Abstract

In this study, waste clay brick powder (CBP) from a Danish recycling plant was studied with the aim of using the material as a partial cement replacement to reduce the need for cement in cementitious products. The focus is on the fineness of the CBP and its influence on the compressive strength, reactivity of the CBP, and phase development of cement pastes containing CBP over time.

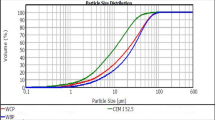

The CBP was characterized with respect to mineralogy, Loss on Ignition and thermogravimetric analysis (TGA), particle density, Frattini test, and particle size distribution. The powders were produced by ball milling or disc milling the brick waste, and, thus, CBPs based on the same raw material but with different particle size distributions were produced.

Mortar specimens were produced with two CBPs, which were based on the same raw material: CBP-C (coarser powder) and CBP-F (finer powder) added in fractions of 0, 10, 20, and 30 wt% to analyse the effect of the powder fineness on the compressive strength at 28 days. The results showed that the reference (0 wt%) and 10 wt% replacement levels obtained the same compressive strength. Regarding the fineness, the addition of 30 wt% CBP-F resulted in a slightly higher compressive strength compared to that with 30 wt% CBP-C.

The reactivity and phase development of the CBP was further studied in cement paste samples containing 0 wt% (reference) and 20 wt% CBP. The pastes were studied using X-ray diffraction (XRD) and TGA at different curing times. The TGA measurements revealed a higher amount of bound water for the pastes containing CBP (normalized to the clinker content). From the XRD measurements, the development of mono-carbonate exceeded the formation of hemi-carbonate, which could explain the higher amount of bound water.

Overall, it was found that replacement levels of 10–20 wt% of cement with CBP resulted in good compressive strength of the mortar specimens, which means that it seems possible to replace up to 20 wt% of the cement in cementitious products. However, further research is necessary and longer curing times would be interesting to study.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Monteiro, P.J.M., Miller, S.A., Horvath, A.: Towards sustainable concrete. Nat. Mater. 16, 698–699 (2017). https://doi.org/10.1038/nmat4930

Yang, K.H., Jung, Y.B., Cho, M.S., Tae, S.H.: Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 103, 774–783 (2015). https://doi.org/10.1016/j.jclepro.2014.03.018

Nygaard Madsen, M.L., Kiilerich, O., Nissen, A.L., Nissen, E.L.: Affaldsstatistik 2018 (2020)

Walker, R., Pavía, S.: Physical properties and reactivity of pozzolans, and their influence on the properties of lime-pozzolan pastes. Mater. Struct. Constr. 44, 1139–1150 (2011). https://doi.org/10.1617/s11527-010-9689-2

Zhao, Y., Gao, J., Liu, C., Chen, X., Xu, Z.: The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod. 242, 118521 (2020). https://doi.org/10.1016/j.jclepro.2019.118521

Shao, J., Gao, J., Zhao, Y., Chen, X.: Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 213, 209–215 (2019). https://doi.org/10.1016/j.conbuildmat.2019.03.307

Zhao, Y., Gao, J., Xu, Z., Li, S., Luo, X., Chen, G.: Long-term hydration and microstructure evolution of blended cement containing ground granulated blast furnace slag and waste clay brick. Cem. Concr. Compos. 118, 103982 (2021). https://doi.org/10.1016/j.cemconcomp.2021.103982

Wong, C.L., Mo, K.H., Yap, S.P., Alengaram, U.J., Ling, T.C.: Potential use of brick waste as alternate concrete-making materials: a review. J. Clean. Prod. 195, 226–239 (2018). https://doi.org/10.1016/j.jclepro.2018.05.193

He, Z., et al.: Research progress on recycled clay brick waste as an alternative to cement for sustainable construction materials. Constr. Build. Mater. 274, 122113 (2021). https://doi.org/10.1016/j.conbuildmat.2020.122113

