Abstract

Carbon nanotubes (CNTs) have attracted the interest of numerous researchers in materials sciences and engineering because of their superior electronic and optoelectronic properties. Extensive progress has been realized through the use of CNTs, especially single-walled carbon nanotubes (SWCNTs), in optoelectronics and energy harvesting devices, including solar cells, light-emitting diodes, touch panels, and transistors. Here, we review the novel applications of CNTs in solar cells. The use of CNTs as additives, light absorbers, carrier transporters, and transparent electrodes in solar cells has been reported over the past decade. CNTs are applicable to various solar cell technologies, including CNTs/Si heterojunction , organic–inorganic perovskite, dye-sensitized, and organic photovoltaic solar cells. This review surveys recent progress in the application of CNTs to photovoltaics.

Similar content being viewed by others

Keywords

- Carbon Nanotubes (CNTs)

- Perovskite Solar Cells (PSCs)

- SWCNT Film

- Dye-sensitized Solar Cells (DSSCs)

- MWCNTs

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

20.1 Introduction

Recently, carbon nanotubes (CNTs) have been used in many types of solar cells with high photovoltaic performance [1,2,3,4,5,6,7]. Initially, the CNTs were incorporated into solar cells as electron acceptors in organic photovoltaic (OPV) devices. Single-walled carbon nanotubes (SWCNTs) form a heterojunction with the employed polymer, poly(3-hexylthiophene) used for the effective dissociation of excitons (bound electron–hole pairs) and the creation of long-lived free charges for the carrier extraction. Suzuki et al. reported the integration of CNTs into dye-sensitized solar cells (DSSCs) as a counter electrode material, where the SWCNTs were deposited onto Teflon membrane filter cells, resulting in a device with a promising photovoltaic conversion efficiency (PCE) of 4.5% [8]. Moreover, CNTs have been incorporated into photoelectrochemical cells as additives in donor–acceptor pairs in conjunction with quantum dots , fullerenes , and many other photoactive polymers [9, 10].

Progressive studies of CNTs combined with Si, which is a well-understood semiconductor used in electronic devices, have recently been conducted to elucidate the mechanisms of photocarrier generation, exciton dissociation, and electron and hole transport . The typical architecture of a CNT and Si heterojunction (CNT/Si) device is similar to that of a single-junction crystalline Si solar device except that p-type or n-type Si is replaced with a thin CNT film to form p-type CNT/n-type Si (p-CNT/n-Si) or n-type CNT/p-type Si (n-CNT/p-Si) solar cells. The Si in the cells mainly absorbs photons and generates electron–hole pairs, which diffuse to the space-charge region. The electron–hole pairs are separated into free charge carriers (electrons and holes) under the driving force of the built-in voltage [11]. Through improvements in CNT films stemming from improvements in fabrication and chemical modification processes, the photovoltaic conversion efficiency (PCE) of CNT/Si solar cells has been improved from 1.3 to 17% in p-CNT/n-Si and from 0.01 to 4.62% in n-CNT/p-Si photovoltaic devices within less than a decade [12,13,14,15]. Notably, the p-CNT/n-Si cells show better performance than the n-CNT/p-Si devices because of their greater open circuit voltage (Voc) and fill factor (FF), suggesting that the p-CNTs are more promising for use in solar cells.

Organic–inorganic hybrid perovskite solar cells (PSCs), which are a new class of photovoltaic (PV) device, have shown excellent photovoltaic performance (a certified efficiency of 22.1%) thus far [16]. However, one of the critical problems with this type of solar cell is poor stability under ambient and light illumination conditions. The devices typically include a hole transport layer (HTL) between a perovskite -structured light absorber and a hole-collecting electrode for efficient charge extraction. However, the performance of HTLs composed of either poly(triarylamine) (PTAA) or 2,2′,7,7′-tetrakis-(N,N-di-p-methoxyphenylamine)-9,9′-spirobifluorene (spiro-OMeTAD) commonly used in organic–inorganic hybrid PSCs decays within a very short time under ambient conditions. CNTs are potential alternative HTL materials for PSCs. Cells fabricated with SWCNTs wrapped with P3HT as a hole transporter exhibit a power conversion efficiency (PCE) as high as 15.3% with better stability than cells with PTAA or spiro-OMeTAD [17]. In previous work, we designed a hole transport/electron blocking layer based on an SWCNT network film combined with graphene oxide (GO) and poly(methyl methacrylate) (PMMA) to reduce shunt recombination and improve hole-selective transport. A PCE of 13.3% was attained in PSCs with a SWCNT/GO/PMMA layer, which is substantially greater than the PCE of the corresponding hole-transport-free device (3.3%) [18]. This SWCNT/GO/PMMA layer also improved the device stability by inhibiting the interaction between ambient moisture and the perovskite layer. In addition to their application as a hole transport material, CNTs have also been used as flexible transparent electrodes to replace the fluorine-doped tin oxide (FTO) substrates used for the film devices in PSCs [19].

CNTs have also been used as light absorber and photocarrier generation materials in solar cells. Yang et al. used semiconducting SWCNTs asymmetrically contacted with Pd and Sc (or Y) electrodes. Ohmic contact between the Pd electrode and the valence band (VB) of the SWCNTs as well as between Sc (or Y) and the conduction band (CB) contributed to barrier-free carrier extraction from the SWCNTs under illumination and resulted in a PCE of 0.11% in the fabricated solar cells [21]. The performance of polychiral semiconducting SWCNT/fullerene -based solar cells also suggests that the SWCNTs participate in both light absorption and carrier generation [23]. Moreover, Zhou et al. reported that a plasmonic nanostructure effectively promotes the photoelectric response in CNT-based devices [20]. A large number of advanced properties have stimulated interesting studies on solar cells with CNTs. We here provide an overview of the CNT-based solar cells, with particular emphasis on CNT/Si- and CNT-based PSCs.

In this review, we survey the roles of CNTs in solar cells and in CNT/Si- and CNT-based PSCs, in particular. In Sect. 20.2, we discuss the fundamentals of solar cells and the general evolution of CNT-based solar cells. In Sect. 20.3, we focus on CNT/Si solar cells, where the roles of CNTs are discussed in detail. In Sect. 20.4, PSCs in which CNTs are incorporated as electrodes, HTLs, or effective additives are demonstrated. In Sect. 20.5, we review the important research related to organic solar cells and sensitized solar cells with incorporated CNTs. Finally, we summarize the current state of CNT-based photovoltaic devices and future challenges facing the advancement of CNT-based optoelectronic devices.

20.2 CNTs in Solar Cells

20.2.1 Principle of Solar Cells

A photovoltaic device is designed to convert incident solar energy into electric power. The photons of the solar light with energy beyond the absorption edge are absorbed by the semiconducting materials. The electrons in the CB are excited to the VB, and holes are generated in the VB (Fig. 20.1). The electrons in the CB quickly decay to the lowest available energy state of the CB, whereas the holes in the VB decay to the highest energy state of the VB on a timescale on the order of 100 fs (10−13 s). The cooled electrons and holes are separated by the built-in electric field, and the electrons and holes as carriers are fed to the external circuit as photogenerated current. Note that the band gap is very important for maintaining the excited electrons at a sufficiently high energy level long enough to be ejected by the electrodes. The performance of a photovoltaic device is strongly dependent on the absorbing materials and on how effectively the carriers are extracted by the external circuit.

Schematic of light absorption and carrier generation in a semiconductor with a bandgap of Eg. The electron in the conduction band is excited to the valence band, creating a hole in the valence band. The electrons (holes) thermalize to the band edges and are then extracted by the electrode under the built-in electric field

In photovoltaic devices, the junction between two electronically different materials introduces an electrostatic dipole field at the interface. The electrostatic dipole field induces a built-in voltage (Vd), which drives the photoexcited electrons and holes in opposite directions. A built-in voltage can be generated by either a Schottky (semiconductor/metal) or a p–n (p-type semiconductor/n-type semiconductor) junction. A band diagram of n-type semiconductor/metal Schottky junction is presented in Fig. 20.2a, where the work function (Φn) of the semiconductor is smaller than that of the metal (Φm). The Fermi levels are realigned because of carriers exchanged across the junction when the interfaces (metal and semiconductor) are connected to each other, resulting in a barrier difference of Φm − Φn between the semiconductor and the metal. If no surface states exist, the electrostatic field generated by the built-in voltage Vd directly corresponds to the energy difference of Φm − Φn. The potential difference Vd is shared between the two materials according to their dielectric permittivities. A p–n junction , as another important heterojunction , is formed between p-type and n-type semiconductors. Figure 20.2b shows a schematic of a p–n junction. A dipole electric field is established at the heterojunction interface because of the difference in work functions, which drives photoexcited electrons toward the n-type semiconductor side and holes toward the p-type semiconductor side. In photovoltaic applications, a p–n junction has advantages over a Schottky barrier junction with low defect densities and a large built-in voltage.

