Abstract

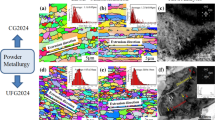

The relationships between the microstructure and thermal behaviour of additively manufactured and cast aluminum A205, a recently developed Al–Cu–Mg–Ag–TiB2 alloy, were investigated. Microstructural characterization performed using scanning electron microscopy (SEM) indicated a significant difference in grain size between laser powder bed fusion (LPBF) and cast specimens. Ultrafine round intercellular precipitates were observed in the LPBF structure, while intergranular precipitates were found in the cast structure. Trans-cellular TiB2 particles were observed in the LPBF structure, while accumulated intergranular TiB2 particles were found in the cast structure. Moreover, X-ray diffraction analysis revealed a higher fraction of precipitates in the LPBF specimen compared to the cast specimen. This was attributed to extremely high cooling rates which extend the solubility of alloying elements in the matrix. The thermo-analytical study demonstrated a strong correlation between the microstructural scale and precipitate dissolution kinetics of A205. The higher diffusion rate inherent in refined microstructures facilitates the dissolution of precipitates in the LPBF A205.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

W.F. Miao, D.E. Laughlin, Precipitation hardening in aluminum alloy 6022, Scr Mater. 40 (1999) 873–878. https://doi.org/10.1016/S1359-6462(99)00046-9.

A. Mehta, L. Zhou, T. Huynh, S. Park, H. Hyer, S. Song, Y. Bai, D.D. Imholte, N.E. Woolstenhulme, D.M. Wachs, Y. Sohn, Additive manufacturing and mechanical properties of the dense and crack free Zr-modified aluminum alloy 6061 fabricated by the laser-powder bed fusion, Addit Manuf. 41 (2021). https://doi.org/10.1016/J.ADDMA.2021.101966.

R. Du, Q. Gao, S. Wu, S. Lü, X. Zhou, Influence of TiB2 particles on aging behavior of in-situ TiB2/Al-4.5Cu composites, Mater Sci Eng A Struct Mater. 721 (2018) 244–250. https://doi.org/10.1016/J.MSEA.2018.02.099.

I.J. Polmear, The Influence of Small Additions of Silver on the Structure and Properties of Aged Aluminum Alloys, JOM. 20 (1968) 44–51. https://doi.org/10.1007/BF03378722.

M. Avateffazeli, P.E. Carrion, B. Shachi-Amirkhiz, H. Pirgazi, M. Mohammadi, N. Shamsaei, M. Haghshenas, Correlation between tensile properties, microstructure, and processing routes of an Al–Cu–Mg–Ag–TiB2 (A205) alloy: Additive manufacturing and casting, Materials Science and Engineering A. 841 (2022). https://doi.org/10.1016/J.MSEA.2022.142989.

P. Mair, L. Kaserer, J. Braun, N. Weinberger, I. Letofsky-Papst, G. Leichtfried, Microstructure and mechanical properties of a TiB2-modified Al–Cu alloy processed by laser powder-bed fusion, Materials Science and Engineering A. 799 (2021). https://doi.org/10.1016/J.MSEA.2020.140209.

S.I. Shakil, A. Hadadzadeh, B. Shalchi Amirkhiz, H. Pirgazi, M. Mohammadi, M. Haghshenas, Additive manufactured versus cast AlSi10Mg alloy: Microstructure and micromechanics, Results in Materials. 10 (2021). https://doi.org/10.1016/J.RINMA.2021.100178.

M. Zamani, I. Belov, E. Sjölander, A. Bjurenstedt, E. Ghassemali, S. Seifeddine, Study on dissolution of Al2Cu in al-4.3cu and a205 cast alloys, Metals (Basel). 10 (2020) 1–17. https://doi.org/10.3390/MET10070900.

X.P. Li, G. Ji, Z. Chen, A. Addad, Y. Wu, H.W. Wang, J. Vleugels, J. van Humbeeck, J.P. Kruth, Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility, Acta Mater. 129 (2017) 183–193. https://doi.org/10.1016/J.ACTAMAT.2017.02.062.

Y.K. Xiao, Z.Y. Bian, Y. Wu, G. Ji, Y.Q. Li, M.J. Li, Q. Lian, Z. Chen, A. Addad, H.W. Wang, Effect of nano-TiB2 particles on the anisotropy in an AlSi10Mg alloy processed by selective laser melting, J Alloys Compd. 798 (2019) 644–655. https://doi.org/10.1016/J.JALLCOM.2019.05.279.

S.L. Sing, S. Huang, G.D. Goh, G.L. Goh, C.F. Tey, J.H.K. Tan, W.Y. Yeong, Emerging metallic systems for additive manufacturing: In-situ alloying and multi-metal processing in laser powder bed fusion, Prog Mater Sci. 119 (2021) 100795. https://doi.org/10.1016/J.PMATSCI.2021.100795.

G.-F. Rafael, The effect of solidification rate and solutionizing on the mechanical properties and hardening response of aluminum alloys, Michigan Technological University, 2016.

Acknowledgements

The authors are thankful to Natural Sciences and Engineering Research Council of Canada (NSERC) under grant no. CRDPJ 533406-18, (CM)2 Labs at Polytechnique Montreal and Amber Andreaco, working in the material supply division at GE Additive, for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Karimialavijeh, H., Ghasri-Khouzani, M., Chakraborty, A., Harvey, JP., Martin, É. (2023). Comparison of Additively Manufactured and Cast Aluminum A205 Alloy. In: Broek, S. (eds) Light Metals 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22532-1_66

Download citation

DOI: https://doi.org/10.1007/978-3-031-22532-1_66

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22531-4

Online ISBN: 978-3-031-22532-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)