Abstract

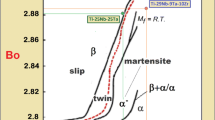

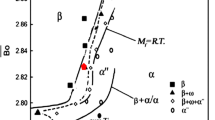

A new beta titanium alloy in the Ti-Al-Mo-Cr-V system has been designed using the d-electron method with the aim of activating a combination of different deformation mechanisms. In this regard Ti-3Al-5Mo-7V-3Cr (Ti-3573) alloy has been designed and compared with a commercial Ti-5Al-5Mo-5V-3Cr (Ti-5553) alloy. To evaluate the accuracy of the d-electron theoretical predictions, uniaxial compression tests were performed at room temperature. The deformation mechanism of Ti-3573 was found to be a combination of slip, stress-induced martensitic transformation and mechanical twinning. As a result of the combined deformation mechanisms, the designed alloy showed enhanced compressive strength and ductility in comparison to the Ti-5553 alloy. The results showed that in the case of twinning the prediction by the d-electron method is consistent with experimental observations but regarding the stress-induced martensitic transformation this method should be used with modifications to the d-electron phase stability map.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Hanada S, Izumi O (1986) MTA 17:1409

Xing H, Sun J (2008) Mechanical twinning and omega transition by <111> {112} shear in a metastable β titanium alloy. Appl Phys Lett 93:031908

Bertrand E, Castany P, Péron I, Gloriant T (2011) Twinning system selection in a metastable β-titanium alloy by Schmid factor analysis. Scr Mater 64:1110–1113

Ohyama H, Nishimura T (1995) Effects of alloying elements on deformation mode in Ti-V based b titanium alloy system. ISIJ Int 35:927–936

Min XH, Emura S, Nishimura T, Tsuchiya K, Tsuzaki K (2010) Microstructure, tensile deformation mode and crevice corrosion resistance in Ti-10Mo-xFe alloys. Mater Sci Eng A 527:5499–5506

Min XH, Emura S, Sekido N, Nishimura T, Tsuchiya K, Tsuzaki K (2010) Effects of Fe addition on tensile deformation mode and crevice corrosion resistance in Ti-15Mo alloy. Mater Sci Eng A 527:2693–2701

Bhattacharjee A, Varma VK, Kamat SV, Gogia AK, Bhargava S (2006) Influence of β grain size on tensile behavior and ductile fracture toughness of titanium alloy Ti-10V-2Fe-3Al. Metall Mat Trans A 37:1423–1433

Paradkar A, Kashyap BP, Gogia AK, Kamat SV (2009) On the influence of alloy composition on the fracture toughness of two-phase Ti-Al-Nb alloys undergoing stress-induced martensitic transformation. Metall Mat Trans A 40:1604–1610

Paradkar AG, Kamat SV, Gogia AK, Kashyap BP (2009) On the validity of Hall-Petch equation for single-phase β Ti-Al-Nb alloys undergoing stress-induced martensitic transformation. Mater Sci Eng, A 520:168–173

Friák M, Counts WA, Ma D, Sander B, Holec D, Raabe D et al (2012) Theory-guided materials design of multi-phase Ti-Nb alloys with bone-matching elastic properties. Materials 5:1853–1872

Raabe D, Sander B, Friák M, Ma D, Neugebauer J (2007) Theory-guided bottom-up design of β-titanium alloys as biomaterials based on first principles calculations: Theory and experiments. Acta Mater 55:4475–4487

Abdel-Hady M, Hinoshita K, Morinaga M (2006) General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scr Mater 55:477–480

Kuroda D, Niinomi M, Morinaga M, Kato Y, Yashiro T (1998) Design and mechanical properties of new β type titanium alloys for implant materials. Mater Sci Eng A 243:244–249

Morinaga M, Yukawa N, Maya T, Sone K, Adachi H (1988) Theoretical design of titanium alloys. In: Sixth world conference on titanium III. Cannes, p 1601