The excited electron–hole pairs in the photovoltaic process are transported, collected, and extracted to an external circuit. A mechanism for charge carrier separation is required, and the intrinsic potential asymmetry for electrons and holes drives the electrons (holes) away from their point of origin in the solar cell. The separated electrons and holes as the carriers are extracted and transported to an external circuit to generate the photocurrent. The photocurrent density of the device is described as

where q is the electronic charge, bs(E) is the incident spectral photon flux density, and QE(E) is the probability that an incident photon with energy E will deliver an electron to the external circuit, which depends on the absorption coefficient of the photoactive material and on the efficiency of charge separation and charge collection. A dark current Idark(V), which acts in the opposite direction to the photocurrent, is generated by the potential difference between the terminals of the cell. Most of the cells exhibit diode behaver under dark conditions . The dark current Jdark(V) flowing across the diode under an applied voltage V is given by

where J0 is a constant, n is an ideality factor, kB is Boltzmann’s constant, and T is the absolute temperature.

The overall current–voltage characteristic can be approximated as the sum of a short-circuit current and the dark current (Fig. 20.3). Therefore, the net photocurrent density in the cell is

At open circuit, Jdark(V) = Jsc. We obtain an equation for the Voc:

In an actual solar cell, the resistance of materials, the resistance between contacts, and the leakage current result in power losses. These resistances are electrically equivalent to two parasitic resistances in series (Rs) and in parallel (Rsh) (inset of Fig. 20.3). The current density is described as follows if we include the resistances:

where A is the effective area of the solar cells. Figure 20.3 shows a typical J–V curve based on Eq. (20.5). The power density of the solar cell is defined by P = JV in the bias range from 0 to Voc. The maximum value of P is the cell’s operating point, at which the voltage and current density are labeled as Vm and Jm, respectively. The FF is defined as

The efficiency (η) of a solar cell is the power density delivered at the operating point as a fraction of the incident light power density (Pin):

where Jsc, Voc, FF, and η are the important parameters used to characterize the performance of solar cells.

20.2.2 Roles of CNTs in Solar Cells

20.2.2.1 Carrier Generation

The photocarrier generation in semiconducting SWCNTs (s-SWCNT) has been extensively studied over the past decade. Figure 20.4 shows a schematic of photocarrier generation in an s-SWCNT. Freitag et al. investigated the infrared-laser-excited photoconductivity of individual s-SWCNTs [21]. The mechanism of photocurrent generation involves resonant excitation of the E22 exciton state in an s-SWCNT. In particular, the phenomenon of multiple electron–hole pair generation has also been reported in SWCNTs, where efficient multiple carrier generation from a single hot E22 exciton occurs [22]. This interesting property, in principle, could contribute to a higher PCE that overcomes the Shockley–Queisser limit, which is defined on the basis of the assumption that an absorbed single photon generates a single electron–hole pair (exciton) in a semiconductor. Shockley and Queisser used a detailed balance calculation to derive a fundamental limit of photovoltaic conversion efficiency (PCE) of a single-junction solar cell [23].

Schematic of photocarrier generation in an s-SWCNT. Reprinted with permission from Ref. [21]. Copyright 2003 American Chemical Society

The photocurrent quantum efficiency (QE), which is the most important factor in assessing the incident light conversion to electric power, was calculated as initial values of 1–5% [24]. Aspitarte et al. reported that a p–n junction device with a suspended carbon nanotube with a diameter of 2–3 nm could yield a photocurrent QE of 20–40% [25]. Aspitarte et al. speculated that the CNTs were excited by high photon energies at the fourth sub-band (S44) and fifth sub-band (S55) states and that large-diameter CNTs contribute to the high QE, which is consistent with the increase of QE with increasing nanotubes diameter and decreasing exciton binding energy [26]. Lee et al. demonstrated the photovoltaic effect in individual SWCNTs using a p–n junction diode, which demonstrated a PCE of 0.2% [27]. Calculations predicts that a high PCE of CNT solar cells will be achieved by further improvements of the quality of SWCNTs and of device architecture in the future [28].

Recently, researchers have developed CNT/Si heterojunction solar cells by taking advantage of the high mobility, conductivity, and transparency of CNTs. Ong et al. reported the photocurrent response of an SWCNT/Si heterojunction solar cell fabricated using SWCNTs with a narrow chirality distribution [29]. They observed a small photocurrent response peak at the E11 exciton band, which demonstrates that the SWCNTs contribute to the photoconversion process not only as a charge separator/transporter/collector but also as a light absorber in the SWCNT/Si heterojunction solar cell.

20.2.2.2 Carrier Transport Material

Because of their high carrier mobility, CNTs show great promise for use as carrier transport materials in optoelectronic devices. The initial success in the application of CNTs in solar cells was achieved with organic solar cells in which the CNTs were used as electron acceptors wrapped with a conjugated polymer [30]. However, the CNTs yielded relatively low PCEs when used as electron acceptors in photovoltaic devices because the Fermi level between the polymer and the nanotubes realigned to energetically favor hole transfer from the polymer to the nanotubes [31, 32]. Dabera et al. applied CNTs as the hole extraction layer in organic solar cells, resulting in improved device performance [33].

In principle, the CNTs in organic solar cells mainly play the role of a “bridge” to facilitate carrier transfer among the organic semiconducting molecules [34]. Three important factors for carrier transport have been identified:

(1) Metallic CNTs (m-CNTs) are not appropriate for improving the performance of OPV devices because they induce short circuits, undergo aggregation, introduce impurities, and exhibit low charge mobility when introduced into organic solar cells [7, 35]. The carrier mobility is dominated by Schottky barriers from the junctions between the m-CNTs and the semiconductors (M–S junctions), leading to poor solar cell performance. This result is similar to that reported by Topinka et al. for m- and s-CNT Schottky barriers [36]. However, the chirality separated m- and s-SWCNTs exhibit higher performance than the mixed m- and s-SWCNTs [37]. The contribution of s-CNTs to the electron charge transfer has been elucidated through ab initio calculations of polymer/CNT heterojunctions [38]. Moreover, the CNTs serve as an effective HTL in CNT/Si and PSCs [18].

(2) The morphology and structure of CNTs greatly affect their carrier transport properties. Highly oriented and isolated SWCNTs coated with a P3HT layer exhibit high carrier transfer ability [39], which strongly suggests that controlling the dispersion of SWCNTs in the polymer is a critical factor affecting photovoltaic performance.

(3) The chemical doping or surface modification of CNTs can considerably improve their carrier transport ability because the carrier density can be improved, reducing the resistance in each individual CNT. Nogueira et al. attempted to mitigate the aggregation of SWCNTs through covalent functionalization with thiophene moieties and achieved a PCE of 1.48% using functionalized SWCNTs and P3OT polymer under 1.55 mW/cm2 illumination [40].

20.2.2.3 Transparent Conducting Electrodes

CNTs are considered promising transparent conducting electrode (TCE) materials because they are fabricated from an abundant raw material; exhibit excellent conductivity, high specular transmittance over a wide spectral range, superior flexibility , and high chemical stability; and are cost-effective to fabricate [41,42,43,44]. Ago et al. first reported the replacement of indium tin oxide (ITO) electrodes with CNTs in polymer solar cells. They observed an enhanced external quantum yield (EQE), which they attributed to the interpenetrating network between the polymer and the MWCNTs and to a higher built-in electric field resulting from the higher work function of the MWCNTs (5.1 eV) compared with that of ITO [45]. Wu et al. demonstrated that conductive thin films made from high-purity SWCNTs represent a promising alternative to ITO [46]. An improved PCE was reported when a SWCNT layer was substituted for the common ITO electrode [47]. However, the photovoltaic performance was very low because of the high sheet resistance of the SWCNT film.

An ideal TCE should exhibit very high light transmission in a broad range from the UV to the NIR region while simultaneously exhibiting low sheet resistance. However, a trade-off exists between these two parameters. Ellmer et al. presented a useful method to judge the properties of a transparent electrode on the basis of the ratio between its dc electrical conductivity (σdc) and its optical conductivity (σOP), which is expressed as [48]

where μ0 and ɛ0 are the free-space permeability and free-space permittivity, respectively, \( T^{\prime} \) is the transmittance, and Rsheet is the sheet resistance. We can calculate the σdc/σOP ratio by measuring \( T^{\prime} \) and Rsheet and obtain a value for comparison with the properties of a CNT film. Different σdc/σOP ratios are required depending on the application. Solar cells usually require high transmittance and low sheet resistance of the CNT films to ensure efficient energy harvesting and transport. A transfer-printing method was used to produce low sheet resistance CNT films (200 Ω/sq) with a high optical transmission of 85% in the visible range [49]. Muramoto et al. fabricated an SWCNT/Si solar cell with a PCE of 10.4% by utilizing a low sheet resistance (268 Ω/sq) and high-transmission (90%) CNT film deposited via vacuum filtration. An SWCNT/Si solar cell with the same window area and similar transmittance (88%) was fabricated using spray-coated CNTs; the resultant film exhibited a very high sheet resistance (7600 Ω/sq) and resulted in a low PCE of 0.83% [50]. These results strongly suggest that the properties of CNTs are critical factor affecting the performance of CNT-based solar cells.

