Abstract

Topology optimization is a powerful tool to automatically generate optimal geometries for Additive Manufacturing (AM). However, to ensure manufacturability, e.g. by material extrusion-based AM (MEX) or Laser-Beam Powder-Bed-Fusion of Metals (PBF-LB/M), a minimum structure thickness has often to be maintained. In this paper, a simple interpolation scheme for penalizing grey-scale densities in topology optimization is applied. It locally reduces the stiffness-to-weight ratio of elements in the variable thickness sheet problem for densities between zero and a critical density. A cantilever beam is optimized, confirming that less penalization produces stiffer structures. Results for the optimization of an L-shaped bell crank are 12% stiffer (and only 4% less stiff) than the design based on conventional (and no) penalization. Simulating and printing the hinge using MEX and PBF-LB/M confirm enhanced manufacturability. In regions of load concentrations, where stresses vary significantly, the results show a general potential for performance improvement, when switching from conventional designs (e.g. sheet metals) to more complex designs that would require advanced manufacturing methods, such as AM.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Manufacturing. Plate-like components, such as sheet metals, are commonly used structural components. However, sheet metal designs are often not optimal, e.g. in bending load cases. Therefore, where applications allow, switching from simple sheet metals to standard profiles (e.g. DIN EN 10055 for T-shaped steel, DIN 1025-5 for I-shaped steel, etc.) is reasonable as the shapes are more appropriate for the specific load case, while still maintaining a low cost of production. Unfortunately, their performance may be limited for complex load cases and design domains. Therefore, predominantly in lightweight design, tailored rolled blanks are used as they are often more appropriate for loadings and functions of the application. They are commonly used, e.g. in the automotive industry. Tailored rolled blanks are manufactured using a combination of technologies, such as rolling, welding, cutting, and others [1]. Unfortunately, tailored rolled blanks are limited with respect to cost for manufacturing and design flexibility. Additive manufacturing overcomes these restrictions and enables the manufacturing of complexly shaped 3D components in various sizes in diverse industries. For example, in [2], a load-carrying sheet-metal design that is replaced by a topology-optimized printed part is the rear elevator bell crank in a Cessna 172. Unfortunately, designs generated by numerical methods, such as topology optimization, usually cannot guarantee manufacturability. Following, Design for Additive Manufacturing (DfAM) approaches were introduced, to consider limitations of AM in numerical optimizations. Well-known challenges include overhang constraints, minimum length scales (e.g. minimum layer thickness), and others. Unfortunately, the realized structures are often not optimal with respect to stiffness when the characteristics and restrictions of AM are taken care of when designing parts.

Topology Optimization. The density-based topology optimization approach SIMP (Solid Isotropic Material with Penalization) was introduced in [3] and usually results in black-and-white designs, with only a few intermediate densities in the final results, when a penalization is applied [3]. Alternative approaches, like bi-directional evolutionary structural optimization (BESO), also generate discrete, frame-like designs [4]. Unfortunately, these frame-like structures are, in several contexts, not optimal in stiffness [5]. Relaxing the restriction to frame-like structures can be accomplished by (partially) not penalizing intermediate densities in the SIMP approach. Structures result, that include grey-scale densities, i.e. intermediate densities between zero (also white or void) and one (also black or solid), which are up to 80 % stiffer for optimization problems with one load case [5]. However, the resulting density fields are not manufacturable per se. So, in practice, grey-scale densities are usually avoided (full penalization), or must be interpreted: (1) as materials (i.e. as porous material [6], as multiple materials with different stiffnesses [7], or as structures with a reduced volume fraction (e.g. filled with lattice structures (cf. Hashin-Strikhman bound for an isotropic material in [8])), or (2) as a dimension, i.e. the thickness of a sheet in 2D. The latter was introduced as the Variable Thickness Sheet problem (VTS) in [9], and is also used in this paper.

