Abstract

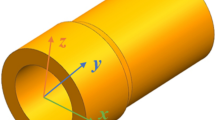

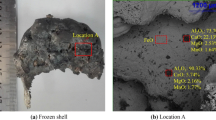

For good quality billet, metal degasing is important consideration in billet casting. In-line degasser processes help to remove 61 to 66% of the dissolved gas. An improved billet quality can increase extrusion speed. A model of degassing delineates the most important key factors for optimization of product design for high quality, productivity and cost savings using computer simulations. The present work focuses on aluminum direct chilled casting process with gas injected in the mold through a submerged entry nozzle. The effects of gas into the melt and a direct casting magnetic field on the mold fluid flow are studied. Considering the effect of complex flow, injection and heat transfer on the gas bubble size the particles model reveals to be an efficient method to study the degassing phenomenon. However, the model treats the gaseous phase as bubbles with multiple sizes providing a new approach to simulate multiphase flow in continuous casting.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

J. Nagai et al. “Steel Flow Control in a High-Speed Continuous Slab Caster Using an Electromagnetic Brake”. In: Iron Steel Eng. 61 (1984), pp. 41–47.

T. Tagawa and H. Ozoe. “Enhancement of Heat Transfer Rate by Application of a Static Magnetic Field During Natural Convection of Liquid Metal in a Cube”. In: J. Heat Trans. 119 (1997), pp. 21–25.

C. Zhang, S. Eckert, and G. Gerbeth. “The flow structure of a bubble-driven liquid-metal jet in a horizontal magnetic field”. In: J. Fluid Mech. 575 (2007), pp. 57–82.

K. Cukierski and B.G. Thomas. “Flow Control with Local Electromagnetic Braking in Continuous Casting of Steel Slabs”. In: Metall. Mater. Trans. B 39 (2008), pp. 94–107.

D.S. Kim, W.S. Kim, and K.H. Cho. “Numerical Simulation of the Coupled Turbulent Flow and Macroscopic Solidification in Continuous Casting with Electromagnetic Brake”. In: ISIJ Int. 40 (2000), pp. 67–676.

Y. Wang and L. Zhang. “Fluid Flow-Related Transport Phenomena in Steel Slab Continuous Casting Strands under Electromagnetic Brake”. In: Metall. Mater. Trans. B 42B (2011), pp. 1319–1351.

H. Shen et al. “Effect of electromagnetic brake on fluid flow in continuous slab casting mould”. In: Int. J. Cast Metals Res. 18 (2005), pp. 209–213.

B. Li, T. Okane, and T. Umeda. “Modeling of molten metal flow in a continuous casting process considering the effects of argon gas injection and static magnetic-field application”. In: Metall. Mater. Trans B 31B (2000), pp. 1491–1503.

A. Idogawa et al. “Control of molten steel flow in continuous casting mold by two static magnetic fields imposed on whole width”. In: Mater. Sci. Eng. A 173 (1993), pp. 293–297.

H. Harada et al. “Effect of Magnetic Field Conditions on the Electromagnetic Braking Efficiency”. In: ISIJ Int. 41 (2001), pp. 1236–1244.

K. Takatani. “Effects of Electromagnetic Brake and Meniscus Electromagnetic Stirrer on Transient Molten Steel Flow at Meniscus in a Continuous Casting Mold”. In: ISIJ Int. 43 (2003), pp. 915–922.

G.M. Evans et al. “Gas dispersion through porous nozzles into down-flowing liquids”. In: Chemical Engineering Science 54 (1999), pp. 4861–4867.

G.B.Wallis. “A simplified one-dimensional representation of two-component vertical fow and its application to batch sedimentation”. In: Symposium on the interaction between yuids and particles. Institute of Chemical Engineers, London. 20–22 June, 1962.

G.M. Evans and G.J. Jameson. “Hydrodynamics of a plunging liquid jet bubble column”. In: Chemical Engineering Research and Design 73(6) (1995), pp. 679–684.

S.M. Shin and I.S. Kang. “Effects of magnetic field on the shape of a bubble in a uniaxial straining flow”. In: Int. J. Multiphase Flow 28 (2002), pp. 105–125.

K. Shibasaki, K. Ueno, and T. Tagawa. “Computation of a rising bubble in an enclosure filled with liquid metal under vertical magnetic fields”. In: ISIJ Int. 50 (2010), pp. 363–370.

K. Takatani. “Mathematical modeling of incompressible MHD flows with free surface”. In: ISIJ Int. 47 (2007), pp. 54–551.

Y.M. Gelfgat, O.A. Lielausis, and E.W. Sherbinin. Liquid Metal under the Action of Electromagnetic Forces. Zinatne, Riga, 1976.

S. Eckert et al. “MHD turbulence measurements in a sodium channel flow exposed to a transverse magnetic field”. In: Int. J. Heat Fluid Flow 22 (2001), pp. 358–364.

Y. Mori, K. Hijikata, and I. Juriyama. “Experimental study of bubble motion in mercury with and without magnetic field”. In: Winter Annual Meeting of ASME, Heat Transfer Division, New York, 5 December (ASME 76-WA/HT-65). 1976.

P. Gherson and P. S. Lykoudis. “Local Measurements in two-phase liquid-metal magneto-fluid-mechanic flow”. In: J. Fluid Mech. 147 (1984), pp. 81–104.

C. Zhang, S. Eckert, and G. Gerbeth. “The flow structure of a bubble-driven liquid-metal jet in a horizontal magnetic field”. In: J. Fluid Mech. 575 (2007), pp. 57–82.

Y. Sato and K. Sekoguchi. “Liquid velocity distribution in two-phase bubbly flow”. In: Int. J. Multiphase Flow 2 (1975), pp. 79–95.

N.G. Deen, T. Solberg, and B.H. Hjertager. “Large eddy simulations of the gas liquid flow in a square cross-sectioned bubble column”. In: Chem. Eng. Sci. 56 (2001), pp. 6341–6349.

O. Simonin and P.L. Viollet. “On the computation of turbulent two-phase flows in Eulerian formulation”. In: Proceedings EUROMECH 234 Conference, Toulouse, France,1998.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Diop, M.A., Hassan, M.I., Xiaomeng, C. (2016). Numerical Simulation of Degassing Phenomena in Direct Chilled Casting Process under External Static Magnetic Field on Flow Pattern in Slab Mold. In: Williams, E. (eds) Light Metals 2016. Springer, Cham. https://doi.org/10.1007/978-3-319-48251-4_134

Download citation

DOI: https://doi.org/10.1007/978-3-319-48251-4_134

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48615-4

Online ISBN: 978-3-319-48251-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)