Yu et al. [1] fabricated CNT TCEs by various approaches and compared their performance. To realize the practical applications of CNT electrodes in optoelectronic devices, especially solar cells, further modification of CNTs toward low resistance but high transparency is needed. The chemical doping of CNTs has been extensively studied and could drastically improve their electrode performance. Numerous p-type dopants (e.g., NO2, Br2, HNO3, SOCl2, HCl, AuCl3, FeCl3, metallic particles, and metal oxides ) and n-type dopants (e.g., poly(ethyleneimine) (PEI), benzyl viologen, and potassium) have been reported. In practice, the p-type dopants are more promising because the CNTs are slightly p-doped by oxygen under ambient conditions [51]. In addition to chemical doping, the hybridization of CNTs with other materials as electrodes has also been investigated. The hybrid electrodes tend to exhibit improved stability and conductivity.

20.3 Carbon Nanotube/Silicon Solar Cells

Solar cells based on CNT and Si (CNT/Si) heterostructures have been extensively studied as model devices [52,53,54]. PCEs greater than 10% have been realized in CNT/Si solar cells by many groups, and a record efficiency of 17% has been reported (see Table 20.1). These large improvements in the performance of the CNT/Si solar cell devices have mainly resulted from various postprocessing techniques and modified device architectures; examples include improvements in the quality of CNT films [55], carrier doping of CNT films by infiltration of acid [50], controlling the electronic junctions [56, 57], and coating the CNT/Si surface with an antireflection layer [58]. Some important research and the obtained photovoltaic performances of various CNT/Si solar cells are summarized in Table 20.1.

20.3.1 Effects of CNT Films

The physical properties of CNT films strongly affect the photovoltaic performance of CNT/Si heterostructure solar cells. The CNT films have been demonstrated to serve as a semitransparent carrier transport layer in CNTs/Si solar cell devices [71]. Hence, one of the major factors limiting the photovoltaic efficiency of previously reported CNT solar cells is likely related to the carrier transport properties of the CNT films.

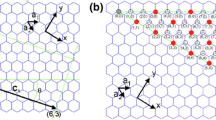

Wei et al. [15] first reported the application of CNTs in planar solar cells based on a double-walled carbon nanotube (DWCNT)/Si heterojunction in 2007. An n-Si wafer with a window of insulating layer was used to pick up a floating DWCNT film for fabricating DWCNT/Si heterojunction solar cells. The nanotubes function as both a photocarrier generator and a collection layer in the fabricated devices. Figure 20.5a shows the prepared nanotube network film, and (b) displays the photovoltaic performance of a fabricated DWCNT/Si heterojunction solar cell. A PCE of only 1.3% was achieved in the DWCNT/Si heterojunction solar cell. This low PCE was caused by a high sheet resistance, which resulted in a low short-circuit current and a low FF. The same group later achieved a high PCE of 7.4% by reducing the thickness of native silicon oxide on the n-Si window [60]. Di et al. reported aligned DWCNT films (Fig. 20.5c), which were drawn from a spinnable nanotube array, for solar cell fabrication [61]. They compared both aligned and random CNTs and concluded that aligned CNTs prefer to densely cover the Si substrate to form a high CNT–Si junction density, whereas the random CNTs result in discrete junctions between the CNTs and Si (Fig. 20.5d). As a result, the aligned-CNT-film-based solar cells showed a substantially higher PCE than the randomly dispersed CNT-based devices (Fig. 20.5e). Because of the superior performance of a densely covered CNT network deposited onto a Si substrate to achieve a high DWCNT–Si junction density, a PCE of 10.5% was achieved without chemical treatments or other postprocess modifications.

a Scanning electron microscopy image of a DWCNT film. b J–V curves of DWCNT/Si solar cells. (a and b) adapted with permission from Ref. [15]. Copyright 2007 American Chemical Society. c Optical image of aligned CNTs on an Si substrate. d Schematic of the connection between the aligned and random CNTs. e J–V curves of the aligned-CNT/n-Si solar cells and random-CNT/Si solar cells. (c–e) Reprinted with permission from Ref. [61]. Copyright 2013 John Wiley & Son, Inc

SWCNTs show a competitive conversion efficiency even in the absence of chemical modifications. Kozawa et al. fabricated solar cells by directly coating a CoMoCAT (6,5)-rich SWCNT solution onto n-type Si and demonstrated that the PCE was strongly dependent on the thickness of the SWCNT film [54]. The highest efficiency of 2.4% achieved at a transmittance of approximately 70% was mainly attributed by the balance between the effective p–n junction area and the light intensity based on an equivalent circuit model. The authors noted that the photocurrent of the devices was mainly generated in the n-Si layer. With the further optimization, a PCE of 3.4% was achieved by the same group [50]. This relatively low PCE value was attributed to the high sheet resistance and low transmittance of the SWCNTs. Our group improved the PCE of SWCNT/Si solar cells by using a floating-catalyst chemical vapor deposited SWCNT (FC-CVD SWCNT) network film, which exhibits a higher σdc/σOP than spray-cast SWCNT films (Fig. 20.6b) [55, 72]. The fabricated devices showed increased PCEs with a decrease of the active window area (Fig. 20.6d), which indicates that the sheet resistance of the SWCNT films plays a critical role in determining the solar cells’ performance. The SWCNT-thickness-dependent PCE for the different active window areas also indicates that thicker SWCNTs are preferred in solar cells with a larger window size to retard the decay of the PCE. These results suggest that we should carefully select suitable CNT films for a designated window size in solar cells to achieve the best performance. With the optimization of both the SWCNT film thickness and the window size of solar cells, the highest PCEs of 12.5, 11.6, 10.6, and 7.2% were achieved with devices with 1-, 1.5-, 2-, and 3-mm windows, respectively (Fig. 20.6d). Moreover, the high reproducibility and stability of the photovoltaic performance of these devices in air were demonstrated (Inset of Fig. 20.6c). These insights reveal promising strategies for further improving the PCE of cells and fabricating large-scale CNT solar cells with high PCEs.

a Schematic of the structure of a CNT/Si solar cell. b Optical micrograph and scanning electron microscopy image of an SWCNT film (\( T^{\prime} \) ≈ 91%). c Best solar cell performance of SWCNT/Si solar cells using FC-CVD SWCNT films. The inset shows the reproducibility of the SWCNT/Si solar cells. d PCEs as a function of window size for devices fabricated using SWCNT films with various thicknesses. Reprinted with permission from Ref. [55]. Copyright 2014 American Chemical Society

MWCNTs have also been used for CNTs/Si solar cells because they are less expensive than SWCNTs. Castrucci et al. reported a MWCNT/Si device in which MWCNTs served as both a photocurrent generator and a semitransparent electrode [73]. However, the reported PCE was very low. Nicola et al. reported MWCNT/Si heterojunction solar cells with a high reproducible PCE of 8 ± 1% by tailoring the optical and electrical properties of CNTs [64]. The heterojunction between the MWCNTs and Si extended the spectral absorption from the near-infrared to the near-UV region, which facilitated charge dissociation and the transport of electrons to the Si layer.

A comparison of the properties of MWCNTs and SWCNTs and their selection for further applications is important because many types of CNTs have been used in solar cells. Grace et al. used suspensions of single-walled, double-walled, and multiwalled CNTs for a reliable comparison of the differences in cell properties [74]. The σdc/σOP ratios for all of the films were approximately the same, and a detailed comparison of the cells was carried out after they were treated with HF and SOCl2. Their comparison shows that cells with SWCNTs and DWCNTs exhibited similar PCEs that differed by less than 0.5%, whereas the MWCNT-based devices exhibited lower PCEs. Grace et al. also noted that large-diameter SWCNT films tended to exhibit the best performance in the CNT/Si solar cells. Harris et al. further demonstrated that, when chirality purified SWCNTs were used in devices, different-type and -chirality SWCNTs strongly affected the solar cell performance [37]. These results strongly suggest that SWCNT properties such as purity, chirality, type, and diameter will strongly affect device performance.

20.3.2 Chemically Functionalized CNTs

The PCE of CNT/Si solar cells can be improved to greater than 10% by the selection of appropriate CNTs. However, the application of pristine CNTs in solar cells is still restricted by the mixtures of both s- and m-CNTs and poorly conductive CNT bundles. Chemical modification effectively improves their properties for solar cell applications. The conductivity of CNT films is determined by the conductivity of the individual CNTs and by the contact resistance between CNTs. Chemical doping improves both aspects by shifting the Fermi level to increase the charge carrier density and reducing the Schottky barrier height between s- and m-SWCNTs [7]. Numerous efforts to modify CNTs through chemical doping to improve the performance of solar cells have been reported, including modification with acids, metal oxides , gold, and ionic liquid electrolytes.