Designing Variable Thickness Sheets using Topology Optimization. To compute manufacturable, plate-like structures with variable thicknesses using SIMP, only parts of the total range of densities are penalized by an interpolation scheme. Modifications of the penalization scheme were introduced, applied and extended in several publications (cf. [10,11,12,13]). For the VTS problem in [12] a tanh-function was used to restrict the solution space. However, \(2.5 \%\) of the resulting densities in an example were below the critical density value \(\eta =0.5\). To overcome the challenge of the resulting densities in the penalized region, two design fields were introduced in [12]. An auxiliary nodal field \(\textbf{s}\) and an element field \(\textbf{x}\) were used to cut irrelevant parts of the structure in order to “clean up solutions” and facilitate dehomogenization [12]. Unfortunately, this approach requires extensive changes in popular codes, such as the 99 lines code in [16], and optimization setup, to find structures only containing densities in the non-penalized region. A simple interpolation scheme for grey-scale densities is qualitatively proposed in [14]. The aim was to ensure manufacturable, porous metal structures [6]. However, its implementation is not documented, and the application to the VTS problem is missing. In this paper, the method is fully documented, implemented and applied to a cantilever beam and a real use case. The results of the optimization are manufactured using material extrusion-based AM (MEX) and Laser-Beam Powder-Bed-Fusion of Metals (PBF-LB/M).

This paper is organized as follows: In Sect. 2, the general problem statement is introduced. In Sect. 3, the scheme is applied to a cantilever beam (Sect. 3.1) and then used to optimize an aerospace component as a use case (Sect. 3.2). Section 4 discusses the potentials and challenges of the approach, as well as limitations, with respect to the design and manufacturing of plate-like components, analysing the manufacturing of the part using MEX and PBF-LB/M. The paper ends with a conclusion in Sect. 5.

2 Problem Statement

Optimization Problem. The following article addresses the minimum compliance design of plate-like components using topology optimization. The mathematical formulation of the underlying optimization problem reads

The objective function is the compliance c, \(\textbf{U}\) and \(\textbf{F}\) are vectors containing the global displacements and applied forces, \(\textbf{K}\) is the global stiffness matrix, \(\textbf{u}_{e}\) is the element displacement vector, and \(\textbf{k}_{e}\) is the stiffness matrix for a single element. A volume fraction f is prescribed as the only constraint in the optimization problem. It is defined by the ratio of the actual volume of the structure (as a function of the design variables) to \(V_{0}\), the maximal volume of the entire design domain. Following the SIMP approach, a Young’s modulus \(E_{0}\) is multiplied by (and potentially reduced by) a modified density \(\tilde{\rho _{e}}\), which again is a function of the design variables \(\rho _{e}\). In the SIMP approach, an element’s contribution to the volume of a structure is kept constant while “artificially” reducing its stiffness if \(\rho _{e} < 1\) and \(p>1\). To only penalize a range of grey-scale densities, the following interpolation scheme is used.

It penalizes intermediate densities up to a critical density \(\rho _{c}\). For \(\rho >\rho _{c}\), a linear relationship between an element’s stiffness and its density exists. The VTS optimization problem without any penalization of grey-scale densities (\(p=1\)) is convex, i.e. the only minimum in the optimization is the global one. Only filtering approaches and spatial discretization prevent the final topologies from being optimal in stiffness [15], ignoring manufacturing challenges. For the introduced approach \(\rho _{c}\) should always be positive and non-zero (as defined in Eq. 3). For \(\rho _{c}=1\) the classical SIMP approach results, making the cases in Eq. 2 obsolete.

Gradients. Due to the modified interpolation scheme, gradients change below the critical density \(\rho _{c}\) and remain linear above it. Thereby, the contribution of the penalization scheme reads

Implementation. In the well-known 99-lines MATLAB code [16], a simple conditional statement (if-else) can be used to switch between the modified, i.e. penalized, and linear updating scheme and its gradients. Additionally, the maximum value for a gradient was limited to the value of the penalization factor p.

3 Application and Use Case

In the following, two problems are introduced to demonstrate and discuss the effects of the modified interpolation scheme. First of all, a 2D cantilever study serves as an example to demonstrate the effectiveness of modifying the penalization of grey-scale densities (Sect. 3.1). Secondly, in a practical use case, an L-shaped bell crank is optimized and printed using MEX and PBF-LB/M (Sect. 3.2).

