Abstract

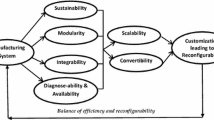

One of the most crucial elements of the mining operation is mineral processing. The majority of mined materials undergo some type of size reduction and/or other beneficiation process, from solid ores to fine minerals such as coal, granite, limestones, and other industrial minerals. Before the invention of large equipment, the operation of “spalling”—the breaking up of raw ore—involved the use of hammers held in the hands. Mechanical methods were soon discovered to do this. Numerous sectors have applied reconfigurable manufacturing systems (RMS) thinking to produce modular, individualized, adaptable, and scalable products. Due to changes in mining equipment users’ needs, the dynamic and complex nature of the mining production environment of the available location, the nature of the mining operation, and the associated risks, RMS is frequently used to produce various product variants of mining equipment with low repair costs, high adaptability, and minimal maintenance costs to meet customer satisfaction. More specifically, the proposed book chapter investigates a variety of literature reviews related to the concepts of reconfigurable manufacturing systems, architectural design features, control capabilities, and its function in the mining machine manufacturing industries, as well as the possible long-term application of RMS in this sector. In addition, related maintenance solutions for proposed machines to functionally assess or predict the condition of machines to ensure the reliability, availability, and maintainability of these machines at any particular time when needed are presented and discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- Cc:

-

Convertibility associated with configuration

- Cm:

-

Convertibility associated with machine

- CH:

-

Convertibility associated with material handling

- I:

-

Convertibility associated with configuration

- R:

-

Convertibility associated with machine

- X:

-

Convertibility associated with material handling

- N:

-

Individual machines in the system

- Q1:

-

Equipped with a screen panel replacement device

- Q2:

-

Easily reprogrammed with flexible software

- Q3:

-

The system is designed to allow addition and subtraction of modular components

- Q4:

-

Flexible fixturing capability

- Q5:

-

Large capacity magazine

- t1:

-

The time necessary to place an order for the precise number of RVS machine subsystems

- t2:

-

The amount of time needed to build exactly how many RVS machine subsystems the clients have ordered

- t3:

-

The length of time needed to examine (to find defects) the precise number of RVS machine subsystems manufactured

- t4:

-

The time needed to rework or repair the damaged RVS subsystems or spare part(s)

- t5:

-

The time needed to transport the manufactured RVS subsystem(s) or spare part(s) (𝑄𝑖) to the users of the RVS machine

- t6:

-

The time required to load and transport the RVS subsystem(s) or spare part(s) (𝑄𝑖) to the users

- t7:

-

The amount of time needed to unload the RVS components or spare parts (Qi) off the truck and place them in the authorized storage space for the RVS machine operator

- Lt − ord:

-

Lead time

- Qi:

-

Total number of RVS spare parts or subsystems

- Rt1:

-

Reconfiguration time

- TPL:

-

Total production loss

- PG:

-

Productivity gain

- PC:

-

Productivity capacity

- CD:

-

The current demand for mineral concentrates

- OD:

-

The demand for old mineral concentrations

References

Abdi, M.R., Labib, A.W., Edalat, F.D. and Abdi, A., 2018. Integrated Reconfigurable Manufacturing Systems and Smart Value Chain: Sustainable Infrastructure for the Factory of the Future. Springer.

Adenuga, O.T., Mpofu, K. and Ramatsetse, B.I., 2020. Exploring energy efficiency prediction method for Industry 4.0: A reconfigurable vibrating screen case study. Procedia Manufacturing, 51, pp.243-250.

Asbjörnsson, G., 2013. Modelling and simulation of dynamic behaviour in crushing plants. Chalmers Tekniska Hogskola (Sweden).

Beerkircher, G. (1997). Banana screen technology. Comminution Practices. Kawatra, S.K. (ed.). SME, Litleton, CO. pp. 37–40.

Cole, M.J. and Broadhurst, J.L., 2021. Measuring the sustainable development goals (SDGs) in mining host communities: A South African case study. The Extractive Industries and Society, 8(1), pp.233-243.

Drzymala, J., 2007. Mineral processing. Foundations of theory and practice of minerallurgy, pp.381-382.

Fuerstenau, M.C. and Han, K.N. eds., 2003. Principles of mineral processing. SME.

Guo, N., Lin, J. and Huang, W., 2011, July. Development of 2YAC2460 super-heavy vibrating screen. In 2011 Second International Conference on Mechanic Automation and Control Engineering (pp. 1225-1227). IEEE.

Gupta, A. & Yan, D. 2006. Mineral Processing Design and Operation, Elsevier Science and Technology.

Hou, Y.J., Fang, P. and Zeng, L., 2012. Finite element analysis of dual-frequency vibrating screen. In Advanced Materials Research (Vol. 479, pp. 2124-2128). Trans Tech Publications Ltd.

Hua, Z., Shirong, G. and Xiaoyan, Y., 2004. A novel low-noise vibrating, screen. Coal Preparation, 24(1/2), pp.85-96.

Katz, R., 2007. Design principles of reconfigurable machines. The International Journal of Advanced Manufacturing Technology, 34(5–6), pp.430–439.

