Abstract

Reinforced concrete (RC) deep beams mainly fail in shear, brittle and sudden in nature can lead to calamitous consequences. Thence, it is critical to determine the shear characteristics of RC deep beams accurately due to involving many parameters at same time. Some of the recent researches have shown that current equations for predicting ultimate shear strength are non-conservative when applied to high strength concrete (HSC) beams as well as some of design codes provisions. There are different approaches for analyzing the behavior of beams in shear.

In this paper, a semi-empirical approach is adopted in which a database of existing experimental and literature results of deep beams, d > 300 mm & d < 300 mm, failing in shear under two point loads statically at mid-span, was constructed. The database, 725 deep beams, was used to propose two simplified shear equations using multiple regression analysis, IBM-SPSS-Statistics, to find out and evaluate the most important factors affecting the ultimate shear strength formulating them in a suitable predictive equation for the ultimate shear strength of deep beams without web reinforcement (stirrups). The test database covers a wide range of individual parameters as: cylindrical concrete compressive strength (20 ≤ f ′ c ≤ 104 MPa), longitudinal main steel reinforcement ratio (0.17% ≤ ρ s % ≤ 6.64%), effective depth of deep beams “d” (127–1000 mm), shear span to effective depth ratio (1 ≤ a/d ≤ 2.5), Beam width “b”; b/d < 1, where all database from literature were based on two point loading.

This paper concluded that, the proposed equations seem to predict the ultimate shear strengths well, conservative and give lower coefficient of variation “COV” and smaller range of results when compared with the available methods of design; ECP203-2007, ACI 318-14, CSA, and BS8110 codes and other equations proposed by Sudheer Reddy, Zararis, Bazant, Zsutty and Shah.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Deep beams

- Predictive design equation

- Shear strength

- Tension reinforcement ratio

- Shear span to effective depth ratio

1 Introduction

Normally, Reinforced concrete has extensively use in the construction industry around the world. Concrete is heterogeneous in nature and that cause difficulty in the calculation of stresses, in addition to the presence of reinforcement steel make the situation more complex.

As well known, among researchers in constructions and concrete technology field, that the shear capacity of high strength reinforced concrete (HSRC) beams unlike that of normal strength reinforced concrete (NSRC) do not increase, in the same proportion, as the compressive strength of concrete increase due to brittle behavior of the High Strength Concrete (HSC).

The use of deep beams in many applications is going faster than developing new design equations in code provisions for shear design. In spite of availability of massive of tested NSRC & HSRC deep beams, but it is seemed that the database still need more specimens to can understand the complex shear mechanism of deep beam especially with HSC. Therefore, the current equations proposed empirically by most of the design codes for shear strength of RC beam are less conservative as compared to those of NSRC beams. This major observation by the authors is the focus of this research.

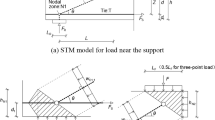

Several researchers discovered that failure mode is dependent on (a/d) substantially. Berg (1962) found increase in shear capacity with decreasing of (a/d) ratio. Nevertheless, Ferguson (1956) explained what Berg shown, increased resistance to diagonal tension in case of small (a/d), a local loading effect because of the thrust of load transfer directly to supports through concrete strut, where diagonal cracking load exceed gradually with increasing shear span for concrete compressive strength up to 28 MPa. Kani (1966) summarized that, f′ c between (17–34 MPa), a decrease in relative flexural strength with increase in (a/d) ≤ 2.5. Most of studies mentioned above had done on non-practical beam size causing un-conservative in results used in formulate new predictive design equation.

The test data of thirty-six reinforced concrete beams carried out in this study, besides results of test beams obtained from the literature by other investigators used in a multiple regression analysis to formulate predictive equations for deep beams taking into account the main factors affecting the ultimate shear strengths.

