the high initial costs associated with owning a solar water heating system, which calls for cost-efficient selection of solar water heating components and their sizing, in order to maximise life-cycle economic benefits.

A solar water heating system essentially consists of a solar thermal collector and a water storage tank although other balance-of-system components such circulation pump, pipe-work and control system may also variably be included. Of the two main components, the solar collector, which is at the heart of the solar water heating system, has greater influence on system performance and costs up to twice or more times the cost of the storage tank [6]. Correct selection of the type and size of the collector to employ in a solar water heating system has great influence in the economic viability of the solar water heating system, as this determines the trade-off between system cost and solar fraction (conventional energy costs displaced). In addition the temperature achieved by the solar water heating system, which is determined by the type and size of the solar collector employed, have some influence on the size of the storage tank required, as a large collector area (higher operating temperature) should result in less required volume of storage tank [7]. Hence it is important to carefully choose the type and optimal size of a solar collector to use for a particular solar water heating application and climatic conditions.

Different attributes may be exclusively or jointly used to appraise the prudency of the choice of the solar thermal collector to purchase for a given application. These attributes include initial cost; energy performance; warranty (which is some guarantee for longevity) and others such as chance of overheating, ability to shed snow and wind-load structural capability. However, a more instructive metric to use when selecting between different types of collectors is the energy-per-dollar metric [8], as it can be made to combine an important-few of collector attributes, which determine the collector’s life-cycle cost-effectiveness, into one metric. In this study, a thermo-economic model is developed to guide the selection of the brand of solar collector(s) to be used in a solar water heating application, for a given required hot water temperature under given climatic conditions. The model is also used to determine the optimal size of collector area to deploy in the solar water heating system, together with corresponding volume of hot water storage tank and solar fraction at optimal collector size. A modified approach to defining and calculating the energy-per-dollar metric, which compares annual energy output of the collector under certain operating temperatures and annualized collector costs, taking into account the assured operating longevity of the collector (warranty life), is used in this study for ranking the cost-effectiveness of different collectors. The Net Present Value of Solar Savings (NPVSS) is used as the objective function to maximize for the selection of the optimal size of collector area to be deployed in the solar water heating system.

1.2 Solar Water Heating System Thermal Model

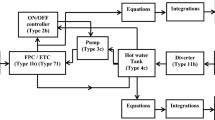

A solar water heating system can be represented by the schematic on Fig. 1.1. At the heart of a solar thermal system is the solar collector. It absorbs solar radiation, converts it into heat, and transfers useful heat to a well-insulated hot water storage tank. A pump is sometimes needed to circulate the heat around the system, but in thermo-siphon systems this is not required as natural gravity circulation is used. In the present model, a secondary smaller storage tank receives water heated by the solar loop and passes on to the load after, if required, boosting the water temperature to the required load temperature, Tload.

For the system on Fig. 1.1, assuming a well-mixed storage tank of mass M and fluid specific heat capacity CP, a simple energy balance can be expressed by the following differential equation:

Equation (1.1) states that the rate of change in the internal energy of the storage tank is equal to the energy interactions taking place over a time step.

The energy interactions are solar-collector-generated heat input Qu; the rate of heat removal (\(\dot{L}_{s}\)) and the storage tank heat losses \(\left( {U_{s} A_{s} \left[ {T_{s} - T_{a} } \right]} \right).\) One can use simple Euler integration [9], (i.e., rewriting the temperature derivative as \(\frac{{T_{s}^{ + } - T_{s} }}{\Delta t}\) and solving for the tank temperature at the end of a time increment). That is:

A time step \(\Delta t = 1 \,{\text{h}}\) is conveniently used since one hour is the smallest time resolution of solar radiation data commonly available.

