Abstract

Rice production significantly contributes to greenhouse gas emissions (GHGE), especially methane (CH4) emissions at various cropping stages. A major source of methane emissions is the decomposition of fertilizers and organic residues in flooded fields during the irrigation cycle. CORIGAP technologies and practices are mainly associated with closing yield gaps by increasing productivity and profitability but have been co-designed to address climatic challenges and to minimize negative environmental impacts. Therefore, over the last decade, the CORIGAP interventions not only helped to reduce yield gaps substantially but also resulted in a significant reduction of the carbon footprint (CF) in rice production. This chapter starts with an in-depth synthesis of scientific-based evidence and knowledge on challenges and constraints to reducing rice CF in CORIGAP countries. The chapter introduces solutions that have been proven to reduce GHGE, in particular, Alternate Wetting and Drying (AWD), rice-straw management, mechanization, and postharvest management. The latter two approaches include laser land leveling, mechanized direct seeding and transplanting, and paddy grain drying will be described in more detail. In addition, life cycle assessments will outline the quantification of the carbon footprint in rice production, for these specific technologies. The chapter presents three country case studies (Thailand, Indonesia, and Vietnam) from data collected through CORIGAP activities to estimate GHGE reductions associated with implementation of best practices for lowland irrigated rice production. Lastly, this chapter provides the outcomes related to GHGE reduction and offers specific recommendations that can be easily implemented in other countries.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

- Rice-carbon footprint

- Greenhouse gas emission

- Life cycle assessment

- Vietnam

- Alternate-wetting-and-drying

5.1 Challenges and Constraints Causing the Rice-Carbon Footprint in CORIGAP Countries

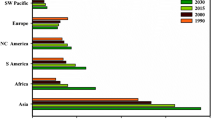

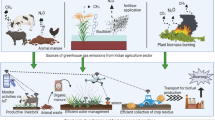

Rice is a staple cereal for half of the world’s population (Sharif et al. 2014), but its production in flood-irrigated systems is one of the major sources of greenhouse gases (GHGs) responsible for 15.6% of the global GHG emissions (GHGE) (Laborde et al. 2021). The GHGs released in rice production are predominantly due to the continuous flooding condition (54.1%), inefficient fertilizer application (11.0%), and straw burning (13.5%) (Wassmann et al. 2021). Ahmed et al. (2020) suggested that the most effective methods to limit the carbon footprint of rice cultivation would include shifting from transplanting to dry direct seeding and improving the management of fertilizer, water, and rice straw, which, together, would be able to cut down more than 900 MtCO2e in global emissions by 2050. Since 2013, CORIGAP has been promoting best management practices (BMPs) to farmers in six rice-producing Asian countries (i.e., China, Indonesia, Myanmar, Sri Lanka, Thailand, and Vietnam) in order to improve regional food security while minimizing the carbon footprint of rice (FDFA 2021). The six CORIGAP countries are collectively responsible for 48% of the global CH4 emissions from rice production (FAOSTAT 2019). By 2017, CORIGAP had reached 375,000 farmers across the six target countries, helping to increase yield from 14 to 30% (Ibabao 2018) while reducing from 5 to 30% of the rice-carbon footprint (Devkota et al. 2022). However, the adoption of BMPs is not without constraints and challenges (Connor et al. 2021b; Tuan et al. 2021; Wehmeyer et al. 2022).

CORIGAP technologies and practices are mainly associated with closing yield gaps by increasing productivity and profitability but were also co-designed to address all three pillars of sustainability (economic, social, and environmental). We start with an in-depth synthesis of scientific-based evidence and knowledge on challenges and constraints to reducing the rice-carbon footprint in all six CORIGAP countries. Furthermore, life cycle assessments will outline the quantification of the carbon footprint in rice production. We will provide case studies on specific technologies, e.g., Alternate Wetting and Drying (AWD), land laser leveling, and residue management at postharvest stages. The outcomes related to GHGE reduction are spelled out, which will be the basis for providing specific recommendations that can be readily implemented in rice-growing countries.

5.2 Life Cycle Assessment Approach to Quantify the Carbon Footprint of Rice Production

Life Cycle Assessment (LCA) is an assessment tool for quantifying and evaluating the environmental impacts of certain practices throughout the life cycle of land preparation, crop production, and stubble management following the guidelines of the ISO (International Organization for Standardization) (2006a, 2006b). Databases of LCA-based carbon footprint (CF) conversion factors can be accessed at different sources such as Ecoinvent (2021) and IPCC (2019), which are incorporated in SIMAPRO software (SIMAPRO 2019). In order to quantify the carbon footprint for the case studies under CORIGAP, we used the LCA approach introduced by Nguyen et al. (2022a) with the boundary of rice production from land preparation to harvesting and the functional unit is kg of paddy grains normalized at 14% of moisture content. We considered rice straw when burned or removed to be carbon–neutral because the CO2 emitted during the incineration comes from the atmospheric CO2 that the plant has fixed during photosynthesis and off-field processing of straw is not included in this study of rice production. On the other hand, straw, when incorporated, emits GHGs and this additional emission is included in the CFsoil of the next season as GHGs are generated from the decomposition of the organic matter, which occurs during the land preparation of the next crop.

Equation 5.1 shows the total rice carbon footprint \(\left( {{\text{CF}}_{{{\text{rice}}}} } \right) \, \left( {{\text{kg kgCO}}_{{2}} - {\text{eq kg rice}}^{{ - {1}}} } \right)\), consisting of four GHG components:

-

1.

CFagro-input emissions from the production of agronomic inputs, e.g., seeds and fertilizers;

-

2.

CFoperation emissions from mechanized operations;

-

3.

CFsoil emissions from soil; and

-

4.

CFricestraw emissions from rice straw management.

The CF conversion factors are in Table 5.1.

Equation 5.2 shows the calculation for CFsoil, which consists of CF and CH4 from pre-season soil management, water management, and rice straw incorporation and N2O from the oxidation of N fertilizers.

Here, Timegrow is the number of days from sowing to harvest. The numbers 28 and 265 are the global-warming potential of CH4 and N2O equivalent to CO2, respectively. EFdefault is the default CH4 emission factor for different rice-cultivation regions. SFwater is the scaling factor corresponding to the number of drainages throughout the crop, excluding the drainage before harvest. SFpre is the scaling factor for water management in the pre-season. SFricestraw is the scaling factor for rice-straw management. EF1FR is the N2O emission factor when N fertilizers are applied in flooded rice systems. All scaling factors and corresponding references can be found in Table 5.1.

5.3 Technologies to Reduce Carbon Footprint in Rice Production

To address the main sources of GHGs emitted from rice production, i.e., flooded fields, Nitrogen (N) fertilizer application, and straw management, CORIGAP introduced BMPs for water, fertilizer, and straw management with subsidiary technologies in crop establishment and land preparation.

5.3.1 AWD

AWD is an economically efficient water management practice (Lampayan et al. 2015) that can reduce up to 70% of GHGE from rice production (Win et al. 2021) (Table 5.2) and was included in several training activities in all CORIGAP countries. When applying AWD, farmers need to let the field dry several times during the cropping season and re-irrigate when the water level drops to 15 cm below the ground level (−15 cm) (Bouman et al. 2007). Farmers can keep track of the water level with a perforated water tube installed in the field. This is a modified tube that combines a plastic ball and an indication sign, allowing farmers to observe the field water level from a distance (Fig. 5.1).

