Abstract

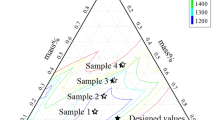

Understanding the transformation mechanism of the viscosity of the CaO–SiO2–FexO slag is of great significance for improving the quality of liquid steel and ensuring the smooth smelting process. In this study, the viscosity values of the CaO–SiO2–FexO system at different temperatures were measured, and its melt structure was analyzed by Raman spectroscopy. The microstructure analysis of the viscosity was then given from the perspective of melt structure. On this basis, a viscosity prediction model that depends on the concentration of oxygen bonds was established using the molar fractions of oxygen bonds calculated by structural analysis. By comparing the measured and calculated values of viscosity, it was found that the deviation of all data was within 0.1 Pa s, showing the higher accuracy and stability of the current model.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhang L, Jahanshahi S (1998) Review and modeling of viscosity of silicate melts: Part I. Viscosity of binary and ternary silicates containing CaO, MgO, and MnO. Metall Mater Trans B 29(1):177–186

Zhang L, Jahanshahi S (1998) Review and modeling of viscosity of silicate melts: Part II. Viscosity of melts containing iron oxide in the CaO–MgO–MnO–FeO–Fe2O3–SiO2 system. Metall Mater Trans B 29(1):187–195

Nakamoto M, Miyabayashi Y, Holappa L (2007) A model for estimating viscosities of aluminosilicate melts containing alkali oxides. ISIJ Int 47(10):1409–1415

Zhang R, Min Y, Wang Y (2020) Structural evolution of molten slag during the early stage of basic oxygen steelmaking. ISIJ Int 60(2):212–219

Kondratiev A, Jak E (2005) A quasi-chemical viscosity model for fully liquid slags in the Al2O3–CaO–‘FeO’–SiO2 system. Metall Mater Trans B 36(5):623–638

Urbain G (1987) Viscosity estimation of slags. Steel Res 58(3):111–116

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant Numbers 52304323], the Open Fund of State Key Laboratory of Vanadium and Titanium Resources Comprehensive Utilization (Grand Number 2023P4FZG07A), the Fundamental Research Funds for the Central Universities (Grant Number N232405-06), and Northeast University Postdoctoral Foundation [Grant Number 20230309].

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Zhang, R., Zhang, Ta., Dou, Z., Chen, M. (2024). Estimation Prediction of CaO–SiO2–FexO Slag System Based on Microstructure Analysis. In: Peng, Z., et al. Characterization of Minerals, Metals, and Materials 2024. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50304-7_2

Download citation

DOI: https://doi.org/10.1007/978-3-031-50304-7_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50303-0

Online ISBN: 978-3-031-50304-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)