Abstract

Asynchronous motors make up 80% of today’s motors in industry. For this reason, the contribution of energy efficiency analyses to asynchronous motors is very important. There are many techniques for measuring the efficiency of electric motors. These are the generally experimental ones as specified in certain standards. Experimental methods can also be divided into direct and indirect methods. The use of experimental methods is not common due to the cost of installing and operating test laboratories worldwide. In this study, direct and indirect experimental methods and which kind of method should be applied to which type of motor will be explained. Then an indirect method will be applied to the motor and an efficiency result and losses will be found. According to this experiment, losses are interpreted. One squirrel cage induction motor, which is being used in the Marmaray project, is utilized in the experiments.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Dincer I, Rosen MA (2013) Exergy: energy, environment and sustainable development, 2nd edn. Elsevier, Oxford, UK

Romero JC, Linares P (2014) Exergy as a global energy sustainability indicator: a review of the state of the art. Renew Sust Energ Rev 33:427–442

Çengel YA, Boles MA (2008) Termodinamik, Güven Bilimsel, 5.Baskı

Lima-Filho AC, Gomes RD, Adissi MO, Borges da Silva TA, Belo FA, Spohn MA (2012) Embedded system integrated into a wireless sensor network for online dynamic torque and efficiency monitoring in induction motors. IEEE/ASME Trans Mechatronics 17(3):404–414

Siraki A, Pillay P (2012) An in situ efficiency estimation technique for induction machines working with unbalanced supplies. IEEE Trans Energy Convers 27(1):85–95

Herndler B, Barendse P, Khan MA (2011) Considerations for improving the non-intrusive efficiency estimation of induction machines using the air gap torque method. In: Proceedings IEEE IEMDC, May 2011, pp 1516–1521

Lu B, Habetler TG, Harley RG (2008) A nonintrusive and in-service motor efficiency estimation method using air-gap torque with considerations of condition monitoring. IEEE Trans Ind Appl 44(6):1666–1674

Sebastian D, Manjusha VA, Anto R (2013) Energy management of induction motors using non-intrusive methods. In: Proceedings ICPEC, Feb. 2013, pp 767–772

Zhang H, Zanchetta P, Bradley KJ, Gerada C (2010) A low-intrusion load and efficiency evaluation method for in-service motors using vibration tests with an accelerometer. IEEE Trans Ind Appl 46(4):1341–1349

Hydraulics & pneumatics: rightsize your electric motors. [Online]. Available: http://hydraulicspneumatics.com/200/TechZone/HydraulicPumpsM/Article/False/21602/TechZone-HydraulicPumpsM. Accessed 5 Sept 2014

IEEE-112: Test Procedure for Polyphase Induction Motors and Generators, Silva WL, AMN L, Oliveira A (2015) A method for measuring torque of squirrel-cage induction motors without any mechanical sensor. IEEE Trans Instrum Meas 64(5):1223–1231

Hsu JS, Scoggins BP (1995) Field test of motor efficiency and load changes through air-gap torque. IEEE Trans Energy Convers 10(3):477–483

Szychta L, Figura R (2012) Analysis of efficiency characteristics of squirrel-cage induction motor for pump applications. In: Proceedings ICEM, Sep. 2012, pp 73–78

Al-Badri M, Pillay P, Angers P (2015) A novel algorithm for estimating refurbished three-phase induction motors efficiency using only no-load tests. IEEE Trans Energy Convers 30(2):615–625

Sakthivel VP, Bhuvaneswari R, Subramanian S (2010) Non-intrusive efficiency estimation method for energy auditing and management of in-service induction motor using bacterial foraging algorithm. IET Electr Power Appl 4(8):579–590

Silva WL, Lima AMN, Oliveira A (2015) A method for measuring torque of squirrel-cage induction motors without any mechanical sensor. IEEE Trans Instrum Meas 64(5):1223–1231

Kueck JD, Olszewski M, Casada DA, Hsu J, Otaduy PJ, Tolbert LM (1996) Assessment of methods for estimating motor efficiency, load under field conditions. Oak Ridge Nat. Lab., Oak Ridge, TN, Rep. ORNL/ TM-13165

In-plant electric motor loading and efficiency techniques. (1990) Ontario hydro, Toronto, ON, Canada, Rep. TSDD-90-043

Charette A, Xu J, Ba-Razzouk A, Pillay P, Rajagopalan V (2000) The use of the genetic algorithm for in situ efficiency measurement of an induction motor. In: Proceedings IEEE power engineering society winter meeting, 2000, pp 392–397

Phumiphak P, Chat-uthai C (2008) Nonintrusive method for estimating field efficiency of inverter-fed induction motor using measured values. In: Proceedings IEEE international conference sustainable energy technology, Signapore, pp 580–583

Aspalli MS, Shetagar SB, Kodad SF (2008) Estimation of induction motor field efficiency for energy audit and management using genetic algorithm. In: Proceedings international conference sensing technology, Venice, Italy, pp 440–445

Lu B, Wenping C, French I, Bradley KJ, Habetler TG (2007) Nonintrusive efficiency determination of in-service induction motors using genetic algorithm and air-gap torque methods. In: Conference record of IEEE 42nd IAS annual meeting, New Orleans, Louisiana, pp 1186–1192

Phumiphak T, Chat-uthai C (2002) Estimation of induction motor parameters based on field test coupled with genetic algorithm. In: Proceedings international conference power system technology, Kunming, China, pp 1199–1120

Pillay P, Levin V, Otaduy P, Kueck J (1998) In-situ induction motor efficiency determination using the genetic algorithm. IEEE Trans Energy Convers 13(4):326–333

Phumiphak T, Chat-uthai C (2004) An economical method for induction motor field efficiency estimation for use in on-field energy audit and management. In: Proceedings international conference power system technology, Taipei, Taiwan, pp 1250–1254

Gomez JR, Quispe EC, de Armas MA, Viego PR (2008) Estimation of induction motor efficiency in-situ under unbalanced voltages using genetic algorithms. In: Proceedings international conference electrical machines, Wuhan, China, pp 1–4

Cunkas M, Sag T (2010) Efficiency determination of induction motors using multi-objective evolutionary algorithms. Adv Eng Softw 41(2):255–261

Sakthivel VP, Bhuvaneswari R, Subramanian S (2010) Non-intrusive efficiency estimation method for energy auditing and management of inservice induction motor using bacterial foraging algorithm. IET Elect Power Appl 4(8):579–590

Tülomsaş, October 2012

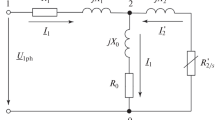

Fitzgerald AE, Kingsley C Jr, Umans SD (2014) Elektrik makinalari. In: Palme yayincilik, 6th edn. McGraw-Hill, New York, pp 330–340

Acknowledgments

The Tülomsaş Company supported this research. This support is gratefully acknowledged. Special thanks to Aylin Tören.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Sertsöz, M., Kurban, M. (2018). Energy Efficiency of a Special Squirrel Cage Induction Motor. In: Nižetić, S., Papadopoulos, A. (eds) The Role of Exergy in Energy and the Environment. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-319-89845-2_16

Download citation

DOI: https://doi.org/10.1007/978-3-319-89845-2_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-89844-5

Online ISBN: 978-3-319-89845-2

eBook Packages: EnergyEnergy (R0)