The method of moving asymptotes (MMA) is applied to solve the optimization problems [17]. Sensitivity filtering with a radius of \(r_{min}=1.2\) is used throughout the optimizations. In all optimizations a penalization exponent of \(p=3\) was used if not stated otherwise. The authors furthermore decided not to apply a continuation method. The termination criterion of the optimization is defined by the greatest absolute change of a design variable in the complete set of design variables \(\mathbf {\rho }_{e}\) in one iteration. For the cantilever study, the termination criterion was set to \(c_{t}=0.01\), whereas in the real use case, it was reduced to \(c_{t}=0.001\). Young’s modulus was set as 1 MPa throughout. The colour scale used for the visualizations of topologies between white and black is linearly interpolated. Black corresponds to a density of \(\rho _{e}=1\) (solids), whereas densities of \(\rho _{e}=0\) are visualized in white (voids). The terminology “grey-scale densities” stems from this visualization and matches the term intermediate densities.

3.1 Application: Cantilever Beam

Problem Statements. The design domain of the cantilever beam is discretized into 120 elements in the horizontal direction and 80 elements in the vertical direction. Each node has two degrees of freedom for the displacement in the x- and y-direction. A unit load (1 N) was applied to the last node on the bottom right in the negative vertical (y-)direction. All degrees of freedom on the very left of the design domain are fixed in both the x- and y-directions. A volume fraction of \(f = 0.3\) is used.

The modified interpolation scheme was applied for eleven different values for the critical density \(\rho _{c}\). In addition, an optimization with the SIMP approach was twice conducted with a penalization exponent of \(p=1\) and \(p=3\), corresponding to \(\rho _{c}=0.0\) and \(\rho _{c}=1.0\). These results are not shown but serve as a validation of our implementation since no difference in results was observed.

Results. In Fig. 1, the resulting topologies are shown with their corresponding compliances. The stiffness of the structures decreases as \(\rho _{c}\) increases, from the optimum \(c=53.62\) Nm for \(\rho _{c}=0.0\) to \(c=60.42\) Nm for \(\rho _{c}=1.0\) (\(+12.7\%\)). In contrast to the topology of the global optimum, which is hardly interpretable as a part (cf. [5, 12]), for \(\rho _{c}>0\), clear shapes of the part become visible in light grey, with local peaks in a darker colour. It can be confirmed, that closed surfaces are preferred for the given load case w.r.t. stiffness when no other objectives exist (cf. [5, 18]).

Penalized intermediate densities are uneconomical and usually disappear in the final results up to a satisfying, practical level. However, the penalization does not guarantee all densities in the results are at zero or above the threshold (\(\rho _{c}\)). As shown in Fig. 2, in the results, densities in the penalized region exist. Densities above zero (plus the termination criterion \(c_{t}=0.01\)) and the critical density (minus \(c_{t}=0.01\)) are coloured in blue. Only at the borders of the structure, densities in the penalized area occur, which is mainly caused by the chosen filter radius. In practice, and for the following use case, a manual redesign follows the topology optimization and thicknesses are manually adjusted to enable manufacturability.

Distribution of the resulting element densities (grey) of the structure in Fig. 1 for \(\rho _{c}=0.6\), with the corresponding penalization scheme (blue) on the left. Density field for \(\rho _{c}=0.6\) with element densities between \(c_{t}\) and \(\rho _{c}-c_{t}\) in blue on the right.

3.2 Use Case: L-Shaped Bell Crank

The reference part of the use case, an L-shaped bell crank, is usually located in the wing of a glider. As a part of the control system, connecting steering rods from the pilot to the ailerons, the component is critical for operation, and a fail-safe design is required and realized in the conventional design as a redundant load path design (two mirror imaged components, i.e. a double sheet metal design). The requirements, and thus objectives of the structural optimization are (1) a weight saving of \(-20 \%\) and (2) a maximization of stiffness while (3) maintaining the attachment areas and dimensions from the reference design.

Problem Statements. Firstly, the design domain of the part is discretized by elements with size 1 mm \(\times \) 1 mm to ensure a minimum length scale in the x- and y-directions. The dimensions of the original component were used (see sketch in Fig. 3) to ensure interchangeability. For the use case, allowed thicknesses in the range \(t \in [0,6.5]\) mm are linearly mapped to the design variables \(\rho _e \in [0,1]\). For example, attachment areas are modelled with a thickness of 2 mm, i.e. \(\rho _e=2/6.5=0.3077\). Non-design regions are modelled as void and passive elements with \(\rho _{passive}=1.0e^{-3}\). Then, different values for the critical density are chosen and described in Table 1. After the optimization, the resulting density fields are simulated by switching off the penalization (\(p=1\)) to calculate the displacements, compliance and weight (real volume fraction) of the resulting structures for comparison.

