Abstract

The state-of-the-art method to reduce CNC machine tool thermal errors is real-time error compensation based on the thermal error estimation models. However, it is difficult to establish a thermal error compensation model with good versatility, high accuracy, and strong robustness due to various manufacturing conditions and a thermally varying surrounding environment. It causes that thermal behaviour of the machine tools is nonlinear and varying in real time. Consequently, the pre-trained and non-adaptive model may not be accurate and robust enough for long-term application. The presented research shows a systematic adaptation technique to update the thermal error compensation model of a horizontal machining centre under varying conditions, which differ from the calibration test. System identification theory is applied to build a dynamic thermal error model for a horizontal machining centre based on calibration test. Linear parametric models of autoregressive with external input (ARX) present an established dynamic method, and its modelling and calculation speed are suitable for real-time applications. Additionally, process-intermittent probing and thermal error model are integrated into the machine management software of the horizontal machining centre to monitor and compensate for thermal errors at the tool centre point (TCP) in real time using C#/C++ programming language. The results show that the prediction accuracy measured as peak-to-peak values and the normalized root mean squared error of the thermal error compensation models are improved by up to 33% and 51%, respectively, when adaptive compensation model is applied.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

One of the most challenging issues in the manufacturing industry is continuous part quality maintenance by reducing machine tool thermal errors. The state-of-the-art method for minimizing thermal errors in CNC machine tools is real-time error compensation based on thermal error estimation models [1].

Numerous error compensation models have been proven to be effective of mitigating thermally induced errors using temperature sensor measurements. A thorough review of the thermal error modelling methods that have been investigated and applied is presented in [2]. The predicted accuracy and robustness of the thermal error model is a key factor here. Robustness reflects the holding capacity of predicted accuracy under various external conditions. It is an important indicator of the thermal error compensation effect on machine tools [3].

However, the low prediction accuracy and poor robustness of these models under varying manufacturing conditions and the thermally varying surrounding environment have also been recognised [4, 5]. The cause is that thermal error compensation models strongly depend on the characteristics of the training data. However, model training conditions cannot typically cover all of the machine working conditions that are necessary to derive an accurate and robust model due to limited resources and limited availability of machine time for testing. Furthermore, potential users of thermal error compensation technique (typically machine tool manufacturers) shy away because of the lengthy period of time required to characterize the thermal behavior of a machine tool. It takes many hours for a machine structure to reach its thermal steady state and then to cool to its original state. As a result, thermal error compensation models represent physics incompletely and the robustness in the prediction performance of thermal behaviour that differs from training phase may be poor. Therefore, various model adaptations have been developed to refine the prediction accuracy and robustness of the model according to continuous changes in machine operation status. This is especially essential in small-batch production, where the manufacturing processes change frequently and the pre-trained thermal error model is typically not robust enough.

A feasible strategy for improving robustness has been updating the model parameters periodically using process-intermittent probing to identify any changes in thermal errors at the tool centre point (TCP). Numerous on-machine measurement methods can be applied to provide thermally induced displacements as feedbacks for compensation model. Gao et al. [6] present state-of-the-art in-process and on-machine measurement systems and sensor technologies. As touch probe systems have become common accessories in a wide variety of precision machine tools, their application seems a promising solution for the adaptation of thermal error models. On-machine measurement (typically by touch probe) represents the common practice of using a machine tool to measure the workpiece while it is still on the machine rather than moving the workpiece to the metrology room. It significantly corrects geometric errors on the part before the part is removed from the machine tool. Consequently, it decreases the scrap parts. In principle, on-machine probing can be used for direct compensation of thermal error at the TCP thanks to intermittently measured resulting displacements at the machine tool TCP (e.g., a test mandrel clamped in the spindle with noncontact displacement sensors placed on the working table as shown in Sect. 2 or a touch probe in combination with a datum sphere mounted on the working table). Subsequently, the measured displacements can be superposed to the desired position of the particular axis. The significant benefit of the on-machine probing approach is that the thermal displacements that have to be compensated are directly available. Nevertheless, a sufficient sampling rate of the on-machine measurement has to be selected, as interruptions to the process lead to lower machine tool productivity.

