Abstract

It has been suggested that South Africa (SA) prioritizes copper recycling in order to ensure that there is an adequate supply as the country’s economy becomes more energy-efficient and less dependent on fossil fuels. Based on this school of thought, this chapter discussed, among other things, the resource recovery and recycling from waste copper dust (WCD). One thing that was noticed is that SA WCD has a different chemical composition (CC) than WCD from other regions of the world. Due to the extremely low concentrations of hazardous compounds like As, Pb, and other substances, the CC of the WCD from SA complies with EU requirements for disposal in landfills. Although returning this WCD to the furnace might not be an economically viable alternative because of its fine size (5–50 μm), which harms the furnace’s refractory bricks, doing so will also result in loss of Cu value. Thus, six (6) unique proposals for resource recovery and recycling from WCD were listed in this chapter to transform this WCD into usable materials. These proposals have been published in their entirety in a number of literary works. The adoption of the ideas in these proposals is anticipated to help reduce adverse environmental consequences while also closing the copper loop (zero-waste production).

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

P.R. Jadhao, S. Mishra, A. Pandey, K.K. Pant, K.D.P. Nigam, Biohydrometallurgy: A sustainable approach for urban mining of metals and metal refining, in Catalysis for Clean Energy and Environmental Sustainability: Biomass Conversion and Green Chemistry, vol. 1, (Springer, Cham, 2021), pp. 865–892

M.L. Free, Metal extraction, in Hydrometallurgy, (Springer, Cham, 2022), pp. 145–196

J.A.D. Cavalcanti, M.S. da Silva, C. Schobbenhaus, H. de Mota Lima, Geo-mining heritages of the Mariana anticline region, southeast of Quadrilátero Ferrífero-MG, Brazil: Qualitative and quantitative assessment of Chico Rei and Passagem mines. Geoheritage 13(4), 1–29 (2021)

Z. Bian, X. Miao, S. Lei, S.E. Chen, W. Wang, S. Struthers, The challenges of reusing mining and mineral-processing wastes. Science 337(6095), 702–703 (2012)

R. Lorenz, J. Senoner, W. Sihn, T. Netland, Using process mining to improve productivity in make-to-stock manufacturing. Int. J. Prod. Res., 59(16), 4869–4880 (2021)

Y. Taha, A. Elghali, R. Hakkou, M. Benzaazoua, Towards zero solid waste in the sedimentary phosphate industry: Challenges and opportunities. Fortschr. Mineral. 11(11), 1250 (2021)

B. Paluchamy, D.P. Mishra, D.C. Panigrahi, Airborne respirable dust in fully mechanised underground metalliferous mines–generation, health impacts and control measures for cleaner production. J. Clean. Prod. 296, 126524 (2021)

M. Mpanza, E. Adam, R. Moolla, Dust deposition impacts at a liquidated gold mine village: Gauteng Province in South Africa. Int. J. Environ. Res. Public Health 17(14), 4929 (2020)

T.L. Noble, A. Parbhakar-Fox, R.F. Berry, B. Lottermoser, Mineral dust emissions at metalliferous mine sites, in Environmental Indicators in Metal Mining, (Springer, Cham, 2017), pp. 281–306

D.H. Brouwer, D. Rees, Can the South African milestones for reducing exposure to respirable crystalline silica and silicosis be achieved and reliably monitored? Front. Public Health 8, 107 (2020)

G. Nelson, Living in the Shadow of a Dust Cloud: Occupational Respiratory Diseases in the South African Mining Industry, 1975 to 2009 (Doctoral Dissertation, 2014)

H. Li, J. Peng, H. Long, S. Li, L. Zhang, Cleaner process: Efficacy of chlorine in the recycling of gold from gold-containing tailings. J. Clean. Prod. 287, 125066 (2021)

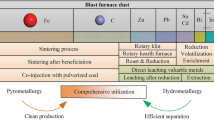

X. Xiao, S. Zhang, F. Sher, J. Chen, Y. Xin, Z. You, L. Wen, M. Hu, G. Qiu, A review on recycling and reutilization of blast furnace dust as a secondary resource. J. Sustain. Metall., 7(2), 340–357 (2021)