AWD applied at the −15 cm water level sometimes is called safe AWD because it will not cause any yield reduction while significantly reducing the CH4 emitted (Htay et al. 2020; Liang et al. 2016) (see Sect. 2.5 about China). At a −15 cm water level, the rice root system is robust and can supply sufficient water to sustain reproduction and growth activities. The GHGE-reducing effect of safe AWD is generally more profound during the dry season (DS) (31–70%) (Tirol-Padre et al. 2018; Win et al. 2021) than in the wet season (WS) where GHGE can be reduced to 16–20% (Htay et al. 2020) depending on the amount of precipitation (Table 5.2). However, the amount of CH4 reduced can be offset by the increased Nitrous oxide (N2O) emission, even at a low level of N fertilizer at 90 kg ha−1, suggesting the field should be flooded during the time of N fertilization for an effective application of AWD (Liao et al. 2020).

However, there are modifications of AWD, including one where the water threshold is lowered to −30 cm (Liang et al. 2016; Yang et al. 2017). At this level, CH4 can be reduced by 99.5% in comparison to continuous flooding, although there was some yield compensation recorded. Therefore, under the scope of CORIGAP, we recommended a safe level of −15 cm for farmers in the target countries, otherwise known as safe AWD. See Lampayan et al. (2015) for findings from the early stages of CORIGAP.

5.3.1.1 Case Studies of CF Reduction from AWD in Vietnam

AWD was introduced to Vietnam in an integrated technology package termed “One must-do, Five reductions” (1M5R). This package includes the use of certified seeds (one must-do) and five reductions in the use of fertilizers, water, pesticides, seed rate, and postharvest losses (see Chap. 4). It was disseminated through a training-of-trainers workshop for provincial extension and government officials, who would later train farmers on the BMPs integrated into the package (Tuan et al. 2021). Even though CF reduction is not stated as one of the main objectives of the technology package, the application of improved practices such as AWD does contribute to reducing the carbon footprint of rice production and therefore contributes to sustainability, which is a core focus of 1M5R. Here, we calculated the total CF from rice production for two crops (winter-spring and summer-autumn) in 2018–2019 under farmers’ practices with two types of water management, i.e., continuous flooding and AWD (Nguyen et al. 2022a). In both crops, AWD reduced the amount of GHG emitted during the cropping season by 37% or 2,100 kg CO2-eq ha−1 for the winter-spring and 3,422 kg CO2-eq ha−1 for the summer-autumn season (Fig. 5.2). According to Connor et al. (2021a) and Flor et al. (2021), about 105,000 farmers in MRD were trained in 1M5R, covering more than 124,000 ha, with an adoption rate for AWD of 34.6% and another 10.8% reported to have been reducing their water use. According to the above figures, when 34.6% of the farmers with an area of 120,000 ha drained their fields at least twice and another 10.8% of farmers drained at least once, the water-saving practice would cut down the CH4 emission from the soil by 0.1 Mt CO2-eq for the winter-spring season and 0.2 Mt CO2-eq for the summer-autumn season. If all of the trained farmers (100%) apply AWD (i.e., drain their fields mid-season at least twice over their 120,000 ha), the amount of CF reduced could reach 0.2–0.4 Mt CO2-eq, equivalent to 0.7–1.2% of the country’s total emissions from rice cultivation in 2020 (FAOSTAT 2019).

5.3.2 Mechanized Postharvest Operations

Postharvest processes can cause losses of up to 20–30% of the total production in rice production (Gummert et al. 2020). In traditional practice, after harvesting by hand cutting, rice would be threshed to separate grains from the straw, then sun-dried until it reached the desired moisture content and, if necessary, stored in granaries before being taken to milling facilities. Gummert et al. (2020) compared the losses incurred by traditional postharvest practices and the improved practices introduced in Myanmar under CORIGAP (i.e., flatbed dryer, IRRI super bag, lightweight thresher, and combine harvester). The improved (mechanized) postharvest scheme (Fig. 5.3) can help reduce 9–16% of postharvest losses. During the 2015 DS, from the yield (crop cut) of 4.8 t ha−1, farmers who used improved practices obtained 3.0 t ha−1 of milled rice, in comparison to 2.7 t ha−1 using traditional practices. Similar figures were also observed during the DS of 2016 (from crop-cut yield of 5.4 t ha−1, the milled rice was 3.6 t ha−1 (for improved practices) compared to 3.0 t ha−1 of traditional practices) (Gummert et al. 2020).

The improved postharvest processes reduced yield losses but raised concerns over environmental trade-offs with the additional consumption of fossil fuels, power, and the production, depreciation, and maintenance of machines and plastic containers. Gummert et al. (2020) reported that even with the additional GHGE from the above-mentioned processes, total GHGE from the improved practices was 8–43% lower than that of traditional practices for both WS (5,297 kg CO2-eq ha−1 for improved practices compared to 5,734 kg CO2-eq ha−1 for traditional practices) and DS (2,039 kg CO2-eq ha−1 for improved practices compared to 2,933 kg CO2-eq ha−1 for traditional practices). If calculated on kg of milled rice, the improved practices had a similar GHGE as traditional practices during the DS but emitted 28% less during the WS (Fig. 5.4) due to the higher milled rice yields in each season.

5.3.3 Straw Removal for Mushroom Production

Burning, incorporating, and removing are three common management practices of rice straw after harvesting. Given the amount of air pollutants generated in open-field straw burning (Le et al. 2020; Junpen et al. 2018; Phuong et al. 2022) and the surge in CH4 flux in straw incorporation as fields are usually flooded to hasten the decomposition (Chareonsilp et al. 2000; Shen et al. 2014; Thu et al. 2016), other practices promoting straw decomposition under more favorable conditions, such as aerobic decomposition in composting or pyrolysis in biochar conversion, have been considered. Under CORIGAP, straw removal for mushroom production was promoted in Vietnam as a way to generate added value to rice while reducing GHGE and air pollution due to straw burning.

For this practice, rice straw is used as a substrate for Volvariella volvacea or straw mushroom, an edible type of mushroom, which is commonly consumed in Southeast Asia and is easy to grow with a 14-day growth duration (Thuc et al. 2020). In the rice straw mushroom production process described by Thuc et al. (2020), rice straw is first collected from the field, best immediately after harvesting to minimize the risk of contamination and the straw should not contain chemical residues from rice production. Afterwards, the collected straw needs to be soaked in CaCO3 solution (3–5%w/w) for 10–15 min. After being soaked, the straw is cleansed with water to remove the remaining CaCO3, piled, and tightly wrapped in plastic and exposed to sunlight for 3 days to increase the temperature of the pile for the first incubation. During this stage, the temperature of the pile should reach 65–75 °C; the pile should be turned once or twice to ensure homogeneity. When the incubation finishes, mushroom spawn can be added alternatively to layers of straw with a layer of straw on top as a cover.

