Abstract

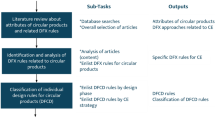

‘Product re-design guidelines’ outline the rethinking of consumer and capital goods design in a context of a transition from a current linear economy towards a circular-oriented economy. These guidelines deliver generalized quality standards addressing various target groups who are to be engaged in order to achieve sustainable results. The definition of crucial counterparts of a system or beneficiaries, respectively, changes the guidelines’ discuss factors that are fundamental for the integration of sustainability aspects into existing and/or novel business models. With regard to the circular progression in future, awareness building for improvements in disassembling and remanufacturing will remain essential among designers and producers.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

As part of ‘Closing the loop’, an EU-action plan for the circular economy, the European commission stated in 2015:

The circular economy will boost the EU’s competitiveness by protecting businesses against scarcity of resources and volatile prices, helping to create new business opportunities and innovative, more efficient ways of producing and consuming. It will create local jobs at all skills levels and opportunities for social integration and cohesion. At the same time, it will save energy and help avoid the irreversible damages caused by using up resources at a rate that exceeds the Earth’s capacity to renew them in terms of climate and biodiversity, air, soil and water pollution.

The transition to a circular economy is a system change, which calls for a rethinking of linear processes in favor of recyclable products and product service systems. In order to ensure a sustainable development on economic, social, and ecological levels, the United Nations have agreed to reach a total of 17 Sustainable Development Goals (SDGs) by 2030. The responsibility to implement these goals—including well-being, quality education, gender equality and others—resides equally with both designers and manufacturers. Designers mediate between all actors involved in the development process and can thereby create transparency. For this (information) exchange to be successful generalized quality standards for circular design aim to provide stakeholders, in particular designers and manufacturers, with a circular re-design manual including comprehensible standards and tips helping to realize the sustainability goals.

The Ellen MacArthur Foundation, launched in 2010 as one of the leading organizations to accelerate changes in our current linear system states in order to ‘make a transition to a more circular economy, and in a broader perspective society, possible, circular economy was defined as transformation from products turning into waste to products being reused to their maximum value before being returned to the biosphere in a productive way’ [1]. This concept offers an alternative to the linear ‘take-make dispose/waste’ model of consumption and production: products and materials are designed circular and are being kept in a closed loop by recycling, recovering and regeneration at the end of each service life.

Within the circular design eco-design strategies are combined with the aim of keeping as many resources as possible in closed loops and transferring them quickly and efficiently from a state of uselessness to a state of use.

As Hora/Tischner [2] state, ‘Even though eco-design aims above all at the best possible design of ecological and economic benefits, the social dimension should also be taken into account as far as possible in the product development process.’ Knowledge about sustainability standards becomes a decisive innovation tool. Knowledge about material use and efficiency, energy output and input and product durability is combined with design strategies, such as reparability, modularity and other strategies of ecological responsible design. Circular design not only includes transformation in ways of ecological change but social development as well. Social Design Lab [3] solidifies the term ‘circular societies’ by incorporating societal changes into the concept of circularity. Thus, transition in terms of circularity comprises both ecological and societal changes.

2 Generalized Product Re-Design Guidelines

Societal changes are realized in a cooperative manner, which includes various counterparts, such as designers and creatives, manufacturers and producers but also consumers, users and policymakers.

The following addresses the benefits of the use of these circular product re-design guidelines, describes their role, responsibilities and potential for a transition in reference to circular design.

2.1 Counterparts of Circular Design

Designers and Creatives. Designers and those working in creative fields acquire orientation with regard to the realization of recyclable products and product service systems, receive support in the search for more detailed information, and take first steps toward implementing the standards. All design sectors are addressed in the circular design manual: Functioning material loops require the involvement of graphic and interactional design to organize information and interactions along the complete value chain. Sharing concepts in product (and textile) design offer new usage possibilities and forms of material use and procurement.