Results

Design. The resulting topologies of the optimization are shown in Fig. 4. The volume fraction after termination and compliance, as well as the relative difference to the optimal topology (for (a) with \(\rho _{c}=0\)), are presented in Table 1. As shown in the example of the cantilever beam, the lower \(\rho _{c}\) was chosen, the lower was the resulting compliance of the structure. In contrast to (a) without any penalization, for structure (b) with \(\rho _{c}=0.1537\) (\(t_{min}=1\)mm), clear shapes of the structure can be observed in most areas facilitating manual post-processing. It is only 4% less stiff than the optimal topology. A general threshold value, where clearly observable shapes start to result was not investigated. Compared to the design of the conventional penalization in (d) (\(\rho _{c}=1.0\)), the resulting structure is still 12% stiffer. Comparing structure (b) with a minimum thickness of 1 mm with the original sheet metal design (f) of constant 2 mm thickness, the reference part (f) is 60.3% less stiff and 24.2% heavier.

For structure (b) with \(\rho _{c}=0.1537\) (\(t_{min}=1\) mm), the resulting topology in several areas is very similar to the optimal one for \(\rho _{c}=0.0\), e.g. for the upper and lower flanges, that mainly transmit bending loads, and for the middle parts distributing shear loads. For higher critical densities, these shear stresses are not transferred by a closed-walled web, but rather by a frame-like structure due to the penalization that is leading to a reduced economic efficiency of low densities. Thereby, sub-optimal structures (frame-like and in the middle of the design domain) also carry bending stresses, i.e. normal stresses, and contribute to the lower compliance of the structures.

For structure (c) with \(\rho _{c}=0.3077\) (\(t_{min}=2\) mm), a smooth transition to the attachment areas was realized, as expected. The stiffness, thereby, is only 9.1% above the optimal design. It is still 34.5% stiffer than the original sheet metal design (with 19.5% less weight).

In general, stiffness potentials of grey-scales can also be seen for the topologies for \(\rho _{c}=1.0\). Intermediate densities still exist when the termination criterion is met, even if a locally reduced stiffness-to-weight ratio is present due to a penalization of all grey-scale densities. The design for (d) is still stiffer than the original sheet with a weight saving of 19.5%, which is mainly due to allowing heights above the initial 2 mm (increased to 6.5 mm).

The results for the 2D topology optimization (e), without the extrusion in the third (out-of-plane) direction above the original sheet thickness, come with an increase in compliance of 11.1%, compared to the original design, but also 20% in weight-savings.

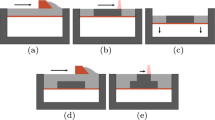

Manufacturing. After the topology optimization, the results were exported in stl-format in 3D, smoothed and manually post-processed in CAD software. Prototypes were printed using MEX before the parts were manufactured using PBF-LB/M.

Plastic prototypes of the structure can be seen in Fig. 5, (a). Without a minimum thickness (\(t_{min}=0.0\)), the part is hardly printable using MEX since, based on experience, a minimum of three layers is recommended to produce robust printing results (Printer used: Raise3d pro2 plus, material: ABS). Built for demonstration purposes, the part without minimum thickness, shown in the picture on the right, is fragile for loads normal to the modelled plane, but stiff for the load case it was optimized for. The higher the minimum thickness was set, the more robust the part appeared to be with respect to stiffness.

