Abstract

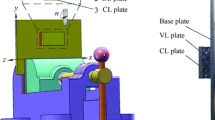

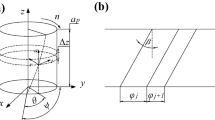

During milling process, the vibration is an unavoidable phenomenon which causes damage in the tool and spindle bearings and leads to poor dimensional accuracy and surface finish of the workpiece. With the ultimate goal of vibration suppression of a thin-walled workpiece during milling process, this paper provides a comparative study of the dynamic behavior simulation of a cantilever rectangular thin plate submitted to a milling operation with and without passive dynamic mass-spring absorbers attached to it. The simulation is carried out taking into account the Kirchhoff model for the plate and the Moradi et al. (2015) model for the cutting force of milling. To solve the equation of motion of the plate with the finite element method the MATLAB software is used. The plate natural frequencies and mode shapes are first identified and then two cases of the plate deflection are determined by the cutting force and taking or neglecting additive absorbers. The obtained results show that the attachment of vibration absorbers to the plate workpiece enlarges its range of natural frequencies. Thus, it can minimize undesired vibration and improves the milling conditions and the surface quality. The proposed vibration absorber design includes other advantages such as design simplicity, intuitive clarity, and hardware and development effective cost. However, the plate deflection remains relatively high because this type of vibration absorber is efficient just in case of one resonance frequency.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Londhe P, Chilwant (2016) Optimization of cutting parameters in milling operation to improve surface finish of EN 31. Int J Eng Sci Manag Res

Moradi H, Bakhtiari-Nejad F, Movahhedy MR, Vossoughi G (2012) Stability improvement and regenerative chatter suppression in nonlinear milling process via tunable vibration absorber. J Sound Vib 331:4668–4690

Moradi H, Vossoughi G, Behzad M, Movahhedy MR (2015) Vibration absorber design to suppress regenerative chatter in nonlinear milling process: Application for machiningof cantilever plates. Appl Math Model 39:600–620

Saadabad NA, Moradi H, Vossoughi G (2014) Global optimization and design of dynamic absorbers for chatter suppression in milling process with tool wear and process damping. Proc CIRP 21:360–366

Sreeram S, Senthil Kumar A, Rahman M, Zaman MT (2006) Optimization of cutting parameters in micro end milling operations in dry cutting condition using genetic algorithms. Int J Adv Manuf Technol 30:1030–1039

Subramanian M, Sakthivel M, Sooryaprakash K, Sudhakaran R (2013) Optimization of cutting parameters for cutting force in shoulder milling of Al7075-T6 using response surface methodology and genetic algorithm. Proc Eng 64:690–700

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Masmoudi, N., Chaari, R., Gafsi, W., Chaari, F., Khabou, M.T., Haddar, M. (2018). Vibration Suppression of a Cantilever Plate During Milling Using Passive Dynamic Absorber. In: Haddar, M., Chaari, F., Benamara, A., Chouchane, M., Karra, C., Aifaoui, N. (eds) Design and Modeling of Mechanical Systems—III. CMSM 2017. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-66697-6_107

Download citation

DOI: https://doi.org/10.1007/978-3-319-66697-6_107

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-66696-9

Online ISBN: 978-3-319-66697-6

eBook Packages: EngineeringEngineering (R0)