Abstract

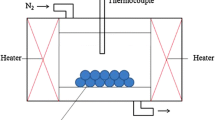

To efficiently utilize high-phosphorus oolitic hematite, phosphorus should be separated from iron, thus a process of direct reduction and magnetic separation was proposed. The physicochemical properties of oolitic hematite before and after treatment were characterized through analysis of the chemical composition, X-ray diffraction (XRD), scanning electron microscope (SEM), and energy-dispersive X-ray spectroscopy (EDS). The influence of various experimental parameters on the upgrading iron and phosphorus removal was investigated, including reduction temperature, reduction dose, and reduction time. Additionally, mass conservation was employed to determine the distribution and migration path of phosphorus from apatite to the slag, gas phase, and metallic iron. Results indicated that the optimal experimental conditions for achieving high recovery ratios of metallic iron and high removal ratios of phosphorus were the temperature of 1200 °C, reduction time of 120 min, and C/O molar ratio of 1.2. Under these conditions, 95.28% of iron was collected as metallic iron, while 70.02% of phosphorus remained in the slag residue. Therefore, the proposed method effectively restrained the reduction of apatite, which led to a good separation of iron from phosphorus.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Xiao JH, Zou K, Wang Z (2020) Studying on mineralogical characteristics of a refractory high-phosphorous oolitic iron ore. SN Appl Sci 2:1–12

Wang HH, Li GQ, Zhao D, Ma JH, Yang J (2017) Dephosphorization of high phosphorus oolitic hematite by acid leaching and the leaching kinetics. Hydrometallurgy 171:61–68

Wu SC, Sun TC, Kou J, Xu HD (2023) A new iron recovery and dephosphorization approach from high-phosphorus oolitic iron ore via oxidation roasting-gas-based reduction and magnetic separation process. Powder Technol 413:118043

Zhu DQ, Guo ZQ, Pan J, Zhang F (2016) Synchronous upgrading iron and phosphorus removal from high phosphorus Oolitic hematite ore by high temperature flash reduction. Metals 6(6):123

Keith Q (2018) A review on the characterisation and processing of oolitic iron ores. Miner Eng 126:89–100

Wu SC, Sun TC, Kou J, Gao EX (2023) Green and efficient separation of iron and phosphorus from high-phosphorus oolitic iron ore by reduction roasting without a dephosphorization agent. Process Saf Environ Prot. https://doi.org/10.1016/j.psep.2023.05.095

Roy SK, Nayak D, Rath SS (2020) A review on the enrichment of iron values of low-grade Iron ore resources using reduction roasting-magnetic separation. Powder Technol 367:796–808

Zhang J, Luo GP, Zhang H, Xin WB, Wang YC, Zhu JG (2023) Effect of the carbon mixing ratio on mineral evolution and gasification dephosphorization during the pre-reduction sintering process of bayan obo iron ore concentrate. ISIJ Int 63(3):455–465

Zhang HQ, Zhang PF, Zhou F, Lu MM (2022) Application of multi-stage dynamic magnetizing roasting technology on the utilization of cryptocrystalline oolitic hematite: a review. Int J Min Sci Technol 32(4):865–876

Pan J, Lu SH, Li SW, Zhu DQ, Guo ZQ, Shi Y, Dong T (2022) A new route to upgrading the high-phosphorus oolitic hematite ore by sodium magnetization roasting-magnetic separation-acid and slkaline leaching process. Minerals 12(5):568

Mansour FA, Ould-Hamou M, Merchichi A, Güven O (2021) Recovery of iron and phosphorus removal from Gara Djebilet iron ore (Algeria). Nat Hirn Univ Nauk Visn 4:82–88

Wu SC, Sun TC, Kou J, Li XH, Xu CY, Chen ZK (2022) Influence of sodium salts on reduction roasting of high-phosphorus oolitic iron ore. Miner Process Extr Metall Rev 43(8):947–953

Matinde E, Hino M (2011) Dephosphorization treatment of high phosphorus iron ore by pre-reduction, mechanical crushing and screening methods. ISIJ Int 51(2):220–227

Chiwandika EK, Jung SM (2023) Effect of H2 on the distribution of phosphorus in the gaseous reduction of hematite ore. JOM. https://doi.org/10.1007/s11837-023-05990-5

Acknowledgements

The authors would like to thank the financial support by the National Natural Science Foundation of China (Grant Number 52174326), the Hunan Scientific Technology Projects (Grant Number 2022SK2080), and the Postgraduate Scientific Research Innovation Project of Hunan Province (CX20230170).

Conflicts of Interest

The authors declare no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Ji, G., Gao, X., Wang, W. (2024). Separation of Iron and Phosphorus from High-Phosphorus Oolitic Hematite Using Direct Reduction and Magnetic Separation. In: Peng, Z., et al. Characterization of Minerals, Metals, and Materials 2024. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50304-7_12

Download citation

DOI: https://doi.org/10.1007/978-3-031-50304-7_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50303-0

Online ISBN: 978-3-031-50304-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)