Components manufactured using PBF-LB/M are also shown in Fig. 5 for a minimum thickness of \(t_{min}=2.0\) mm (cf. structure (c) in Fig. 4). A critical density of 2 mm was chosen, because out-of-plane properties were not modelled, but a critical density corresponding to the height of the attachment structures resulted in designs that are expected being robust also for loads perpendicular to the modelled plane. For the building of the structures, first, manufacturing simulations in Siemens NX 2011 with Simcenter 3D Powder Bed Fusion were used to analyse stresses after print when varying support structure designs and the orientation of the part in the printer (meshing number of elements: 228793). The best results were a distortion after printing of a maximum of 0.0963 mm (abs) (cf. Fig. 6) obtained with solid support printed flat on the (rigidly modelled) base plate. Fillets were added to the support structure (height of 3 mm) to avoid delamination. Then, the parts were printed on a calibrated EOS E290 (material: Ti6Al4V). Due to reasons of confidentiality printing parameters cannot be published. After the print, a heat treatment followed. The heat treatment consisted of four steps, where steps one to three were in vacuum with atmospheric pressure of \(p \le 1 \times 10^4\) mbar. Step one comprises the heating of the base plate and the hinges at a rate of \(10\,^\circ \)/min. to \(835\,^\circ \)C \(\pm 10\,^\circ \)C. The second process step kept the temperature at \(835\,^\circ \)C \(\pm 10\,^\circ \)C for 2 h. Third, a cool down to \(\le 300\,^\circ \)C was applied, before in step 4 a quench with Argon gas applied by a fan was done until temperatures of \(\le 50\,^\circ \)C were reached. Next, wire EDM was applied to remove the parts from the base plate before a sandblasting treatment was applied. The final parts can also be seen in Fig. 5 (c) and (d). Two parts were manufactured, both without failures during print or post-processing.

4 Discussion

Stresses. As discussed, two types of stresses dominate in the bell crank: shear stresses and bending stresses. Whereas the former connect the flanges of the structure, bending stresses normal to the section cuts characterize the stress state within these flanges. As shown in Fig. 7 for \(\rho _{c}=0.0\), the cross-sections resemble the U- or H-profileFootnote 1 discussed in Sect. 1. However, small deviations between element densities at the inner (position \(e_1\) in Fig. 7) and outer (position \(e_{20}\) in Fig. 7) sides of the hinge exist. As the section becomes closer to the ends of the part, it narrows down, as loads were applied point-wise in the optimization setup. Complex, highly individual shapes of the cross-section become optimal (e.g. see \(d_{cut}=0\) mm in Fig. 7). This emphasizes the need for advanced manufacturing methods, such as AM, to realize structures that are close to optimal in stiffness-to-weight ratios. In areas close to the boundary conditions (in the middle of the bell crank), as well as close to load introductions (at the end of the bell crank close to \(e_{20}\)), individually shaped cross-sections are required to distribute stresses optimally. So, in an advanced and larger production setting, one could potentially replace sections of the part with pre-products (such as H-shaped standard profiles) and attachment areas by applying AM, in a hybrid manufacturing process.

Element densities for different sections for the reference topology with \(\rho _{c}=0.0\) (\(t_{min}=0.0\), cf. structure (a) in Fig. 4). The first section (\(d_{cut}= 0\) mm) is located in the second row of elements after the prescribed attachment areas.

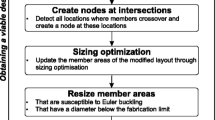

Manufacturing. In combination with the chosen discretization of the elements, a “minimum printable volume” of 1 mm\(^3\), or minimum thickness approach in the x-, y- and z-directions, was established. However, the structures found still require manual post-processing. Sharp edges and corners remaining from the coarse discretization must be smoothed, and, potentially, densities below \(\rho _{c}\) must be reduced to zero or increased to \(\rho _{c}\) to prepare structures for printing. A volume-preserving approach for this is described in [12]. In the use case, this was done manually in CAD Software, when structures were smoothed and prepared for printing.

Within the process of redesigning components using AM, one must decide on the orientation of the part in the printer. With the approach followed in this paper, one orientation is particularly favourable for MEX, as the minimum thickness implicitly incorporates the build direction if 2D densities are extruded in one direction only. For MEX, this may be very efficient, as flat printing on the base plate is usually feasible, accurate and robust. In the use case of the metal hinge, only two parts were printed in a single build job. A horizontal orientation was chosen to reduce print time. Using wire EDM, the parts could easily be removed from the base plate. However, the introduced approach could also be used to ensure a minimum thickness in directions perpendicular to the build direction, for a vertical alignment of the resulting closed walls in the printer. This may enhance process robustness due to several reasons: First, closed surfaces enhance the heat convection within the part. Since heat convection is reduced by powder surrounding a frame-like structure and decreases when adjacent and contacting structures exist, non-uniform strains in the part caused by thermal gradients are reduced [19]. Second, closed-wall structures are often self-supporting in themselves (depending on the orientation in the printer), reducing warping effects and the required support structures. Finally, the closedness helps to ensure dimensional accuracy, e.g. when frames are separated in the build process and later fused again, which often leads to errors in powder-based printing processes for frame-like structures. These advantages come with the increase in stiffness for the given load case in the use case.

