Abstract

In the design of open battery systems, especially flow batteries (FBs), power (P) and energy (E) may be scaled independently. Thus, the battery design is characterized by the E/P ratio. The resulting wide variety of battery systems requires a close linkage of technical and economic aspects in cost assessment. This subchapter provides an assessment framework for techno-economics of open battery systems designed as FBs.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Bottom-Up Approach in Techno-economics

Techno-economics of emerging technologies require a bottom-up approach. Ideally, it should consist of three different interlinked modeling levels (Fig. 15.1). The basis is built by the electrochemical level. The calculation of the battery performance considering thermodynamic constraints (open cell voltage, OCV) and losses allows for the assessment of the achievable power P, while the available amount of redox-active species in the electrolyte determines the energy content E. On the component level, the costs for the key elements of the cells (membranes, electrodes, bipolar plates) and the electrolyte are determined. Finally, the system level must consider the technical system design including power electronics and balance of plant (BOP) for the considered application.

1.1 Electrochemical Characteristics of Flow Batteries

The achievable power P in a FB can be calculated with the number of cells N and the power of a single cell, which is given by the cell voltage Ucell, the applied current density I, and the cell area Acell:

The cell voltage can then be easily calculated on the basis of the open cell voltage U0 and losses Rcell:

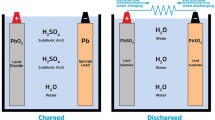

The open cell voltage is dependent on the thermodynamic equilibrium potential and the composition of the electrolyte, i.e., the state of charge (SOC) of the battery, as well as different losses. Its precise calculation with the Nernst equation is quite complex, because the concentrated electrolyte mixture exhibits nonideal behavior [4]. Even more demanding is the determination of the current density-dependent losses caused by the ohmic resistance of the electrolyte and the battery components (membrane, electrodes, bipolar plates), the kinetic overpotentials of the half-cell reactions, and the additional concentration polarization through mass transfer resistances [1]. Moreover, side reactions such as hydrogen evolution [16] and transport of redox-active species through the membrane, i.e., crossover [15], are further effects, which have to be taken into account for a precise description of the dynamic FB performance.

However, for a simplified yet sufficiently exact assessment of these losses in the view of the techno-economic analysis, an overall cell resistance Rcell is employed [17], which can be conveniently obtained from measured polarization curves or from more detailed physicochemically based FB models. The resulting equation for the battery power is:

The energy content E of the battery is the product of the power P and the charge/discharge time t:

With Faraday’s law, one can calculate the required molar flow rate \( {\dot{n}}_{\mathrm{R}} \)of the redox-active species in the electrolyte with the elementary charge e, the number of transferred electrons z, and the Avogadro number NA:

The volumes of the positive electrolyte PE and the negative electrolyte NE are then obtained with

Here, cR is the concentration of the redox-active species, and DOD is the depth of discharge, which is the difference between the minimum and maximum SOC of the battery.

Finally, the pumping power Ppump can be estimated with the electrolyte flow rate through the cells \( \dot{V} \) and the corresponding pressure drop Δp:

The factor f is a reasonably chosen multiple, e.g., tenfold, of the theoretically required flow rate in order to maintain approximately constant concentrations in both half-cells, while the pressure drop is usually calculated with Darcy’s law.

With the quantities given above, one can also calculate the energy efficiency of the FB cell stack or system:

Here, the coulombic efficiency ηC and the voltage efficiency ηV of the cell are defined as the ratio of discharge and charge voltage, respectively. The coulombic efficiency is mainly affected by side reactions and crossover processes and usually has values above 95%. On the other hand, the voltage efficiency is determined by the current density-dependent losses with typical values in the range of 80% for properly chosen current densities.

1.2 Component Costs of Flow Batteries

The key components of FBs are the electrolyte containing the redox-active species and the core elements of the stack, i.e., membrane, bipolar plates (BPPs), and electrodes.

