Abstract

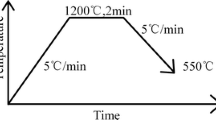

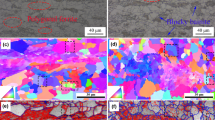

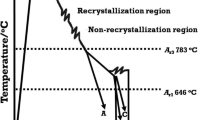

With the rapid development of oil and gas industry long distance pipelines inevitably pass through regions with complex geological activities. In order to avoid large deformation the pipelines must be designed based on strain criteria. In this paper the alloy system of X80 high deformability pipeline steel was designed which was 0.25%Mo-0.05%C-1.75%Mn. The effect of controlled cooling process on microstructure and mechanical properties of X80 high deformability pipeline steel were systematically investigated. Through the two-stage controlled cooling process the microstructure of the X80 high deformability pipeline steel were ferrite, bainite and M/A island. There were two kinds of ferrite which were polygonal ferrite (PF) and quasi-polygonal ferrite (QF). The bainite was granular bainite ferrite (GF). Along with the decrease of the start cooling temperature, the volume fraction of ferrite and M/A both increased, the yield ratio (Y/T) decreased, the uniform elongation (uEl) increased firstly with the content of ferrite increased but then decreased with the content and size of M/A increased. When the finish cooling temperature decreasing, the size of M/A became finer. As the start cooling temperature was 690 °C and the finish cooling temperature was 450 °C the volume fraction of ferrite was 23%, the size of ferrite grain was 5μm, the size of M/A island was below 1μm and the structure uniformity was the best. The deformation mechanism of X80 high deformability pipeline steel was analyzed. The best way to improve the work hardening rate was reducing the size of M/A islands on the premise of a certain volume fraction. The decreasing path of instantaneous strain hardening index (n*-value) showed three stages in the deformation process. The n*-value kept stable in the second stage, the reason was that the retained austenite transformed into martensite and the phase transition improved the strain hardening ability of the microstructure. This phenomenon was called transformation induced plasticity effect (TRIP).

Supported by High Technology Research and Development Program of China(863) (No.2013AA031601) and National Key Technology R&D Program during the 12th Five Year Plan (No.2012BAF04B01)

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

Reference

Pan J H, “Several concernment task under development of high strength pipeline steel,” Welded Pipe and Tube, 28(4), (2005), 1–2.

Denys R and Lefevre A, “Material Test Requirements For Strain-Based Pipeline Design,” (Paper presented at CNPC Seminar on High Strain Linepipe, Beijing, 2008), 101–122.

Ishikawa N et al., “Mechanical and Metallurgical Properties of High Strength Linepipes for High Strain Application,” (Paper presented at International Pipeline Steel Forum, Beijing, 2008), 1–14.

Nobuyuki Ishikawa et al., “Design concept and production of high deformability linepipe,” (Paper presented at Proceedings of 6th International Pipeline Conference, Calgary, Alberta, Canada, September 25–29, 2006), 215–222.

Shinohara Y et al., “Development of a high strength steel line pipe for strain-based design applications,” (Paper presented at Proceedings of The Seventeenth 2007 International Offshore and Polar Engineering Conference, Lisbon, Portugal, 2007), 2949–2954.

Ishikawa N et al., “Design concept and production of high deformability linepipe,” (Proceedings of IPC 2006 6th International Pipeline Conference, Calgary, Canada, 2006), 215.

Wang C M, et al, “Transmission electron microscopy of martensite/austenite islands in pipeline steel X70,” Materials Science and Engineering: A, 438/440, (2006), 267–271.

N K Balliger and T Gladman, “Work hardening of dual-phase steels,” Materials Science and Technology, 15 (1981), 95–108.

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 2014 TMS

About this paper

Cite this paper

Hesong, Z., Yonglin, K. (2014). Effect of Cooling Mode on Microstructure and Mechanical Properties of Pipeline Steel for Strain Based Design and Research on its Deformation Mechanism. In: Energy Materials 2014. Springer, Cham. https://doi.org/10.1007/978-3-319-48765-6_75

Download citation

DOI: https://doi.org/10.1007/978-3-319-48765-6_75

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48598-0

Online ISBN: 978-3-319-48765-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)