Abstract

In machine tools, it is important to maintain accuracy against heat in the entire machining space. The reduction of thermal displacement is achieved by measuring it accurately and then clarify the relationship between the temperature change and the thermal deformation and then creating the prediction and compensation model or applying the countermeasure to suppress the thermal deformation. To solve this issue, the authors have developed methods to measure thermal deformation in two-dimensional space using a laser tracker and cameras. A laser tracker method achieved higher accuracy and smaller measurement uncertainty. Vision-based methods achieved equivalent measurement accuracy to a laser tracker method at shorter measurement time and lower cost. To compensate thermal displacement, convolutional neural network model was developed. Thermal displacement was predicted from temperature sensors with higher accuracy than conventional models. These methods contribute to the development of higher precision machine tools.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Thermal displacement is one of the most significant factors that degrade machine accuracy. With the progress of process integration and automation of machining process, it has become more important to maintain dimensional and geometric accuracy over the entire machining space of a machine during operation. The reduction of thermal displacement is achieved by measuring it and thermal deformation accurately and clarify the relationship between the temperature change and the thermal deformation and then creating the prediction and compensation model or applying the countermeasure to suppress the thermal deformation. Many studies have been conducted about reduction of thermal displacement [1]. The laser tracker was used to measure the thermal displacement of 5-axis machine tool [2]. About compensation for thermal displacement, the method using temperature sensors [3] and NC unit internal data [4] are developed and robust and accurate prediction models are developed for compensation [5, 6]. To reduce thermal deformation, isolation of heat sources, reduction of generated heat and equalization of temperature distribution are applied [7].

We have developed both measurement method and compensation method of tool trajectory. A laser tracker and vision cameras are used to measure the thermal displacement on a two-dimensional plane to visualize thermal deformation. Deep-learning is used for accurately predicting and compensating thermal displacement from temperature sensors. A measurement using a laser tracker achieved higher accuracy and smaller measurement uncertainty than the previous method. A measurement using vision cameras achieved shorter measurement time and lower cost than a laser tracker method. Deep-learning prediction model achieved higher accuracy than conventional models. In this paper, we present the detail of these methods.

2 Thermal Displacement Prediction by Deep-Learning

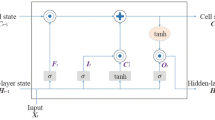

2.1 Convolutional Neural Network (CNN)

By using convolutional neural network (CNN), a type of deep learning, thermal displacement can be predicted with higher accuracy [8]. CNN is a commonly used method in the field of image recognition, which extracts image features by convolution and pooling process. Figure 1 shows a conceptual diagram of a CNN. In predicting thermal displacement, temperature data of machine structure is used as input and displacement as output.

2.2 Thermal Sensitivity

To predict thermal displacement from temperature data, it is necessary to know the contribution of temperature variation of the machine structure to thermal displacement and install temperature sensors at the large contribution. Therefore, we defined the relationship between temperature and thermal displacement as thermal sensitivity as follows:

where W is the thermal sensitivity, K is the stiffness matrix of the structure, and H is the temperature-load transformation matrix expressed as:

where p is the load applied to the machine structure by the temperature variation and \(\Delta t\) is the temperature variation.

The thermal sensitivity was calculated on a turning center. Figure 2 shows the thermal sensitivity in the X-axis direction. The red area shows the displacement of the turret and headstock away from each other as the temperature increases, and the blue area is in the opposite direction.

2.3 The Prediction Results

Figure 3 shows the performance of the CNN. By using temperature data from 10 locations, calculations were performed with ridge regression, non-convolutional NN and CNN. The CNN prediction error was 59.5% smaller than ridge regression and 71.6% smaller than non-convolutional NN.

Figure 4 shows the learning results. The prediction result of the evaluation data shows small error. The results show that CNN compensations can reduce the thermal displacement by 81.2% and 88.5% than non-compensation results.

