Abstract

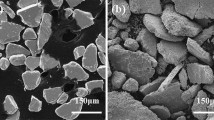

FeSiBCCr gas–water combined atomization amorphous powders were divided into five size groups (1#: ≥104 μm; 2#: 74–104 μm; 3#: 48–74 μm; 4#: 38–48 μm; 5#: ≤38 μm) to study the relationship between powder properties and size distribution, and then to prepare high-performance magnetic powder cores (MPCs) through particle size classification. The results of powder characterization show that the circularity of the powder increases with the decrease of the particle size. Due to the finest particle size, the comprehensive properties of 5# powder are better than other powders, with the saturation magnetization of 144.2 emu g–1 and the coercivity of 0.13 Oe. MPCs prepared by a cold pressing process using 5# powder show excellent soft magnetic properties. The effective permeability is 19.62, and the core losses are 224.10 mW cm–3 (Bm = 0.05 T, f = 100 kHz) and 1441.5 mW cm–3 (Bm = 0.02 T, f = 1 MHz), respectively.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Han L, Maccari F, Souza Filho IR et al (2022) A mechanically strong and ductile soft magnet with extremely low coercivity. Nature 608:310–316

Silveyra JM, Ferrara E, Huber DL et al (2018) Soft magnetic materials for a sustainable and electrified world. Science 362(6413):eaao0195

Jiang C, Lu J, Liu W et al (2020) Corrosion resistance of plasma-sprayed Fe-based coatings by using core-shell structure powders. J Market Res 9(6):12273–12280

Li Y, Chen WZ, Dong B et al (2018) Effects of phosphorus and carbon content on the surface tension of FeSiBPC glass-forming alloy melts. J Non-Cryst Solids 496:13–17

Meng LB, Yu HC, Lv SY et al (2021) Study on amorphous soft magnetic powder with high sphericity. Powder Metall Ind 31(5):105–110

Chi Q, Xie L, Chang L et al (2021) Study on the properties of carbonyl iron powder/FeSiBCCr composite amorphous magnetic powder core. Mater Rep 35(10):10023–10028

Li Z, Dong Y, Pauly S et al (2017) Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J Alloy Compd 706:1–6

Qian K, Sokolov AS, Li Q et al (2020) High performance metallic amorphous magnetic flake-based magnetodielectric inductors. IEEE Magn Lett 11:1–5

Lee Y, Jeon J, Nam S et al (2018) Soft magnetic properties of Fe-based amorphous/nanocrystalline hybrid materials. Powder Technol 339:440–445

Yoshida K, Bito M, Kageyama J et al (2016) Unusual high B s for Fe-based amorphous powders produced by a gas-atomization technique. AIP Adv 6(5):055933

Zhao T, Chen C, Wu XJ et al (2021) FeSiBCrC amorphous magnetic powder fabricated by gas-water combined atomization. J Alloy Compd 857:157991

Zhang Y, Dong Y, Liu L et al (2019) High filling alumina/epoxy nanocomposite as coating layer for Fe-based amorphous powder cores with enhanced magnetic performance. J Mater Sci Mater Electron 30(16):14869–14877

Wang P, Wei M, Dong YN et al (2022) Crystallization evolution behavior of amorphous Fe85.7Si7.9B3.6Cr2C0.8 powder produced by a novel atomization process. J Non-Cryst Solids 594:121824

Liu JQ, Pang J, Wang P et al (2022) Research progress of liquid metal atomization technology and preparation of its amorphous powders. China Metall 32(2):1–14

Dong Y, Liu J, Wang P et al (2022) Study of bulk amorphous and nanocrystalline alloys fabricated by high-sphericity Fe84Si7B5C2Cr2 amorphous powders at different spark-plasma-sintering temperatures. Materials 15(3):1106

Miller SA, Giles WB (1981) Effect of process variables on atomization of metals and alloys. Mod Dev Powder Metall 1:113–128

Zhou B, Dong Y, Liu L et al (2019) The core-shell structured Fe-based amorphous magnetic powder cores with excellent magnetic properties. Adv Powder Technol 30(8):1504–1512

Yu H, Zhou S, Zhang G et al (2022) The phosphating effect on the properties of FeSiCr alloy powder. J Magn Magn Mater 552:168741

Woo HJ, Ahn JH, Kim CP et al (2022) Effect of the particle size classification of FeSiCrB amorphous soft magnetic composites to improve magnetic properties of power inductors. J Non-Cryst Solids 577:121309

Li B, Zheng ZG, Yu HY et al (2017) Improved permeability of Fe based amorphous magnetic powder cores by adding Permalloy. J Magn Magn Mater 438:138–143

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Dong, Yn. et al. (2023). FeSiBCCr Amorphous Fine Powders with High Saturation Magnetization Based on Particle Size Classification and Its Magnetic Powder Cores with Low Core Loss. In: TMS 2023 152nd Annual Meeting & Exhibition Supplemental Proceedings. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22524-6_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-22524-6_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22523-9

Online ISBN: 978-3-031-22524-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)