Abstract

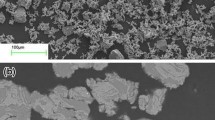

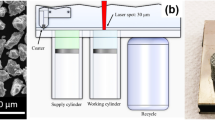

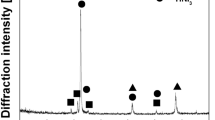

Nitinol shape memory alloys are used in a wide range of biomedical applications because of their biocompatibility, shape memory and superelasticity properties, and high corrosion resistance. Processing NiTi using additive manufacturing has led to even wider possibilities for use in the biomedical field. The focus of the study was on producing ultra-thin (±500 um strut), porous nitinol (NiTi) structures with varying levels of porosity using laser powder bed fusion (LPBF). Their functional and mechanical response was characterized. The effect of increased engineered porosity shifted the transformation temperatures higher and widened the hysteresis. As the amount of porosity increased, the compressive strength decreased as did the elastic modulus. The size and geometry of lattice unit cells were found to have a significant effect on the mechanical response of these porous structures. All the porous structures had an elastic modulus below 20 GPa. This low stiffness makes porous nitinol promising candidates for biomedical implants.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chen Y, Sun J, Liu Y, Leng J (2012) Variable stiffness property study on shape memory polymer composite tube. Smart Mater Struct 21(9):094021

Qader IN, Mediha KÖK, Dagdelen F, Aydoğdu Y (2019) A review of smart materials: researches and applications. El-Cezeri 6(3):755–788

Parvizi S, Hashemi SM, Moein S (2022) NiTi shape memory alloys: properties. In: Nickel-Titanium smart hybrid materials. Elsevier, pp 399–426

Safaei K, Abedi H, Nematollahi M, Kordizadeh F, Dabbaghi H, Bayati P, Javanbakht R, Jahadakbar A, Elahinia M, Poorganji B (2021) Additive manufacturing of NiTi shape memory alloy for biomedical applications: review of the LPBF process ecosystem. JOM 1–16

Chekotu JC, Groarke R, O’Toole K, Brabazon D (2019) Advances in selective laser melting of nitinol shape memory alloy part production. Materials 12(5):809

Xue L, Atli KC, Zhang C, Hite N, Srivastava A, Leff AC, Wilson AA, Sharar DJ, Elwany A, Arroyave R, Karaman I (2022) Laser powder bed fusion of defect-free NiTi shape memory alloy parts with superior tensile superelasticity. Acta Mater 229:117781

Farber E, Zhu JN, Popovich A, Popovich V (2020) A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater Today: Proc 30:761–767

Gil FJ, Planell JA (1998) Shape memory alloys for medical applications. Proc Inst Mech Eng [H] 212(6):473–488

Lu HZ, Ma HW, Luo X, Wang Y, Wang J, Lupoi R, Yin S, Yang C (2021) Microstructure, shape memory properties, and in vitro biocompatibility of porous NiTi scaffolds fabricated via selective laser melting. J Market Res 15:6797–6812

Hodgson D, Russell S (2000) Nitinol melting, manufacture and fabrication. Minim Invasive Ther Allied Technol 9(2):61–65

Olsson S (2016) Evaluation of a production route for cold-drawn Nitinol wires

Safaei K, Abedi H, Nematollahi M, Kordizadeh F, Dabbaghi H, Bayati P, Javanbakht R, Jahadakbar A, Elahinia M, Poorganji B (2021) Additive manufacturing of NiTi shape memory alloy for biomedical applications: review of the LPBF process ecosystem. JOM 1–16

Tan C, Li S, Essa K, Jamshidi P, Zhou K, Ma W, Attallah MM (2019) Laser powder bed fusion of Ti-rich TiNi lattice structures: process optimisation, geometrical integrity, and phase transformations. Int J Mach Tools Manuf 141:19–29

Namatollahi M, Jahadakbar A, Mahtabi MJ, Elahinia M (2019) Additive manufacturing (AM). In: Niinomi M (ed) Metals for biomedical devices. Elsevier, Sawston, UK, pp 331–353

Zadpoor AA (2019) Additively manufactured porous metallic biomaterials. J Mater Chem B 7(26):4088–4117

Walker JM (2014) Additive manufacturing towards the realization of porous and stiffness-tailored NiTi implants. Doctoral dissertation, University of Toledo

Obeidi MA, Monu M, Hughes C, Bourke D, Dogu MN, Francis J, Zhang M, Ahad IU, Brabazon D (2021) Laser beam powder bed fusion of nitinol shape memory alloy (SMA). J Market Res 14:2554–2570

Biffi CA, Bassani P, Fiocchi J, Tuissi A (2020) Microstructural and mechanical response of NiTi lattice 3D structure produced by selective laser melting. Metals 10(6):814

Taheri Andani M, Haberland C, Walker JM, Karamooz M, Sadi Turabi A, Saedi S, Rahmanian R, Karaca H, Dean D, Kadkhodaei M, Elahinia M (2016) Achieving biocompatible stiffness in NiTi through additive manufacturing. J Intell Mater Syst Struct 27(19):2661–2671

Andani MT, Saedi S, Turabi AS, Karamooz MR, Haberland C, Karaca HE, Elahinia M (2017) Mechanical and shape memory properties of porous Ni50. 1Ti49. 9 alloys manufactured by selective laser melting. J Mech Behav Biomed Mater 68:224–231

Dadbakhsh S, Speirs M, Van Humbeeck J, Kruth JP (2016) Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: from processes to potential biomedical applications. MRS Bull 41(10):765–774

Acknowledgements

The authors would like to acknowledge the Department of Science and Innovation South Africa and CSIR South Africa through the Collaborative Program in Additive Manufacturing for funding.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Motibane, L., Tshabalala, L., Hagedorn-Hansen, D., Chikosha, S., Becker, T. (2024). Functional and Mechanical Behavior of Ultra-Thin, Porous NiTi Fabricated via Laser Powder Bed Fusion. In: TMS 2024 153rd Annual Meeting & Exhibition Supplemental Proceedings. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50349-8_9

Download citation

DOI: https://doi.org/10.1007/978-3-031-50349-8_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50348-1

Online ISBN: 978-3-031-50349-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)