In the following step, the straw pile enters the second incubation (10–14 days) where the optimal level of temperature (30–35 °C) and moisture content (75–85%) for the development of the spawn should be maintained. Here, a net or plastic can be used as the topmost cover to increase the temperature. After the first 5 days of the second incubation, mushroom pinheads will appear. At this pinning stage, the straw pile should be slightly watered every 2–3 days to maintain the desired moisture content and avoid damaging the mycelium and small mushrooms. Twelve to 15 days after the spawn inoculation, the mushrooms are ready to be harvested. The mushrooms suitable for harvest should be large and round with their cap not yet opened (Thuc et al. 2020).

Mushroom production from rice straw can be done in an open field or in growing houses. The breakdown of costs and benefits of the two management practices (open field and growing house) is shown in Table 5.3. For an average straw yield of 2 t ha−1 (moisture content of 28%) and a production rate of 0.8 kg of mushroom per 1 kg of dry straw, farmers would earn around USD $120 ha−1, in comparison to $14 ha−1 if selling fresh straw (Can Tho City extension staff, pers. Comm.) or no additional income if burning or incorporating straw. In addition to the increased income, according to Arai et al. (2015), rice straw for mushroom production generated 107–637 g CO2-eq. kg dry straw−1 or 0.95 t CO2-eq. ha-paddy−1 year−1, which is less GHGE than produced during straw burning.

5.3.4 Land Laser Leveling

There are further mechanization options that can help reduce carbon footprint, such as laser land leveling (LLL) (Nguyen et al. 2022b). Inputs and outputs of the operations are reviewed in this section. The inputs of mechanized operations mainly include fuel consumption, machine production and depreciation, and operating labor while the outputs can be accounted for the increase of farming efficiency, agronomic input use efficiency, and yield and grain quality (Fig. 5.5).

Laser land leveling is a technique using a laser to guide a drag bucket, whether to scrape up soil or to release it, to create a flattened field surface (IRRI 2019; Jat et al. 2006). A system of LLL contains five main components, namely a drag bucket, laser transmitter, laser receiver, control box, and hydraulic system with a pulling tractor. Before the leveling process starts, the field should be plowed when the soil is slightly moist. At the beginning of the leveling process, the laser receiver is attached to the tractor and the transmitter with the base plate is put on an even ground. After that, a topographic survey is conducted to record the height of the field at different points. The tractor should move from highs to lows according to the amount of soil contained in the bucket. At the end of the leveling process, the field should be re-surveyed to ensure the desired level is achieved. LLL can improve the effectiveness of water and nutrient management as well as improve the accessibility for other machinery, e.g., mechanized transplanters and row and hill seeders by maintaining a uniform condition of the field.

A study on LLL in Vietnam, Thailand, Philippines, Cambodia, and India indicated that, although there was an increase in the GHGE due to machinery operation, the total GHGE was reduced due to reductions in water use, agronomic inputs, and an increase in yield. Specifically, LLL can help to save at least 10% of agronomic inputs, 20% of irrigation water; reduce at least 2% of postharvest losses caused by rice plant lodging, and increase at least 5% of grain yield (Nguyen-Van-Hung et al. 2022b). A net reduction of at least 10% of GHG emissions was obtained on average, which offset the increased carbon footprint from machines and operations, as shown in Fig. 5.6.

Effect of laser land leveling on greenhouse gas emisisons (GHGE) in five Asian countries (Adapted from Nguyen et al. 2022b)

5.3.5 Mechanized Direct Seeding and Transplanting

During the CORIGAP project, field demonstrations helped promote direct seeding (DSR) in regions such as the MRD in Vietnam. DSR entails sowing seeds directly to the field instead of transplanting (TPR) seedlings from nursery beds (Farooq et al. 2011). DSR includes three crop establishment methods: (1) dry seeding (dry seeds into dry soil), (2) wet seeding (pre-germinated seeds into wet soil), and (3) water seeding (seeds into standing water). In comparison to TPR, DSR has the advantages of less labor and less water consumption, plus the crop matures 7–10 days earlier due to no transplanting shock. Overall, the outcome is less GHGE.

In contrast, transplanting consists of two processes—seedling production and transplanting—whether manually or by machines. After being grown in seedlings trays or nursery mats for 14–18 days, seedlings are rolled out in the trays and loaded into the transplanters. There are two types of transplanters, walk-behind and self-propelled transplanters. Both can adjust the row distance, hill-to-hill spacing and seedling rate per hill, using a seed rate of around 50–70 kg ha−1. By being transplanted into the field during the seedling stage, rice will have a competitive advantage over the weeds and will have a lower risk of being eaten by birds, snails, and rats (Nguyen et al. 2020).

In addition, Nguyen et al. (2022a) reported that mechanized crop establishment reduced GHGE by addressing the problem of excessive use of agronomic inputs. The study compared the performance of broadcast seeding and mechanized transplanting in a two-cropping season field experiment (2018–2019) in Can Tho. Mechanized transplanting reduced the seed rate by 40% and pesticide use by 30–40% in the WS cropping season without any yield penalty. While mechanized transplanting does consume additional fuel and machinery costs, its net energy balance, net income, and total GHGE were on par with those of non-mechanized crop establishment methods (Fig. 5.7). Therefore, we suggest that mechanized transplanting can be promoted in the MRD for the improvement of the economic and environmental sustainability of the region’s rice production (Nguyen et al. 2022a).

(Adapted from Nguyen et al. 2022a)

Greenhouse gas emissions (GHGE) from rice cultivation under two crop establishment methods, broadcast seeding and mechanized transplanting

5.3.6 Site-Specific Nutrient Management

Site-specific nutrient management (SSNM) is a dynamic nutrient management that utilizes a model to quantify the amount of additional N, P, and K fertilizers to reach the target yield, given a specific indigenous nutrient supply (INS) (Dobermann and White 1998). The proposed procedure of SSNM includes five steps: (1) estimation of the INS of N, P, K; (2) estimation of the nutrient requirements based on yield target and the INS; (3) through the growing season, optimize the amount and timing of N application with the assistance of additional tools; (4) estimation of N, P, K removed from the field, thus changes in INS after harvest; and (5) incorporating the new data into the model for the next crop estimation.

For the first step, soil testing can be used to assess the INS. However, this approach requires uniformity in sampling and analytical methods as well as a well-developed infrastructure and quality control (Dobermann et al. 2003), which may not be available in developing regions or affordable for small farmers (Schut and Giller 2020). In such cases, nutrient omission trials were conducted where either of the three main macronutrients would not be added to the plot while the other nutrients would be adequately supplied (Chivenge et al. 2022). This approach will take one cropping season to determine the INS of the soil.

In addition to the crop-, field-, and season-specific requirements calculated at the beginning of the crop season, other tools are developed to address the dynamics of crop growth under the variable conditions of biotic and abiotic stresses such as heavy rainfall, drought periods, or pest and disease occurrences. One such tool is a leaf color chart, a plastic strip with four to six color panels ranging from yellowish green to dark green, which indicates the leaf color at different N content stages (Witt et al. 2005). Based on the greenness of the leaf, farmers can adjust the N fertilizer to reach the desired yield level. Other digital tools were also developed, adapting the initial model for rice in Asia to other regions and crops, providing farmers with a user-friendly interface and straightforward nutrient management recommendations, such as the Rice Crop Manager (Buresh et al. 2019), Nutrient Expert (Pampolino et al. 2012), RiceAdvice (Zossou et al. 2020).