In Eq. (1.1), solar input Qu is determined using Eq. (1.3). For a collector of area AC with solar irradiance GT incident on its plane, the rate of useful thermal energy gained is given by the well-known Hottel-Whillier-Bliss equation:

In Eq. (1.3), \(\left( {\tau \alpha } \right)_{n}\) is the normal-incidence transmittance-absorptance product of the collector—the fraction of incoming radiation absorbed at normal incidence. The ratio of absorbed incident radiation at any angle of incidence θ, to that at normal incidence is called the ‘incident angle modifier’, \(K_{\tau \alpha }\). The collector heat loss coefficient UL, is a measure of the rate of collector heat loss per unit area and per unit temperature difference between the collector and the ambient. If the reference collector temperature used is the fluid inlet temperature, the collector heat removal factor FR is applied as a multiplier to convert the energy gain if the whole collector were at fluid inlet temperature to the actual collector energy gain. The collector fluid inlet temperature is assumed to be equal to the average storage tank temperature TS and the heat loss is to the ambient environment at temperature Ta.

Data for the collector characteristics \(F_{R} \left( {\tau \alpha } \right)_{n}\) (the y-intercept of the collector efficiency curve); \(F_{R} U_{L}\) (the negative of the slope of the efficiency curve) and the incident-angle-modifier \(K_{\tau \alpha }\) are indispensable for the prediction of collector energy performance under specific operating-temperature and climatic conditions. These data are sometimes provided on manufacturers’ product data sheets. However, the authentic information should be obtained from internationally accredited certifying bodies such as the Solar Rating & Certification Corporation (SRCC) [10]. The SRCC clearly gives values of \(F_{R} \left( {\tau \alpha } \right)_{n}\) and \(F_{R} U_{L}\) with respect to the gross area for each tested collector together with the variation of \(K_{\tau \alpha }\) with angle of incidence of beam radiation on the collector. Figure 1.2a, b compare typical plots of collector efficiency curves and incidence angle of modifiers typical for flat plate and evacuated tube collectors. The plots are based on SRCC data for collectors from the same manufacturer. With reference to gross area, flat plate collectors generally have much greater values of both \(F_{R} \left( {\tau \alpha } \right)_{n}\) and \(F_{R} U_{L}\), making them superior to evacuated tube collectors for relatively low operating \(\frac{{\left( {T_{s} - T_{a} } \right)}}{{G_{T} }}\) (e.g. for domestic solar water heating applications in warm climates with high solar radiation). On the other hand, the optical efficiency of flat plate collectors is affected more adversely by increase in angle of incidence than evacuated tube collectors. It is always interesting to find out which of the characteristics has greater influence on energy output and which collector “wins” for specific operating and climatic conditions.

a Typical efficiency curves with respect to gross area for flat plate and evacuated tube collectors. b Typical variation of \(K_{\tau \alpha }\) with 1/cosθ−1 for flat plate and evacuated tube collectors. At angle of incidence θ = 0°, the incidence angle modifier \(K_{\tau \alpha } = \, 1\) and at θ = 90°, \(K_{\tau \alpha } = \, 0\)

Continuing with expounding Eq. (1.1), the rate of heat extraction from the solar part of the system Ls is considered next. The rate of heat removal from the solar-side storage tank is given by:

In Eq. (1.4), \(\dot{m}_{s}\) (kg/s) is the mass rate of water withdrawal; CP is the specific heat capacity of water; Ts is the temperature of water in the storage tank and Tmains is temperature of the cold water coming from the mains supply. The mass rate of water withdrawal \(\dot{m}_{s}\) depends on the amount of water withdrawal \(\dot{m}_{load}\) required by the system user at load temperature \(T_{load}\) and the comparison between Ts and Tload. If \(T_{s}\) > \(T_{load}\), then the required water withdrawal \(\dot{m}_{s} \; < \;\dot{m}_{load}\)(less water needs to be withdrawn from the system and the volume is made up by cold water from outside the system). On the other hand, if \(T_{s} \; < \;T_{load}\) an amount of hot water \(\dot{m}_{load}\) needs to be withdrawn and its temperature is boosted by the auxiliary heater. Therefore, one can be write:

The solar fraction is the ratio of the amount of input heat energy contributed by the solar energy system to the total input energy required for the water heating application for a specified period of time. Then instantaneous solar fraction SF can be written:

The hourly conventional energy displaced by solar energy each hour is \(3600 \times S_{F} \times \dot{m}_{load} \left( { T_{load} - T_{mains} } \right)\), if a constant rate of hot water withdrawal is assumed during the hourly period. The average monthly contribution of displaced energy is obtained by summing the hourly contributions over the average solar radiation day of the month, Klein [11], and multiplying this sum by the number of days of the month. The annual solar contribution of required thermal energy \(L_{annual}\) is obtained by summing the monthly contributions.