Abdel-Hady M, Hinoshita K, Fuwa H, Murata Y, Morinaga M (2008) Change in anisotropy of mechanical properties with β-phase stability in high Zr-containing Ti-based alloys. Mater Sci Eng A 480:167–174

Laheurte P, Prima F, Eberhardt A, Gloriant T, Wary M, Patoor E (2010) Mechanical properties of low modulus beta titanium alloys designed from the electronic approach. J Mech Behav Biomed Mater 3:565–573

Brozek C, Sun F, Vermaut P, Millet Y, Lenain A, Embury D et al (2016) A β-titanium alloy with extra high strain-hardening rate: design and mechanical properties. Scr Mater 114:60–64

Marteleur M, Sun F, Gloriant T, Vermaut P, Jacques PJ, Prima F (2012) On the design of new β-metastable titanium alloys with improved work hardening rate thanks to simultaneous TRIP and TWIP effects. Scr Mater 66:749–752

Sun F, Zhang JY, Marteleur M, Brozek C, Rauch EF, Veron M et al (2015) A new titanium alloy with a combination of high strength, high strain hardening and improved ductility. Scr Mater 94:17–20

Fanning JC (2005) Properties of TIMETAL 555 (Ti-5Al-5Mo-5V-3Cr-0.6Fe). J Materi Eng Perform 14:788–791

Morinaga M, Murata Y, Yukawa H (2007) Molecular orbital approach to alloy design. In: Bozzolo G, Noebe RD, Abel PB (eds) Applied computational materials modeling: theory, simulation and experiment. Springer, USA, pp 255–306

Yang Y, Wu SQ, Li GP, Li YL, Lu YF, Yang K et al (2010) Evolution of deformation mechanisms of Ti-22.4Nb-0.73Ta-2Zr-1.34O alloy during straining. Acta Mater 58:2778–2787

Qu L, Yang Y, Lu YF, Feng L, Ju JH, Ge P et al (2013) A detwinning process of {332} <113> twins in beta titanium alloys. Scr Mater 69:389–392

Min XH, Tsuzaki K, Emura S, Sawaguchi T, Ii S, Tsuchiya K (2013) {332} <113> Twinning system selection in a β-type Ti-15Mo-5Zr polycrystalline alloy. Mater Sci Eng A 579:164–169

Sun F, Zhang JY, Marteleur M, Gloriant T, Vermaut P, Laillé D et al (2013) Investigation of early stage deformation mechanisms in a metastable β titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects. Acta Mater 61:6406–6417

Zhou X, Xa Min, Emura S, Tsuchiya K (2017) Accommodative {332} <113> primary and secondary twinning in a slightly deformed β-type Ti-Mo titanium alloy. Mater Sci Eng A 684:456–465

Li C, Wu X, Chen JH, van der Zwaag S (2011) Influence of α morphology and volume fraction on the stress-induced martensitic transformation in Ti-10 V-2Fe-3Al. Mater Sci Eng, A 528:5854–5860

Li C, Chen JH, Wu X, Wang W, van der Zwaag S (2012) Tuning the stress induced martensitic formation in titanium alloys by alloy design. J Mater Sci 47:4093–4100

Ahmed M, Wexler D, Casillas G, Ivasishin OM, Pereloma EV (2015) The influence of β phase stability on deformation mode and compressive mechanical properties of Ti-10V-3Fe-3Al alloy. Acta Mater 84:124–135

Grosdidier T, Philippe MJ (2000) Deformation induced martensite and superelasticity in a β-metastable titanium alloy. Mater Sci Eng A 291:218–223

Hao YL, Li SJ, Sun SY, Zheng CY, Yang R (2007) Elastic deformation behaviour of Ti-24Nb-4Zr-7.9Sn for biomedical applications. Acta Biomater 3:277–286

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Sadeghpour, S., Abbasi, S.M., Morakabati, M. (2018). Design of a New Multi-element Beta Titanium Alloy Based on d-Electron Method. In: & Materials Society, T. (eds) TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72526-0_36

Download citation

DOI: https://doi.org/10.1007/978-3-319-72526-0_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72525-3

Online ISBN: 978-3-319-72526-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)