A detailed comparison performed between the experimental values of the ultimate shear strengths obtained from this study and those of the literature and the estimated values using the proposed equations and the other predictive equations proposed by other investigators.

2 Experimental Program

2.1 Specimens

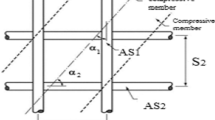

Comprehensive research work carried out on the shear mechanism of full scale of eighteen RC deep beams, two sets; nine deep beams each, without stirrups, Table 1, and dimension details shown in Fig. (1). The main parameters of the first set are h = 700 mm, 3600 mm length (L), the second set h = 400 mm, 3000 mm length (L). All sets have three values of \( \varvec{\rho}_{\varvec{s}} \% = \left( {0.73\% ,1.21\% ,1.83\% } \right) \) and three values of \( \left( {{\mathbf{a}}/{\mathbf{d}}} \right) = \left( {2,1.5,1} \right) \), to can anticipate typical shear failure. All tested beams subjected to two monotonic point loads symmetrically to examine the contribution of studied parameters on the shear capacity of beams. The research carried out at Structure laboratory of Engineering College, King Saud University, Kingdom of Saudi Arabia.

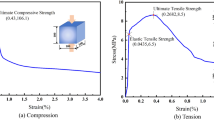

2.2 Material Properties

A local ready-mix supplier provided the desired concrete for tested beams. Two patches, for two sets of beams, of same concrete mix was placed in wooden forms and vibrated to ensure the concrete workability. From the same patches, concrete cylinders 150 × 300 mm are casted for standard concrete tests, and cured at room temperature for 28 days. The concrete strength was monitored by compression testing of the cylinders; 3, 7 and 28 days. The concrete strength is ranged in between (73–77) MPa with an average value of 75 MPa at 28 days age. High strength deformed bars 10, 12, 14, 18 and 20 mm and of 765, 650, 670, 670, and 670 MPa proof strengths respectively were used for tensile steel. Plain bars 8 mm used in compression zone just to hold the stirrups, which used to prevent bearing failure occur, at supports area in place during casting.

2.3 Test Set-up

Hydraulic jack in a load frame “200 kN actuator” is used to apply the load on each specimen as a simply supported beam under four point loading, Fig. (2). Four LVDT are calibrated, two at mid-span and one at each of mid-shear span. Specimens subjected to a constant load rate and deflection were recorded. The crack patterns were noted at each increment of load until beam fails. All cylinders were tested in according to ASTM C39-86.

3 Equations Predicting Ultimate Shear Strength

Egyptian Code, ECP203-10 (2010); the equation used for predicting the shear strength, compression strength up to 60 MPa, provided by concrete is:

Where, \( {\text{P}}_{\text{u}} \) is compression axial force on cross section of beam. The ECP 203 code limit for strength reduction factore for concrete “safety factor” is \( 1 < \left( {{\upgamma }c} \right) \le 1.5 \), here will be taken = 1, where there is no axial force.

The ACI Building Code 318-14 (1987, 1993, 2014) is no doubt the most widely applied Code for the shear design of concrete. The nominal shear capacity of reinforced concrete beam \( {\text{V}}_{\text{n}} \), is given as the sum of Concrete contribution \( {\text{V}}_{\text{c}} \), and contributions of stirrups \( {\text{V}}_{\text{s}} \).

Where Vc is nominal shear strength of concrete, and Vs nominal shear strength of beams due to stirrups. For beams without shear reinforcement, the shear capacity is given as:

Where f′c is cylinder compressive strength of concrete, ρ is longitudinal steel ratio, Vu is Factored shear at the section, Mu is Factored Moment at the section, bw is Width of beams web, d is Effective depth of beam, and s is Spacing of stirrups.