Kesler, S.E., 2007. Mineral supply and demand into the 21st century. In Proceedings for a Workshop on Deposit Modeling, Mineral Resource Assessment, and Their Role in Sustainable Development. Circular (Vol. 1294, pp. 55–62).

Koren, Y., Jovane, F., Heisel, U., Moriwaki, T., Pritschow, G., Ulsoy G., and VanBrussel, H.: Reconfigurable Manufacturing Systems. A keynote paper. CIRP Annals, Vol. 48, No. 2, pp. 6-12, November 1999.

Makinde, O.A., Ramatsetse, B.I. and Mpofu, K., 2015a. Review of vibrating screen development trends: Linking the past and the future in mining machinery industries. International Journal of Mineral Processing, 145, pp.17-22.

Makinde, O.A., 2014. Functionality assessment of a reconfigurable vibrating screen (Doctoral dissertation, Tshwane University of Technology).

Makinde, O.A., Mpofu, K. and Ramatsetse, B., 2016a. Establishment of the best maintenance practices for optimal reconfigurable vibrating screen management using decision techniques. International Journal of Quality & Reliability Management.

Makinde, O.A., Mpofu, K. and Ramatsetse, B., 2016b. Mining business optimisation through a reconfigurable vibrating screen design. African Journal of Science, Technology, Innovation and Development, 8(1), pp.88-96.

Makinde, O.A., Mpofu, K., Ramatsetse, B.I., Adeyeri, M.K. and Ayodeji, S.P., 2018. A maintenance system model for optimal reconfigurable vibrating screen management. Journal of Industrial Engineering International, 14, pp.521-535.

Makinde, O.A., Ramatsetse, B.I., Mpofu, K. and Oyesola, M.O., 2015b, March. Holistic methodologies for optimal reconfigurable vibrating screen design, development, production, utilization and management Part I. In SAIMM Conference (pp. 11-12).

Maler-Speredelozzi, V., Koren, Y.H.S.J. and Hu, S.J., 2003. Convertibility measures for manufacturing systems. CIRP annals, 52(1), pp.367-370.

Mehrabi, M. G., A. G. Ulsoy, Y. Koren, and P. Heytler. 2002. “Trends and perspectives in flexible and reconfigurable manufacturing systems.” Journal of Intelligent Manufacturing13 (2): 135–146. doi:10.1023/A:1014536330551

Mesquita, M.J., Corazza, R.I., Souza, M.C.O., Gomes, G.N., Noronha, I. and Macedo, D., 2021. Mining and sustainability. In Environmental Sustainability (pp. 155–179). CRC Press.

Monteiro, N.B.R., da Silva, E.A. and Neto, J.M.M., 2019. Sustainable development goals in mining. Journal of Cleaner Production, 228, pp.509-520.

Moss, S., 2011. Development and Testing of a Scale Model Clamshell Mucker, and Validation by Discrete Element Modelling.

Napier-Munn, T. J., Morrell, S. & Morrison, R. D. 2005. Mineral Comminution Circuits Their Operation and Optimisation, Queensland: Julius Kruttschnitt Mineral Research Centre.

Ramatsetse, B.I., Matsebe, O., Mpofu, K. and Desai, D.A., 2013. Conceptual design framework for developing a reconfigurable vibrating screen for small and medium mining enterprises. SAIIE25 Proceedings, Stellenbosch, South Africa, p.1.

Ramatsetse, B., Mpofu, K. and Makinde, O., 2017. Failure and sensitivity analysis of a reconfigurable vibrating screen using finite element analysis. Case Studies in Engineering Failure Analysis, 9, pp.40-51.

Ramatsetse, B., Mpofu, K., Daniyan, I. and Makinde, O., 2022. Assessment of Reconfigurable Vibrating Screen Technology for the Mining Industries. In Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus: Proceedings of FAIM 2022, June 19–23, 2022, Detroit, Michigan, USA (pp. 79-87). Cham: Springer International Publishing.

Wang, C.J., Ma, L.Z. and Li, Y.M., 2011. Multi-Dimensional Vibrating Screen Design and Motion Analysis. In Advanced Materials Research (Vol. 201, pp. 1672–1677). Trans Tech Publications Ltd.

Wang, W. and Koren, Y., 2012. Scalability planning for reconfigurable manufacturing systems. Journal of manufacturing systems, 31(2), pp.83-91.

Wills, B.A. & Napier-Munn, T. 2006. Mineral Processing Technology 7th ed., UK: Elsevier Science and Technology Books.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Olasumbo, M., Mpofu, K., Ramatsetse, B. (2024). Application of Reconfigurable System Thinking in Mining and Mineral Processing Environment: Toward Sustainable Mineral Beneficiation. In: Dunmade, I.S., Daramola, M.O., Iwarere, S.A. (eds) Sustainable Engineering. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-031-47215-2_14

Download citation

DOI: https://doi.org/10.1007/978-3-031-47215-2_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-47214-5

Online ISBN: 978-3-031-47215-2

eBook Packages: EngineeringEngineering (R0)