Abstract

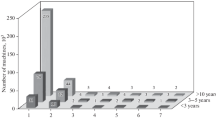

Due to the seasonal nature of farming, farm machinery is used for relatively short periods of time, resulting in a need to maximize output and minimize downtime. Since lost time is very costly, agricultural machines are designed for high field availability, reliability, and high maintainability. This is a case study where technical assessment was needed for the cultivation equipment operation system monitoring and control. This was for 2017 and 2018 cropping seasons of 1300 ha to optimize expenditure on maintenance and system operation. Among the calculated values, equipment utilization ranged from 81% to 0%, availability from 100% to 0%, and reliability from 36% to 0%. Additionally, there were maintainability values of 1 (functioning state) and 0 (failure state) for 120 equipment fleets assessed for the cropping seasons. Most of the equipment was well utilized, readily available, reliable, and easy to maintain, while few was underutilized, unavailable, unreliable, and difficult to maintain. All these factors help to improve availability and reliability and decrease equipment downtime for higher agricultural operational productivity. This technical soundness and operational overall effectiveness assessment were crucial to decide what equipment to retain, replace, or trade off.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abernethy, R. B. (1996). Reliability (Eingineering). The New Weibull Handbook, 3rd Ed. Gulf Publishing Company. Hunston TV.

Adisa, A. F. (2012). Appropriate Management and Operational Planning Technique for Mechanized Soybean and Maize Production in Nigeria. Journal of Science, Technology, Mathematics and Education. Published by Department of Science Education, Federal University of Technology, Minna, Nigeria, 8 (2).

ASAE EP456 DEC 1986 (R2015). Test and Reliability Guidelines. American Society of Agricultural and Biological Engineers, ASABE Standard.

De Carlo, F. 2013. Reliability and Maintainability in Operations Management. Published by IntechOpen edited by Massimilliano M. Schiradi. Chapter 4: p81–111.

Deere, J. 1984. Machinery Management, Fundamentals of Machine Operation, Deere, and Company Service Training. Illinois, USA.

Dharmasiri, M. 2013. Measuring Agricultural Productivity using the Average Productivity Index (APL). Archived 2013 at the Wayback machine.

Dunn, S. (2002). The Reliability Revolution. Webmaster, Plant Maintenance Resource Centre, info@maintenanceresources.com.

Eti, M. C., Nkakini, S. O., and Nkoi, B. 2006. Application of Availability and Reliability Analysis Techniques to Improve Bayelsa Water Board Productivity. Nigeria Journal of Engineering Research and Development.

INFRALERT, 2016. D5.1 – RAMS Data Collection and Failure Rate Analysis at Component Level, Revision 4. Linear Infrastructure Efficiency Improvement by Automated Learning and Optimized Predictive Maintenance Techniques: P14.

Kepner, R. A., Bainer, R., and Barger, E. L. 2005. Principles of Farm Machinery. 3rd Edition, CBS Publishers & Distributors, India.

Limblecmms, 2018. MTTR vs MTBF vs MTTF: A visual simple guide to failure metrics, Streamline work with Limble.

MaxGrip, 2022. Reliability Metrics 101: Mean Time Between Failure (MTBF)-MaxGrip.

Nakajima, S. 1988. Introduction to TPM: Total Productive Maintenance. Productivity Press, Inc. p:129.

National Research Council. (1991). The Competitive Edge: Research Priorities for U.S. Manufacturing: Equipment Reliability and Maintenance. Washington, DC: The National Academies Press. https://doi.org/10.17226/1618; p54–55.

Nkakini, S. O., Eti, M. E. and Barinyima, N. 2008. Tractor Functionability Assessment using Reliability and Availability Technique. Journal of Agricultural Engineering and Technology (JAET), Published by The Nigeria Institution of Agricultural Engineers 16 (2): p4–13.

Ryan, C. 2019. Maintainability Definition and Calculation. Maintenance Question and Answer Preventive Maintenance. Upkeep Maintenance Management.

Severino, J. 2019. Incident Management Handbook. Atlassian, Lex Neva, SRE weekly.

Srivastava, A. K., Goering, C. E., Rohrbach, R. P. and Buckmaster, D. R. 2006. Engineering Principles of Agricultural Machines, America Society of Agricultural and Biological Engineers, USA. ASAE publication 801M0206, second edition: pp525–549.

Thompson, P. 2018. Manufacturing Maintenance Tips: 5 factors that affect maintainability. SAGE Group Automation Company.

UN-GA, 2015. Sustainable Development Goals. United Nations General Assembly. Wikipedia.

Acknowledgments

I hereby acknowledge the World Bank Sponsored Project of African Centre of Excellence in Agricultural Development and Sustainable Environment (CAEDESE); the Federal University of Agriculture, Abeokuta, Nigeria, for sponsoring this Faculty Outreach (2018) study at Flour Mills Nigeria Plc, Sunti Golden Sugar Company, Niger State, Nigeria; and, also, the Sunti Golden Sugar Company staff who contributed immensely to the success of this study.

Conflict of Interest

There is no conflict of interest on this manuscript; the work is purely original author’s work.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Adisa, A.F. (2024). Technical Assessment of Agricultural Equipment Condition for Sustainability. In: Dunmade, I.S., Daramola, M.O., Iwarere, S.A. (eds) Sustainable Engineering. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-031-47215-2_4

Download citation

DOI: https://doi.org/10.1007/978-3-031-47215-2_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-47214-5

Online ISBN: 978-3-031-47215-2

eBook Packages: EngineeringEngineering (R0)