The General design method of Canadian code CSA (2004) has been based on MCFT (Modified Compression Field Theory) and applies to concrete up to 81 MPa (16000 psi). According to CSA A- 23.3-94:

Where; f ′ c is compressive strength of concrete at 28 days in MPa, “b w d” is width and depth effective cross-section respectively in mm, “A v ” is the stirrups cross-sectional area. The Canadian standard has not considered the effect of shear span to depth ratio and longitudinal tension reinforcement effect on shear strength of concrete.

European Code EC2 (2011), according to CEB-FIB model the shear strength of concrete members is given by the following equation:

BS 8110 (1985) is a code of practice for the structural use of concrete. The relevant committee of the British Standards Institute considers that there is no need to support BS 8110 as the Department for Communities and Local Government have indicated that European Code EC2-2011is acceptable for design according to the Building Regulations.

Where; f ′ c is compressive strength of concrete at 28 days in MPa, “b w d” is width and depth effective cross-section respectively in mm, a/d – Shear span to Depth ratio.

Sudheer Reddy.

Established new equation to study shear strength of HSC beams (70 MPa) with different shear span to depth ratios (a/d = 1, 2, 3 and 4) without web reinforcement and compare the test results with the available shear models. By estimating the shear capacity of HSC beams, the parameters as tensile strength of concrete, shear span to depth ratio (a/d) and tensile reinforcement ratio were taken into account in form of “Shear Influencing Parameters” (SIP):

Where; f t is tensile strength of concrete in Mpa, a/d is Shear Span to Depth Ratio, and ρ s is Longitudinal Reinforcement Ratio.

Zararis (2010) derived formulas from this analysis that are verified by comparisons to extensive sets of experimental data from literature, which have been obtained on deep beams with various strengths of concrete, main steel ratios, shear reinforcement ratios, and shear span to depth (a/d) ratios between 1.0 and 2.5.

where; \( {\mathbf{1}}{\mathbf{.2}} - {\mathbf{0}}{\mathbf{.2}}\left( {\frac{\varvec{a}}{\varvec{d}}} \right)\varvec{d} \ge {\mathbf{0}}{\mathbf{.65}}\quad \left( {\varvec{d}\;\varvec{in}\,\varvec{m}} \right) \)

Bazant and Yu (2005) has formulated the following equation for shear strength of concrete members:

Zsutty (1968) segregated the data and performed separate regression analysis for short beams and long beams. However, the main problem of performing separate regression analysis for deep beams and slender beams is that his approach would lead to two different equations and would discontinuity to occur for a certain value of a/d as follows:

Shah et al. (2009) developed regression model for shear strength of beam without stirrups

4 Regression Analysis

4.1 Introduction to Regression Analysis

Regression analysis is described as the study of relationship between variables. Regression analysis is used to predict a continuous dependent variable from a number of independent variables.

A linear relationship between two random variables refers to simple linear regression and the linear relationship between more than two random variables is called multiple linear regression. When the relationship is sought between a single predictor and the response variable, it is called simple linear regression. Relationships involving more than one variable are of the form. For this research, multiple linear regression is adopted.

A multiple regression equation involves more than one regression coefficient to describe the data. The best way to choose between alternative regression coefficients is to compare the errors of prediction associated with different linear regression equations. Errors of prediction are defined as the differences between the observed values of the independent variable and the predicted values for that variable obtained using a given regression equation and the observed values of the independent variable.

SPSS-IBM .v20 is powerful software that solves many statistical problems with ease. This software is frequently used in area of mathematics, statistics, economics, and engineering. This is a general purpose statistical computing system, designed especially for students and researchers. SPSS-IBM is designed to be used interactively. This means that a command is immediately carried out and the results are shown. For the purpose of this research, regression analysis has been carried out using this software.

For the shear database, the response variable is the ultimate shear strength, predicted by code equations and other investigators, and the predictors are the concrete compressive strength f′c, longitudinal main steel reinforcement ratio ρ s %, and Effective depth of beams d, shear span to effective depth ratio a/d, and Beam width, b.