Detailed techno-economics of membranes have been provided in previous work [13]. It has been shown that for cation exchange membranes with relatively high price, i.e., NafionTM, the membrane has a significant impact on total costs. Moreover, given the complex production process and the costly raw materials, it is unlikely that these prices will fall significantly. Alternatives are cost-effective membranes based on sulfonated poly ether ether ketone (SPEEK) or other low-cost materials [3] or even more cost-effective nanoporous separators. However, the enhanced convective flow compared to dense membranes would require an effective control of the pressure difference between the two half-cells [20].

BPPs show the second highest impact on costs as demonstrated in techno-economics of carbon-polymer BPPs [10]. In particular, the choice of graphite raw materials determines the processability of the compound, the production costs, and the electrochemical performance. A remaining challenge is the manufacturing of large-area BPPs. For square meter size, standard methods, i.e., injection molding, are no longer applicable, and appropriate extrusion techniques have yet to be developed for commercial applications [12].

Considering that two electrodes are required per unit cell, the electrode costs for the carbon electrodes can be set at about the same level as the costs for BPPs. However, considerable differences might occur depending on the raw materials used for the carbon electrode production [11].

Last but not least, the electrolyte shows very high significance for the overall FB costs. A detailed analysis for the most advanced all-vanadium flow battery (VFB) system has shown that depending on the E/P ratio of the battery, up to 50% of the overall costs can be attributed to the vanadium raw material [14]. Huge problems in this context are the strongly fluctuating vanadium prices and the uncertain future prospects for the price development. In spite of the possible development of more cost-effective electrolyte production processes based on vanadium pentoxide [5, 8], the raw material costs for VFB will remain high.

For this reason, the development of FB technologies based on (potentially) more inexpensive redox-active components has been recently intensified. One prominent example is the all-iron FB with very low electrolyte costs [19]. Other researchers have proposed organic redox-active components such as quinones [7]. However, in contrast to inorganic energy carriers with practically unlimited lifetime, these organic substances are prone to chemical and electrochemical degradation. Thus, the stability of these materials is a key parameter for their cost-effectiveness [2, 6].

The calculation of the required quantity of key components is straightforward for a FB with given nominal power P and energy content E [12]:

-

The number of membranes is equal to the number of cells N.

-

The number of BPPs is equal to the sum of cells and stacks (N + Nstack).

-

The number of electrodes is twice the number of cells (2N).

-

The total electrolyte volume is the sum of positive and negative electrolyte volume (VPE + VNE).

1.3 System Costs of Flow Batteries

The system description may be defined individually. Nevertheless, a linear and comprehensive system definition is highly recommended for accuracy and transparency of techno-economic studies. In Fig. 15.2, a detailed technical system definition for a flow battery is illustrated.

It is structured in the energy subsystem with the key component electrolyte, the power subsystem with the cell stacks, the power electronics, and balance of plant components. Other aspects, e.g., building and site, are usually not considered in detail in a technical model but may be included within a full-system definition in the techno-economic model.

2 Data Basis and Quality in Techno-economics

The quality of input data is crucial for any quantitative assessment. Input data consist of technical and economic data. Data quality covers the nature and origin of data (primary, secondary, estimate) combined with aspects of uncertainty (accuracy, validity, time dependency).

2.1 Input Data

Input data is required in terms of technical and economic figures. Technical data should at least include the following key figures:

-

Nominal power P in kW

-

Energy-to-power ratio E/P in h

-

System efficiency η

In a preferably more detailed technical description, the list of key figures is completed with:

-

Depth of discharge DOD

-

Current density i in mA cm−2

-

Single cell area Acell in m2

-

Number of cells N and stacks Nstack in a system

-

Active material concentration in electrolyte cR in mol l−1

Considering the manufacturing of a battery system, data on materials, cell geometries, and manufacturing processes, including energy demand, should be provided. The battery operation requires detailed data derived from electrochemical measurements in order to give a quantitative description of performance, lifetime, and cycle life.