1.3 Economic Model

In this section, the energy-per-dollar of a solar collector and the Net Present Value of Solar Savings are defined.

In an economy where the prevailing interest rate is i per annum and the rate of inflation is j per annum, it can be shown that the discount rate d is related to i by the expression:

The annualized cost of a solar collector array of area Ac (m2) and cost per unit area Cc ($/m2), with annual operation and maintenance cost OM over w warranted operating years, is then given by:

In Eq. (1.8) the initial cost of the collector \(A_{c} C_{c}\) is multiplied by the cost recovery factor \(\frac{d}{{1 - \left( {1 + d} \right)^{ - w} }}\) and the product added to the annual operation and maintenance cost, in order to obtain the total annualized cost.

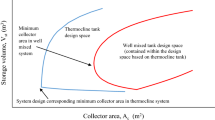

The annual thermal yield of the solar collector array \(Q_{annual}\) is the instantaneous rate \(Q_{u}\) integrated over the whole year. The marginal heat productivity (thermal yield per unit area) of the collector, when employed in the closed system of the solar water heater, diminishes as the area of collectors deployed in a solar heating system increases [12], as shown on Fig. 1.3. There is a corresponding diminishing marginal increase in solar fraction and, as result, the solar fraction follows the ‘elbowed’ curve shown on Fig. 1.3. Although engineering intuition suggests that there is a ‘sweet spot’ for sizing the solar collector array, i.e. around the ‘elbow’ of the solar fraction curve, there is need to for a way to pin-point the exact coordinates of this optimal point.

A suitable metric to compare the level of cost-effectiveness of different collectors is the energy-per-dollar (epd), which divides the average annual yield of the collectors by the annualized life-cycle (warranty-life) cost, \(Q_{annual} /C_{annual}\) at the sweet-spot collector area and solar fraction.

When selecting among collectors to use for a specified application (hot water temperature and climatic conditions) the collector model that gives the highest energy-per-dollar, as calculated from Eqs. (1.6, 1.7, 1.8, 1.9), should be preferred. The annualized-cost definition of the energy-per dollar allows for a comparison of the cost-effectiveness of different solar collectors that takes into account for the differences in guaranteed service life (warranty) of the collector. The energy-per-dollar for each candidate collector should be calculated at its sweet spot in the solar water heating system, for objective comparison, as again illustrated on Fig. 1.3.

The precise selection of the sweet spot of solar fraction for a solar water heating system is done by using the Net Present Value of Solar Savings (NPVSS) as the objective function to maximize. The NPVSS for a solar water heating system replacing electricity as the heating fuel is given by:

In Eq. (1.9), the new terms are the price of electricity PE [$/kWh]; the electric-to-heat efficiency \(\eta_{E}\); the hot water tank storage volume Vs and the cost of the storage tank per unit volume Cs. The cost of balance-of-system components CBOS (which also includes installation labour costs) may be taken as a discretionary percentage of the cost \(A_{C} C_{C} + V_{S} C_{S}\). The annual solar energy contributed \(L_{annual}\) is expressed in kWh.

To obtain the sweet spot of solar fraction, the collector area is progressively varied, which in turn alters the storage tank temperature Ts and the solar fraction and \(L_{annual}\). The required storage tank volume Vs also varies as dictated by Eq. (1.4), decreasing as the collector area (and tank temperature) increases. Therefore the NPVSS varies with increase in collector area, first increasing as collector area increases, and then decreasing when the collector area is increased beyond its optimal (sweet-spot) value.