An issue related to the updating the compensation model parameters periodically using on-machine measurements is the reduction in machine productivity, since the machining cycle may be unnecessarily interrupted during probing. Early methods used process-intermittent probing to constantly update the model. Mou [7] presented an adaptive error correction method using feature-based analysis techniques for machine tool error correction. Process-intermittent gauging and state observation techniques were integrated to track the thermal effect in real time and fine tune the error model coefficients as the cutting process proceeds. A multiple linear regression model was derived to identify the time-varying thermally induced errors and form the state observer model. However, these techniques were based on the conventional static thermal error model. As a result, the thermal error model thus developed may not accurately reveal the dynamic nature of the thermoelastic system.

Yang and Ni [8] proposed an adaptive model estimation of thermal errors based on a recursive dynamic modeling strategy. This approach significantly improved the accuracy and robustness of the thermal error model by considering the dynamic effects of machine thermo-elastic systems. Intermittent probing was carried out periodically using a sampling time of 3.5 min. Thus, the probing may occur when not required. Consequently, it decreases the machine productivity. Blaser et al. [9] developed a thermal error compensation of 5-axis machine tools that is extended by on-machine measurements. The compensation model predicts the thermally induced errors caused by the rotary axis C, environmental temperature change and cutting fluid. The information gained by the process intermittent probing is used to adaptively update the model parameters. During the compensation phase, periodic measurements are essential to control the required precision of the compensation model. Measurement interval times only from 5 to 60 min were tested in 5 min steps. It was proposed that the measurement cycle should be performed every 25 min or less to ensure stable compensation by the model. However, such periodic on-machine measurements significantly reduce the obtainable productivity of the machine tools. Furthermore, Zimmermann et al. [10] replaced periodically performed on-machine measurements with adaptive on-machine measurements which are triggered based on temperature measurements when unknown thermal conditions occur to optimize the trade-off between the precision and productivity of the proposed compensation model.

This paper presents a new insight into the adaptation of thermal error compensation models using on-machine measurements to improve the prediction performance of the compensation algorithm. In contrast to the previous research, this study is focused on wider range of the on-machine sampling interval from 30 to 180 min. The goal is to increase the sampling interval to minimize interruption of the machining process by intermittent probing. The relationship between compensation model accuracy, the sampling interval length, the size of the tolerance band and required number of model updates is investigated in detail. The rest of this paper is organized as follows. In Sect. 2, the machine tool and experimental setup are described. Section 3 deals with the modelling approach, thermal error model structure, and approximation quality expression. Furthermore, Sect. 3 involves the calibration of the model parameters and identification procedures. In Sect. 4, the adaptive compensation model is derived using process-intermittent probing. A brief summary is discussed in Sect. 5.

2 Thermal Error Experiments

The tested machine tool is a large horizontal machining centre with table dimensions of 1250 × 1250 mm, and a retractable spindle with a diameter of 112 mm was used to demonstrate the method. The machine tool has a spindle with 31 kW power and the maximal spindle speed is 6000 rpm. Basic heavy machine parts (table, palettes, longitudinal and transverse beds) are casted from grey iron, see [11]. The machine column is designed as a twin shell casting also made of grey iron with an optimized structure. The tested machining centre is placed in a machine tool producer’s shop floor, which is a non-air-conditioned room. The machining centre is equipped with a standard Siemens SINUMERIK 840D sl CNC controller and a unique programming environment (TOS Control management software). The thermal error model (see Sect. 3) is implemented in the TOS Control programming environment as an independent application developed in C#/C++ programming language.

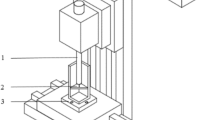

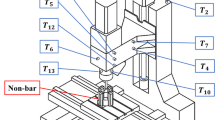

The large horizontal machining centre is equipped with temperature sensors (Pt100, Class A, 3850 ppm/K) placed close to the main heat sources by the machine tool manufacturer. Today, almost every spindle is equipped with sensors to monitor the bearing temperature, including the tested machine centre. Of all heat sources that lead to thermal distortion, the spindle is a dominant contributor to total thermal errors due to the large amount of heat generated by its high-speed revolutions and quick response inducing thermal errors at the TCP. Therefore, the thermal error compensation model will focus on the heat source represented by the spindle. The key input of the model is the temperature measured close to the spindle front bearing (ΔTin). Tests for thermal distortion caused by rotating spindles were carried out according to the ISO 230-3 international standard [12]. To measure relative displacements in the X, Y and Z directions between the TCP represented by a test mandrel (length, 125 mm; diameter, 40 mm) and the working table of the horizontal machining centre, non-contact eddy current displacement sensors with a resolution ratio of 0.1 μm were installed (sensor type PR6423, produced by Emerson [13]). Eddy current sensors are supported by a magnetic stand and the measurement point is placed at the side of the table to sense thermally induced displacements at the zero position of the retractable spindle position (W = 0 mm). The experimental setup on the horizontal machining centre per ISO 230-3 including the machine tool structure with the indicated kinematics is shown in Fig. 1.