Economic input data has to be provided in analogy to the technical bottom-up system description. Thus, in a first processing step, price data has to be adapted to the technical component description, which is for FB typically specified areal or power specific and volume or energy specific. Price data for materials, components, or systems are usually complemented by manufacturing or at least assembly costs. Furthermore, detailed cost data are often limited to key components, whereas costs of further system components, e.g., BOP, are calculated using supplement factors.

2.2 Data Quality

Input data may be derived from primary or secondary sources. Primary data is a type of data that is procured directly from main sources, i.e., specific manufacturing processes or specific batteries at operation sites. It is rarely possible to collect all data as primary data. Therefore, secondary or generic data are widely used. These include data from literature, databases, or handbooks. In case of any data gaps, estimates and analogies may be used and carefully documented. By their very nature, estimates have the lowest data quality. To conclude, data quality is closely linked to data availability.

A reasonable exception of this data quality ranking is price data. Price data may be highly volatile over time due to complex market and socioeconomic developments. Thus, discrete primary data in the form of specific price information from a vendor might be less reliable. In this perspective, generic data derived from a database with reasonable technical, geographic, and temporal assessment limits are preferable.

Aspects of uncertainty cover accuracy, validity, and time dependency of data. Accuracy addresses reliability and completeness of data. Additionally, a balance in accuracy for all system components is preferable in order to prevent asymmetries within the model. Validity and time dependency refer to the applicability and temporal correlation of data to the date of study. It is not uncommon for input data to be recited while the design of the battery is being adjusted, e.g., a scale-up from kilowatt to megawatt scale. Temporal correlations are especially important in prospective techno-economics aiming on the prediction of future developments. These are generally subject to uncertainties which have to be appropriately reflected by means of sensitivity analyses.

3 Target Figures in Techno-economics

In this section, economic modeling approaches for five widely used economic target figures in techno-economics of open battery systems are presented. These are production costs C, capital and operational expenditures CAPEX and OPEX, and derived total cost of storage as well as levelized cost of storage LCOS.

3.1 Capital Costs

A common goal of a techno-economic assessment is the calculation and sensitivity analysis of capital costs C (synonyms are system costs or production costs) of FB systems. For this purpose, an accurate and detailed bottom-up modeling approach in combination with high-quality input data is favorable. A common level of detail is an inventory of component listing mass-, volume-, area-, or unit-specific costs. In literature, a wide variety in the level of detail can be found. On the one hand, the inventory may be limited to key components. On the other hand, each production process of any component may be described in a detailed process model covering input materials, machining, and labor, in order to provide a maximum detail degree.

Capital costs C may be expressed as absolute costs in EUR (or any other currency) per FB or in the form of specific costs. These may be power- or energy-specific costs, usually related to nominal system power (EUR/kW) or nominal energy capacity (EUR/(kWh)). In any techno-economic model, the dependence of results on the E/P ratio cannot be overemphasized. Thus, the cost structure in techno-economic assessments does usually reflect the independent scalability of energy E and power P. Two different approaches are commonly used [14]. In one approach, all items are allocated to either a predefined power or energy subsystem. This leads to a mathematical equation describing total system costs C in EUR as the sum of power and energy subsystem costs:

with cost rates of power and energy subsystem cP,sub in EUR/kW and cE,sub in EUR/(kWh), respectively. The individual summands of cP,sub and cE,sub are costs of components listed in Fig. 15.2.

In another approach, fixed costs Cfix are added to the equation following the idea that not everything can be allocated to the energy and power subsystems:

In order to calculate specific system costs in EUR/kW and EUR/(kWh), total system costs may be divided by nominal system power cP = C/P or energy capacity cE = C/E.

The informative value of these figures is limited and must always be considered in the context of the E/P ratio. An illustrative example is the application to VFB in a power range of 10 to 1000 kW providing energy for E/P = 2 to 10 h:

This empirical formula is based on a detailed qualitative and quantitative analysis of literature and prices [12].