Li et al. used SOCl2 to modify SWCNT films for an SWCNT/Si solar cell that showed a 45% improvement in PCE because of modification of the Fermi level and increases in the carrier concentration and mobility [75]. Hall-effect measurements demonstrated that the carrier density increased from 3.1 × 1015 to 4.6 × 1017 cm−2 after the SOCl2 treatment. Another effective doping method was reported by Jia et al.; their process is shown in Fig. 20.7a. The HNO3 infiltrated into the CNT network and into the interface of the CNT/Si heterojunction , resulting in an increase of the PCE of doped CNT/Si cells to 13.8 from 6.2% in the pristine cell (Fig. 20.7c). They also investigated the acid doping effect on the performance of CNT/Si solar cells and concluded that both a decrease in sheet resistance and an increase in heterojunction density after HNO3 doping contributed to an increase of the PCE of the solar cells [65]. Nicola et al. also reported the fabrication of photovoltaic devices with CNTs treated using HNO3 vapors for 10 s; the devices exhibited a PCE as high as 12% and a record internal quantum efficiency of 100% [76].

a Illustration of the CNTs/Si solar cell and infiltration of nitric acid into the CNT network to form Si-acid-CNT photoelectrochemical units at the interface. b Process of vacuum evaporation of MoOx onto a CNT film. c J–V curves of the CNTs/Si solar cell. (a and c) Reprinted with permission from Ref. [65]. Copyright 2011, American Chemical Society. d Series resistance before and after MoOx coating. Reprinted with permission from Ref. [14]. Copyright 2015, Nature Publishing Group

In addition to acids, gold(III) chloride (AuCl3) has also been reported to enhance the PCE of CNT/Si solar cells. Li et al. prepared SWCNT films by a super-acid sliding method and transferred them onto patterned Si wafers to fabricate SWCNT/Si solar cells [77]. A high PCE of 11.5% was achieved using SWCNTs treated with the nitric acid and AuCl3 because of a large increase in the Jsc. The Au has been proposed to function as a precursor for Cl adsorption to effectively improve electron extraction from the CNTs [78].

Although the wet state doping with acids can increase the performance of solar cells, the stability of such devices is problematic because of the volatility of the acids. The dry-state doping was introduced as an alternative method for improving both performance and stability. We deposited a layer of molybdenum oxide (MoOx) onto SWCNTs, which can effectively dope carriers into the CNTs (Fig. 20.7b) [14]. Figure 20.7d shows the \(I(dV/dI)\) plots for the pristine-SWCNT/Si and MoOx-SWCNT/Si (SWCNTs with MoOx coating) solar cells as a function of the current (I). The series resistance (Rs) of the solar cells without and with the MoOx coating was evaluated from the slope of this plot, and the resistance of the MoOx-SWCNT/Si solar cell (244 Ω) was substantially lower than that of the pristine-SWCNT/Si (360 Ω). This decrease in series resistance was also confirmed independently by the two-probe method, indicating that the MoOx could effectively dope carriers into the CNTs. This result is also consistent with the results of a previous report [79].

Chemical doping can also change the electronic properties of CNTs from p-type to n-type. CNT films functionalized with PEI to form n-type semiconductors have been reported [13]. Li et al. introduced cobaltocene (Cp2Co) to improve the n-type (electron) doping of CNT films, resulting in a PCE of 4.62% with assistance from the current-stimulated oxygen removal process [12]. Li et al. emphasized that the oxygen removal process is critical for n-type CNTs and reported a record PCE of 7.53% for SWCNT/p-Si cells when an HF treatment was used to remove the oxygen [66]. We reported that zinc oxide (ZnO)-assisted β-nicotinamide adenine dinucleotide (NADH) enabled effective n-type doping into SWCNTs, which we subsequently used to fabricate n-SWCNT/p-Si solar cells. The PCE of these cells increased from 1.3% in the absence of ZnO to 4%. This increased performance arises from a reduction in the loss of solar light reflectance, the efficient extraction of electrons to the contact, and a decrease in the series resistance of the SWCNTs [14].

20.3.3 Interfacial Engineering

The performance of a solar cell is not only determined by the materials quality but also by the structure of the devices. In particular, the interface between different layers can result in a large recombination loss in the solar cells. In CNT/Si solar cells, interfacial optimization between the CNTs and the Si was achieved through comparing the CNT/Si solar cells with and without the native silicon oxide layer. A low PCE of 1.3% was obtained for CNT/Si solar cells with a native silicon oxide layer [15]. In the oxide-free CNT/Si solar cells, more efficient heterojunctions were formed between the CNTs and the Si, resulting in a higher PCE of 7.4% [60]. Jia et al. also reported the CNT/Si solar cells with a thin oxide layer (1 nm) grown by immersing the CNT/Si heterojunction into acid to create a CNT-oxide-Si structure. A PCE of 10.1% was achieved, which is more than 1% greater than that achieved with a structure without a thin oxide layer (PCE = 8.9%) [80]. The oxide layer in the solar cells could suppress the dark saturation current, inhibiting recombination and leading to an increase of both the Voc and the minority carrier lifetime. An organic interlayer between the SWCNTs and the Si also could minimize the recombination loss at the interface [68]. Spiro-OMeTAD was used as an interlayer between a GO/SWCNT/Si heterojunction. The authors speculated that the organic interlayer improves the diode properties and increases the Schottky barrier height, resulting in a large Voc. Moreover, the spiro-OMeTAD interlayer could improve the stability of devices by avoiding the formation of SiO2 on the Si substrate under ambient conditions, which could drastically reduce the performance if the SiO2 thickness exceeded 2 nm [68].

Wadhwa et al. reported a novel method for improving CNTs/Si solar cells through electronic junction control using an ionic liquid gate of 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide (EMI-BTI) (Fig. 20.8a, b). The device exhibited a PCE of 8.5%, which was dynamically and reversibly adjustable between 4 and 11% via the ionic liquid gating [56]. The mechanism of the electronic junction control was explained by considering the gate-induced modulation of the CNTs’ Fermi level and the gate-modulated control of the interface dipole at the junction (Fig. 20.8c). The interface dipole also could be controlled by inserting materials between the SWCNTs and the electrode of Au via the effective hole extraction layer. The deposition of MoOx between the SWCNT and the Au electrode in SWCNT/Si solar cells was reported to modify the SWCNT surface potential and to optimize the SWCNT/Au band alignment. The change in the band alignment due to the insertion of the MoOx layer promoted photocarrier extraction from the SWCNTs to the Au electrode. The MoOx could enhance the photovoltaic performance by preventing current leakage and consequent counter-diode formation [81]. SWCNT/Si solar cells with and without insertion of the MoOx layer between the SWCNT network and the Au have been reported. Figure 20.9a shows the performance of both pristine-SWCNT/Si and MoOx-SWCNT/Si solar cells. The pristine-SWCNT/Si solar cell shows a Jsc of 29.4 mA/cm2, an FF of 65%, and a Voc of 0.58 V, which results in a PCE of 11.2%. For the MoOx-SWCNT/Si solar cell, the Jsc, FF, and Voc were 31 mA/cm2, 78%, and 0.59 V, respectively, and an improved PCE of 14.2% was attained. The enhancement in the PCE mainly arises from a reduction of the energy barrier (Fig. 20.9b, c) for charge carrier (hole) extraction and efficient transport over the interface between the SWCNT film and the Au contact, which increases the Jsc and FF values. Because of the interfacial modification, both the recombination loss and the contact resistance of the MoOx-SWCNT/Si solar cells were reduced.

a Structure of an electrically gated nanotube/Si solar cell. b Cross-section of the solar cell structure. c J–V curves of the device with variation of the gate voltage. The inset shows the change in built-in potential Vbi due to more or less Si band bending with the gate voltage. Reprinted with permission from Ref. [56]. Copyright 2010, American Chemical Society

a J–V curves of solar cells without and with an MoOx layer. Schematics of the device structures are shown in the figure. b Bandgap alignments of the pristine-SWCNT/Au and c the MoOx-SWCNT/Au interfaces. Reprinted with permission from Ref. [14]. Copyright 2015, Nature Publishing Group

20.3.4 Optical Absorption in Solar Cells

The large difference in the refractive index between air and Si results in a substantial power loss by a high reflectance of approximately 30–40% in the range from the UV to the visible region [14]. Thus, a strategy to improve the optical absorption is quite important to improving the performance. A mature technology is to etch the Si surface with an alkaline solution to form a random pyramid to improve the light scattering and absorption. Muramoto et al. reported, for the first time, microsized pyramids formed on a CNT/Si active window using a dilute sodium hydroxide solution [62]. The pyramid effectively improved the incident light absorption, leading to a high PCE of 10.4%, which is a substantial improvement (~27%) compared with that without pyramid textures. This substantial improvement of PCEs mainly arises from an increase of the Jsc. Moreover, the polymer coating on the CNT films to improve the optical absorption has also been investigated. The PMMA was used in the CNT/Si solar cells as an antireflection layer, which reduces the reflectance up to less than 10% in the wavelength range from 600 to 1000 nm and results in an increase of the Jsc from 24.3 to 35.6 mA/cm2 [70]. Other polymers such as PDMS and polystyrene have also been reported as antireflection coatings for CNT/Si solar cells [82].