Limitations. Several limitations of the proposed approach for the redesign of (double) sheet metal designs exist. The shown results all rely on 2D models, only considering the in-plane stresses of a bending load case. However, when element densities are interpreted as the thickness of a sheet (i.e. after the extrusion), large variations in the thickness of neighbouring elements (i.e. steps or jumps) in the final designs may exist. For these large steps, the assumption of only in-plane stresses cannot hold. Stresses may not distribute equally over the full thickness of an element, when building and loading the structures. Also, smoothing cannot be guaranteed to overcome these drawbacks.

The assumption that the material is under plane stress is clearly violated locally. A local constraint for the design variables, or a finer discretization, could be applied to overcome this challenge. Alternatively, a density-based filtering could be applied to smooth transitions but also does not guarantee a homogeneous stress distribution in the single elements.

In-plane stresses may lead to out-of-plane strains and deformations, which were not considered in the optimization and finite element modelling. A 3D model of hinge (b) in Fig. 4 was simulated in Altair OptiStruct, where out-of-plane deformations were found at a maximum of 0.1 mm, for the load the structure was optimized for. At the same time a bending (in-plane) of 1.15 mm occurred (Material: Ti6Al4V, force applied: 1kN). Thus, for the use case the out of plane bending is evaluated as non-critical.

Even though topology optimizations in 3D are computationally more intense compared to 2D optimizations, a 3D model may still capture effects that, if applicable, can only be implicitly considered in 2D models (e.g. loads perpendicular to the modelled plane).

Moreover, for the results shown, a mesh dependency is always present [5]. However, here, a certain mesh discretization was used as a minimum length scale for AM. A further limitation of the approach is that intermediate densities in the penalized area, below \(\rho _{c}\) may occur, as discussed above, and therefore post-processing is always required (cf. Sect. 3 or [12]).

Furthermore, it was assumed that solid elements could be printed. In fact, porosity and anisotropic material properties characterise the builds of many AM technologies. Fatigue failure, buckling and eigenstresses (e.g. induced by thermal gradients while manufacturing) were not considered in the optimization either.

5 Conclusion

In density-based topology optimizations, stiffness potentials can be used, when intermediate densities are not fully penalized and thus included in the final designs. For flat components, this can be accomplished by topology optimization in 2D, where the resulting densities are interpreted as the thickness of a sheet. To find manufacturable designs, a penalization scheme was investigated that allows a critical density to be chosen, up to which densities are penalized. Results for two test cases are promising: The scheme can be applied as a lower limit, and thus unidirectional minimum thickness constraint, to find manufacturable designs using AM. The lower the critical density was set, the stiffer the structure was found to be for in-plane bending load cases. In a use case, different section types were identified, some similar to standard profiles (e.g. H-profiles) and others individually shaped. The latter, mainly found close to the load introduction and supports, have lightweight potential when employing advanced manufacturing technologies, such as AM. However, it remains questionable if, or up to what thickness, the assumption of planar stress states is generally reasonable. Future work should focus on the testing and validation of the topologies found.

Notes

- 1.

Here, densities (in 2D) were only extruded in one direction, leading to a U-profile. Of course, extrusion in both directions is also feasible (and favourable for introducing stresses into neighbouring elements with different thicknesses), leading to an H-profile in the presented use case. However, for some 3D printers a flat surface is easily manufacturable and therefore an extrusion to only one side was chosen.