3.2 Total Cost of Storage

Total cost of storage is a common term in techno-economics, especially in comparative studies on different energy storage technologies. Nevertheless, this term is not standardized in the form of an appropriate mathematical definition. In general, seen from a user’s perspective, it includes all expenses associated with purchasing and using the battery system.

A more standardized term in this context is levelized cost of storage (LCOS). It is defined and applied in analogy to levelized cost of energy (LCOE) which is calculated for electric energy generation technologies, e.g., photovoltaic systems. The basic idea is to calculate the price of a kilowatt hour of energy emitted by the system. Thus, LCOS is defined as the total cost of ownership over the investment period divided by the energy delivered by the energy storage system.

In order to calculate LCOS, the above-described capital cost assessment approach may be extended in two ways: first, by considering additional cost items for CAPEX and thus for the investment and, second, by considering the operation phase with associated OPEX. LCOS are expressed in EUR/(kWh) of energy E emitted by the FB over its lifetime in a total number of charge-discharge cycles Ncycle. Thus, LCOS is dependent on the system’s energy efficiency, DOD, lifetime, and the electricity price. A simplified mathematical description of these interrelations is:

Referring to the nature of an extended capital value method, the full mathematical equation including time dependency of monetary values is formulated as follows:

with considered lifetime from t = 0 to year n, residual value R of storage components at their end of life, electricity price cel, energy emitted from the battery in each year Et, system energy efficiency η, and discount rate i.

Additional cost items for the calculation of CAPEX are interest rates and other costs incurred in connection with borrowing of funds and asset management as well as freight and installation costs for FB components and systems.

OPEX usually include operating and maintenance rates as well as costs of energy that is fed into the battery. These have to be divided by the system efficiency in order to calculate the amount of energy that can be discharged from the system. Resulting energy losses are considered in techno-economics when it comes to profitability assessments, where CAPEX and OPEX are compared to revenues over lifetime. Some examples for economic parameters used in techno-economics of FBs [18] are listed below:

-

Freight cost in USD/mile

-

Effective income tax rate in %

-

Cost of capital in %

-

Annual taxes and insurance premiums as fraction of capital investment in %

-

Fixed charge rate in %

-

Capital recovery factor in %

-

Rate of general inflation in %

-

Escalation rate for capital costs and operating and maintenance costs in %

This key figure is very complex, so some sample figures for VFB are given below for reference. In analogy to the considerations in the previous section on capital costs, for an E/P ratio between 2 and 10 h, LCOS = 0.05 to 0.30 EUR/(kWh) are calculated, decreasing with increasing E/P [17]. Two comparable studies consider VFBs with E/P = 4 h [9, 18]. These three independent studies show a consensus on a probable range of LCOS = 0.10 to 0.25 EUR/(kWh). However, when considering maintenance costs in order to increase the service life of VFB, higher LCOS in a range of 0.15 to 0.35 EUR/(kWh) are assumed, increasing with increasing maintenance efforts [9].

4 Conclusion

To conclude, there are no standards defined on scope or level of detail concerning techno-economics for FBs. This subchapter provides an assessment framework for techno-economics of emerging technologies that are usually subject to uncertainties. FBs are developed in many variants covering a wide range of active species, nominal power, energy capacity, cell geometry, choice of materials, and operation strategies. With this degree of complexity, detailed and transparent techno-economics are all the more important.

In consequence, a special emphasis should be put on the highly complex technical dimension of FBs. The technical model may be kept quite simple but should at least include key figures, i.e., E/P ratio, overall ohmic cell resistance, current density, system energy efficiency, and lifetime of components and system. Techno-economics with transparent technical data lead to more relevant results, especially when validated by measurement data.