Numerous researchers are interested in the polymers used in CNT/Si solar cells because they not only reduce the reflectance to increase the PCE but also protect the CNTs and the Si from moisture and oxygen to improve device stability [82]. In addition to polymers, metal oxides have also been used to enhance the optical absorption of CNT/Si solar cells. Shi et al. reported the effect of TiO2 uniformly dispersed onto the SWCNT/Si solar cells to reduce the solar light reflection (Fig. 20.10a) [58]. The Jsc of the cell improved from 24.4 to 32.2 mA/cm2 after the TiO2 coating was applied; the enhanced Jsc is very similar to the calculated values before (23.8 mA/cm2) and after (31.7 mA/cm2) the antireflection layer coating was applied (Fig. 20.10f). Note that the optimized layer thickness of TiO2 for best optical absorption is 68 nm, in agreement with the reported value (70 nm) to minimize the light reflection (Fig. 20.10d).

a, c Scanning electron microscopy image of CNT/Si solar cells coated with TiO2 and MoOx layers, respectively. b Structure of a CNT/Si solar cell an MoOx layer between the CNT film and the gold electrode. d, e Reflectance spectra of CNT/Si without and with TiO2 and MoOx layers, respectively. f, g The J–V curves of solar cells. (a, d, and f) Reprinted with permission from Ref. [58]. Copyright 2012, Nature Publishing Group. (b, c, e, and g) Reprinted with permission from Ref. [14]. Copyright 2015, Nature Publishing Group

MoOx can also contribute to an increase of the optical absorption in solar cells (Fig. 20.10b, c) [14]. The reflectance spectra of the SWCNT/Si solar cells without and with an MoOx layer are shown in Fig. 20.10e. The reflectivity (R) of the SWCNT/Si was approximately 30% and was reduced to less than 20% over the entire spectral region from 300 to 1100 nm by the MoOx coating. The Jsc of the device, therefore, was improved from 29 to 35 mA/cm2. The substantial increase in the short-circuit current density is due to the deposition of the MoOx on the active area of the cell as an antireflection layer, contributing higher PCE than without MoOx (Fig. 20.10g). The increase in the Jsc of 5.9 mA/cm2 was calculated on the basis of the difference in reflectivity of the pristine-SWCNT/Si and the MoOx-SWCNT/Si; this increase in the Jsc was approximately the same as the experimentally obtained value of 6 mA/cm2. The role of the MoOx layer was to reduce the refractive index mismatch between the Si and the air because MoOx has an intermediate refractive index (n0 = 2.2) [83]. The increase of the optical absorption in the MoOx-SWCNT/Si solar cell reduces the loss of solar light and increases the photocarrier generation because the MoOx layer operates as an antireflection layer.

20.4 Carbon Nanotubes in Perovskite Solar Cells

The organo-lead halide perovskites CH3NH3PbX3 (X = Cl, Br, I) have attracted much interest since the first report of their use in solar cells [84]. Their direct bandgaps, large absorption coefficients, and high charge carrier mobilities render them very promising photoactive layers in photovoltaic devices. PSCs constructed from mesoporous scaffolds, perovskite light absorbers (such as CH3NH3PbI3), and organic HTLs have exhibited outstanding performance [85]. The continuous improvement and engineering of interfaces [86, 87], solvents [88], and materials [89] have led to a substantial increase in the PCEs of PSCs from the first reported value of 3.8% to greater than 20% [16, 84]. However, many problems remain unsolved for the realistic application of organo-lead halide PSCs, such as the instability of both the perovskite and the organic transport layer when exposed to the atmosphere. By contrast, CNTs, being a chemically stable, flexible , and highly conductive material, have the prospect of wide application as the flexible electrode, HTL, and additives in the PSCs. A schematic of the typical device structure includes FTO, a dense TiO2 layer, a mesoporous TiO2 layer, the perovskite , a HTM, and a metal electrode, as shown in Fig. 20.11a. The CNTs could replace the HTM in the PSCs, as shown in Fig. 20.11b. Although different operating principles of PSCs have been reported, the most widely accepted one is similar to the operating principle of DSSCs, where the electron injection from the dye molecules is driven by the energy level gradient between the TiO2 and dye interface [90]. The detailed mechanism has been reported in other papers [90, 91]. Here, we mainly focus on recent progress in elucidating the roles of CNTs in PSCs. Table 20.2 presented major results of PSCs by using CNTs.

20.4.1 CNT-Based Electrodes

CNTs have been extensively used as electrode materials in PSCs because they can realize a high PCE with greater stability than PSCs with a metal electrode even in the absence of an expensive organic HTM. In the first studies where CNTs were used as the counter electrode in mesostructured PSCs, a free-standing SWCNT film was laminated onto the perovskite layer as a cathode (Fig. 20.12a) [94]. In the resulting device, the CNT film plays the roles of both hole transporter and electrode, and the obtained PCE of the PSCs with a CNT cathode was 6.87% (Fig. 20.12b), which is higher than that of an otherwise identical PSC with an Au electrode (5.14%). This result indicates that CNTs can outperform precious metals as electrode materials in PSCs. Moreover, the efficiency of the PSC fabricated with the CNT cathode was improved to 9.9% when the CNTs were doped with spiro-OMeTAD. Wei et al. reported that MWCNTs could be used to replace the metal as the back electrode in PSCs [99]. They achieved a PCE of 12.67% with a very high FF of 0.80, which is attributed to the superior conductivity of the MWCNTs and low recombination loss at the CH3NH3PbI3/MWCNT interface. The devices with MWCNTs display a negligible hysteresis of only 1.53%, which is much smaller than those of devices with spiro-OMeTAD and HTM-free PSCs. Wei et al. attributed the very low hysteresis in the devices with MWCNTs to the extraordinary charge transport along the MWCNTs.

a Schematic of a PSC with a CNT film. b J–V curves. (a, b) Adapted with permission from Ref. [94]. Copyright 2014, American Chemical Society. c Schematic of B-doped MWCNT solar cells. d J–V curves. (c, d) Adapted with permission from Ref. [111]. Copyright 2017, American Chemical Society. e Structure of a fiber solar cells with CNTs as electrode. Reprinted with permission from Ref. [112]. Copyright 2014, John Wiley & Son, Inc

In addition to improving the solar cell efficiency , upgrading the CNT properties is another effective approach to improving solar cell performance. The use of chirality-sorted CNTs in PSCs would bring a remarkable improvement in performance because the chirality-sorted CNTs could improve the carrier selectivity [110]. Another simple method is chemically doping CNTs to improve their conductivity, thereby enabling a high charge extraction rate. Thus, the chemical functionalization of CNTs to further improve the performance of solar cells is a promising approach. Zheng et al. doped boron (B) into CNTs for use as the counter electrode in a PSC [111]. The devices fabricated using the B-MWCNTs as the back electrode for hole collection and transport showed a PCE (14.6%) substantially greater than that of devices without B-MWCNTs (10.7%). They further improved the PCE to 15.23% (Fig. 20.12d) by depositing a thin Al2O3 layer between the TiO2 and the perovskite layer; the Al2O3 layer functions as an insulating barrier to avoid possible leakage between the m-TiO2 and the B-MWCNTs and further reduces the charge carrier losses by restraining the charge recombination processes (Fig. 20.12c). The PSCs with MWCNTs show negligible hysteresis behavior and also impressive durability and stability, as also reported by other groups [99]. The SWCNT films infiltrated with spiro-OMeTAD were used as electrodes in PSCs, which yielded a PCE greater than 16% with better stability than PSCs with metal electrodes [97]. Li et al. introduced SWCNTs into a hole-collecting carbon electrode composed of graphite and carbon black . Their study showed that the addition of 0.05 wt% SWCNTs to the carbon composite improve the PCE of the device from 9.9 to 14.7%, mainly by improving the Voc and the FF [92].

CNTs are considered an ideal transparent electrode material for flexible devices because of their extraordinary network properties. Jeon et al. fabricated inverted PSCs using HNO3-functionalized SWCNTs as a front transparent conductive electrode to replace the commercial ITO transparent electrode. They achieved a PCE of 5.38% in PSCs on polyethylene terephthalate (PET) substrates [19]. Wang et al. demonstrated a solid-state, flexible PSC based on an electrode composed of Ti foil and transparent CNTs, where the CNTs were laminated on top of a perovskite layer as the hole collector and the transparent electrode for light illumination [98]. The best PCE of 8.31% was attained using spiro-OMeTAD covered by CNTs. The device’s tolerance to mechanical bending was tested, and the device was found to operate at approximately 85% of its initial PCE after 100 bending cycles. A coaxial-fiber-shaped PSC with excellent flexibility was fabricated using stainless steel wires with a TiO2 blocking layer, CH3NH3PbI3, spiro-OMeTAD, and CNTs as the anode, absorber, HTL, and cathode, respectively (Fig. 20.12e) [112]. The CNTs function as a flexible and conductive electrode in the flexible solar cell, which yields a PCE of 3.3%. A PCE of 6.8% was realized by improving the coverage of the perovskite layer, which prevents direct contact between the electron transport material and the CNT sheet electrode. Because of the high series resistance of the CNT electrode, Ag was introduced to increase its conductivity; a 7.1% of PCE was attained upon optimization of the Ag thickness [113]. With further improvements in the perovskite crystal size, a 9.49% PCE was attained because of a substantial improvement of the lifetime of charge carriers [100]. The fabricated devices maintained better than 90% of their initial PCE after 500 bending cycles at a bending curvature radius of 7.5 mm. More interestingly, the photovoltaic parameters Jsc, Voc, and FF were independent of the incident light illumination angle because of the symmetric coaxial structure of the devices.