4.2 Factors Influencing Ultimate Shear Strength

There are different approaches for analyzing the behavior of beams in shear. In this study, a semi-empirical approach is adopted in which shear data collected from the past literature is analyzed and an equation is generated which can be used to predict the ultimate shear strength of a high strength concrete beam. This is done by using regression analysis using a variety of parameters and beam properties.

4.3 Data Sources

The use of regression analysis requires a large amount of data to evaluate accurately the significance of every variable in any process. Based on the observations of cracks in ultimate shear load of the performed experimental results in this study and test results carried out by other investigators, this collection database is the most numerous ever collected for shear without stirrups, in the literature. Totally, 743 reinforced concrete beams without web reinforcement failed in shear (18 test results obtained from this study and 725 deep beams test results from other previous investigators) were used in multiple regression analysis, IBM-SPSS-Statistics, to find out the most important factors affecting the shear strength, formulating them in a suitable predictive equation. The test databases cover a wide range of individual parameters as, Ramadan (2015):

-

Cylindrical concrete compressive strength (20 ≤ fc′ ≤ 104 MPa).

-

Longitudinal main steel reinforcement ratio (0.17% ≤ ρ s % ≤ 6.64%).

-

Effective depth of deep beams, d, (127–1000 mm) & slender beams (70–2000 mm).

-

Shear span to effective depth ratio (1 ≤ a/d ≤ 2.5).

-

Beam width, b; b/d < 1, All database from literature were based on two-point loading.

4.4 Need for Statistical Analysis

One of the statistical methods for modeling the association among two or more random variables and the predictors using a linear equation is regression analysis. The effect of one variable upon another can be investigated using regression analysis. A linear relationship between two random variables refers to simple linear regression and the linear relationship between more than two random variables is called multiple linear regressions. For this research, multiple linear regressions are adopted.

In the study of HSC beams in shear, experimental data collected from previous studies involving different parameters affecting the ultimate shear strength is collected. This analysis also gives an assessment of “statistical significance” of the estimated relationships, that is, the degree of confidence that the true relationship is close to the estimated relationship.

5 Proposed Equations and Codes Comparison: Results and Discussions

5.1 Proposed Design Formulas for Ultimate Shear Strength

Modified equations are proposed to predict the ultimate shear strength based on the statistical analysis of the above-mentioned test data. Regression analysis yielded the following:

ν u,1 for Deep beams/300 mm: “Ramadan 1”

ν u,2 for Deep beams <300 mm: “Ramadan 2”

5.2 Comparisons of Test Results of Deep Beams with Codes and the Proposed Equations

To evaluate the three proposed models, nine well-known expressions for computing the ultimate beam shear strength have been selected for comparison with respect to the overall number 743 of beams.

The experimental results were used to check the validity of the shear strength equations given by Egyptian Code “ECP203-2010”, American Code “ACI 318-14”, Canadian Code “CSA”, British Standard “BS8110” and some interested equations by other investigators. The test data specimens, here considered, have been collected from almost 240 papers, Ramadan (2015).

There is something have to say, before analyzing and evaluating the proposed equations, about choosing a certain depth 300 mm for the deep beams as a basic depth, Author’s definition for the current study, or as Shuraim (2014) named it as basic shear strength; the intersection of the shear demand curve and the shear resistance curve. Where, at beams/300 mm, the behavior of deep beams very different from beams < 300 mm in shear resistance mechanism. Iguro et al. (1984), on RC beams under uniformly distributed loading with beam depth varying between 100 mm and 3000 mm without shear reinforcement have revealed that as the effective depth of beam increases the shear strength decreases sequentially. As the depth of the beam increases, Rao and Prasad (2010), from 600 mm to 1200 mm, the diagonal cracking strength decreases with increasing the beam depth. Small size beams exhibited improved shear ductility, also as the depth of the beam increases, the beams exhibit relatively brittle failure about 20–25% decrease in the diagonal cracking strength was observed when the beam depth increases from 600 mm to 1200 mm. For (1.0 ≤ a/d ≤ 3.0), Kim and Park (1996) proposed a model for estimation of the shear strength of RC deep beams in which d ≥ 250 mm. Carmona and Ruiz (2014), Beam failure occurs when a flexural crack reaches a certain depth, which call critical depth, Zararis and Papadakis (2001). It depends on the crack position and on the boundary and loading conditions.