References

Arenas LF, Ponce de León C, Walsh FC (2019) Redox flow batteries for energy storage: their promise, achievements and challenges. Curr Opin Electrochem 16:117–126

Brushett FR, Aziz MJ, Rodby KE (2020) On lifetime and cost of redox-active organics for aqueous flow batteries. ACS Energy Lett 5(3):879–884

Düerkop D, Widdecke H, Schilde C, Kunz U, Schmiemann A (2021) Polymer membranes for all-vanadium redox flow batteries: a review. Membranes 11(3)

Hayer N, Kohns M (2020) Thermodynamically rigorous description of the open circuit voltage of redox flow batteries. ECS Trans 167(11):110516

Kazacos M, Skyllas-Kazacos M (2006) High energy density vanadium electrolyte solutions, methods of preparation thereof and all-vanadium redox cells and batteries containing high energy vanadium electrolyte solutions US6468688B2

Kwabi DG, Ji Y, Aziz MJ (2020) Electrolyte lifetime in aqueous organic redox flow batteries: a critical review. Chem Rev 120(14):6467–6489

Lin K, Chen Q, Gerhardt MR, Tong L, Kim SB, Eisenach L, Valle AW, Hardee D, Gordon RG, Aziz MJ, Marshak MP (2015) Alkaline quinone flow battery. Science (New York, N.Y.) 349(6255):1529–1532

Martin J, Schafner K, Turek T (2020) Preparation of electrolyte for vanadium redox-flow batteries based on vanadium pentoxide. Energy Technol 8(9):2000522

Minke C, Dorantes Ledesma MA (2019) Impact of cell design and maintenance strategy on life cycle costs of vanadium redox flow batteries. J Energy Storage 21:571–580

Minke C, Hickmann T, dos Santos AR, Kunz U, Turek T (2016) Cost and performance prospects for composite bipolar plates in fuel cells and redox flow batteries. J Power Sour 305:182–190

Minke C, Kunz U, Turek T (2017a) Carbon felt and carbon fiber – a techno-economic assessment of felt electrodes for redox flow battery applications. J Power Sour 342:116–124

Minke C, Kunz U, Turek T (2017b) Techno-economic assessment of novel vanadium redox flow batteries with large-area cells. J Power Sour 361:105–114

Minke C, Turek T (2015) Economics of vanadium redox flow battery membranes. J Power Sour 286:247–257

Minke C, Turek T (2018) Materials, system designs and modelling approaches in techno-economic assessment of all-vanadium redox flow batteries – a review. J Power Sour 376:66–81

Perry ML, Saraidaridis JD, Darling RM (2020) Crossover mitigation strategies for redox-flow batteries. Curr Opin Electrochem 21:311–318

Rudolph S, Schröder U, Bayanov IM (2013) On-line controlled state of charge rebalancing in vanadium redox flow battery. J Electroanal Chem 703:29–37

Skyllas-Kazacos M (2019) (Invited) performance improvements and cost considerations of the vanadium redox flow battery. ECS Trans 89(1):29–45

Viswanathan V, Crawford A, Stephenson D, Kim S, Wang W, Li B, Coffey G, Thomsen E, Graff G, Balducci P, Kintner-Meyer M, Sprenkle V (2014) Cost and performance model for redox flow batteries. J Power Sour 247:1040–1051

Zhang H, Sun C (2021) Cost-effective iron-based aqueous redox flow batteries for large-scale energy storage application: a review. J Power Sour 493(2):229445

Zhou XL, Zhao TS, An L, Zeng YK, Wei L (2016) Modeling of ion transport through a porous separator in vanadium redox flow batteries. J Power Sour 327:67–76

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2024 The Author(s)

About this chapter

Cite this chapter

Minke, C. (2024). Techno-economics of Open Battery Systems. In: Passerini, S., Barelli, L., Baumann, M., Peters, J., Weil, M. (eds) Emerging Battery Technologies to Boost the Clean Energy Transition. The Materials Research Society Series. Springer, Cham. https://doi.org/10.1007/978-3-031-48359-2_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-48359-2_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-48358-5

Online ISBN: 978-3-031-48359-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)