Abstract

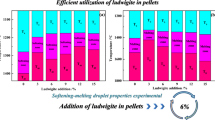

In this paper, study on the influences of different Ti-bearing materials on MgO-bearing pellets metallurgical properties was carried out. The results show that, pellets compression strength will decrease while using ilmenite. However, TiO2 reagents help to improve pellets compression strength. The reduction swelling decreases while using TiO2 reagents, but different ilmenites have diverse impacts on the reduction swelling. Pellets compression strength will decrease and reduction swelling will be improved while adding magnesium additives. In order to produce qualified Magnesium-Titanium bearing pellets, the firing temperature should be no less than 1270 ℃.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Nogueira P, Fruehan R (2003) Blast furnace burden softening and melting phenomena-melting onset in acid and basic fluxed pellets. Iron Steelmaking 30(7):29–35

Yadav US et al (2002) Influence of magnesia on sintering characteristics of iron ore. Ironmaking Steelmaking 29(2):91–95

Friel JJ, Erickson ES (1980) Chemistry, microstructure, and reduction characteristics of dolomite-fluxed magnetite pellets. Metall Trans B 11(2):233

Dwarapudi S et al (2011) Effect of pellet basicity and MgO content on the quality and microstructure of hematite pellets. Int J Mineral Process 99(1):43–53

Ge-Le Q et al (2013) Effect of different magnesium additives on process parameters and pellet quality. Iron Steel 48(7):17–22

Gao Q-j et al (2013) Effects of MgO containing additive on low-temperature metallurgical properties of oxidized pellet. J Iron Steel Res Int 20(7):25–28

Narita K et al (1976) Formation of titanium compounds, so-called titanium-bear, in the blast furnace hearth. Tetsu-to-Hagane 62(5):525–534

Yan Z et al (2015) Study on influences of different Ti-bearing materials on compression strength of pellets. Sinter Pelletizing 40(6):28–30, 44

Yunqing T et al (2014) Experimental research on production of Ti-bearing pellets with titanium sand. Sinter Pelletizing 39(6):31–35

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Zhang, Y. et al. (2018). Study on Influences of Different Ti-Bearing Materials on MgO-Bearing Pellets Metallurgical Properties. In: Hwang, JY., et al. 9th International Symposium on High-Temperature Metallurgical Processing. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72138-5_80

Download citation

DOI: https://doi.org/10.1007/978-3-319-72138-5_80

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72137-8

Online ISBN: 978-3-319-72138-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)