20.4.2 CNT-Based Carrier-Selective Layer

Spiro-OMeTAD, PTAA, and P3HT are effective HTMs in PSCs. However, the high cost and poor long-term stability of many organic hole conductors prompts the further development of hole collection and transport layers. CNTs are an ideal alternative material because of their high stability and high hole conductivity. The initial use of CNTs as a hole-collecting layer was reported by Habisreutinger et al., who directly deposited the polymer-wrapped SWCNTs onto the perovskite surface and then coated them with an inert polymer layer [17]. The polymer-wrapped SWCNTs act as a carrier-selective transport layer, which results in a PCE as high as 15.3%. The SWCNTs effectively extract the photogenerated holes from the perovskite to the cathode, while the inert polymer matrix could eliminate shunting pathways and reduce recombination losses between the perovskite film and the metal electrode. The best performance device yielding a PCE of 15.4% with a low series resistance of 1.8 Ω/cm2 was achieved by replacing the inert polymer with an organic matrix (spiro-OMeTAD). The photovoltage decay of devices with the spiro-OMeTAD and the SWCNTs/spiro-OMeTAD demonstrated that the charge extraction rate was approximately one order of magnitude greater when the CNTs were present [103].

The CNT network filling with PMMA without HTM for improving the stability of devices has also been reported [33]. Figure 20.13a exhibits the architecture of CH3NH3PbI3/SWCNT/GO/PMMA PSC devices, which could yield a Jsc of 20.1 mA/cm2, a Voc of 0.95 V, and an FF of 61%, resulting in a PCE (η) of 11.7% (Fig. 20.13e). The SWCNT layer functions as an efficient carrier dissociation and hole extraction layer. The photoluminescence (PL) and time-resolved PL of perovskite and perovskite /SWCNT thin films were compared to elucidate the charge extraction properties. The PL intensity in the perovskite/SWCNT is drastically quenched, and the time-resolved PL shows shorter carrier lifetime for the perovskite/SWCNT than for a perovskite layer without the CNTs, which suggests that the SWCNT layer plays an effective role in charge carrier dissociation and extraction across the interface between the perovskite and the SWCNTs. However, the SWCNTs, whose bandgap is narrower than that of CH3NH3PbI3, cannot block the electron leakage, resulting in recombination losses at the interface. By contrast, the much larger bandgap of the GO compared with that of the perovskite and the SWCNTs may enable the GO to serve as an effective electron blocking layer. Figure 20.13c shows the energy levels of a perovskite/SWCNT/GO solar cell, where the bandgaps for CH3NH3PbI3 and s-SWCNT films (diameter: 1.6 nm) were approximately 1.6 and 0.9 eV, respectively [14, 114]. The energy barrier between the perovskite and the GO layer effectively limits the electron diffusion, preventing carrier recombination loss at the anode and increasing the Voc value. The stability of the perovskite/SWCNT/GO/PMMA solar cell is much better than that of the perovskite/spiro-OMeTAD solar cell because of the inert PMMA layer, which functions as an effective barrier to moisture and oxygen penetration and prevents degradation of the organo-lead perovskite.

a Schematic of a perovskite /SWCNT/GO/PMMA solar cell. c Band alignment and e typical J–V curve of a perovskite/SWCNT/GO solar cell. The inset shows a histogram of the device performance for 25 perovskite/SWCNT/GO/PMMA solar cells. (a, c, and e) Reprinted with permission from Ref. [18]. Copyright 2016, The Royal Society of Chemistry. b Fast photoinduced hole transfer is observed from MAPbI3 to s-SWCNTs, whereas the recombination is slow. d Tracking hole extraction at the SWCNT–MAPbI3 interface using the MAPbI3 bleaching signals at 750 nm (inset). f Tracking hole back transfer and recombination at the SWCNT–MAPbI3 interface using the (6,5) SWCNT bleaching signals at 1000 nm (inset). Reprinted with permission from Ref. [105]. Copyright 2016, The Royal Society of Chemistry

Ihly et al. reported highly enriched s-SWCNT films as a hole extraction layer for PSCs, where the enriched s-SWCNT films provide a material-specific spectroscopic signature that enables tracking of the charge extraction and recombination and enables very long-lived charge separation [105]. The carrier transport dynamics in the CH3NH3PbI3 layer with the SWCNTs were demonstrated; the process is shown in Fig. 20.13b. The processes of both photogenerated carriers in the pristine CH3NH3PbI3 layer extracted by the SWCNTs and extracted carrier back transfer or recombination at the SWCNT/perovskite interface were investigated using time-resolved spectroscopy. Figure 20.13d shows that the generated hole was extracted from the perovskite to the s-SWCNTs extremely fast (sub-picosecond after carrier generation ). Once transferred into the SWCNTs, the holes show a long lifetime, which is several orders of magnitude longer than that in the perovskite layer (Fig. 20.13f). These results indicate that s-SWCNTs establish the appropriate interfacial energetics to facilitate fast charge extraction and very slow recombination. A 5-nm-thick SWCNT film was used as the HTL between the perovskite and doped spiro-OMeTAD to enhance the charge extraction, resulting in an improvement of the PCE from 14.7 to 16.5%.

Wang et al. used MWCNT/spiro-OMeTAD as the HTL in PSCs to improve the devices’ performance [106]. The electron lifetime was improved by the MWCNTs, resulting in a low recombination in the PSCs with the MWCNTs. They also demonstrated that MWCNTs in the HTL could reduce current loss during the charge transfer process and result in an enhanced Jsc. Acid-treated MWCNTs for improving device performance were reported by the same group [115]. A PCE of 8.7% was achieved because the acid treatment improved the dispersibility of MWCNTs because of the π–π interactions between the –COOH groups and the spiro-OMeTAD.

20.4.3 CNTs as Additives

The CNTs have been also used in organic solar cells and DSSCs as dopants to improve the carrier dissociation, extraction, and transport [116]. This strategy has also been applied in PSCs. Batmunkh et al. incorporated SWCNTs into the TiO2 nanofiber (NF) photoelectrode for the PSCs, which significantly improved the PCE of the devices [3]. The SWCNTs provide fast electron transport pathways within the TiO2 NF photoelectrode, resulting in an increase in the Jsc. Simultaneously, the energy level of the photoelectrodes was optimized by the introduction of SWCNTs, which improved the Voc of the devices. Furthermore, SWCNTs introduced into the TiO2 NFs reduced the hysteresis effect and improved the stability of the PSCs. A best PCE of 14.03% was achieved using an optimized concentration of SWCNTs both in the compact TiO2 layer and in the photoelectrode. In subsequent work, the same group [117] reported a best PCE of 16.11% for PSCs with 0.10 wt% SWCNTs incorporated into their TiO2 photoelectrode. The obtained PCE is significantly higher than the highest PCE of 13.53% for a control PSC fabricated without SWCNTs in its photoelectrode.

The SWCNTs functionalized with oligophenylenevinylenes drastically improved the performance and reproducibility of the PSCs. Cai et al. used CNTs to improve the charge transport properties in the P3HT hole transport material for PSCs [109]. The SWCNTs effectively enhance the crystallization of the polymer, whereas the MWCNTs enhance its conductivity. The CNTs used in the studies were a mixture of SWCNTs and MWCNTs for structural reasons; these mixtures were dubbed “bamboo-like carbon nanotubes.” The performance of the P3HT solutions with low concentrations of CNTs was investigated in devices, and the highest PCE obtained was 8.3% for the device with a CNT loading of 1 wt%. The improvement resulting from the incorporation of the CNT additives was ascribed to the improved crystallinity and grain size of P3HT for effective hole extraction and transport, which is consistent with the findings of previous reports [118].

Gatti et al. reported the incorporation of both organic functionalized SWCNTs and reduced GO in the P3HT matrix for PSCs [107]. A PCE of ~11% was attained in a device with 2 wt% SWCNTs in the P3HT blend used as a hole extraction layer. The observed results indicate that the improvement of the performance could be linked with the enhancement of local contacts at the hybrid interfaces, such as the perovskite /HTM and the HTM/top electrode interfaces, leading to an effective extraction of the photogenerated carriers from the HTM in the presence of CNTs. They also noted that the stability of the solar cells was remarkably improved by the incorporation of CNT-doped P3HT.

The enriched semiconducting (7,6)-SWCNTs with chemical functionalization were used to dope the spiro-MeOTAD as the HTL in PSCs, which yielded a maximum PCE of 9.6% [108]. MWCNTs were also used as additives to improve the conductivity of spiro-OMeTAD; however, because of back-electron transfers, cell performance suffered when the CNTs were allowed to contact the perovskite layer directly [104]. The authors coated an additional layer of spiro-OMeTAD between the perovskite and the MWCNT/spiro-OMeTAD hybrid layer as a barrier to improve the performance of PSCs. When the concentration of CNTs was controlled and the structures were optimized, the loading of 2 wt% of MWCNTs in the spiro-OMeTAD solution improved the PCE from 12.8 to 15.1%.

The CNTs have also been doped into the perovskite layer for improving the grain size and reducing recombination losses. Bag et al. reported the incorporation of MWCNTs into the perovskite layer, which drastically reduced the recombination losses and the charge accumulation at the perovskite/PEDOT:PSS interface [119]. Zhang et al. demonstrated that the incorporation of sulfonate CNTs could enhance the grain size and reduce the grain boundary of the perovskite layer [120].