Data were acquired using a cRIO 9024 programmable automation controller (PAC) [14] with LabVIEW software (the sampling rate was 1 s). Temperature sensors installed by the machine tool manufacturer and other NC data such as effective power, electric current, torque, feed rate, and motor temperatures were logged using OPC UA (Open Platform Communications United Architecture) communication between the machine controller and the PAC cRIO 9024.

A one-dimensional network of spindle excitation points was proposed for the Y-axis (the vertical position of the spindle stock on the column) with a constant W-axis position (retractable spindle position W = 0 mm). Spindle excitation was performed in 3 different linear Y-axis positions in total (Fig. 1). Tests with a constant spindle speed, along with a spindle speed spectrum test, were designed to validate the thermal error model and the adaptive compensation model using on-machine measurement (Table 1).

Each test in Table 1 was followed by a cooling phase until the machine tool was close to a steady state with the surrounding environment, which took several hours. As a result, one test was conducted per day. Data acquisition was only realized during the heating phase (working cycles according to Table 1). It is supposed that the compensation model is always updated by the first on-machine measurement at the beginning of each work shift when the machine tool is cooled down (in the morning). Thus, the initial error is removed and it is not necessary to measure during the cooling phase.

The heating phase of test no. 1 was chosen to identify a thermal error compensation model (see Sect. 3). Verification tests (tests no. 2 to no. 5) were carried out under different conditions than the calibration test. The spindle speed and the position of the heat source (the vertical position of the spindle stock on the column) varied during the verification tests; see Table 1.

3 Thermal Error Model for a Horizontal Machining Centre

A discrete transfer function (TF) is used to describe the link between the excitation and its response

The vector u(t) in Eq. (1) is the TF input vector in the time domain, y(t) is the output vector in the time domain, ε represents general TF in the time domain, e(t) is the disturbance value (further neglected). The difference form of a discrete TF (generally suitable for programming languages like Python or C#/C++) in the time domain is introduced in Eq. (2)

where n is the order of the TF numerator, m is the order of the TF denominator, m > n, k represents the examined time instant, k − n (k − m) is the n-multiple (m-multiple) delay in sampling frequency of the measured input vector (simulated output vector), an is the calibration coefficient of the TF input and bm is the calibration coefficient of the TF output.

Linear parametric models of autoregressive with external input (ARX) or outputs error (OE) identifying structures are used with the help of Matlab Identification Toolbox [15]. The linear parametric model ARX as an optimal model structure (with the best fitting quality and robustness) is discussed in [16] where MISO (multiple input single output) models handling with arbitrary TCP measurements are introduced. Excitations in the case of the applied TFs mean temperatures measured close to heat sinks or sources, and the responses stand for the linear deflections in the examined directions.

The approximation quality of the simulated behaviour is expressed by a local peak-to-peak approach

where p2p is the abbreviation for a peak-to-peak evaluation method, δZmea in Eq. (3) represents the measured output (thermal displacement at the TCP in the Z direction) and δZsim is the simulated (predicted) thermal displacement obtained by applying the thermal error compensation model. In this paper, the approximation quality of the identified compensation models is also expressed by the fit value, the normalized root mean squared error expressed as a percentage, see [15], defined as follows

The \({\overline{{\varvec{\delta}}{\varvec{Z}}} }_{{\varvec{m}}{\varvec{e}}{\varvec{a}}}\) stands for the arithmetic mean of the measured output (thermal displacement) over time. The fit represents a global approach to express the approximation quality of the compensation model, it is a percentage value where 100% would equal a perfect match of measured and simulated behaviours.

