Abstract

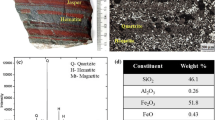

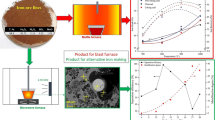

The reduction of chromite ore is an important step in the production of ferrochromium alloy and stainless steel. The comparison between conventional and microwave reduction of chromite ore was investigated in this study with a focus on the effect of reduction time. Compared to conventional reduction, microwave reduction of chromite ore was more efficient by breaking the stable chromium-containing spinel structure, improving reduction performance of the ore with generation of large Fe–Cr particles. By fixing reduction temperature of 1100 °C and C/O molar ratio of 1.2, the metallization degrees of chromium and iron of the briquettes constituted by chromite ore and coke after microwave reduction increased from 91.57 and 83.03% to 93.53 and 85.78%, respectively, with increasing time from 0 to 120 min, which were higher than those obtained by conventional reduction for 4 h (7.00% for chromium and 67.26% for iron).

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Murthy YR, Tripathy SK, Kumar CR (2011) Chrome ore beneficiation challenges and opportunities: a review. Miner Eng 24:375–380

Nafziger RH (1984) A review of the deposits and beneficiation of lower-grade chromite. Metall Ore Dress Abroad 5:19–28

Tripathy SK, Murthy YR, Suresh N, Filippov LO (2021) Carbothermic reduction roasting for processing of ferruginous chromite ore using conventional and microwave heating. Adv Powder Technol 32:2234–2247

Kumar P, Patra SK, Tripathy SK, Sahu N (2021) Efficient utilization of nickel rich chromite ore processing tailings by carbothermic smelting. J Clean Prod 315:128046

Harsh R, Paswan DN, Jha SK (2016) Optimization of process parameter for smelting and reduction of ferrochrome. Int J Eng Res Technol 5:509–513

Zhang F, Zhu D, Pan J, Guo Z, Yang C (2019) Effect of basicity on the structure characteristics of chromium-nickel bearing iron ore pellets. Powder Technol 342:409–417

Yu D, Paktunc D (2019) Carbothermic reduction of chromite fluxed with aluminum spent potlining. Trans Nonferr Metal Soc 29:200–212

Ye Q, Peng Z, Li G, Liu Y, Liu M, Ye L, Wang L, Rao M, Jiang T (2021) Rapid microwave-assisted reduction of ferromanganese spinel with biochar: correlation between phase transformation and heating mechanism. J Clean Prod 286:124919

Hu T, Dai L, Guo Q, Liu B, Gui Q, Gang R, Ji H, Zhang L (2020) Dielectric properties of silicothermic reduction chromite in the microwave field. ACS Omega 5:12672–12681

Peng Z, Hwang J-Y (2015) Microwave-assisted metallurgy. Int Mater Rev 60:30–63

Parirenyatwa S, Escudero-Castejon L, Sanchez-Segado S, Hara Y, Jha A (2016) Comparative study of alkali roasting and leaching of chromite ores and titaniferous minerals. Hydrometallurgy 165:213–226

Xue Y, Zhu D, Pan J, Li G, Lv X (2023) Reduction of carbon footprint through hybrid sintering of low-grade limonitic nickel laterite and chromite ore. J Sustain Metall 9(2):648–664

Ma W, Wang J, Wu L (2018) Research on dielectric characterization of laterite ores under microwave radiation. J Microw Power Electromagn Energy 52:255–265

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China under Grant 72088101.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Tang, H., Peng, Z., Yin, T., Ye, L., Zhong, Q., Rao, M. (2024). Microwave and Conventional Carbothermic Reduction of Chromite Ore: A Comparison. In: Peng, Z., et al. Characterization of Minerals, Metals, and Materials 2024. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50304-7_6

Download citation

DOI: https://doi.org/10.1007/978-3-031-50304-7_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50303-0

Online ISBN: 978-3-031-50304-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)