1.4 Materials and Methods

A computer spreadsheet program was designed to handle the thermal and economic calculations necessary for appraisal of solar collectors and optimal sizing of the solar water heating system. The computations are done on hourly time-steps for the average day of each month. Starting with only the monthly-average daily global horizontal irradiation (GHI), obtained in this case from the Zimbabwe database developed in [13], the hourly-average GHI for each month was obtained by the model of Collares-Pereira and Rabl [14]. The monthly average diffuse radiation on a horizontal surface was obtained from global radiation by using a diffuse-ratio versus clearness index correlation function suitable for Zimbabwe [15]. The hourly-average diffuse radiation values were determined in a similar fashion as the hourly GHI. Collector-plane hourly irradiation was obtained by applying the isotropic tilted-plane model of [16], with ground albedo fixed at 0.2.

Hourly ambient temperature was generated from monthly-average minimum and maximum ambient temperature using the prediction-model of [17]. The temperature of the cold water entering the solar water heating system Tmains was assumed to be equal to the temperature of the soil in which the water mains is buried and predicted through its correlation with air temperature [18].

The required monthly average meteorological data for the case study site (Kwekwe, Zimbabwe) is shown in Table 1.1.

To obtain the surface area of the storage tank (over which heat losses occur) with only knowledge of the tank volume, a cylindrical tank with height twice the diameter is assumed. Then it can be shown that the tank surface area As is related to the volume by:

The diurnal variation of hot water consumption that was used is adapted from the diurnal pattern measured by [19] for hotels in South Africa and is shown on Fig. 1.4. The seasonal variation of daily hot water demand was again adopted from South Africa data given by [20].

Adapted from Rankin and Rousseau [19]

Normalized diurnal variation of hot water demand (at temperature 50 °C) for a hotel in Southern Africa.

The computations for the hourly variation in heat contribution proceeded as shown on Table 1.2. The determination of the storage tank temperature during the first hour of the day is done iteratively, given that the concept of the average day implies that the performance of the solar heating system is identical for all days in a given month. Therefore, the tank temperature in hour 1 is equal to the tank temperature in hour 24 plus the temperature gain/loss in hour 24 (i.e. \(T_{s} \left( {hour 1} \right) = T_{s} \left( {hour 24} \right) + \Delta T_{s} \left( {hour 24} \right)\). This also implies that the sum of the hourly temperature gains/losses over the average day is equal to zero (i.e. \(\sum\nolimits_{1}^{24} {\Delta Ts = 0}\)), Hove and Mhazo [21], as indicated in Table 1.1.

1.5 Results and Discussion

Ten (10) different brands of non-concentrating collectors, including both flat plate and evacuated tube collectors, all of which have been rated under the OG-100 collector certification program of the Solar Ratings & Certification Corporation (SRCC), were ranked by the energy-per-dollar metric of Eq. (1.9). In order to make a fair comparison, the energy-per-dollar metric for all the collector arrays was calculated when the collectors are sized such that heat 1000 L of hot water to a temperature 50 °C at an annual solar fraction that results in maximizing the net present value of solar savings. The reference area used for specifying collector efficiency parameters FRτα and FRUL and other area-related parameters in Table 1.3, is the gross collector area.

The actual names of the collector manufacturers and brands are withheld, but the individual manufacturers will surely recognize their product from its performance characteristics given on Table 1.3. The collector with rank 1 with an energy-per-dollar score of 26.1 kWh/$ should rationally be selected ahead of its competitors for the water heating system, at the specified temperature (50 °C), for climatic conditions similar to those prevailing in central Zimbabwe. Other selection metrics, which are normally used by different individuals in deciding which collector to buy, are also shown on Fig. 1.3. These metrics include the collector cost/unit area; the collector efficiency parameters (FRτα, FRUL and the incidence angle modifier function); the warranty period offered by the supplier and the collector footprint area per unit volume of hot water demand. However, it is argued here that the energy per dollar is the most objective metric for selecting among collectors. Using individual collector attributes as selection criteria may result in a non-objective decision about the most cost-effective collector to employ. For example the collector with the lowest cost per gross area ($157/m2) ranked 10th according to the energy-per-dollar criterion because of its other less favourable attributes such as low optical efficiency and short warrant period. On the other, a collector which is more than twice as expensive ($345/m2) ranked a respectable 4th, because of its other more favourable attributes such as higher optical efficiency and longer guaranteed longevity (warrant period).