Design will no longer be defined and used as marketing strategy. In Circular Design the principle of beta versions will define the understanding of design. Based on the concept of beta versions in software development, partly finished or uncompleted versions of products will be released. Developed in its basic principles these versions are open to changes and adaptions by its users. Hence, the user turns into a ‘prosumer’ (producers + consumers) by contributing to the development of a product or service. The advantages of beta versions are wide-ranging feedbacks with the possibility of further adaptions or developments, thus resulting in a more sustainable service or product. Furthermore, products will become more resilient; have longer lifespans and the possibility to carry out updates. Modularity as well as decentralized production and design development will be part of the design work in a circular economy. Instead of disregarding the extension of the product life cycle, reuse is planned and all resources ideally remain in a closed loop.

Manufacturers and Producers. Producing industry specialists receive sets of criteria and inspiration related to potential circular economic models, which are to be addressed and fulfilled in collaboration with designers. The manual brings both parties (designers and manufacturers) to the same level of negotiation and aims to help to understand each point of view.

Products and the possession of products are no longer the source of added value. Instead, its functionality and use define the source of added value. The focus shifts from products without service to product service systems that consider users’ needs and include the principles of a circular model: repair, reuse, and remanufacturing. Globalized, cost effective production is no longer desirable. Alternatively, the ‘global/local” principle will be complemented into manufacturing processes: knowledge generation takes place on a globalized level while production and distribution is realized locally.

Waste Managers. As a general supplier of waste removal and recycling services, as well as dismantlers and logistical operators, waste managers provide evaluation of optimal logistic scenarios for specific supply/value chains by taking into account different phases of waste management. Since waste management as a whole is developing towards resource management, it is becoming more important to recover, reuse and recycle as much raw material as possible from waste products.

Consumers and Users. Consumers and users are no longer passive members of consumption processes. As ‘prosumers’ they actively use and test products and turn into experts while taking part in development stages. Instead of owning products, prosumers use products. Products are no longer globally produced and cheap but locally manufactured and available. Local resources and skills are being used. They are characterized by durability, reparability and are service friendly.

Policymakers. Manufacturing processes will no longer be determined or dominated by cost efficiency. Henceforth, the focus lies on quality in material as well as in human resources. Glocal structures in terms of insourcing replace global structures where production and qualification are being outsourced. Furthermore, resources are considered as common goods. The responsibility for closed material and production loops is a rule and not the exception. The focus shifts to promoting individuals and not solely the economy.

2.2 Guidance to Circular Design Processes

What questions need to be asked before starting circular design projects?

The following notions and principles are to be considered for one’s own project work in the spirit of ecological sustainability. They serve as guidelines for the circular design process and as first steps into the direction of a circular economy.

Purpose: Is the design of a service or system possible? Can the design of a product be avoided? How useful is the purchase of a product?

Service Units: How can one successfully design service and utilization units? Which services does the product provide?

Attitude (personal, corporate): How can attitude be refined and awareness be raised toward ecologically sustainable concepts and systems, and how can this be shared with other actors?

Information and Research: How and where do I find information and figures related to the environmental aspects of my project? Are there existing environmental declarations on comparable products and services? How do I inform users and educate them in the resource-efficient use of a product or service?

Optimizing Use: Which requirements apply regarding service life, intensity of use, life cycle, and disposal scenarios? Do the rules and standards correspond with the actual use? Where do I find information about the existing rules and standards?

Resilience: How do products and services become resilient and independent from external factors like short-lived fashions and trends? Which tools can help to achieve circular design products/projects?

2.3 Mapping the Circular Design Process

Sketching out the product life cycle

Where does it come from? Where does it go? Which resources does your product/service consume? Which requirements apply for this product/service category?

Disassemble products to understand functions and processes.

Working from the future to the present

Sketch out the ideal usage scenario and break it down into real possibilities.

Prioritizing possibilities

Create new contexts instead of products. Select appropriate design strategies.

Identifying the impact

Illustrate the impacts of actions. How do the materials affect the environment (soil, air, water)? Which influences does your design have on society?

Recognizing hurdles and barriers

Clarify the limitations of your actions: What effects can I provoke? Where do I need help?

