Abstract

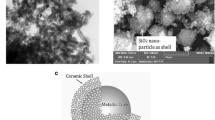

In metal matrix composites (MMCs), the interface between the metal matrix and reinforcement critically influences mechanical properties of MMCs because the load can transfer at the interface via the interfacial shear stress. We develop a new aluminum matrix composite (Al-O/SiC composite) reinforced with silicon carbide (SiC) particles which are dispersed in an interstitial aluminum alloy (called as I-Al) matrix containing oxygen atoms. The new composites reinforced with SiC particles are fabricated via powder metallurgy. Mechanical milling induces uniform dispersion of SiC particles in the matrix and also enables oxygen in the I-Al to be redistributed in the composite powder. Oxygen is observed at the interface between the matrix and SiC particles in the Al-O/SiC composite. Oxygen at the interface can provide additional chemical bonding other than mechanical interlocking at the interface, improving interface bonding of the composites. With the same amount of SiC particles, the mechanical properties of the Al-O/SiC composites including Vickers hardness, compressive yield strength, and elastic modulus are enhanced as compared to those of the Al/SiC composites. Therefore, the intercalated oxygen contributes to increasing reinforcing efficiency of the Al-O/SiC composites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kamrani S, Simchi A, Riedel R, Seyed Reihani SM (2007) Effect of reinforcement volume fraction on mechanical alloying of Al-SiC nanocomposite powders. Powder Metall 50:276–282. https://doi.org/10.1179/174329007X189621

Miracle DB (2005) Metal matrix composites - from science to technological significance. Compos Sci Technol 65:2526–2540. https://doi.org/10.1016/j.compscitech.2005.05.027

Baron C, Springer H (2017) Properties of particle phases for metal-matrix-composite design. Data Br 12:692–708. https://doi.org/10.1016/j.dib.2017.04.038

Bakshi SR, Lahiri D (2010) A Agarwal, CARBON nanotube reinforced metal matrix composites - a review. Int Mater Rev 55:41–64. https://doi.org/10.1179/095066009X12572530170543

Shin SE, Choi HJ, Hwang JY, Bae DH (2015) Strengthening behavior of carbon/metal nanocomposites. Sci Rep 5:16114. https://doi.org/10.1016/j.carbon.2014.10.044

Jeon JH, Jeon JG, Joo MR, Lee JW, Bae DH (2022) Deformation behavior of an A356 alloy containing small sub-grains with wide low-angle boundary. J Alloys Compd 908:164550. https://doi.org/10.1016/j.jallcom.2022.164550

Shin JH, Choi HJ, Cho MK, Bae DH (2014) Effect of the interface layer on the mechanical behavior of TiO2 nanoparticle reinforced aluminum matrix composites. J Compos Mater 48:99–106. https://doi.org/10.1177/0021998312469238

Levitas VI, Pantoya ML, Chauhan G, Rivero I (2009) Effect of the alumina shell on the melting temperature depression for aluminum nanoparticles. J Phys Chem C 113:14088–14096

Levitas VI, Samani K (2011) Size and mechanics effects in surface-induced melting of nanoparticles. Nat Commun 2:284. https://doi.org/10.1038/ncomms1275

Tarantili P, Andreopoulos A, Galiotis C (1998) Real-time micro-Raman measurements on stressed polyethylene fibers. 1. Strain rate effects and molecular stress redistribution. Macromolecules 31:6964–6976. http://pubs.acs.org/doi/abs/https://doi.org/10.1021/ma961498l

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Joo, M.R., Bae, D.H. (2023). Enhancing Reinforcing Efficiency of SiC Particles in Aluminum Matrix Composites with Intercalated Oxygen Atoms. In: Li, B., et al. Advances in Powder and Ceramic Materials Science 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22622-9_9

Download citation

DOI: https://doi.org/10.1007/978-3-031-22622-9_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22621-2

Online ISBN: 978-3-031-22622-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)