Acceptable results are obtained from the application of proposed Eqs. (12) and (13) on the 743 tested beams. According to the statistical analysis for measured to proposed values of deep beams ≥ 300, <300; the mean value of the observed shear strength to the predicted shear strength is 1.05, 1.07 with a standard deviation (S.D.) of 0.36, 0.26 and coefficient of variation (COV) is 0.35, 0.24 respectively. Based on the statistical analysis for measured values of deep beams ≥ 300, <300; the mean standard error of estimate (M.S.E) is found to be 0.17, 0.22 and the correlation coefficient (r) is 0.8, 0.78 respectively.

Based on the statistical study, it is concluded that, the experimental values of the ultimate shear strength would be best fitted in the proposed equations. Figures 3 and 4 show the results of the comparison between the observed shear strength values with the predicted values for database of deep beams ≥ 300 mm, and deep beams < 300 mm respectively.

For all database tests, Figs. 5 and 6 the ratios “νu,test/νu, pro” of the measured shear strength values to the predicted one, by means of each of the nine above mentioned expressions and the proposed formulas, are plotted versus the shear span-to effective depth ratio “a/d” for deep “≥300”, deep “<300”, respectively. Also, Figs. 7 and 8, the ratios “νu,test/νu, pro” of the measured shear strength values to the predicted one, by means of each of the nine above mentioned expressions and the proposed formulas, are plotted versus the compressive concrete strength “f′c” for deep “≥300”, deep “<300”, respectively. Finally, Figs. 9 and 10 the ratios “νu,test/νu, pro” of the measured shear strength values to the predicted one, by means of each of the nine above mentioned expressions and the proposed formulas, are plotted versus the main steel reinforcement “ρ s %” for deep “≥300”, deep “<300”, respectively.

The horizontal line at (1) represents the perfect correspondence between experimental and computed shear strength values. Therefore, the closer to the line, the points are, the more accurate the shear strength prediction is. The thinner the width of the strip including the points is, the greater the prediction uniformity.

The relationships between ѵu,test/ѵu, pred. and a/d, or f′c or ρ s % for all the database tests considered in this work. The following comments are made on those figures:

-

1.

The best predictions, with least scatter, are with Eqs. (12) and (13); the proposed ones.

-

2.

The scatter is greater in the other predicted code equations or others except ECP203-10 and CSA Eqs.

-

3.

From the points of view of safety (ѵu,test/ѵu, pred. > 1) the proposed equations are the best among all other equations considered in this work.

The performance of building codes and the proposed models were compared with the experimental results compiled from the literature. The comparison was assessed with six statistical parameters, which are commonly used for shear prediction models by researchers (Machial et al. 2012; Slater et al. 2012).

The proposed equations for predicting shear strength without web reinforcement were more conservative than the other equations. Comparing other equations ECP, ACI CSA, BS, SIP, Zararis, Bazant, Zsutty, and Shah in the value of AAE were 79, 86, 89, 61, 564, 157, 150, 139 and 114% higher than proposed equation “Ramadan1”. Except equations of codes, the others were more unconservative and unsafe. In addition, CSA had very high SD (2.29), r (0.02), COV (75%), and AAE (53%) which were higher than the ACI and BS values.