5.4 Case Studies of the Carbon Footprint of Rice Production in Selected CORIGAP Countries

5.4.1 Carbon Footprint of Rice Production in Indonesia

For Indonesia, the main sources of GHG were the flooded rice production and the decomposition of organic fertilizers and rice straw under submerged conditions, especially during the DS (Carlson et al. 2017; Setyanto et al. 2000). To mitigate those sources, a range of techniques was introduced to Indonesian farmers (e.g., water-saving techniques, drum seeders, postharvest management), allowing farmers to grow double or triple crops, with 93,000 ha planted in the 2017 DS compared to only 30 ha in the 2012 DS (Singleton and Quilloy 2017).

The techniques require specific inputs, which sometimes are not available (fertilizers usually arrive late for the application schedule or are not the right type) or not suitable for farmers’ use (e.g., the drum seeders being too heavy given the soil conditions) (Flor 2016). Another constraint was associated with collective decisions for community actions such as pest management, or irrigation management where farmers usually hired service providers who have little or no knowledge of AWD or water-saving techniques. As such, usually only farmers who irrigate by themselves applied some kind of water-saving practices.

A study by Connor et al. (2021a) showed that time constraints, labor shortage, and incompatibility with the farming pattern were the main reasons for farmers to discontinue their use of BMPs after 1–3 years of implementation. AWD was the most popular practice with an adopted rate of 80.6% and a continuation rate of 55.2%, with the reasons for discontinuation being difficult to apply and time constraints. In comparison, the IRRI Superbag (postharvest management) was the least popular, adopted by 46% of introduced farmers and continued by one farmer (16.7%). The reasons given were the technique’s incompatibility with the field conditions and cropping pattern. Furthermore, many farmers opted to sell their wet paddy directly from their field.

5.4.1.1 Calculation of Carbon Footprint (CF) from Rice Production in Indonesia

We used the methods described in Sect. 5.2 to calculate the CF from rice production in Indonesia. The management practices of rice straw, water pre- and mid-season, as well as yield were collected from farmer questionnaires. Other parameters such as crop duration were assumed as the average duration of all commonly grown varieties in the study site. Qualitative answers about the amount of straw used for each management practice in the questionnaire (i.e., 1 = none at all, 6 = all of the straw) were converted to percentages as 1 = 0%, 2 = 20%, 3 = 40%, 4 = 60%, 5 = 80%, 6 = 100%. We assumed that rice straw was the only organic matter incorporated and straw composted before being incorporated was categorized as rice straw incorporated for more than 30 days pre-season.

In Indonesia, the baseline study in 2014 reported that the CF of DS and WS were 0.6 kg CO2-eq kg-grain−1 and 1.1 kg CO2-eq kg-grain−1, respectively (Devkota et al. 2019). After 7 years, the endline survey conducted in 2021 showed that the BMPs integrated into CORIGAP have reduced CF in WS rice by 39%, to 0.8 kg CO2-eq kg-grain−1, increasing yield by 7%. However, for the DS, while BMPs increased yield by 9%, the CF also increased by 41% to 0.9 kg CO2-eq kg-grain−1. The rising of CF in the DS maybe due to the increasing use of irrigation water. In the endline survey, 29 of 52 farmers (56%) responded that their fields were kept flooded continuously. In a study by Devkota et al. (2019), Indonesia was the country that irrigated the least in terms of both number of irrigation applications and mm of irrigation applied. This result further stresses the importance of improved water management practices such as AWD for smallholder farmers in lowland irrigated rice systems in Indoneisa.

5.4.2 Carbon Footprint of Rice Production in Thailand

In Thailand, the main challenges for rice farmers include the overuse of inputs, which results in environmental damage, increasing input and labor costs, decreasing paddy prices, and water scarcity (Stuart et al. 2018). Rice production generates 58% of Thailand’s total GHGE (Devkota et al. 2019), or about 3.65 t CO2e ha−1 year−1 (Maraseni et al. 2018). While other major rice producers (e.g., China and Vietnam) have been increasing their yields, and at the same time, decreasing their rates of carbon density (Maraseni et al. 2018), Thailand’s performance in reducing its carbon footprint was the lowest compared to other major rice producers in the region such as India, China, or Vietnam (Maraseni et al. 2018). Field emissions (70%) and farming (20%) are the two main contributors to the life cycle GHGE of rice production (Yodkhum et al. 2018). BMPs that help reduce GHGE (e.g., mechanized direct seeding with drum seeders, LLL, SSNM by soil analysis, and AWD) were introduced in Thailand.

The use of drum seeders reduced seed rate by 60–67%, which in turn reduced the rates of fertilizers and pesticide application and, consequently, roughly 50% of production cost with no reduction in yield (Stuart et al. 2018). Using the equations introduced in Sect. 5.2, we estimated that, with the reduction in agronomic inputs achieved when farmers followed the BMP, together with AWD, as detailed in Stuart et al. (2018), the GHGE would be 45% lower than that of FP in both the WS and DS. The total GHGE per kg of paddy grain reduced from 0.83 kg CO2-eq kg-paddy−1 to 0.48 kg CO2-eq kg-paddy−1. Notably, in the BMP schemes, the amount of fertilizers applied can be as little as a third for N (43.47 and 121.53 kg ha−1), and a tenth for P (4.39 and 43.76 kg ha−1) compared to FP, and yet no significant difference in yield was observed. In other words, applying fertilizers heavily to rice fields in Thailand does not always translate to more grain yield, rather it would reduce farmers’ net income due to rising costs of fertilizers and pesticide applications (Stuart et al. 2018; Pame et al. 2023) and significantly increases GHGE as per our calculation.

The application of laser land leveling had been shown to increase yield while reducing inputs (seed, water, and fertilizers) and postharvest losses and GHGE (Nguyen et al. 2022b). SSNM greatly reduced fertilizer input (51–54%) and its costs ($79 ha−1) and also reduced GHGE at the rate of 363.52 kg CO2-eq ha−1, while maintaining or increasing yield in farmers’ field trials (Arunrat et al. 2018; Attanandana et al. 2010). Similar to SSNM, AWD aims to generate profits for farmers by reducing inputs while applying no damage to yield. Maneepitak et al. (2019) reported that AWD increased grain yield by 7–15%, and reduced water input by 46–77%. This practice is also reported to help mitigate the carbon footprint of rice cultivation by 144.5 CO2-eq ha−1 (Arunrat et al. 2018).

Despite the visible benefits, some of the advanced practices are not widely adopted in Thailand; for example, there are only eight LLL units in Thailand covering merely 530 ha (Nguyen et al. 2022b), even though a flattened field surface is recommended for effective implements of other techniques. As for other practices, the reported limited factors include weed management and fear of yield reduction (Maneepitak et al. 2019; Ngo et al. 2019).

5.4.3 Carbon Footprint of Rice Production in Vietnam

Most of the most productive provinces in Vietnam are located in the two major deltas of the Mekong and Red River and a minor central delta. This is not surprising as increasing productivity has been the focus of the Vietnamese government’s policies for rice production, especially in MRD, for the nation’s food security. While this emphasis did make Vietnam a leading rice exporter, it also resulted in soil degradation, overuse of fertilizers and plant protection chemicals, and low grain quality (Thai and Giang 2015). Methane emission from Vietnam was 230% higher than IPCC defaults for Southeast Asia (Vo et al. 2020), while the country is 3.7 t ha−1 crop−1 behind its yield potential (Yuan et al. 2022).

