Abstract

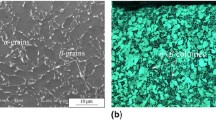

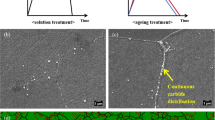

The 718 alloy possesses excellent mechanical properties at high temperatures, good process ability, therefore, it has been widely used in aero engine turbine disks, compressor disks, and power turbine shafts (i.e., rotating components). The fatigue properties of the 718 alloy are a key factor that determines the safety and reliability of the engine. In this paper, the fatigue properties of the 718 alloy are investigated under high temperature conditions at 455 and 600 °C. The initiation of fatigue cracks, and the relationship between fatigue life and grain size are discussed. The results show that the twin boundaries in large grains and carbides are acting as a crack initiation site for plate specimens, and string-type or heap-type carbides distribution promotes crack propagation and shortens fatigue life. Carbides respond as a crack initiation site for cylindrical specimens. The grain size is smaller, and the low cycle fatigue properties of the alloy are improved.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Tiley J, Viswanathan GB, Strinivasan R, Banerjee R, Dimiduk DM, Fraser HL (2009) Acta Mater 57:2538–2549

Gopinath K, Gogia AK, Kamat SV, Ramamurty U (2009) Acta Mater 57:1243–1253

Zhang JM, Gao ZY, Zhuang JY, Zhong ZY, Janschek P (1997) J Mater Proc Technol 70:252–257

Kuo CM, Yang YT, Bor HY, Wei CN, Tai CC (2009) Mater Sci Eng, A 510–511:289–294

Lu XD, Du JH, Deng Q, Zhuang JY (2014) J Mater Res Technol 3:107–113

Warren J, Wei DY (2006) Mater Sci Eng, A 428:106–115

Chaturvedi MC, Han YF (1989) In: Loria EA (ed) Superalloy 718-metallurgy and applications. TMS, Pennsylvania, pp 489–498

Praveen KVU, Singh V (2008) Mater Sci Eng, A 485:352–358

Prakash DGL, Walsh MJ, Maclachlan D, Korsunsky AM (2009) Int J Fat 31:1966–1977

Shyam A, Torbet CJ, Jha SK, Larsen JM, Caton MJ, Szczepanski CJ, Pollock TM, Jones JW (2004) In: Green KA, Pollock TM, Harada H, Howson TF, Reed RC, Schirra JJ, Walston S (eds) Superalloys 2004. TMS, Pennsylvania, pp 259–268

Tryon RG, Dey A, Krishnan G, Chandran KSR, Oja M (2004) Larsen JM (ed), Materials damage prognosis-proceedings of a symposium of the materials science and technology 2004 conference. TMS, Pennsylvania, pp 105–112

Lu XD, Du JH, Deng Q (2013) Mater Sci Eng, A 588:411–415

Miao JS, Pollock TM, Jones JW (2009) Acta Mater 57:5964–5974

Kromp W, Wesis B, Stickler R (1973) Metall Trans 4:1167–1169

Cameron DW, Hoeppner DW (1983) Int J Fat 5:225–229

Kim KC, Nam SW (1988) Mater Sci Eng 244:257–262

Biallas G, Essert M, Maier HJ (2005) Int J Fat 27:1485–1493

Maier HJ, Gabor P, Karaman I (2005) Mater Sci Eng, A 410–411:457–461

Li WF, Zhang XP (2001) Mater Sci Eng, A 318:129–136

Zhu SJ, Peng LM, Moriya T, Mutoh Y (2000) Mater Sci Eng, A 290:198–206

Gilbert CJ, Ritchie RO (1998) Acta Mater 46:609–616

Tanaka Y, Deng ZY, Liu YF (2003) C. Masuda. Acta Mater 51:6329–6340

Biallas G, Maier HJ (2007) Int J Fat 29:1413–1425

Onofrio G, Osinkolu GA, Marchionni M (2001) Int J Fat 23:887–895

Tong J, Byrne J (1999) Fat Frac Eng Mat Struct 22:185–193

Brooks RR, Rainforth WM (1999) Fat Frac Eng Mat Struct 22:821–829

Sundararaman M, Mukhopadhyay P, Banerjee S (1988) Metal Trans 19A:453–465

Burke MG, Miller MK (1991) Loria E (ed), Superalloy 718,625 and various derivatives, TMS, pp 337–350

Andersson H, Persson C (2004) Int J Fat 26:211–219

Acknowledgements

The authors would like to acknowledge the financial support of the National Important Base Research and Development Program of China under Contract Number 2010CB631203.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Xudong, L., Jinhui, D., Qun, D., Minqing, W., Zhongnan, B., Yuchun, Z. (2018). Research of Twin Induced LCF Cracking the 718 Alloy Using In-Situ Observation. In: Ott, E., et al. Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-89480-5_50

Download citation

DOI: https://doi.org/10.1007/978-3-319-89480-5_50

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-89479-9

Online ISBN: 978-3-319-89480-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)