3 Thermal Deformation Measurement on a Two-Dimensional Trajectory

3.1 Principle of Error Estimation

Table 1 shows the geometric error parameter to be identified as an example of the measurement on the YZ plane of a vertical machining center. The two-dimensional trajectory can be calculated by using them. The purpose of the algorithm is to identify them for every point of measurement range, (y1, . , yNy in Y-axis and z1, . , zNz in Z-axis). (y0, z0) are the reference point where all geometric errors are defined zero [9]. EYY(yj) are defined as the values measured at z = z0.

The measurement is taken in YZ plane with the laser tracker. As shown in Fig. 5 a retroreflector attached to the spindle is positioned at every stop position \({\mathbf{P}}_{\mathbf{n}}^{\mathbf{*}}\) = [yj, zk]T(n = 1,…, N) and the distance d0 (n = 1,…, N) between the tracker and the retroreflector is measured. The 2D positioning error \(\Delta {\mathbf{P}}_{{\mathbf{n}}}\) for each command position can be expressed as follows by using the symbols in Table 1.

With these definitions, the parameters in Table 1 can be identified by solving the following problem.

where, Q = [yq, zq]T is the tracker position and d0 is the dead path length. e is unknown values consisting of Q, d0, and parameters in Table 1. (\(\Delta\)y0, \(\Delta\)z0) is defined as the displacement of reference point. The assumption that the tracker position Q is constant throughout the experiment leads to increased uncertainty [2]. By these additional parameters, the tracker position can be handled as a constant. (\(\Delta\)y0, \(\Delta\)z0) is directly measured with a displacement sensor and then uncertainty is greatly reduced.

3.2 Experimental Results

Thermal deformation in the YZ plane of vertical machining center was measured. Figure 6 shows the configuration of the machine. The following measurements are performed at each measurement cycle. The distance between the tracker and the retroreflector was measured at every stop position along the rectangular trajectory shown in Fig. 5. EYY is measured directly by the tracker at the tracker’s Z position and EAY is measured by a level simultaneously. EZZ is measured at the tracker’s Y position. (\(\Delta \)y0, \(\Delta \)z0) is measured directly by displacement sensors. The above measurements were taken twice at one-hour intervals while the Z-axis was moving back and forth at the maximum speed, and then twice again at one-hour intervals while the machine was stopped. Figure 7 shows the experimental result and calculated 2D trajectory. The estimated trajectory is shifted to Z + direction due to heat generated by Z-axis movement. At the same time, Z-axis is tilted to the Y- direction. This indicates that heat generated by Z-axis movement caused thermal deformation of the machine column.

4 Vision-Based Machine Accuracy Measurement

4.1 Displacement Measurement Using Vision Camera

Figure 8 shows the principle of displacement measurement by camera. The deviation in the image due to camera movement is measured as a displacement. The grid intersection is defined as a target and the amount of movement is defined as the displacement. Figure 9 shows the process of detecting an intersection of the grid.

4.2 Accuracy Measurement Using Vision Camera

Figure 10 shows the setup to measure the displacement in the XY-plane. The camera is mounted on the spindle of the machine tool. Move the camera in the X-direction while overlapping the imaging range by 1mm and repeat capturing the image. The geometric accuracy is measured by identifying the displacement x, y and angle θ in the XY-plane and the displacement is calculated as follows [11]:

Figure 11 shows the setup for multiple cameras to obtain a higher accuracy of angular deviation. The two-dimensional positional error \(\Delta p_{E}\) for each command can be described as follows:

The relationship among the measurement result pd, the position of each camera xcam, the command position pcmd, the positioning error of the machine \(\Delta p_{{\text{E}}}\) and the measurement target xtgt can be described as follows:

The geometric error parameters are obtained to solve the minimalize problem.

where e represents all the parameters obtained from Eq. 10 noted in Table 2. N represents the number of measurements. The squareness error EC(0X)Y can be estimated by pre-calibration of the camera position.