To improve yield and mitigate GHGE, best practices, including AWD, LLL, and rice straw management, have been implemented in Vietnam and shown promising results. Studies in the MRD region showed AWD reduces 35–72% of CH4 emissions in rice production with no yield penalty or even increases yield (Khai et al. 2018; Uno et al. 2020). From our own calculation, AWD can lower the carbon footprint of rice production by 37% in both the WS and DS. AWD requires precise timing of flooding; as such, a flattened field surface is of crucial importance. LLL was introduced to Vietnamese farmers and helped increase land use efficiency, yield, and reduce inputs and postharvest losses (Nguyen et al. 2022b).

The alternative use of rice straw for mushroom production provides growers with an additional profit of $30 ton-straw−1 cycle−1 (Trúc and Huong 2016) while emitting 1 t CO2-eq. ha-paddy−1 year−1 less (Arai et al. 2015). However, in the MRD, the main management for rice straw was burning (Cuong 2019), even though the incineration generates less energy and more GHG pollutants, plus increases respiratory health risks of farming families, than other management practices (Nguyen et al. 2019). Connor et al. (2020) reported that farmers were most aware of direct uses of rice straw and also practiced those (burning, incorporation, and collection), while practices utilizing rice straw as input material for other productions were less well-known and adopted by only half of the farmers (compost, mushroom production) or even fewer farmers when considering biogas or fodder production. Farmers were well aware that straw burning is a high-risk, low-benefit practice, and were in favor of other straw management practices. However, straw burning offered a quick and simple removal of the straw in the field, which is crucial when the fallow period usually lasts only a month for farmers practicing three rice-cultivating seasons. A lack of enforcement in prohibiting straw burning and available alternatives, especially in the winter-spring season, contributed to farmers opting for straw burning.

Using the method described in Sect. 5.2, it is calculated that by the end of CORIGAP, GHGE from rice production in MRD was 2.3–2.5 t CO2-eq crop−1 ha−1, or approximately 0.5 kg CO2-eq kg-grain−1. Compared to the GHGE reported for the baseline survey in Devkota et al. (2019), which was 5.4 t CO2-eq ha−1 for the WS and 3.9 t CO2-eq ha−1 for the DS, the GHGE ha−1 was reduced 54% for the WS and 41% for the DS, while increasing mean rice yield by 7%.

Despite the potential benefits, the implementation of advanced practices in the MRD is currently limited by various factors. For AWD, farmers’ choice to use a pumping service is the major constraint as irrigation water will be delivered to individual fields at a fixed cost at the same schedule (Le 2021), in addition to other constraints, such as AWD being deemed too difficult to implement, incompatible to farmers’ cropping pattern or weather conditions (Connor et al. 2021b). Access to machines is the major constraint to LLL (Tuan et al. 2021). Lack of capital resources is also a main constraint for mushroom production from rice straw (Truc and Huong 2016). Minas et al. (2020) reported that additional costs in gathering and transporting straw for off-field use could prevent farmers with limited financial capacity from adopting alternative straw management, in addition to a lack of access to technical and financial support.

5.4.3.1 Carbon Footprint Reduction with One Must-Do, Five Reductions (1M5R) in Vietnam

We used the method described in Sect. 5.2 to calculate the CF from rice production for farmers following the 1M5R technology package or FP presented by Nguyen et al. (2022a). In our calculation for the case of rice production in the MRD of Vietnam, the parameters other than the target criteria of 1M5R were considered to be the same as of FP. The differences between FP and 1M5R are listed in Table 5.4. Implementation of 1M5R practices effectively reduced GHGE by 41–42% in irrigated rice production because of reduced use of seeds, N fertilizers, pesticides, and CH4 emission from flooded soil (Fig. 5.8). In total, applying 1M5R can help cut down the CF by 0.36 and 0.59 kg CO2-e kg paddy−1 in the winter-spring and summer-autumn seasons, respectively.

FP as surveyed by Nguyen et al. (2022a), 1M5R followed One must-do, Five reductions criteria.

5.5 Summary and Recommendations for Further Application

The climate risks and adverse farming practices in rice production, particularly in the CORIGAP countries, cause high carbon footprint or GHG emissions per kg of rice produced. Following are common constraints and possible solutions.

-

Irrigated rice–flood-prone with continuous stagnant water is a common practice in the Mekong Delta and other delta and lowland regions, which causes high methane emission. Water-saving solutions (e.g., AWD) can reduce up to 50% of methane emissions in rice production (Chidthaisong et al. 2018; Arai 2022). However, the AWD application usually requires the support of interventions such as inbound and efficient water management systems to enable drainage of the fields and land leveling. Possible solutions include better coordination of water use by farming communities plus the introduction of the “internet of things” to provide real-time feedback on field water levels.

-

Adverse rice-straw management practices can generate a high CF. Rice-straw burning causes losses of nutrients contained in the straw and environmental pollution that indirectly generates and increases the carbon footprint of rice. On the other hand, the incorporation of rice straw combined with flooded fields causes high methane emissions. There are solutions for sustainable rice-straw management introduced by Gummert et al. (2020) such as biogas production, mushroom production, and harvest of stubble for stock feed.

-

High agronomic input use for rice production due to lack of mechanization and precision farming is an ongoing challenge. This issue can be addressed by improving scale-appropriate farming systems and practices. For example, precision crop establishment and fertilization requires an integrated system of precision land leveling, mechanical transplanters or seeders, soil-nutrient-based nutrient management tools, etc. (Nguyen et al. 2022a, b).

-

High postharvest losses due to poor technologies and management also cause a high carbon footprint for each kg of rice produced (Broeze et al. 2023). The solutions for reducing postharvest losses can be addressed by the practices covered in Chap. 4, such as the use of combine harvesters, mechanical dryers, hermetic storage bags, and EasyHarvest for smart postharvest management.

References

Ahmed J, Almeida E, Aminetzah D, Denis N, Henderson K, Katz J, Kitchel H, Mannion P (2020) Agriculture and climate change. McKinsey & Company. Retrieved March 10, 2020, from https://www.mckinsey.com/~/media/mckinsey/industries/agriculture/our%20insights/reducing%20agriculture%20emissions%20through%20improved%20farming%20practices/agriculture-and-climate-change.pdf

Arai H (2022) Increased rice yield and reduced greenhouse gas emissions through alternate wetting and drying in a triple-cropped rice field in the Mekong Delta. Sci Total Environ 842:156958. https://doi.org/10.1016/j.scitotenv.2022.156958

Arai H, Hosen Y, Pham Hong VN, Thi NT, Huu CN, Inubushi K (2015) Greenhouse gas emissions from rice straw burning and straw-mushroom cultivation in a triple rice cropping system in the Mekong Delta. Soil Sci Plant Nutr 61:719–735. https://doi.org/10.1080/00380768.2015.1041862

Arunrat N, Sereenonchai S, Pumijumnong N (2018) On-farm evaluation of the potential use of greenhouse gas mitigation techniques for rice cultivation: a case study in Thailand. Clim 6:36. https://doi.org/10.3390/cli6020036

Attanandana T, Kongton S, Boonsompopphan B, Polwatana A, Verapatananirund P, Yost R (2010) Site-specific nutrient management of irrigated rice in the central plain of Thailand. J Sustain Agric 34:258–269. https://doi.org/10.1080/10440041003613297

Bouman BAM, Lampayan RM, Tuong TP (2007) Water management in irrigated rice: coping with water scarcity.