E. Matinde, G.S. Simate, S. Ndlovu, Mining and metallurgical wastes: A review of recycling and re-use practices. J. South. Afr. Inst. Min. Metall. 118(8), 825–844 (2018)

A. Halog, S. Anieke, A review of circular economy studies in developed countries and its potential adoption in developing countries. Circ. Econ. Sustain., 1(1), 209–230 (2021)

S. Jawadand, K. Randive, A sustainable approach to transforming mining waste into value-added products, in Innovations in Sustainable Mining, (Springer, Cham, 2021), pp. 1–20

A. Upadhyay, T. Laing, V. Kumar, M. Dora, Exploring barriers and drivers to the implementation of circular economy practices in the mining industry. Resour. Policy 72, 102037 (2021)

F. Pavloudakis, C. Roumpos, P.M. Spanidis, Optimization of surface mining operation based on a circular economy model, in Circular Economy and Sustainability, (Elsevier, Amsterdam, 2022), pp. 395–418

Mandarin Finance and Economics, African Copper Development Association calls on South Africa to increase the scale of waste copper recycling. (2020). https://news.metal.com/newscontent/101199398/african-copper-development-association-calls-on-south-africa-to-increase-the-scale-of-waste-copper-recycling

V.R. Nalule, Transitioning to a low carbon economy: Is Africa ready to bid farewell to fossil fuels? in The Palgrave Handbook of Managing Fossil Fuels and Energy Transitions, (Palgrave Macmillan, Cham, 2020), pp. 261–286

G. Mutezo, J. Mulopo, A review of Africa’s transition from fossil fuels to renewable energy using circular economy principles. Renew. Sust. Energ. Rev. 137, 110609 (2021)

B. Barlow, E. Fosso-Kankeu, K. Nyembwe, F. Waanders, E.N. Malenga, Prediction of Dissolution of Copper from a Chalcopyrite Carbonatite Ore of South Africa (EARET, 2018)

H. Paetzold, P. Lourens, R. Brazier, Reopening and closure of a block cave, in MassMin 2020: Proceedings of the Eighth International Conference & Exhibition on Mass Mining, (University of Chile, 2020 December), pp. 103–114

L. Hockaday, Solar thermal applications in minerals processing in South Africa, in Proceedings of the 6th South African Solar Energy Converence, (2019)

D.O. Okanigbe, A.P.I. Popoola, A.A. Adeleke, Characterization of copper smelter dust for copper recovery. Procedia Manuf. 7, 121–126 (2017)

D.O. Okanigbe, A.P.I. Popoola, A.A. Adeleke, Hydrometallurgical processing of copper smelter dust for copper recovery as nano-particles: A review. Energ. Technol. 2017, 205–226 (2017)

D. Okanigbe, P. Olawale, A. Popoola, A. Abraham, A. Michael, K. Andrei, Centrifugal separation experimentation and optimum predictive model development for copper recovery from waste copper smelter dust. Cogent Eng. 5(1), 1551175 (2018)

D.O. Okanigbe, A.P.I. Popoola, A.A. Adeleke, I.O. Otunniyi, O.M. Popoola, Investigating the impact of pretreating a waste copper smelter dust for likely higher recovery of copper. Procedia Manuf. 35, 430–435 (2019)

D.O. Okanigbe, M.K. Ayomoh, O.M. Popoola, P.A. Popoola, V.S. Aigbodion, Oxidative roasting experimentation and optimum predictive model development for copper and iron recovery from a copper smelter dust. Results Eng. 7, 100125 (2020)

W.G. Davenport, M. King, M.E. Schlesinger, A.K. Biswas, Extractive Metallurgy of Copper (Elsevier, Amsterdam, 2002)