References

Merklein, M., Johannes, M., Lechner, M., Kuppert, A.: A review on tailored blanks - production, applications and evaluation. J. Mater. Process. Technol. 214(2), 151–164 (2014)

Megan, L., Brian, C., Hubert, L., Sridhar, R., Robert, Y.: White paper: a design-validation-production workflow for aerospace additive manufacturing. Technical report, DatapointLabs Technical Center for Materials Sridhar Ravikoti and Robert Yancey, Altair Engineering Inc. (2016)

Bendsøe, M.P.: Optimal shape design as a material distribution problem. Struct. Multidiscip. Optim. 1(4), 193–202 (1989)

Xie, Y.M., Steven, G.P.: A simple evolutionary procedure for structural optimization. Comput. Struct. 49(5), 885–896 (1993)

Sigmund, O., Aage, N., Andreassen, E.: On the (non-)optimality of Michell structures. Struct. Multidiscip. Optim. 54(2), 361–373 (2016)

Højbjerre, K.: Additive manufacturing of porous metal components. In: Proceedings of the 6th International Conference on Additive Manufacturing. Loughborough, UK (2011)

Zuo, W., Saitou, K.: Multi-material topology optimization using ordered SIMP interpolation. Struct. Multidiscip. Optim. 55(2), 477–491 (2017)

Bendsøe, M.P., Sigmund, O.: Material interpolation schemes in topology optimization. Arch. Appl. Mech. 69(9–10), 635–654 (1999)

Rossow, M.P., Taylor, J.E.: A finite element method for the optimal design of variable thickness sheets. AIAA J. 11(11), 1566–1569 (1973)

Groen, J.P., Sigmund, O.: Homogenization-based topology optimization for high-resolution manufacturable microstructures. Int. J. Numer. Meth. Eng. 113(8), 1148–1163 (2018)

Wang, F., Lazarov, B.S., Sigmund, O.: On projection methods, convergence and robust formulations in topology optimization. Struct. Multidiscip. Optim. 43(6), 767–784 (2011)

Giele, R., Groen, J., Aage, N., Andreasen, C.S., Sigmund, O.: On approaches for avoiding low-stiffness regions in variable thickness sheet and homogenization-based topology optimization. Struct. Multidiscip. Optim. 64(1), 39–52 (2021)

Larsen, S.D., Sigmund, O., Groen, J.P.: Optimal truss and frame design from projected homogenization-based topology optimization. Struct. Multidiscip. Optim. 57(4), 1461–1474 (2018)

Brackett, D., Ashcroft, I., Hague, R.: Topology optimization for additive manufacturing. In: Proceedings of the 22nd Annual International Solid Freeform Fabrication Symposium, pp. 348–362. University of Texas, Austin, Texas, USA (2011)

Abdelhamid, M., Czekanski, A.: Revisiting non-convexity in topology optimization of compliance minimization problems. Eng. Comput. 39(3), 893–915 (2022)

Sigmund, O.: A 99 line topology optimization code written in MATLAB. Struct. Multidiscip. Optim. 21(2), 120–127 (2001)

Svanberg, K.: The method of moving asymptotes - a new method for structural optimization. Int. J. Numer. Meth. Eng. 24(2), 359–373 (1987)

Sigmund, O.: On the optimality of bone microstructure. In: Pedersen, P., Bendsøe, M.P. (eds.) IUTAM Symposium on Synthesis in Bio Solid Mechanics, Solid Mechanics and its Applications, vol. 69, pp. 221–234. Springer, Netherlands, Dordrecht (2002). https://doi.org/10.1007/0-306-46939-1_20

Kruth, J.P., Froyen, L., van Vaerenbergh, J., Mercelis, P., Rombouts, M., Lauwers, B.: Selective laser melting of iron-based powder. J. Mater. Process. Technol. 149(1–3), 616–622 (2004)

Acknowledgements

This research was conducted as part of the PROVING research project in the national aeronautical research program VI-1 funded by the Bundesministerium für Wirtschaft und Klimaschutz. We wish to thank our industry partners Oerlikon AM Europe GmbH and RS.aero for the industrial use case, manufacturing of reference parts and inspiring discussions. The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Endress, F., Zimmermann, M. (2024). Designing Variable Thickness Sheets for Additive Manufacturing Using Topology Optimization with Grey-Scale Densities. In: Klahn, C., Meboldt, M., Ferchow, J. (eds) Industrializing Additive Manufacturing. AMPA 2023. Springer Tracts in Additive Manufacturing. Springer, Cham. https://doi.org/10.1007/978-3-031-42983-5_5

Download citation

DOI: https://doi.org/10.1007/978-3-031-42983-5_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-42982-8

Online ISBN: 978-3-031-42983-5

eBook Packages: EngineeringEngineering (R0)