Broeze J, Axmann H, Castelein B, Guo X, Sander BO, Nelson KM, Wassmann R, Nguyen VH (2023) Reducing greenhouse gas emissions by reducing food loss and waste—Value chain interventions from farmer to fork. In: Campbell B et al. (eds) Transforming food systems under climate change through innovation. Cambridge University Press. https://doi.org/10.1017/9781009227216

Buresh RJ, Castillo RL, Dela Torre JC, Laureles EV, Samson MI, Sinohin PJ, Guerra M (2019) Site-specific nutrient management for rice in the Philippines: calculation of field-specific fertilizer requirements by rice crop manager. Field Crop Res 239:56–70. https://doi.org/10.1016/j.fcr.2019.05.013

Carlson KM, Gerber JS, Mueller ND, Herrero M, MacDonald GK, Brauman KA, Havlik P, O’Connell CS, Johnson JA, Saatchi S, West PC (2017) Greenhouse gas emissions intensity of global croplands. Nat Clim Chang 7:63–68. https://doi.org/10.1038/nclimate3158

Chareonsilp N, Buddhaboon C, Promnart P, Wassmann R, Lantin RS (2000) Methane emission from deepwater rice fields in Thailand. Nutr Cycl Agroecosyst 58:121–130. https://doi.org/10.1023/A:1009890418537

Chidthaisong A, Cha-un N, Rossopa B, Buddaboon C, Kunuthai C, Sriphirom P, Towprayoon S, Tokida T, Padre AT, Minamikawa K (2018) Evaluating the effects of alternate wetting and drying (AWD) on methane and nitrous oxide emissions from a paddy field in Thailand. Soil Sci Plant Nutr 64:31–38. https://doi.org/10.1080/00380768.2017.1399044

Chivenge P, Zingore S, Ezui KS, Njoroge S, Bunquin MA, Dobermann A, Saito K (2022) Progress in research on site-specific nutrient management for smallholder farmers in sub-Saharan Africa. Field Crop Res 281:108503. https://doi.org/10.1016/j.fcr.2022.108503

Connor M, de Guia AH, Quilloy R, Van Nguyen H, Gummert M, Sander BO (2020) When climate change is not psychologically distant—Factors influencing the acceptance of sustainable farming practices in the Mekong river Delta of Vietnam. World Dev Perspect 18:100204. https://doi.org/10.1016/j.wdp.2020.100204

Connor M, de Guia AH, Pustika AB, Sudarmaji KM, Hellin J (2021a) Rice farming in Central Java, Indonesia—Adoption of sustainable farming practices, impacts and implications. Agron 11:881. https://doi.org/10.3390/agronomy11050881

Connor M, Tuan LA, DeGuia AH, Wehmeyer H (2021b) Sustainable rice production in the Mekong River Delta: factors influencing farmers’ adoption of the integrated technology package “One Must Do, Five Reductions” (1M5R). Outlook on Agriculture 50:90–104. https://doi.org/10.1177/0030727020960165

Cuong OQ (2019) Farmers’ preference for improvement of rice straw management in Mekong Delta, Vietnam. Ph.D. Thesis, University of the Philippines Los Baños

Devkota KP, Beebout SEJ, Yadav S, Bunquin MA (2022) Setting sustainability targets for irrigated rice production and application of the sustainable rice platform performance indicators. Environ Impact Assess Rev 92:106697. https://doi.org/10.1016/j.eiar.2021.106697

Devkota KP, Pasuquin E, Elmido-Mabilangan A, Dikitanan R, Singleton GR, Stuart AM, Vithoonjit D, Vidiyangkura L, Pustika AB, Afriani R, Listyowati CL, Keerthisena RSK, Kieu NT, Malabayabas AJ, Hu R, Pan J, Beebout SEJ (2019) Economic and environmental indicators of sustainable rice cultivation: a comparison across intensive irrigated rice cropping systems in six Asian countries. Ecol Ind 105:199–214. https://doi.org/10.1016/j.ecolind.2019.05.029

Dobermann A, White PF (1998) Strategies for nutrient management in irrigated and rainfed lowland rice systems. Nutr Cycl Agroecosyst 53:1–18. https://doi.org/10.1023/A:1009795032575

Dobermann A, Witt C, Abdulrachman S, Gines HC, Nagarajan R, Son TT, Tan PS, Wang GH, Chien NV, Thoa VTK, Phung CV, Stalin P, Muthukrishnan P, Ravi V, Babu M, Simbahan GC, Adviento MAA, Bartolome V (2003) Estimating indigenous nutrient supplies for site-specific nutrient management in irrigated rice. Agron J 95:924–935. https://doi.org/10.2134/agronj2003.9240

Ecoinvent (2021) Ecoinvent Database v3.7.1. https://ecoinvent.org/the-ecoinvent-database/data-releases/ecoinvent-3-7-1/

FAOSTAT (2019) Data for 2019. https://www.fao.org/faostat/en/#data/GR. Aaccessed 10 March 2023

Farooq MKHM, Siddique KH, Rehman H, Aziz T, Lee DJ, Wahid A (2011) Rice direct seeding: experiences, challenges and opportunities. Soil Tillage Res 111:87–98. https://doi.org/10.1016/j.still.2010.10.008

Federal Department of Foreign Affairs (FDFA) (2021) Closing rice yield gaps in Asia phase 1 press release. https://www.eda.admin.ch/deza/en/home/aktuell/news.html/content/dezaprojects/SDC/en/2012/7F08412/phase1.html?oldPagePath=. Accessed 10 Mar 2023

Flor RJ, Tuan LA, Nguyen VH, Phung MNT, Connor M, Stuart AM, Sander BO, Wehmeyer H, Cao BT, Tchale H, Singleton GR (2021) Unpacking the processes that catalyzed the adoption of best management practices for lowland irrigated rice in the Mekong Delta. Agron 11:1707. https://doi.org/10.3390/agronomy11091707

Flor, RJB (2016) Network formation, learning and innovation in multi-stakeholder research projects: Experiences with adaptive research and learning alliances in rice farming communities in Southeast-Asia. Doctoral dissertation, Wageningen University and Research

Gummert M, Nguyen VH, Cabardo C, Quilloy R, Aung YL, Thant AM, Kyaw MA, Labios R, Htwe NM, Singleton GR (2020) Assessment of postharvest losses and carbon footprint in intensive lowland rice production in Myanmar. Sci Rep 10:1–13

Htay KM, Myaing K, Su C (2020) Methane emission from different rice fields as affected by water management. In: FAO, YAU Proceedings: national workshop on promoting climate smart agriculture in Myanmar Nay Pyi Taw, pp 26–35

Ibabao N (2018) Paving the way for sustainable rice production in Asian countries. IRRI News. Retrieved 11 August 2022, from, http://news.irri.org/2018/03/paving-way-for-sustainable-rice.html