3.1 Identification of the Compensation Model

A thermal error compensation model is developed for large horizontal machining centre (see Sect. 2). As the spindle is a dominant contributor to total thermal errors, model predicts thermally induced displacements at the TCP caused by the spindle. It is a simple compensation model, other influences (linear axis etc.) on thermally induced errors at the TPC are not taken into account. To reduce the major thermal error of the horizontal machining centre (in the Z-axis direction), a compensation ARX model was calibrated on test no. 1 (see Table 1). The input is the temperature measured on the spindle front bearing (ΔTin) and the output is the displacement measured in the Z-axis direction (δZmea). The TF-based model of thermal displacement in the Z-axis direction is expressed by Eq. (5) as

where δZsim is the simulated thermal displacement in the Z-axis direction) and ε is the TF identified in the time domain.

The measured input (ΔTin), measured output (δZmea) and simulated output (δZsim) used in the identification process of the TF model are shown in Fig. 2 (all quantities are expressed in relative coordinates). Temperature fluctuations (see ΔTin in Fig. 2) are caused by the control of the cooling fluid circuit. The approximation quality is fit = 89% and p2p = 16.6 µm.

The stability of the identified TF model is expressed by the Linear Time Invariant (LTI) step response test shown in Fig. 3. System excitation represents the sudden change of the key temperature equal to 1 K (red curve in the graph in Fig. 3), and system response is the predicted displacement at the TCP in the Z-axis direction given by Eq. (5), see black curve in Fig. 3.

The established calibration coefficients an and bm of the identified 2nd order discrete TF are summarised in Table 2. The order of the TF was selected based on the best fit value, see Eq. (4).

3.2 Verification Tests Results

The model identified in Sect. 3.1 was applied to the heating phase of tests no. 2 to no. 5 (see Table 1). Figure 4 depicts the behaviour of the front bearing temperature ΔTin, ambient temperature ΔTamb behaviour over time, the position of the TCP in the Y-axis direction and the spindle speed during verification tests on the large horizontal machining centre. The data measured during the heating phases (active heat source represented by spindle rotation) of tests no. 2, 3, 4, 5 according to Table 1 are presented in Fig. 4. The cooling phases of each measurement are omitted, as the data acquisition was not realized during the cooling phases. Moreover, the heating phases of tests no. 2 to no. 5 are linked together in order to present the measured data in a single graph in Fig. 4. This data representation is in accordance with the intended adaptation of the compensation model using on-machine measurement presented in Sect. 4.

The resulting displacements at the TCP obtained by on-machine measurement can be employed as feedbacks for the compensation model to refine its prediction accuracy. Consequently, this leads to a lower sampling rate for the on-machine measurement. Since a manufacturing process begins basically from an initial alignment of the workpiece, the on-machine measurement is often the first task that must be performed. Subsequently, the compensation model is supposed to always be updated at the beginning of each work shift (see Sect. 4). Figure 5 depicts the thermal displacement measured at the TCP in the Z-direction (solid blue curve) and the predicted thermal displacement (solid red curve) of the large horizontal machining centre obtained from the TF model calculated by Eq. (5) for the verification tests no. 2 to no. 5. The data in Fig. 5 are presented analogously to Fig. 4 (linked heating phases of the verification tests without the cooling phases).

Approximation quality expressed by the fit value given by Eq. (4) is only 41.5%. The approximation quality expressed by the p2p value of the thermal error compensation model according to Eq. (3) is 64 µm for the verification tests. Identification of the TF-based model is derived from test no. 1 which was set at the zero position of the linear Y-axis (the lowest vertical position of the spindle stock on the column, Y = 0 mm). The model training conditions applied in Sect. 3.1 evidently differ from the machine tool working conditions during the verification tests no. 2 to no. 5, see Table 1.

Firstly, the position of the heat sources (the vertical position of the spindle stock on the column) varied during the verification tests. Secondly, the spindle speed also varied during the tests. Previous studies (e.g., [17, 18]) showed that a TF-based compensation model is capable of sustaining the high approximation quality (stability in prediction performance) in the event of a changeable spindle speed that differs from the training phase. However, in the previous studies mentioned above, the compensation model of a medium-sized CNC machining centre was investigated only in one spindle excitation position. On the contrary, the verification tests on a large horizontal machining were intended to excite the heat source, represented by the spindle, in various machining centre positions. It results in low compensation model prediction accuracy of thermal errors at the TCP in the Z direction, as shown in Fig. 5.