Table 1.3 shows that flat plate collectors (FPC) generally rank higher than evacuated tube collectors (ETC) for solar water heating applications for the climatic conditions considered, according to the energy-per-dollar criterion. For a comparable solar energy output (comparable solar fraction), e.g. collector 2 and collector 5, the required collector footprint area for an FPC is considerably smaller than that for an ETC because of the higher gross area efficiency of the FPC in the considered temperature-gain range. The required footprint area may be used as a secondary selection criterion where collector-placement space is an issue.

Once the most cost-effective collector to buy for a specific application and climatic conditions has been selected, the next questions to be answered are; which the most economic area is to deploy for the solar water heating system; what size of storage tank should fit this collector area and what is the optimal solar fraction. These questions can be answered by employing a thermo-economic model, like the one used in this paper, and making the net present value (NPV) of solar savings the objective function.

Figure 1.5 shows the variation solar fraction, NPV and storage-ratio (volume of storage tank to daily hot water demand at load temperature), applied for a solar water heating system at the selected location and employing the top ranked collector on Table 1.3. The value of the collector area for which the net present value is maximum is the optimal collector area to be specified for the solar water heating system. The values of the normalized storage tank volume and the solar fraction read from the chart corresponding to the optimal collector area, at this “sweet spot”, are the optimal specifications for these variables. For instance, at the selected location in central Zimbabwe (latitude 19° South and longitude 30° East), when using the top-ranked flat plate collector on Table 1.3 to heat water to 50 °C, the optimal collector area is 18 m2 per every m3 of daily hot water consumed. The required storage volume is 900 L (0.9 × 1000 L) per m3 of daily hot water demanded. The required hot water storage volume decreases as the deployed collector area increases, while the solar fraction increases, with diminishing marginal returns, until it saturates at a value of unity. At optimal design point, the solar fraction is 0.91 and the amount of solar savings in present value terms is $5881 for every m3 of daily hot water consumed. Due to diminishing marginal thermal energy returns, attempting to increase the solar fraction by only 8%, from the optimal 91 to 99%, will require increasing the collector area from 18 to 40 m2, resulting in the net present value diminishing from $5881 to $1019. On the other hand, reducing the size of the collector area below 4 m2, will result in a loss-making solar water heating system—the net present value will be less than zero.

The input data used to come up with the results of Fig. 1.5 is listed on Table 1.4.

The diurnal temperature performance of the 1000-L solar water heating system is shown on Fig. 1.6, together with the simulated incident solar irradiance and ambient temperature. For this particular optimally sized solar water heating system, the temperature of water in the storage tank reaches a maximum of 69 °C (19 °C above the load temperature) and a minimum of 40 °C (10 °C below the load temperature). With the assumed hot water withdrawal pattern (Fig. 1.4), the back-up heater will be required between 6 am and 12 pm, when the temperature of the water supplied by the solar system is less than load temperature 50 °C. The storage tank temperature dips to a low at about 9 am due to large hot water withdrawal at 7 and 8 am, then because of powerful solar radiation, it rises fairly fast from 9 am until 2 pm, despite some substantial hot water withdrawal. Between 2 pm and 5 pm, the rate of temperature rise slows down as the solar radiation tapers down, even though there is little hot water withdrawal during this period. After 5 pm, the combination of no radiation income, substantial water withdrawal and storage tank heat losses contribute to the tank temperature falling significantly. It is important to check that the maximum temperature in the storage tank does not exceed a critical design threshold (e.g. boiling point) over all weather conditions. For this system, the maximum storage tank temperature in October (hottest and highest radiation month) was determined to be below 80 °C, which is considered low enough to avoid boiling and associated system component failures.