4.3 Two-Dimensional Thermal Displacement Measurement Under the Ambient Temperature Change

The thermal displacement of a two-dimensional plane is measured under the ambient temperature change. Figure 12 shows the results and comparison to our previous method using a tracker [8]. The results tend to be in good agreement. The measurement time was about twice as fast as the previous method by a tracker.

Two-dimensional thermal deformation measurement results. (a) laser-based method [8], (b) vision-based method.

5 Conclusion

By using deep learning model, thermal displacement can be predicted with higher accuracy. The thermal displacement on a two-dimensional plane can be measured in a short time with high accuracy by using a laser tracker. Furthermore, vision cameras can measure thermal displacement in a shorter time and at a lower cost. Two-dimensional displacement can be used to see thermal deformation of the machine structure. Thermal displacement is caused by thermal deformation of machine structures by temperature variations. Therefore, these methods will clarify the root causes of thermal displacement and contribute to the development of machine tools with thermally robust and high accuracy.

References

Mayr, J., et al.: Thermal issues in machine tools. CIRP Ann. Manuf. Technol. 61(2), 771–791 (2012)

Ibaraki, S., Blaser, P., Shimoike, M., Takayama, N., Nakaminami, M., Ido, Y.: Measurement of thermal influence on a two-dimensional motion trajectory using a tracking interferometer. CIRP Ann. Manuf. Technol. 65(1), 483–486 (2016)

Moriwaki, T., Shamoto, E.: Analysis of thermal deformation of an ultraprecision air spindle system. CIRP Ann. Manuf. Technol. 47(1), 315–319 (1998)

Brecher, C., Hirsch, P., Weck, M.: Compensation of thermo-elastic machine tool deformation based on control internal data. CIRP Ann. Manuf. Technol. 53(1), 299–304 (2004)

Moriwaki, T., Shamoto, E., Kawano, M.: Estimation of thermal deformation of machine tool by applying neural network (improvement of estimation accuracy by utilizing time-series data of temperature on machine surfaces). Trans. Japan Soc. Mech. Eng. Ser. C 61(584), 1691–1696 (1995). (in Japanese)

Mayr, J., Blaser, P., Ryser, A., Hernández-Becerro, P.: An adaptive self learning compensation approach for thermal errors on 5-axis machine tools handling an arbitrary set of sample rates. CIRP Ann. Manuf. Technol. 67(1), 551–554 (2018)

Ito, Y.,: Thermal Deformation in Machine Tools. McGraw-Hill books, New York. ISBN: 978–0–07–163517–2 (2010)

Fujishima, M., Narimatsu, K., Irino, N., Ido, Y.: Thermal displacement reduction and compensation of a turning center. CIRP J. Manuf. Sci. Technol. 22, 111–115 (2018)

Mori, M., Irino, N., Shimoike, M.: A new measurement method for machine tool thermal deformation on a two-dimensional trajectory using interferometer. CIRP Ann. Manuf. Technol. 68(1), 551–554 (2019)

Ibaraki, S., Knapp, W.: Indirect measurement of volumetric accuracy for three-axis and five-axis machine tools: a review. Int. J. Autom. Technol. 6(2), 110–124 (2012)

Irino, N., Shimoike, M., Mori, K., Yamaji, I., Mori, M.: A vision-based machine accuracy measurement method. CIRP Ann. Manuf. Technol. 69, 445–448 (2020)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Ethics declarations

This article is a keynote contribution and as such non peer-reviewed.

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Ota, K., Mori, M., Irino, N. (2023). Development of Thermal Displacement Prediction Model and Thermal Deformation Measurement Methods. In: Ihlenfeldt, S. (eds) 3rd International Conference on Thermal Issues in Machine Tools (ICTIMT2023). ICTIMT 2023. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-34486-2_1

Download citation

DOI: https://doi.org/10.1007/978-3-031-34486-2_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-34485-5

Online ISBN: 978-3-031-34486-2

eBook Packages: EngineeringEngineering (R0)