4 Adaptive Compensation Model

Due to the complexities of manufacturing processes, real machining conditions may not be identical to the experimental conditions used for the compensation model derivations shown in Sect. 3. Therefore, to increase the robustness of the prediction performance of thermal error Z-direction displacement, a process intermittent probing is used to adaptively update the model parameters (on-machine measurement with eddy current type displacement sensors and the test mandrel, see Sect. 2).

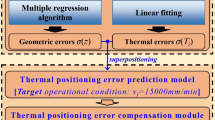

4.1 Principle of Model Adaptation

Adaptation of the compensation model is realised using the gain. The gain is defined as follows

where δZmea(tU) represents the measured thermal displacement in the Z-axis direction at times tU, δZsim(tU) is the simulated thermal displacement obtained by the thermal error compensation model according to Eq. (5), see Sect. 3, τ is the on-machine measurement sampling interval, and parameter tol is the size of the tolerance band of the residual error res (residuum res is given by Eq. (8), see below) at times tU..

The initial value of the gain in Eq. (6) is equal to 1. The simulated displacement calculated by the adaptive compensation model is defined as

where \({{\varvec{\delta}}{\varvec{Z}}}_{sim}\) is the original compensation model of thermal errors at the TCP in Z-axis direction calculated according to Eq. (5).

The residual error of the original compensation model (see Eq. (5)) is expressed as

Thus, the adaptive compensation model is only updated if

There are two adjustable parameters of the adaptive model. First, it is the sampling interval τ. The second is the selected tolerance band tol of the residual error res. This approach enables rapid updating of the original thermal error compensation models with minimal additional modelling effort, since only one quotient needs to be calculated (\(gai{n}_{tol}^{\tau }\)). Primarily, no special software (e.g., System Identification Toolbox™ for Matlab software [15]) is required to continually update the compensation model as it is needed for the adaptive model, which has to identify completely new set of transfer function parameters (see [9]). Consequently, the proposed method of model updating using a gain factor can be quickly and easily implemented into the standard CNC controller of the machining centre without additional costs (e.g., no industrial PC with software is required for the identification process of the transfer function parameters).

Moreover, the substantial advantage of the proposed solution is that the original compensation model parameters can remain unaffected, thus preserving model transparency. Instead, the gain is modified to multiply the original compensation model. Furthermore, the method also provides information on the required sampling frequency of the on-machine measurement and its effect on the resulting approximation quality of the updated model, which is discussed in Sect. 4.2.

4.2 Adaptive Compensation Results

The adaptive compensation model was tested for various values of the sampling interval τ. Specifically, the parameter τ was set as τ = {30, 60, 90, 120, 150, 180} minutes and for different values of the parameter tol (specifically for tol = {1, 3, 5, 10, 15, 20, 25} µm).

Figure 6 depicts the measured, simulated displacement in the Z-axis direction (identified in Sect. 3.1) and the predicted displacements by adaptive model with sampling interval values τ = 30 min and tolerance band tol = 10 µm. The black dashed line shows the value of the set tolerance band and the purple curve shows the absolute value of the residual displacement res; see Eq. (8). The red dotted lines indicate the sampling intervals when the condition in Eq. (9) is evaluated. The green dotted lines indicate moments when the compensation model was adapted according to Eq. (7). In this example, a significant reduction in the required number of the model updates (NoU) depending on the selected value of the parameter tol can be observed (red dotted lines vs. green dotted lines).

The results of the adaptive compensation model for the other tolerance band tol are shown in Fig. 7.

Figure 7 depicts the approximation quality of the simulated displacement in the Z-axis direction (dashed lines) and the approximation quality of the displacement calculated by the adaptive model depending on the selected value of the parameter tol at τ = 30 min. The yellow curve represents the required number of model updates (NoU) depending on the selected value of the parameter tol for the adaptive compensation model. As mentioned in Sect. 3.2, the approximation quality of the thermal behaviour during verification tests is expressed by the p2p value of the thermal error compensation model according to Eq. (6) is 64 µm (see black dashed line in Fig. 7) and the fit value is only 42% (see red dashed line in Fig. 7). The fit value for the adaptive model according to Eq. (7) increases from 78% to 92% (solid red line in Fig. 7) depending on the tolerance band tol (from 25 µm to 1 µm). The p2p value for the adaptive model is reduced from 51 µm to 45 µm on the tolerance band tol (from 25 µm to 1 µm). The application of the adaptive model has a positive effect on the resulting fit value and the p2p value, as expected.