1.6 Conclusion

Systematic methodologies are needed in order to make cost-effective decisions about choice and size of solar collector to employ in a solar water heating system. The energy-per-dollar metric as defined in this study, is one such instructive decision-making metric, as it includes all the important few collector attributes that influence life-cycle cost-effectiveness, i.e. collector warranty life; energy output per unit area and cost per unit area. In the study, a sample of SRCC-rated collectors, with differently-attractive attributes such as low cost-per-area, excellent efficiency curves or long warranty lives, were ranked using the energy-per-dollar metric. Flat plate type of collectors occupied the top four ranks, for the climatic conditions and load temperature under consideration. For the top-ranked collector (26.1 kWh/$), the collector area prescribed in the optimally-sized solar water heating system was 18 m2/m3 of hot water demand, the solar fraction 0.91, the storage-demand ratio 0.90 and the NPV was 5881/m3 of hot water demand. Although the method of this paper approach was applied only for a solar water heating application of specified operating temperature, at a specified location, it can be applied equally well for any other solar water heating application and at any other location.

Abbreviations

- \(\Delta t\) :

-

Finite time-step period over which the solar process is simulated [s]

- \(T_{s}\) :

-

Temperature of hot water storage tank contents at the beginning of the period \(\Delta t\;\left[ {^{ \circ } {\text{C}}} \right]\)

- \(\Delta T_{s}\) :

-

Temperature gain/loss for storage tank during time-step period \(\Delta t\;\left[ {^{ \circ } {\text{C}}} \right]\)

- \(T_{s}^{ + }\) :

-

Temperature of storage tank contents at the end of \(\Delta t\;\left[ {^{ \circ } {\text{C}}} \right]\)

- \(T_{a}\) :

-

Ambient temperature [°C]

- \(T_{mains}\) :

-

Incoming cold water temperature [°C]

- \(T_{load}\) :

-

Temperature required by the load [°C]

- \(\dot{m}_{s}\) :

-

Mass rate of water abstraction [kg/s]

- \(m_{{\mathop {load}\limits^{.} }}\) :

-

Mass rate of water abstraction required by the load at temperature \(T_{load}\) [kg/s]

- M :

-

Mass of hot water storage tank [kg]

- V s :

-

Volume of hot water storage tank [m3]

- U s :

-

Storage tank heat loss coefficient [W/m2/oC]

- As :

-

Storage tank surface area [m2]

- Q u :

-

Rate of useful heat generated by the solar energy collector

- \(\dot{L}_{s}\) :

-

Rate of removal of solar-generated heat [Watts]

- G T :

-

Global solar irradiance incident on the plane of the collector [W/m2]

- A C :

-

Solar collector gross area [m2]

- F R :

-

Collector heat removal factor [–]

- \(\left( {\tau \alpha } \right)_{n}\) :

-

Transmittance-absorption product [–]

- U L :

-

Collector heat loss coefficient [W/m2/°C]

- \(K_{\tau \alpha }\) :

-

Angle of incidence modifier [–]

- S F :

-

Solar fraction; the fraction of required heat contributed by solar energy [–]

- C C :

-

Collector cost per unit area [$/m2]

- C S :

-

Storage tank cost per unit volume [$/m3]

- i :

-

Annual interest rate [–]

- j :

-

Annual inflation rate [–]

- d :

-

Annual discount rate [–]

- \(Q_{annual}\) :

-

Energy generated by solar collector over an average year [kWh/m2/yr]

- \(C_{annual}\) :

-

Annualized cost of collector based on warranty period [$/m2/yr]

References

Wbdg.org., Solar Water Heating | WBDG Whole Building Design Guide (2018). [online] Available at: https://www.wbdg.org/resources/solar-water-heating. Accessed 5 Jan 2018

Zetdc.co.zw., Tariffs | ZETDC (2018). [online] Available at: http://zetdc.co.zw/tariffs/. Accessed 5 Jan 2018

T. Hove, E. Manyumbu, G. Rukweza, Developing an improved global solar radiation map for Zimbabwe through correlating long-term ground- and satellite-based monthly clearness index values. Renew. Energy 63, 687–697 (2014)

Zesa.co.zw., Why do we have Load Shedding? (2018). [online] Available at: http://www.zesa.co.zw/index.php/component/k2/item/17-why-do-we-have-load-shedding. Accessed 6 Jan 2018

Nama-database.org., National Solar Water Heating Programme—NAMA Database (2018). [online] Available at: http://www.nama-database.org/index.php/National_Solar_Water_Heating_Programme. Accessed 6 Jan 2018