International Organization for Standardization (ISO) (2006a) ISO 14040:2006—Environmental management—Life cycle assessment—Principles and framework [WWW Document]. 7.30.2021. https://www.iso.org/standard/37456.html

International Organization for Standardization (ISO) (2006b) ISO 14044:2006—Environmental management—Life cycle assessment—Requirements and guidelines. https://www.iso.org/standard/38498.html

International Rice Research Institute (IRRI) (2019) Laser land leveling. GHG mitigation in rice. https://ghgmitigation.irri.org/mitigation-technologies/laser-land-leveling.Accessed 10 March 2023IPCC

IPCC (2006) In: Eggleston HS, Buendia L, Miwa K, Ngara T, Tanabe K IPCC guidelines for national greenhouse gas inventories

IPCC (2013) Emissions factor database. http://www.ghgprotocol.org/Third-Party-Databases/IPCC-Emissions-Factor-Database

IPCC (2019) Task force on national greenhouse gas inventories. In: Calvo Buendia E, Tanabe K, Kranjc A, Baasansuren J, Fukuda M, Ngarize S, Osako A, Pyrozhenko Y, Shermanau P, Federici S 2019 Refinement to the 2006 IPCC guidelines for national greenhouse gas inventories. https://www.ipcc-nggip.iges.or.jp/public/2006gl/corrigenda11.html

Jat ML, Chandna P, Gupta R, Sharma SK, Gill MA (2006) Laser land leveling: a precursor technology for resource conservation. Rice-Wheat Consort Tech Bull Ser 7:48

Junpen A, Pansuk J, Kamnoet O, Cheewaphongphan P, Garivait S (2018) Emission of air pollutants from rice residue open burning in Thailand. Atmos 9:449

Khai NH, Tinh TK, Tin HQ, Sanh NV (2018) Reducing greenhouse gas emissions in rice grown in the Mekong Delta of Vietnam. Environ Pollut Clim Change 2:2–6. https://doi.org/10.4172/2573-458x.1000158

Laborde D, Mamun A, Martin W, Piñeiro V, Vos R (2021) Agricultural subsidies and global greenhouse gas emissions. Nat Commun 12:2601. https://doi.org/10.1038/s41467-021-22703-1

Lampayan R, Rejesus R, Bouman BA, Singleton GR (2015) Adoption and economics of alternate wetting and drying water management for irrigated lowland rice. Field Crop Res 170:95–108. https://doi.org/10.1016/j.fcr.2014.10.013

Le HA, Phuong DM, Linh LT (2020) Emission inventories of rice straw open burning in the Red River Delta of Vietnam: evaluation of the potential of satellite data. Environ Pollut 260:113972. https://doi.org/10.1016/j.envpol.2020.113972

Le LT (2021) Alternate wetting and drying technique in paddy production in the Mekong Delta, Vietnam: economic evaluation and adoption determinants. J Agribus. Dev. Emerg. Econ 11:42–59. https://doi.org/10.1108/JADEE-09-2019-0153

Leon A, Izumi T (2022) Impacts of alternate wetting and drying on rice farmers’ profits and life cycle greenhouse gas emissions in An Giang Province in Vietnam. J Clean Prod 354:131621. https://doi.org/10.1016/j.jclepro.2022.131621

Liang K, Zhong X, Huang N, Lampayan RM, Pan J, Tian K, Liu Y (2016) Grain yield, water productivity and CH4 emission of irrigated rice in response to water management in South China. Agric Water Manag 163:319–331. https://doi.org/10.1016/j.agwat.2015.10.015

Liao B, Wu X, Yu Y, Luo S, Hu R, Lu G (2020) Effects of mild alternate wetting and drying irrigation and mid-season drainage on CH4 and N2O emissions in rice cultivation. Sci Total Environ 698:134212. https://doi.org/10.1016/j.scitotenv.2019.134212

Maneepitak S, Ullah H, Paothong K, Kachenchart B, Datta A, Shrestha RP (2019) Effect of water and rice straw management practices on yield and water productivity of irrigated lowland rice in the Central Plain of Thailand. Agric Water Manag 211:89–97. https://doi.org/10.1016/j.agwat.2018.09.041

Maraseni TN, Deo RC, Qu J, Gentle P, Neupane PR (2018) An international comparison of rice consumption behaviours and greenhouse gas emissions from rice production. J Clean Prod 172:2288–2300. https://doi.org/10.1016/j.jclepro.2017.11.182

Minas AM, Mander S, McLachlan C (2020) How can we engage farmers in bioenergy development? Building a social innovation strategy for rice straw bioenergy in the Philippines and Vietnam. Energy Res Soc Sci 70:101717. https://doi.org/10.1016/j.erss.2020.101717

Ngo DM, Truong TKN, Vo TTL, Nguyen TTT, Nguyen TP (2019) The current adoption of dry-direct seeding rice (DDSR) in Thailand and lessons learned for Mekong River Delta of Vietnam. CCAFS Working Paper No. 273. Wageningen, the Netherlands: CGIAR Research Program on Climate Change, Agriculture and Food Security (CCAFS)

Nguyen VH, Stuart AM, Nguyen TMP, Pham TMH, Nguyen NPT, Pame ARP, Sander BO, Gummert M, Singleton GR (2022a) An assessment of irrigated rice cultivation with different crop establishment practices in Vietnam. Sci Rep 12:1–11. https://doi.org/10.1038/s41598-021-04362-w

Nguyen VH, Balingbing C, Sandro J, Khandai S, Chea H, Songmethakrit T, Meas P, Hitzler G, Zwick W, Viriyangkura L, Bautista E, Gummert M (2022b) Precision land leveling for sustainable rice production: case studies in Cambodia, Thailand, Philippines, Vietnam, and India. Precision Agric 23:1633–1652. https://doi.org/10.1007/s11119-022-09900-8

Nguyen VH, Migo MV, Quilloy R, Chivenge P, Gummert M (2020) Life cycle assessment applied in rice production and residue management. In: Sustainable rice straw management. Springer Nature, pp 161‒174. https://doi.org/10.1007/978-3-030-32373-8_10

Nguyen VH, Sander BO, Quilty J, Balingbing C, Castalone AG, Romasanta R, Alberto MCR, Sandro JM, Jamieson C, Gummert M (2019) An assessment of irrigated rice production energy efficiency and environmental footprint with in-field and off-field rice straw management practices. Sci Rep 9:1–12. https://doi.org/10.1038/s41598-019-53072-x

Pame ARP, Vithoonjit D, Meesang N, Balingbing C, Gummert M, Nguyen VH, Singleton GR, Stuart AM (2023) Improving the sustainability of rice cultivation in Central Thailand with biofertilizers and laser land levelling. Agronomy 13:587. https://doi.org/10.3390/agronomy13020587

Pampolino MF, Witt C, Pasuquin JM, Johnston A, Fisher MJ (2012) Development approach and evaluation of the nutrient expert software for nutrient management in cereal crops. Comput Electron Agric 88:103–110. https://doi.org/10.1016/j.compag.2012.07.007

Phuong PTH, Nghiem TD, Thao PTM, Nguyen TD (2022) Emission factors of selected air pollutants from rice straw open burning in the Mekong Delta of Vietnam. Atmos Pollut Res 13:101353