G.A. Flores, C. Risopatron, J. Pease, Processing of complex materials in the copper industry: Challenges and opportunities ahead. JOM 72(10), 3447–3461 (2020)

M.E. Schlesinger, K.C. Sole, W.G. Davenport, G.R. Alvear, Extractive Metallurgy of Copper (Elsevier, Amsterdam, 2021)

B. Lucheva, P. Iliev, D. Kolev, Hydro-pyrometallurgical treatment of copper converter flue dust. J. Chem. Technol. Metall. 52(2), 320–325 (2017)

S.A. Awe, J.E. Sundkvist, N.J. Bolin, Å. Sandström, Process flowsheet development for recovering antimony from Sb-bearing copper concentrates. Miner. Eng. 49, 45–53 (2013)

A. Yazawa, Thermodynamic considerations of copper smelting. Can. Metall. Q. 13(3), 443–453 (1974)

A. Yazawa, T. Azakami, Thermodynamics of removing impurities during copper smelting. Can. Metall. Q. 8(3), 257–261 (1969)

F. Habashi, Copper metallurgy at the crossroads. J. Min. Metall. B: Metall. 43(1), 1–19 (2007)

T. Utigard, G. Sanchez, J. Manriquez, A. Luraschi, C. Diaz, D. Cordero, E. Almendras, Reduction kinetics of liquid iron oxide-containing slags by carbon monoxide. Metall. Mater. Trans. B 28(5), 821–826 (1997)

V. Montenegro, H. Sano, T. Fujisawa, Recirculation of Chilean copper smelting dust with high arsenic content to the smelting process. Mater. Trans. 49(9), 2112–2118 (2008)

H. Zhou, G. Liu, L. Zhang, C. Zhou, Formation mechanism of arsenic-containing dust in the flue gas cleaning process of flash copper pyrometallurgy: A quantitative identification of arsenic speciation. Chem. Eng. J. 423, 130193 (2021)

T.K. Ha, B.H. Kwon, K.S. Park, D. Mohapatra, Selective leaching and recovery of bismuth as Bi2O3 from copper smelter converter dust. Sep. Purif. Technol. 142, 116–122 (2015)

F. Bakhtiari, H. Atashi, M. Zivdar, S.S. Bagheri, Continuous copper recovery from a smelter’s dust in stirred tank reactors. Int. J. Miner. Process. 86(1–4), 50–57 (2008)

F. Bakhtiari, M. Zivdar, H. Atashi, S.S. Bagheri, Bioleaching of copper from smelter dust in a series of airlift bioreactors. Hydrometallurgy 90(1), 40–45 (2008)

A.B. Vakylabad, M. Schaffie, M. Ranjbar, Z. Manafi, E. Darezereshki, Bio-processing of copper from combined smelter dust and flotation concentrate: A comparative study on the stirred tank and airlift reactors. J. Hazard. Mater. 241, 197–206 (2012)

A. Morales, M. Cruells, A. Roca, R. Bergo, Characterization of flue dusts from a copper smelter furnace, copper recovery and arsenic stabilization, in The John E. Dutrizac International Symposium on Copper Hydrometallurgy, Cu 2007, ed. by P.A. Riveros, D.G. Dixon, D.B. Dreisinger, M.J. Collins, vol. 4, (2007), pp. 177–189

E. Balladares, U. Kelm, S. Helle, R. Parra, E. Araneda, Chemical-mineralogical characterization of copper smelting flue dust. Dyna 81(186), 11–18 (2014)

B. Xu, Y. Ma, W. Gao, J. Yang, Y. Yang, Q. Li, T. Jiang, A review of the comprehensive recovery of valuable elements from copper smelting open-circuit dust and arsenic treatment. JOM 72(11), 3860–3875 (2020)

D.O. Okanigbe, Production of Copper and Copper Oxide Nano-Particles from Leach Solution of Low Grade Copper Smelter Dust (2019)

L. Qiang, I.S. Pinto, Z. Youcai, Sequential stepwise recovery of selected metals from flue dusts of secondary copper smelting. J. Clean. Prod. 84, 663–670 (2014)