The dependence of the required number of model updates NoU on the sampling interval values τ and the tolerance band tol is shown in Fig. 8. The dependence of the number of the model updates NoU on the values of the τ and tol in Fig. 8 reveals that the maximum model updates NoU is 58 for the shortest (tested) sampling interval τ = 30 min and the strictest (tested) tolerance band tol = 1 µm as expected. The minimum number of model updates NoU is 5 for the longest sampling interval τ = 240 min and the most benevolent tolerance band tol = 25 µm, also as expected. The number of model updates NoU increases significantly for the strict tolerance band (especially 5 µm and smaller).

Similar graphs for the approximation quality expressed by fit and p2p are shown in Fig. 9 and Fig. 10. The dependence of the approximation quality on the sampling interval values τ and the tolerance band tol is not unambiguous. For the global approximation quality expressed by fit, the results are always better with a smaller sampling interval (the smaller the sampling interval, the higher the fit value). However, the local approximation quality expressed by the peak-to-peak (p2p) method can be worse in some cases, as shown in Fig. 10. Taken together, these findings suggest that the length of the sampling interval has to be selected carefully and the shorter sampling interval is not always beneficial. The relationships between length of the sampling interval, number of model updates, tolerance band and achievable accuracy were detailly explored for particular adaptive compensation model of the horizontal machining centre. This analysis enables to select proper on-machine sampling interval and tolerance band tol to achieve required accuracy of the machine tool (compensation model) and to ensure high productivity of the machining process without excessive interruption by on-machine probing.

Generally, specific thermal error compensation model has to be developed for particular machine tools depending on the machine tool structure, its size, heat sources and heat sinks etc. However, the proposed updating of the compensation model using a gain factor can be universally applied as extension for this particular (original) compensation model of thermally induced errors for particular machine tool. Thus, the adaptive compensation model using a gain factor will be always based on this ‘original’ compensation model for a particular machine tool. However, the method of updating the model using a gain factor is fully transferable. Furthermore, it can be assumed that the length of the sampling interval, number of model updates and the resulting precision of the adaptive model will be significantly influenced by the prediction accuracy and the robustness of the ‘original’ compensation model.

5 Conclusions

This paper investigates the adaptation of thermal error compensation models using on-machine measurements to improve prediction performance. Specifically, the relationships between compensation model accuracy, the sampling interval length, the size of the tolerance band and required number of model updates are discussed in detail. The study is focused on wider range of the on-machine sampling interval from 30 to 180 min. The goal is to increase the sampling interval to minimize interruption of the machining process by intermittent probing.

First, a TF-based model was built to compensate for the thermal errors of the large horizontal machining centre caused by the spindle. Tests with spindle excitation were performed in 3 different linear Y-axis positions in total. TF-based model identification is derived from measurement at the lowest linear Y-axis position. Furthermore, the developed model was applied in verification tests with the spindle excitation in different Y-axis positions. This resulted in a low prediction accuracy of thermal errors at the TCP in the Z-axis direction. Consequently, an adaptive model was proposed using on-machine measurements and gain factor technique. The presented findings confirm that the prediction accuracy measured as peak-to-peak values and the normalized root mean squared error of the thermal error compensation models are significantly improved by up to 33% (from 64 µm to 43 µm) and 51% (from 78% to 92%) respectively when adaptive compensation model is applied using on-machine measurement. Future studies should concentrate on experimental verification of the proposed compensation model updating using a gain factor for different machine tools (thermal error compensation models) to show if the results are transferable. Additional data collection would help to determine if the relationship between the length of the sampling interval, number of model updates, tolerance band and achievable accuracy shows similar trends.