20.5 CNTs in Other Solar Cells

20.5.1 Organic Photovoltaics

The typical structure of an OPV device is shown in Fig. 20.14a; it is composed of a transparent conductive electrode (ITO or FTO glass), an HTL, an active layer, and a back electrode with a lower-work-function metal such as Al. In the OPV systems, CNT films have been incorporated into devices as the transparent anode, the cathode, the hole extraction layer, and the electron acceptor [4, 7]. Chaudhary et al. incorporated CNT films into OPVs and found that the use of SWCNTs as the anode or HTL improved the devices’ performance [10]. These findings indicate that the SWCNTs can be made suitable for use in the HTL either through tuning the nanotube Fermi level [31] or through p-type doping effects. Barnes et al. reported using an SWCNT film as the transparent electrode to replace both the ITO electrode and the HTL. However, Lagemaat et al. found that an HTL was still required for efficient charge extraction [121]. Nevertheless, the SWCNTs have displayed several advantages such as the flexibility of nanotubes much better than conventional transparent electrodes of ITO and FTO [49]. However, the CNTs could be also used as the electron acceptor in polymer solar cells, which always exhibit poor performance [30, 122,123,124]. The observed low PCEs are caused by large connections between m-CNTs and polymers; these connects result from the stronger electrostatic interaction induced by the charge transfer, which results in large recombination and inefficient performance [38]. Moreover, the use of CNTs as an additive dispersed in P3HT to enhance the P3HT:PCBM solar cell performance has been reported [125]; this approach increases the hole mobility and reduces carrier recombination [126].

The utilization of SWCNTs as additives in PTB7:PCBM OPVs results in a high PCE of 6.3%, suggesting that the SWCNTs can be used as additives in modern OPV blends. The SWCNTs were utilized as light-harvesting materials in OPV devices for the exciton dissociation and the electron transfer [127, 128]. The authors initially used a polyfluorene sorting route to achieve a monochiral dispersion of SWCNTs and a PCE of ~1% [4]. An EQE of 43% was achieved but only at the sharp van Hove singularities of SWCNTs, which could harvest the energy only in a fraction of the solar spectrum [129]. Thus, a polychiral distribution of s-SWCNTs was used to broaden the solar light-harvesting, resulting in an average certified PCE of 2.5% and a highest PCE of 3.1% [130]. Moreover, Ihly et al. demonstrated that the driving force and reorganization energy could result in efficient photoinduced electron transfer between the SWCNTs and fullerene derivatives, indicating that further improvements to the SWCNT/acceptor systems could be realized through the selection of appropriate of SWCNT donor materials and fullerene derivatives [131]. Notably, the CNT active layer in the solar cells strongly absorbs light in the near-infrared region, which enables the harnessing of a portion of the solar spectrum that is currently inaccessible to many other thin-film OPV technologies.

20.5.2 Sensitized Solar Cells

A typical DSSC geometry is shown in Fig. 20.14b; it consists of a thin mesoporous TiO2 layer with adsorbed dye molecules, a catalytic counter electrode [Pt-coated transparent conducting oxide (TCO)], and a redox-active electrolyte. CNTs have been used as the transparent conductive film in either the counter electrode or the photoanode. Aitola et al. deposited a SWCNT film onto a PET substrate as a counter electrode (ITO and Pt free) in the DSSC, resulting in a PCE of only 0.74%. The PCE of 1.53% was obtained using nitrogen (N)-doped CNTs as the counter electrode, which generates free electrons for easy reduction of the electrolyte and enhances the performance. Recently, Arbab et al. reported a textile fabric counter electrode containing activated charcoal (AC)-doped MWCNTs for N719-dye DSSCs [132]. They confirmed that the carbon composite exhibited a high electrocatalytic activity and showed a low charge transfer resistance, which resulted in a high PCE of 7.29%. A reference solar cell prepared using an FTO counter electrode exhibited a PCE of 7.16%, suggesting that the carbon fabric composite electrode is promising as a counter electrode for DSSCs. The CNTs function as an alternative electrode material to conventional TCOs in Pt-based counter electrodes for DSSCs, where the CNTs and the Pt salts can be dispersed well with the assistance of poly(oxyethylene)-backboned polyimide. The fabricated DSSC showed a PCE of 6.96%, which is similar to PCE of the cell fabricated with a Pt/FTO counter electrode [133].

CNTs are a promising candidate to replace the catalyst layer (Pt) in DSSCs [134,135,136]. Both SWCNTs and MWCNTs have been investigated as the catalyst layer in devices, which show comparable performance to the Pt-based cells [8, 137]. These results are ascribed to the excellent electrocatalytic activity, low charge transfer resistance, and high conductivity of CNTs. The presence of defects in CNTs is one of the critical factors for the electron transfer to enhance the catalytic rate at the counter electrode–electrolyte interface [137]. Thus, the “bamboo”-structured MWCNTs with abundant defects was used as the counter electrode material of a DSSC, which yielded a high PCE of 7.67%. Moreover, highly purified and well-aligned CNTs on an FTO substrate as the counter electrode for a DSSC have been reported; the resultant devices show a high PCE of 10.04%, which is even higher than the PCEs of devices fabricated with benchmark Pt-counter electrodes of 8.8% [138]. These results strongly suggest that CNTs are a promising material for use in counter electrodes to realize higher PCEs in DSSCs.

CNT films are also a potential alternative to TCO-coated glass used as the photoanode in DSSCs. Wei et al. reported a flexible solid-state DSSC with CNT-coated PET as the transparent electrode [139]. Because of the high sheet resistance (250 Ω/sq) and low transmittance (\( T^{\prime} \) = 65%), the PCE of the resultant devices was less than 0.5%. Du et al. improved the PCE of DSSCs to 2.5% by employing the electrodeposited CNT film (Rs = 470 Ω/sq at 86% transmittance) as the photoanode [140]. Compared with the PCE of 3.7% for ITO/PET-based devices (15 ≤ Rs ≤ 70 Ω/sq at \( T^{\prime} \) ≈ 85%), the CNT-based photoanode is promising because the optoelectronic properties of CNTs could be much improved. Kyaw et al. proposed TiOx coating onto sulfuric-acid-doped CNT films to reduce the charge recombination between the nanotubes and the electrolyte [141]. A PCE of 1.8% was achieved in a DSSC with a TiOx/CNT electrode, which was substantially higher than that of devices fabricated using CNT films without TiOx (PCE of 0.004%).

CNTs have been incorporated into the semiconducting layer of DSSCs to reduce recombination and improve electron transport. Sawatsuk et al. reported a high PCE of 10.29% for CNT/TiO2 photoelectrode-based DSSCs, which is higher than the PCE of benchmark cells with a TiO2-only electrode (6.31%) [142]. The concentration of CNTs doped into the semiconducting layer plays a critical role in determining the performance of the DSSCs. Grace et al. reported that typical concentrations with and without chemically modified CNTs range from 0.1 to 0.3 wt% and from 0.01 to 0.03 wt%, respectively [143]. Dang et al. achieved an impressive result by first doping the TiO2 to semiconducting SWCNTs in the DSSCs and achieved a record PCE of 10.6% [144]. The s-SWCNTs with a band gap could transport the electrons from the conduction band to the electrode quickly without recombination. Moreover, the electron diffusion length was also improved after incorporation of the s-SWCNTs. These results indicate that the collection of electrons from dye molecules to the electrode can be more effective if s-SWCNTs are incorporated into the semiconducting layer.

20.6 Summary and Future Outlook

CNTs have many superior structural, electronic, and optical properties that render them suitable for solar cell applications. First, they have been extensively used as transparent conductive electrodes in several types of solar cells because of their excellent conductivity, superior flexibility with low brittleness, and high transmittance over a broad spectral range. Although solar cells with a CNT electrode usually show a slightly lower PCE than those fabricated using convectional electrodes, they are still very promising as transparent electrodes because the properties of the CNTs can be further improved. Second, the CNTs also play the role of an HTL in the photovoltaic devices, especially PSCs, where the CNTs enable the rapid extraction of holes with suppression of recombination and raise the quasi-Fermi level in the perovskite , thereby increasing the driving force for electron injection into the TiO2 [105]. The CNTs associated with GO or spiro-OMeTAD for both the HTL and the electron blocking layer could further improve the performance. However, the CNT HTL improves the stability of solar cells, which is strongly required for the commercialization of devices. Third, CNTs can be doped into the photoelectrode to improve the electron injection to the TiO2 and can be doped into the active layer of a solar cell to effectively dissociate the excitons and to collect and transport the carriers to the external circuit. The s-SWCNTs with a bandgap that enables the effective transport of electrons from the conduction band to the electrode quickly improve the diffusion length of the holes. Finally, the photocurrent generation in s-SWCNTs is quite interesting for solar cells. Theoretical estimations suggest that the PCE of CNT p–n junction devices will increase with decreasing tube diameter, irrespective of the exciton diffusion length [47]. Moreover, carrier multiplication in the CNTs is, in principle, highly promising for solar cells whose performance exceeds the thermodynamic limitation.

Although CNTs have been intensively studied and have been shown to exhibit numerous superior properties, many problems toward the industrial application of CNTs in solar cells remain to be solved. First, most of the CNTs used in investigations are mixtures of both s- and m-nanotubes, which causes Schottky barriers because of their different bandgaps and work functions , resulting in a high contact resistance. Moreover, in some specific applications, high-quality single-chirality nanotubes are strongly required. Second, most of the synthesis methods of CNTs are energy-intensive, and producing large area CNT films is still expensive. Moreover, the issue of long-term stability in CNT-based devices remains unresolved. In particular, chemically doped CNTs do not maintain adequate long-term performance for use in solar cell applications. Also, UV light could de-dope or cause traps in the CNTs, which would result in high sheet resistance. Thus, the controlled and precise synthesis of high-quality single-chirality CNTs via a low-cost fabrication process will be important not only for solar cells but also for many other devices. Despite the great challenges, the future of CNTs is very promising because of their unique properties for many applications.