M. Vítková, V. Ettler, J. Hyks, T. Astrup, B. Kříbek, Leaching of metals from copper smelter flue dust (Mufulira, Zambian Copperbelt). Appl. Geochem. 26, S263–S266 (2011)

O. Font, N.A.T.A.L.I.A. Moreno, G. Aixa, X.A.V.I.E.R. Querol, R.O.D.R.I.G.O. Navia, Copper smelting flue dust: A potential source of germanium. Rev. Soc. Esp. Mineral. 15, 87–88 (2011)

A.B. Vakylabad, A comparison of bioleaching ability of mesophilic and moderately thermophilic culture on copper bioleaching from flotation concentrate and smelter dust. Int. J. Miner. Process. 101(1–4), 94–99 (2011)

F.J. Alguacil, I. Garcia-Diaz, F. Lopez, O. Rodriguez, Recycling of copper flue dust via leaching-solvent extraction processing. Desalin. Water Treat. 56(5), 1202–1207 (2015)

V. Ettler, M. Vítková, M. Mihaljevič, O. Šebek, M. Klementová, F. Veselovský, P. Vybíral, B. Kříbek, Dust from Zambian smelters: Mineralogy and contaminant bioaccessibility. Environ. Geochem. Health 36(5), 919–933 (2014)

Z.F. Xu, L.I. Qiang, H.P. Nie, Pressure leaching technique of smelter dust with high-copper and high-arsenic. Trans. Nonferrous Metals Soc. China 20, s176–s181 (2010)

V. Montenegro, H. Sano, T. Fujisawa, Recirculation of high arsenic content copper smelting dust to smelting and converting processes. Miner. Eng. 49, 184–189 (2013)

T. Li, Y. Wang, W.J. Li, J.M. Chen, T. Wang, W.X. Wang, Concentrations and solubility of trace elements in fine particles at a mountain site, southern China: Regional sources and cloud processing. Atmos. Chem. Phys. 15(15), 8987–9002 (2015)

X. Guo, J. Shi, Y. Yi, Q. Tian, D. Li, Separation and recovery of arsenic from arsenic-bearing dust. J. Environ. Chem. Eng. 3(3), 2236–2242 (2015)

J. Gao, Z. Huang, Z. Wang, Z. Guo, Recovery of crown zinc and metallic copper from copper smelter dust by evaporation, condensation and super-gravity separation. Sep. Purif. Technol. 231, 115925 (2020)

A. Shahnazi, S. Firoozi, D.H. Fatmehsari, Selective leaching of arsenic from copper converter flue dust by Na2S and its stabilization with Fe2 (SO4) 3. Trans. Nonferrous Metals Soc. China 30(6), 1674–1686 (2020)

A. Morales, M. Cruells, A. Roca, R. Bergó, Treatment of copper flash smelter flue dusts for copper and zinc extraction and arsenic stabilization. Hydrometallurgy 105(1–2), 148–154 (2010)

L.G. Twidwell, A.K. Mehta, Disposal of arsenic bearing copper smelter flue dust. Nucl. Chem. Waste Manag. 5(4), 297–303 (1985)

V. Dutre, C. Vandecasteele, Immobilization mechanism of arsenic in waste solidified using cement and lime. Environ. Sci. Technol. 32(18), 2782–2787 (1998)

Acknowledgments

The author wishes to express his gratitude to Tshwane University of Technology in Pretoria, South Africa, for allowing use of facilities.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Okanigbe, D.O. (2023). Resource Recovery and Recycling from Waste Metal Dust (II): Waste Copper Dust. In: Ogochukwu Okanigbe, D., Popoola, A.P. (eds) Resource Recovery and Recycling from Waste Metal Dust. Springer, Cham. https://doi.org/10.1007/978-3-031-22492-8_2

Download citation

DOI: https://doi.org/10.1007/978-3-031-22492-8_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22491-1

Online ISBN: 978-3-031-22492-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)