SIP proposed model was the least accurate in its prediction since it had the highest AAE value (186%). On the contrary, British model (BS8110) was the most conservative model where it’s average PF and SD values were 1.76 and 1.99, respectively. In case of other models, in spite of high SD, COV, and AAE values, the models still underestimated the shear strength since their average PF is upper one, Therefore, it was clearly observed that these models (i.e., SIP, Zararis, Bazant, Zsutty, and Shah) were poor in predicting the shear strength of deep beams without web reinforcement. After comparing all the models, it can be concluded that the proposed equations “Ramadan1” and “Ramadan2” predicted the shear strength more accurately and safely than the other models. Since both PF (1.05) and Correlation coefficient (r) are very close to unity and AAE value (28%) is the lowest one than the codes and other equations, so, this make “Ramadan1” and “Ramadan2” highly conservative.

6 Conclusions

An experimental investigation on the shear mechanism of reinforced concrete beams without web reinforcement made of HSC is presented. Two equations were proposed for predicting the ultimate shear strengths depending on the studied test variables. A detailed comparison was made between the experimental values of the ultimate shear strengths obtained from this study and from the literature and the estimated values using the proposed equations in this study and the other predictive equations proposed by other investigators.

Findings from the experimental study and the analysis of such test results and variables brought out a number of interesting points. Although most of these findings are written in their proper location through the text, they will be summarized here for reference:

-

HSRC deep beams without stirrups exhibit very brittle behavior.

-

The failure mode was significantly altered by changing the beam depth, where sufficient ductility was achieved in small size beams, and relatively very high brittleness was observed in large size beams.

-

The ultimate loads increase as shear span to depth ratio (a/d) decreases, this is because cracks form in the shear regions at places of high moments which are towards the applied concentrated loads, as shear span to depth ratio (a/d) decreases this distance also decreases, and the slope of the cracks become more steep.

-

The shear carrying capacity of tested deep beams was observed to increase in a slightly rate between (10–50%) with the increase in ρs% ratio, but in case of h = 700 mm, a/d = 2 and 1.5 a gradual decrease except some anomalies of the tested beams.

-

The main steel percentage increase, the increase in values of Vtest/Vpred. was, measured to predicted shear strength values of codes and comparative equations, mainly recorded due to the dowel action which improves with the amount of longitudinal steel crossing the cracks. Hence, it may be noted that the tensile reinforcement significantly affects the deflection of a beam, thus this is the most important parameter in controlling deflections of HSC beams.

-

Two equations have been proposed for predicating the ultimate shear strength of reinforced concrete deep beams, for d ≥ 300 mm and d < 300 mm based on the multiple regression analysis for the test data of 743 reinforced concrete beams with and without stirrups failed in shear obtained from this study and from other previous investigators including the major factors affecting the ultimate shear strength.

-

The different design equations considered in this study do not accurately reflect the increase in shear capacity of beams with shorter shear spans (a/d = 1.5). Most of the design models are excessively conservative, and the code predictions only seem to be more accurate as a/d increases beyond a value of 2.0.

-

The ACI code prediction overestimates the ultimate shear strength of deep beams with overall depth 700 mm. Thus, it can be expected that the ACI code prediction regarding the ultimate shear strength of deep beam is conservative for HSRC deep beams with overall depth 400 and 700 mm.

-

SIP, Zararis, Bazant, Zsutty, and Shah were poor in predicting the shear strength of deep beams without web reinforcement. Comparing all the models, it could be concluded that the proposed equations “Ramadan1” and “Ramadan2” predicted the shear strength more accurately and safely than the other models since both PF (1.05) and Correlation coefficient (r) are very close to one and AAE value (28%) is the lowest one than the codes and other equations, so, this make “Ramadan1” and “Ramadan2” highly conservative.

-

ACI, CSA, and Shah models, in spite of high COV, and AAE values, the models still underestimated the shear strength since their average PF is upper one. It was clearly observed that these models (i.e., BS, SIP, Zararis, Bazant, and Zsutty) were poor in predicting the shear strength of slender beams without web reinforcement.