References

Yu L, Shearer C, Shapter J (2016) Recent development of carbon nanotube transparent conductive films. Chem Rev 116:13413–13453. https://doi.org/10.1021/acs.chemrev.6b00179

Li X, Lv Z, Zhu H (2015) Carbon/silicon heterojunction solar cells: state of the art and prospects. Adv Mater 27:6549–6574. https://doi.org/10.1002/adma.201502999

Batmunkh M, Macdonald TJ, Shearer CJ, Bat-Erdene M, Wang Y, Biggs MJ, Parkin IP, Nann T, Shapter JG (2017) Carbon nanotubes in TiO2 nanofiber photoelectrodes for high-performance perovskite solar cells. Adv Sci 4:1600504. https://doi.org/10.1002/advs.201600504

Barbero DR, Stranks SD (2016) Functional single-walled carbon nanotubes and nanoengineered networks for organic- and perovskite-solar-cell applications. Adv Mater 28:9668–9685. https://doi.org/10.1002/adma.201600659

Hecht DS, Hu L, Irvin G (2011) Emerging transparent electrodes based on thin films of carbon nanotubes, graphene, and metallic nanostructures. Adv Mater 23:1482–1513. https://doi.org/10.1002/adma.201003188

Liu Y, Wang S, Peng L-M (2016) Toward high-performance carbon nanotube photovoltaic devices. Adv Energy Mater 6:1600522. https://doi.org/10.1002/aenm.201600522

Ratier B, Nunzi J-M, Aldissi M, Kraft TM, Buncel E (2012) Organic solar cell materials and active layer designs—improvements with carbon nanotubes: a review. Polym Int 61:342–354. https://doi.org/10.1002/pi.3233

Suzuki K, Yamaguchi M, Kumagai M, Yanagida S (2003) Application of carbon nanotubes to counter electrodes of dye-sensitized solar cells. Chem Lett 32:28–29. https://doi.org/10.1246/cl.2003.28

Brown P, Takechi K, Kamat PV (2008) Single-walled carbon nanotube scaffolds for dye-sensitized solar cells. J Phys Chem C 112:4776–4782. https://doi.org/10.1021/jp7107472

Chaudhary S, Lu H, Müller AM, Bardeen CJ, Ozkan M (2007) Hierarchical placement and associated optoelectronic impact of carbon nanotubes in polymer-fullerene solar cells. Nano Lett 7:1973–1979. https://doi.org/10.1021/nl070717l

Tune DD, Hennrich F, Dehm S, Klein MFG, Glaser K, Colsmann A, Shapter JG, Lemmer U, Kappes MM, Krupke R, Flavel BS (2013) The role of nanotubes in carbon nanotube–silicon solar cells. Adv Energy Mater 3:1091–1097. https://doi.org/10.1002/aenm.201200949

Li X, Guard LM, Jiang J, Sakimoto K, Huang J-S, Wu J, Li J, Yu L, Pokhrel R, Brudvig GW, Ismail-Beigi S, Hazari N, Taylor AD (2014) Controlled doping of carbon nanotubes with metallocenes for application in hybrid carbon nanotube/Si solar cells. Nano Lett 14:3388–3394. https://doi.org/10.1021/nl500894h

Li Z, Saini V, Dervishi E, Kunets VP, Zhang J, Xu Y, Biris AR, Salamo GJ, Biris AS (2010) Polymer functionalized n-type single wall carbon nanotube photovoltaic devices. Appl Phys Lett 96:033110. https://doi.org/10.1063/1.3284657

Wang F, Kozawa D, Miyauchi Y, Hiraoka K, Mouri S, Ohno Y, Matsuda K (2015) Considerably improved photovoltaic performance of carbon nanotube-based solar cells using metal oxide layers. Nat Comun 6:6305. https://doi.org/10.1038/ncomms7305

Wei J, Jia Y, Shu Q, Gu Z, Wang K, Zhuang D, Zhang G, Wang Z, Luo J, Cao A, Wu D (2007) Double-walled carbon nanotube solar cells. Nano Lett 7:2317–2321. https://doi.org/10.1021/nl070961c

National Revewable Energy Laboratory (NREL) (2016). http://www.nrel.gov/ncpv/images/efficiency_chart.jpg. Accessed Sept 2016

Habisreutinger SN, Leijtens T, Eperon GE, Stranks SD, Nicholas RJ, Snaith HJ (2014) Carbon nanotube/polymer composites as a highly stable hole collection layer in perovskite solar cells. Nano Lett 14:5561–5568. https://doi.org/10.1021/nl501982b

Wang F, Endo M, Mouri S, Miyauchi Y, Ohno Y, Wakamiya A, Murata Y, Matsuda K (2016) Highly stable perovskite solar cells with an all-carbon hole transport layer. Nanoscale 8:11882–11888. https://doi.org/10.1039/c6nr01152g

Jeon I, Chiba T, Delacou C, Guo Y, Kaskela A, Reynaud O, Kauppinen EI, Maruyama S, Matsuo Y (2015) Single-walled carbon nanotube film as electrode in indium-free planar heterojunction perovskite solar cells: investigation of electron-blocking layers and dopants. Nano Lett 15:6665–6671. https://doi.org/10.1021/acs.nanolett.5b02490

Zhou C, Wang S, Sun J, Wei N, Yang L, Zhang Z, Liao J, Peng L-M (2013) Plasmonic enhancement of photocurrent in carbon nanotube by Au nanoparticles. Appl Phys Lett 102:103102. https://doi.org/10.1063/1.4794937

Freitag M, Martin Y, Misewich JA, Martel R, Avouris P (2003) Photoconductivity of single carbon nanotubes. Nano Lett 3:1067–1071. https://doi.org/10.1021/nl034313e

Gabor NM, Zhong Z, Bosnick K, Park J, McEuen PL (2009) Extremely efficient multiple electron-hole pair generation in carbon nanotube photodiodes. Science 325:1367–1371. https://doi.org/10.1126/science.1176112

Shockley W, Queisser HJ (1961) Detailed balance limit of efficiency of p-n junction solar cells. J Appl Phys 32:510–519. https://doi.org/10.1063/1.1736034

Malapanis A, Perebeinos V, Sinha DP, Comfort E, Lee JU (2013) Quantum efficiency and capture cross section of first and second excitonic transitions of single-walled carbon nanotubes measured through photoconductivity. Nano Lett 13:3531–3538. https://doi.org/10.1021/nl400939b

Aspitarte L, McCulley DR, Minot ED (2016) Photocurrent quantum yield in suspended carbon nanotube p–n junctions. Nano Lett 16:5589–5593. https://doi.org/10.1021/acs.nanolett.6b02148

Kazaoui S, Cook S, Izard N, Murakami Y, Maruyama S, Minami N (2014) Photocurrent quantum yield of semiconducting carbon nanotubes: dependence on excitation energy and exciton binding energy. J Phys Chem C 118:18059–18063. https://doi.org/10.1021/jp500105f

Lee JU (2005) Photovoltaic effect in ideal carbon nanotube diodes. Appl Phys Lett 87:073101. https://doi.org/10.1063/1.2010598

Stewart DA, Léonard F (2005) Energy conversion efficiency in nanotube optoelectronics. Nano Lett 5:219–222. https://doi.org/10.1021/nl048410z

Pang-Leen O, William BE, Igor AL (2010) Hybrid solar cells based on single-walled carbon nanotubes/Si heterojunctions. Nanotechnology 21:105203. https://doi.org/10.1088/0957

Kymakis E, Alexandrou I, Amaratunga GAJ (2003) High open-circuit voltage photovoltaic devices from carbon-nanotube-polymer composites. J Appl Phys 93:1764–1768. https://doi.org/10.1063/1.1535231

Dissanayake NM, Zhong Z (2011) Unexpected hole transfer leads to high efficiency single-walled carbon nanotube hybrid photovoltaic. Nano Lett 11:286–290. https://doi.org/10.1021/nl103879b

Lan F, Li G (2013) Direct observation of hole transfer from semiconducting polymer to carbon nanotubes. Nano Lett 13:2086–2091. https://doi.org/10.1021/nl400395c

Dabera GDMR, Jayawardena KDGI, Prabhath MRR, Yahya I, Tan YY, Nismy NA, Shiozawa H, Sauer M, Ruiz-Soria G, Ayala P, Stolojan V, Adikaari AADT, Jarowski PD, Pichler T, Silva SRP (2013) Hybrid carbon nanotube networks as efficient hole extraction layers for organic photovoltaics. ACS Nano 7:556–565. https://doi.org/10.1021/nn304705t

Lee JM, Park JS, Lee SH, Kim H, Yoo S, Kim SO (2011) Selective electron- or hole-transport enhancement in bulk-heterojunction organic solar cells with N- or B-doped carbon nanotubes. Adv Mater 23:629–633. https://doi.org/10.1002/adma.201003296