K. Hudon, T. Merrigan, J. Burch, J. Maguire, Low-cost Solar Water Heating Research and Development Roadmap (2018) [online] Available at: http://www.ctgn.qc.ca/images/bulletins/bulletin_vol4no3/pdf/gb_solar_nrel_report.pdf. Accessed 6 Jan 2018

S. Sillman, The Trade-Off Between Collector Area, Storage Volume, And Building Conservation In Annual Storage Solar Heating Systems (1981). [online] Nrel.gov. Available at: https://www.nrel.gov/docs/legosti/old/907.pdf. Accessed 7 Jan 2018

A. Rushforth, Comparing Collectors Using SRCC Rating Data (2007). [online] Builditsolar.com. Available at: http://www.builditsolar.com/References/Ratings/CollectorCompare.htm. Accessed 7 Jan 2018

J.A. Duffie, W.A. Beckman, Solar Engineering of Thermal Processes (Wiley, Hoboken, NY, 2013), p. 399

Solar-rating.org., Solar Rating & Certification Corporation—Certification & Listing Directory (2018). [online] Available at: http://www.solar-rating.org/certification_listing_directory/. Accessed 7 Jan 2018

S.A. Klein, Calculation of flat-plate collector utilizability. Sol. Energy 21(5), 393–402 (1978)

B. Gravely, Optimal Design in Solar Hot Water Systems—How Does Size Alter Performance? (2018) [online] http://www.solarhotwater-systems.com. Available at: http://www.solarhotwater-systems.com/optimal-design-in-solar-hot-water-systems-how-does-size-alter-performance/. Accessed 7 Jan 2018

T. Hove, E. Manyumbu, G. Rukweza, Developing an improved global solar radiation map for Zimbabwe through correlating long-term ground- and satellite-based monthly clearness index values. Renew. Energy 63, 687–697 (2014)

M. Collares-Pereira, A. Rabl, The average distribution of solar radiation-correlations between diffuse and hemispherical and between daily and hourly insolation values. Sol. Energy 22(2), 155–164 (1979)

T. Hove, J. Goettsche, Mapping global, diffuse and beam solar radiation over Zimbabwe. Renew. Energy 18(4), 535–556 (1999)

B. Liu B, R. Jordan R, Daily insolation on surfaces tilted towards the equator. Trans. ASHRAE, 526–541 (1962)

C. Wit, Simulation of assimilation, respiration and transpiration of crops (Centre for Agricultural Publishing and Documentation, Wageningen, 1978), p. 148

T. Toy, A. Kuhaida, B. Munson, The prediction of mean monthly soil temperature from mean monthly air temperature. Soil Sci. 126(3), 181–189 (1978)

R. Rankin, P.G. Rousseau, Sanitary hot water consumption patterns in commercial and industrial sectors in South Africa: impact on heating system design. Energy Convers. Manage. 47(6), 687–701 (2006)

J.P. Meyer, A review of domestic hot water consumption in South Africa. R & D J. 16(2000), 55–61 (2000)

T. Hove, N. Mhazo, Optimal sizing and economic analysis of low-cost domestic solar water heaters for Zimbabwe. J. Energy South Afr. 14(4), 141–148 (2003)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

<SimplePara><Emphasis Type="Bold">Open Access</Emphasis> This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.</SimplePara> <SimplePara>The images or other third party material in this book are included in the book's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the book's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.</SimplePara>

Copyright information

© 2018 The Author(s)

About this paper

Cite this paper

Hove, T. (2018). A Thermo-Economic Model for Aiding Solar Collector Choice and Optimal Sizing for a Solar Water Heating System. In: Mpholo, M., Steuerwald, D., Kukeera, T. (eds) Africa-EU Renewable Energy Research and Innovation Symposium 2018 (RERIS 2018). RERIS 2018. Springer Proceedings in Energy. Springer, Cham. https://doi.org/10.1007/978-3-319-93438-9_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-93438-9_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-93437-2

Online ISBN: 978-3-319-93438-9

eBook Packages: EnergyEnergy (R0)