Likes, L., Markandeya, A., Haider, M.M., Bollinger, D., McCloy, J.S., Nassiri, S.: Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. J. Clean. Prod. 364, 132651 (2022). https://doi.org/10.1016/j.jclepro.2022.132651

Liu, Q., Li, B., Xiao, J., Singh, A.: Utilization potential of aerated concrete block powder and clay brick powder from C&D waste. Constr. Build. Mater. 238, 117721 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117721

Ge, Z., Wang, Y., Sun, R., Wu, X., Guan, Y.: Influence of ground waste clay brick on properties of fresh and hardened concrete. Constr. Build. Mater. 98, 128–136 (2015). https://doi.org/10.1016/j.conbuildmat.2015.08.100

Grellier, A., Bulteel, D., El Karim Bouarroudj, M., Rémond, S., Zhao, Z., Courard, L.: Alternative hydraulic binder development based on brick fines: influence of particle size and substitution rate. J. Build. Eng. 39, 102263 (2021). https://doi.org/10.1016/j.jobe.2021.102263

Scrivener, K., Snellings, R., Lothenbach, B.: A Practical Guide to Microstructural Analysis of Cementitious Materials. CRC Press, New York (2018). https://doi.org/10.1201/b19074

Jensen, E.: The typical Danish Brick. Kgl. Vet.-Og Landbohøjsk. Årsskrift. 53–63 (1978)

Navrátilová, E., Rovnaníková, P.: Pozzolanic properties of brick powders and their effect on the properties of modified lime mortars. Constr. Build. Mater. 120, 530–539 (2016). https://doi.org/10.1016/j.conbuildmat.2016.05.062

Baronio, G., Binda, L.: Study of the pozzolanicity of some bricks and clays. Constr. Build. Mater. 11, 41–46 (1997). https://doi.org/10.1016/S0950-0618(96)00032-3

Tironi, A., Trezza, M.A., Scian, A.N., Irassar, E.F.: Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 37, 319–327 (2013). https://doi.org/10.1016/j.cemconcomp.2013.01.002

Rahhal, V.F., et al.: Complex characterization and behavior of waste fired brick powder-Portland cement system. Mater. (Basel) 12, 1–20 (2019). https://doi.org/10.3390/ma12101650

Ulukaya, S., Yüzer, N.: Assessment of pozzolanicity of clay bricks fired at different temperatures for use in repair mortar. J. Mater. Civ. Eng. 28, 04016052 (2016). https://doi.org/10.1061/(asce)mt.1943-5533.0001560

Pitarch, A.M., et al.: Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements. J. Clean. Prod. 279, 123713 (2021). https://doi.org/10.1016/j.jclepro.2020.123713

Wu, H., Liang, C., Wang, C., Ma, Z.: Properties of green mortar blended with waste concrete-brick powder at various components, replacement ratios and particle sizes. Constr. Build. Mater. 342, 128050 (2022). https://doi.org/10.1016/j.conbuildmat.2022.128050

Justnes, H.: Performance of SCMs – chemical and physical principles. In: 2nd International Conference on Sustainable Building Materials, pp. 1–19 (2019)

Acknowledgment

Grundejernes Investeringsfond (GI) and Danielsens Fond are acknowledged for the financial support for this study, which is part of the project “Reuse of waste clay brick powder as partial cement replacement”. The waste bricks were kindly provided by Norrecco, Denmark.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bertelsen, I.M.G., Kahr, S.A., Kunther, W., Ottosen, L.M. (2023). Clay Brick Powder as Partial Cement Replacement. In: Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D. (eds) International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-based Materials and Concrete Structures. SynerCrete 2023. RILEM Bookseries, vol 44. Springer, Cham. https://doi.org/10.1007/978-3-031-33187-9_14

Download citation

DOI: https://doi.org/10.1007/978-3-031-33187-9_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-33186-2

Online ISBN: 978-3-031-33187-9

eBook Packages: EngineeringEngineering (R0)