Schut AGT, Giller KE (2020) Soil-based, field-specific fertilizer recommendations are a pipe-dream. Geoderma 380:114680. https://doi.org/10.1016/j.geoderma.2020.114680

Setyanto P, Makarim AK, Fagi AM, Wassmann R, Buendia LV (2000) Crop management affecting methane emissions from irrigated and rainfed rice in Central Java (Indonesia). Nutr Cycl Agroecosyst 58:85–93

Setyanto P, Pramono A, Adriany TA, Susilawati HL, Tokida T, Padre AT, Minamikawa K (2018) Alternate wetting and drying reduces methane emission from a rice paddy in Central Java, Indonesia without yield loss. J Soil Sci Plant Nutr 64:23–30. https://doi.org/10.1080/00380768.2017.1409600

Sharif MK, Butt MS, Anjum FM, Khan SH (2014) Rice bran: a novel functional ingredient. Crit Rev Food Sci Nutr 54:807–816

Shen J, Tang H, Liu J, Wang C, Li Y, Ge T, Jones DL, Wu J (2014) Contrasting effects of straw and straw-derived biochar amendments on greenhouse gas emissions within double rice cropping systems. Agr Ecosyst Environ 188:264–274. https://doi.org/10.1016/j.agee.2014.03.002

SIMAPRO (2019) SIMAPRO–LCA software. https://www.pre-sustainability.com/simapro

Singleton G, Quilloy R (2017) Helping Indonesia keep its rice bowl full. Rice Today 16(1):14–16 https://ricetoday.irri.org/helping-indonesia-keep-its-rice-bowl-full/

SRP (2021) Sustainable rice platform performance indicators for sustainable rice cultivation (January)

Stuart AM, Pame ARP, Vithoonjit D, Viriyangkura L, Pithuncharurnlap J, Meesang N, Suksiri P, Singleton GR, Lampayan RM (2018) The application of best management practices increases the profitability and sustainability of rice farming in the central plains of Thailand. Field Crop Res 220:78–87. https://doi.org/10.1016/j.fcr.2017.02.005

Thai NQ, Giang NK (2015) Vietnam needs new policy for rice production. VietNamNet. http://english.vietnamnet.vn/fms/special-reports/141324/vietnam-needs-new-policy-for-rice-production.html

Thu TN, Phuong LBT, Van TM, Hong SN (2016) Effect of water regimes and organic matter strategies on mitigating greenhouse gas emission from rice cultivation and co-benefits in agriculture in Vietnam. Int J Environ Sci Dev 7:85–90

Thuc LV, Corales RG, Sajor JT, Truc NTT, Hien PH, Ramos RE, Bautista E, Tado CJM, Ompad V, Son DT, Nguyen VH (2020) Rice-straw mushroom production. In: Sustainable rice straw management. Springer International Publishing, pp 93–109. https://doi.org/10.1007/978-3-030-32373-8_6

Tirol-Padre A, Minamikawa K, Tokida T, Wassmann R, Yagi K (2018) Site-specific feasibility of alternate wetting and drying as a greenhouse gas mitigation option in irrigated rice fields in Southeast Asia: a synthesis. Soil Sci Plant Nutr 64:2–13. https://doi.org/10.1080/00380768.2017.1409602

Trúc NTT, Hương NTQ (2016) Hiệu quả kinh tế sản xuất nấm rơm (Volvariella volvacea) ngoài trời ở huyện Long Mỹ, Hậu Giang. Tạp Chí Khoa Học Nông Nghiệp Việt Nam 15:210–219 (In Vietnamese with English abstract)

Tuan LA, Wehmeyer H, Connor M (2021) “One must do, five reductions” qualitative analysis of the diffusion and adoption constraints in Vietnam. Dev Pract 32:768–780. https://doi.org/10.1080/09614524.2021.1937556

Uno K, Ishido K, Nguyen Xuan L, Nguyen Huu C, Minamikawa, K (2020) Multiple drainage can deliver higher rice yield and lower methane emission in paddy fields in An Giang Province, Vietnam. Paddy Water Environ 19:623–634 https://doi.org/10.1007/s10333-021-00861-8

Vo TBT, Wassmann R, Mai VT, Vu DQ, Bui TPL, Vu TH, Dinh QH, Yen BT, Asch F, Sander BO (2020) Methane emission factors from Vietnamese rice production: pooling data of 36 field sites for meta-analysis. Clim 8:74. https://doi.org/10.3390/CLI8060074

Wassmann R, Nguyen VH, Yen BT, Gummert M, Nelson KM, Gheewala SH, Sander BO (2021) Carbon footprint calculator customized for rice products: concept and characterization of rice value chains in Southeast Asia. Sustain 14:315. https://doi.org/10.3390/su14010315

Wehmeyer H, Malabayabas A, San SS, Thu AM, Tun MS, Thant AA, Connor M (2022) Rural development and transformation of the rice sector in Myanmar: introduction of best management practices for sustainable rice agriculture. Outlook Agric 51:223–237. https://doi.org/10.1177/00307270221086008

Win EP, Win KK, Bellingrath-Kimura SD, Oo AZ (2021) Influence of rice varieties, organic manure and water management on greenhouse gas emissions from paddy rice soils. PLoS ONE 16:e0253755. https://doi.org/10.1371/journal.pone.0253755

Witt C, Mutters R, Buresh RJ, Pasuquin MJ (2005) New leaf color chart for effective nitrogen management in rice. Better Crop 89:36–39

Yang J, Zhou Q, Zhang J (2017) Moderate wetting and drying increases rice yield and reduces water use, grain arsenic level, and methane emission. Crop J 5:151–158. https://doi.org/10.1016/j.cj.2016.06.002

Yodkhum S, Sampattagul S, Gheewala SH (2018) Energy and environmental impact analysis of rice cultivation and straw management in northern Thailand. Environ Sci Pollut Res 25:17654–17664

Yuan S, Stuart AM, Laborte AG, Rattalino Edreira JI, Dobermann A, Kien LVN, Thúy LT, Paothong K, Traesang P, Tint KM, San SS, Villafuerte MQ, Quicho ED, Pame ARP, Then R, Flor RJ, Thon N, Agus F, Agustiani N, Deng N, Li T, Grassini P (2022) Southeast Asia must narrow down the yield gap to continue to be a major rice bowl. Nat Food 3:217–226. https://doi.org/10.1038/s43016-022-00477-z

Zossou E, Saito K, Assouma-Imorou A, Ahouanton K, Tarfa BD (2020) Participatory diagnostic for scaling a decision support tool for rice crop management in northern Nigeria. Dev Pract 31:11–26. https://doi.org/10.1080/09614524.2020.1770699

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this chapter

Cite this chapter

Nguyen-Van-Hung, Ha-An, N.T., Singleton, G.R., Connor, M. (2023). Carbon Footprint Reduction from Closing Rice Yield Gaps. In: Connor, M., Gummert, M., Singleton, G.R. (eds) Closing Rice Yield Gaps in Asia. Springer, Cham. https://doi.org/10.1007/978-3-031-37947-5_5

Download citation

DOI: https://doi.org/10.1007/978-3-031-37947-5_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-37946-8

Online ISBN: 978-3-031-37947-5

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)