References

ACI Building Code Requirements for Structural Concrete (318-14). American Concrete Institute

ECP-203. Egyptian code of practice for design and construction of concrete structures. Ministry of Housing, Cairo, Egypt (2007) (in Arabic)

ACI Committee 226. Silica Fume in Concrete. ACI Materials Journal, No. 84-M18, March–April, pp. 158–166 (1987)

ACI Committee 212. Guide for the use of high-range water-reducing admixtures (Superplasticizers) in concrete. Concr. Int. 15(4), 40–47 (1993)

BS8110. Structural Use of Concrete. British Standards Institution, London (1985)

ACI Committee 318-14. Building Code Requirements for Reinforced Concrete (ACI 318-14) and Commentary (318R-95). American Concrete Institute, Farmington Hills, Michigan, p. 369 (2014)

CSA Standard A23.3-94. Design of Concrete Structures, Canadian Standards Association (2004)

Reddy, S.L., Rao, R.N.V., Gunneswara, R.T.D.: Shear resistance of high strength concrete beams without shear reinforcement. Int. J. Civ. Struct. Eng. 1(1), 101–113 (2010)

Zararis, P.: Shear compression failure in reinforced concrete deep beams. J. Struct. Eng. 129(4), 544–553 (2003)

Bazant, Z.P., Yu, Q.: Introducing size effect into design practice and codes for concrete infrastructure, part 1: designing against size effect on shear strength of reinforced concrete beams without stirrups. ASCE J. Struct. Eng. (2005)

Zsutty, T.C.: Beam shear strength prediction by analysis of existing data. ACI Struct. J. Proc. 65(11), 943–951 (1968)

Shah, A., Ahmad, S.: Statistical model for the shear strength of high strength concrete beams. Arab. J. Sci. Eng. (AJSE) 34(2B), 400 (2009)

Ramadan, A.I.H.: Shear strength of high strength reinforced concrete (HSRC) beams without web reinforcement. Ph.D. dissertation, Assiut University, Egypt (2015)

Shuraim, A.B.: A novel approach for evaluating the concrete shear strength in reinforced concrete beams. Lat. Am. J. Solids Struct. 11(1), 93–112 (2014)

Iguro, M., Shioya, T., Nojir, I.Y., Akiyama, H.: Experimental studies on shear strength of large reinforced concrete beams under uniformly distributed loads. JSCE Proc. 1(345), 137–154 (1984)

Rao, G.A., Prasad, B.S.R.K.: Effect of depth and distribution of horizontal shear reinforcement on shear strength and ductility of RC deep beams. In: Fracture Mechanics of Concrete and Concrete Structures, Proceedings of FraMCoS-7, 23–28 May 2010

Kim, J., Park, Y.: Prediction of shear strength of reinforced concrete beams without web reinforcement. ACI Mater. J. 93(24), 213–222 (1996)

Carmona, J.R., Ruiz, G.: Bond and size effects on the shear capacity of RC beams without stirrups. Eng. Struct. 66, 45–56 (2014)

Zararis, P., Papadakis, G.: Diagonal shear failure and size effect in RC beams without web reinforcement. J. Struct. Eng. 127(7), 733–742 (2001). ASCE

Acknowledgements

The authors would like to acknowledge the financial support from the Center of Excellence for Research in Engineering Materials (CEREM) at the College of Engineering—King Saud University. The help of engineers and technicians in the Center of Excellence for Concrete Research and Testing (CoE-CRT) and in the structural laboratory is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Ramadan, A.I., Aly Abd-Elshafy, A.G. (2018). Statistical Prediction Equations for RC Deep Beam Without Stirrups. In: Rodrigues, H., Elnashai, A., Calvi, G. (eds) Facing the Challenges in Structural Engineering. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-61914-9_26

Download citation

DOI: https://doi.org/10.1007/978-3-319-61914-9_26

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61913-2

Online ISBN: 978-3-319-61914-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)