Abstract

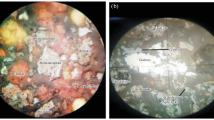

An efficient method of separating valuable elements (copper, cobalt, chromium, and sulphur) from copper smelting slag of Luanshya district of the Copperbelt province in Zambia has been developed. The as-received slag material was characterised via scanning electron microscope. The valuable elements were separated through a combination of magnetic separation, flotation, and gravity separation steps. Magnetic separation of the as-received material separates cobalt/iron and copper/sulphur/chromium rich fractions due to differences in magnetic properties. Residual copper in the magnetic fraction was upgraded to more 25 weight% via flotation. By comparison, flotation of the non-magnetic fraction yielded low grade copper concentrate due to high presence of sulphur. Chromium was upgraded by a factor of more than 5 when the non-magnetic fraction was subjected to gravity concentration. The effect of particle size was studied during magnetic separation of feed material.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Davenport WGL et al (2002) Extractive metallurgy of copper, 4th edn. Chemical, Petrochemical and Process, Elsevier, pp 1–452

Laxmi V, Kaushik G (2020) toxicity of hexavalent chromium in environment, health threats, and its bioremediation and detoxification from tannery wastewater for environmental safety. In: Saxena G, Bharagava R (eds) Bioremediation of industrial waste for environmental safety

Shrivastava R et al. (2002) Effects of chromium on the immune system. FEMS Immunol Med Microbiol 34(1):1–7

Yotamu RS, Hara AJ (2016) Carbothermic processing of copper–cobalt mineral sulphide concentrates and slag waste for the extraction of metallic values. CRC Press, Boca Raton

Das BMB, Angadi S, Pradhan SK, Prakash S, Mohanty J (2009) Characterization and recovery of copper values from discarded slag. Waste Manag Res 6:561–567

Betteridge W (1982) Cobalt and its alloys, 1st edn. Industrial metals. Ellis Horwood Limited, Chichester

Anon (1960) Cobalt monograph, vol 515. Centre d'Information du Cobalt, Brussels, Belgium

Wang J-P, Erdenebold U (2020) A study on reduction of copper smelting slag by carbon for recycling into metal values and cement raw material. Sustainability 12(4):1421

Altundoǧan HS, Tümen F (1997) Metal recovery from copper converter slag by roasting with ferric sulphate. Hydrometallurgy 44(1–2):261–267

Deng T, Ling Y (2007) Processing of copper converter slag for metal reclamation. Part I: extraction and recovery of copper and cobalt. Waste Manage Res 25(5):440–448

Zhai X-J et al. (2011) Recovery of cobalt from converter slag of Chambishi copper smelter using reduction smelting process. Trans Nonferrous Met Soc China 21(9):2117–2121

Sukla LB, Panda SC, Jena PK (1986) Recovery of cobalt, nickel and copper from converter slag through roasting with ammonium sulphate and sulphuric acid. Hydrometallurgy 16(2):153–165

Arslan C, Arslan F (2002) Recovery of copper, cobalt, and zinc from copper smelter and converter slags. Hydrometallurgy 67(1):1–7

Tümen F, Bailey N (1990) Recovery of metal values from copper smelter slags by roasting with pyrite. Hydrometallurgy 25(3):317–328

Ettler VE et al. (2022) Cobalt-bearing copper slags from Luanshya (Zambian Copperbelt): mineralogy, geochemistry and potential recovery of critical metals. J Geochem Explor 237

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Namiluko, Y.C. et al. (2023). Extraction of Valuable Metals from Luanshya Copper Smelting Slag with Minimal Waste Generation. In: Alam, S., et al. Energy Technology 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22638-0_10

Download citation

DOI: https://doi.org/10.1007/978-3-031-22638-0_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22637-3

Online ISBN: 978-3-031-22638-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)