References

Mayr, J., et al.: Thermal issues in machine tools. CIRP Ann. Manuf. Technol. 61(2), 771−791 (2012)

Li, Y., Yu, M., Bai, Y., Hou, Z., Wu, W.: A review of thermal error modeling methods for machine tools. Appl. Sci. 11(11), 5216 (2021)

Liu, H., Miao, E.M., Wei, X.Y., Zhuang, X.D.: Robust modeling method for thermal error of CNC machine tools based on ridge regression algorithm. Int. J. Mach. Tools Manuf. 113(2017), 35–48 (2017)

Mareš, M., Horejš, O., Hornych, J., Smolík, J.: Robustness and portability of machine tool thermal error compensation model based on control of participating thermal sources. J. Mach. Eng. 13(1), 4–36 (2013)

Miao, E.-M., Gong, Y.-Y., Niu, P.-C., Ji, C.-Z., Chen, H.-D.: Robustness of thermal error compensation modeling models of CNC machine tools. Int. J. Adv. Manuf. Technol. 69(9–12), 2593–2603 (2013). https://doi.org/10.1007/s00170-013-5229-x

Gao, W., et al.: On-machine and in-process surface metrology for precision manufacturing. CIRP Ann. 68(2), 843–866 (2019)

Mou, J.: A method of using neural networks and inverse kinematics for machine tools error estimation and correction. ASME J. Manuf. Sci. Eng. 119(2), 247–254 (1997)

Yang, H., Ni, J.: Adaptive model estimation of machine-tool thermal errors based on recursive dynamic modeling strategy. Int. J. Mach. Tools Manuf. 45(1), 1–11 (2005). https://doi.org/10.1016/j.ijmachtools.2004.06.023

Blaser, F., Pavliček, F., Mori, K., Mayr, J., Weikert, S., Wegener, K.: Adaptive learning control for thermal error compensation of 5-axis machine tools. J. Manuf. Syst. 44(2), 302–309 (2017)

Zimmermann, N., Breu, M., Mayr, J., Wegener, K.: Autonomously triggered model updates for self-learning thermal error compensation. CIRP Ann. 70(1), 431–434 (2021)

WHT 110 (C). https://www.tosvarnsdorf.cz/files/machines/tos-katalog-wht-2017-aj.pdf. TOS VARNSDORF a. s., Accessed 21 Sept 2022

ISO 230-3 - Test Code for Machine Tools - Part 3: Determination of Thermal Effects, Geneva (2020)

Eddy Current Displacement Transducer Specifications. https://www.emerson.com/documents/automation/specifications-sheet-eddy-current-displacement-transducer-specifications-pr-6423-003-0d1-asset-optimization-en-39116.pdf. Emerson, Accessed 19 Oct 2022

NI cRIO-9024 User manual and specifications. https://www.ni.com/pdf/manuals/375233f.pdf. National Instruments. Accessed 25 Oct 2022

Ljung, L.: System Identification Toolbox™ User’s Guide. The MathWorks, Inc. (2021)

Mayr, J., et al.: An adaptive self-learning compensation approach for thermal errors on 5-axis machine tools handling an arbitrary set of sample rates. CIRP Ann. 67(1), 551–554 (2018). ISSN 0007-8506

Mares, M., et al.: Thermal error compensation of a 5-axis machine tool using indigenous temperature sensors and CNC integrated Python code validated with a machined test piece. Precis. Eng. 66(1) (2022). ISSN 0141-6359. https://doi.org/10.1016/j.precisioneng.2020.06.010

Horejs, O., et al.: Compensation of thermally induced errors in five-axis computer numerical control machining centers equipped with different spindles. J. Manuf. Sci. Eng. 144(10), 101009-1–101009-10 (2022). ISSN 1087-1357. https://doi.org/10.1115/1.4055047

Acknowledgement

This work was supported by the Grant Agency of the Czech Technical University in Prague, grant no. SGS22/159/OHK2/3T/12. The results are also obtained thanks to previous funding support from the Czech Ministry of Education, Youth and Sports under the project CZ.02.1.01/0.0/0.0/16_026/0008404 “Machine Tools and Precision Engineering” financed by the OP RDE (ERDF), co-financed by the European Union.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Horejš, O., Mareš, M., Straka, M., Švéda, J., Kozlok, T. (2023). Adaptive Thermal Error Compensation Model of a Horizontal Machining Centre. In: Ihlenfeldt, S. (eds) 3rd International Conference on Thermal Issues in Machine Tools (ICTIMT2023). ICTIMT 2023. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-34486-2_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-34486-2_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-34485-5

Online ISBN: 978-3-031-34486-2

eBook Packages: EngineeringEngineering (R0)