Abstract

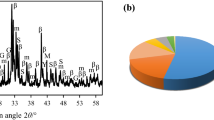

The article deals with the role of supplementary cementitious materials (SCMs) on the properties of laboratory belite-rich cements prepared from low-energy clinker doped with SO3. The low lime saturation factor (LSF) clinker with belite as the main phase was synthesized at 1350 °C using industrial raw materials. Alite/belite ratio is opposite to that of ordinary Portland cement (OPC). ß-C2S and M1 alite are the main modifications in doped clinkers. Cements were prepared by grinding clinkers to 400 m2/kg fineness in a laboratory ball mill. Replacement of 10, 20 and 30 wt.% of calcined clay, ground limestone, blast-furnace slag, ground glass and 5, 10 and 15 wt.% of silica fume were tested. Along with clinker properties, early properties of cement pastes and mortars were studied by isothermal calorimetry. Strength development of mortars were monitored after 2, 7, 28 and 90 days. Heat flow development during early hydration is strongly affected by SCMs, as seen in the position and intensities of aluminate, silicate, second aluminate and ettringite to monosulfate (AFt-AFm) conversion peaks. Despite low alite content, the cements have decent early and good long-term strengths, even at higher replacement levels. Binary combinations of OPC with calcined clay, blast-furnace slag or ground grass gave the best results. The introduction of such cements would significantly decrease the CO2 emissions and energy demand and partly save the primary sources of limestone.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Scrivener, K., Martinera, F., Bishnoi, S., Maity, S.: Calcined clay limestone cements (LC3). Cem. Concr. Res. 114(1), 49–56 (2018)

Juenger, M.C.G., Bernal, S.A., Snellings, R.: Supplementary cementitious materials: new sources, characterization, and performance insights. Cem. Concr. Res. 122, 257–273 (2019)

Tushar, Q., Bhuiyan, M.A., Zhang, G., Tasmin, T.: Application of a harmonized life cycle assessment method for supplementary cementitious materials in structural concrete. Constr. Build. Mater. 316, 125850 (2022)

Maier, M., Beuntner, N., Thienel, C.: Mineralogical characterization and reactivity test of common clays suitable as supplementary cementitious material. Appl. Clay Sci. 20, 105990 (2021)

Magni Darwich Higuchi, A., Gorett dos Santos Marques, M., Farias Ribas, L., Pereira de Vasconcelos, R.: Use of glass powder residue as an eco-efficient supplementary cementitious material. Constr. Build. Mater. 304, 124640 (2021)

Navarrete, I., Kurama, Y., Escalona, N., Lopez, M.: Impact of physical and physicochemical properties of supplementary cementitious materials on structural build-up of cement-based pastes. Cem. Concr. Res. 130, 105994 (2020)

Snellings, R.: Assessing, understanding and unlocking supplementary cementitious materials. RILEM Tech. Lett. 1, 50 (2016)

Al-Shmaisani, S., Kalina, R.D., Douglas Ferron, R., Juenger, M.C.G.: Critical assessment of rapid methods to qualify supplementary cementitious materials for use in concrete. Cem. Concr. Res. 153, 106709 (2022)

Scrivener, K.L., et al.: TC 238-SCM: hydration and microstructure of concrete with SCMs: state of the art on methods to determine degree of reaction of SCMs. Mater. Struct. 48(4), 835–862 (2015)

Staněk, T., Sulovský, P.: Active low-energy belite cement. Cem. Concr. Res. 68, 203–210 (2015)

Boháč, M., et al.: The role of Li2O, MgO and CuO on SO3 activated clinkers. Cem. Concr. Res. 152 (2022)

Scrivener, K.L., John, V.M., Gartner, E.M.: Eco-efficient cements: potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 114, 2–26 (2018)

Odigure, J.O.: Grindability of cement clinker from raw mix containing metallic particles. Cem. Concr. Res. 29(3), 303–307 (1999)

de Souza, V.C.G., Koppe, J.C., Costa, J.F.C.L., Vargas, A.L.M., Blando, B., Hübler, R.: The influence of mineralogical, chemical and physical properties on grindability of commercial clinkers with high MgO level. Cem. Concr. Res. 38(8–9), 1119–1125 (2008)

Genç, Ö., Benzer, A.H.: Single particle impact breakage characteristics of clinkers related to mineral composition and grindability. Mater. Eng. 22, 1160–1165 (2009)

Bullard, J.W., et al.: Mechanisms of cement hydration. Cem. Concr. Res. 41(12), 1208–1223 (2011)

Boháč, M., Palou, M., Novotný, R., Másilko, J., Všianský, D., Staněk, T.: Investigation on early hydration of ternary Portland cement-blast-furnace slag-metakaolin blends. Constr. Build. Mater. 64, 333–341 (2014)

Acknowledgements

Thanks are due to Czech Science Foundation project no. 23-05122S.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Boháč, M., Kubátová, D., Zezulová, A., Staněk, T. (2023). Properties of Belite-Rich Cement with Supplementary Cementitious Materials. In: Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D. (eds) International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-based Materials and Concrete Structures. SynerCrete 2023. RILEM Bookseries, vol 44. Springer, Cham. https://doi.org/10.1007/978-3-031-33187-9_11

Download citation

DOI: https://doi.org/10.1007/978-3-031-33187-9_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-33186-2

Online ISBN: 978-3-031-33187-9

eBook Packages: EngineeringEngineering (R0)