Planning next steps

Who do I want to collaborate with in the future?

2.4 The Role of Life Cycle Assessment (LCA)

Whether and to what extent the abovementioned strategies have an effect on the environmental balance of a product or service can only be determined with the help of effect categories. The figures are derived from the results of an LCA. Different tools can be used for a general estimate and the comparison of environmental impacts. Checklists functions as reminders of which steps need to be completed and which requirements have to be made. Material categories may give an overview of materials and other resources. They provide a simple first analysis for designers becoming acquainted with the concept of circular design. Material databases (analogue or digital) provide raw numeric values.

2.5 Circular Design Criteria

Knowledge about sustainability standards and circular design criteria become a decisive innovation tool in future design projects. As described in this report various ecological aspects and requirements have to be considered when designing circular services and products. The following seven circular design criteria have been selected in order to give an overview of requirements that have to be met by designers and manufactures. They do not claim to completeness but are defined as first steps into a circular design process and further a circular economy. For further criteria and possibilities of establishing the standards in the work of designers, manufacturers and producers, we recommend the different label types ISO 14020 provided by the International Organization for Standardization.

Type I (ISO 14024) Environmental Labelling. These certifications are made in the framework of an independent review by a third party. Products with one of these labels have better environmental performance than comparable products (e.g.: EU Ecolabel, Austrian Ecolabel, Blue Angel).

Type II (ISO 14021) Self-Declared Environmental Claims. This certification is made by the manufacturers themselves. They stipulate criteria for a comparison. Products that bear this label exhibit an improvement in terms of environmental aspects, for instance, in comparison to previous models (e.g.: Recycling code).

Type III (ISO/TR 14,025) Environmental Declarations. This certification is based on the results of an eco-balance and comprises environmental data and information about the complete life cycle of the product. The review of various criteria enables a differentiated product comparison (e.g.: EU Energy Label, EPD—Environmental Product Declaration).

2.6 Circularity Potential—Thinking in Loops

Linear economic models—from the cradle to the dump—are being replaced by planned closed loops as demonstrated in Circular Economy System Diagram (Fig. 1) by the Ellen MacArthur Foundation. Following this concept, there is no longer waste produced. Natural loops are created for natural materials, for example, compostable packaging. Technical products and components are routed into technical loops. External impacts, such as emissions, are taken into consideration throughout the complete life cycle as stated by inter alia Ellen MacArthur Foundation and IDEO.

Effective: Effectiveness is defined as an increased resource productivity. More benefits with less resources and materials needed.

Consistent: Instead of using new resources, materials and services of existing ecosystems (technical as well as natural) should be used and sustained.

Sufficient: Sufficiency describes the absolute reduction of resource usage through changes in behavior and decreased demand. Planned obsolescence is not an option having a sufficient and working technical or natural loop in place. Generally speaking, circulation in a loop without additional external energy or processing aid is impossible. It is important to identify these flows of materials. A distinction is made between emissions in the air, water, and soil and effects on biodiversity.

As first steps or starting points we recommend deciding for a technical or natural loop when designing products and services. In which loop will your product or service fit in? A distinction has to be made between materials in terms of natural resources and those of technical characteristics. When designing a product, responsibility for the afterlife and return of the product has to be taken.

2.7 Determination of the Optimal Lifespan

Designers define the service life of products and services. The technical lifespan of all components accounts for the real service life and intensity of use. A long lifespan in terms of durability guarantees the longest possible usage that corresponds with the usage context. Emotional product bonding can be named as an important factor for durability. Besides the technical service life, a high appreciation and bond with the product on the user’s side should be attained in order to extend the real service life—regardless of trends and fashions. A shorter lifespan of a product is only aspired if it is ecologically justifiable and particularly circular. It is advisable to create incentives for longer use of products and materials. Generally speaking, the assumption holds that the cumulative expenditure of energy and resources is amortized with a longer lifespan. In rare cases do other factors achieve a better environmental impact. For example, one forgoes reparability when using materials made of carbon fiber but attains a more efficient product. As first step we recommend researching the average service life of the product that is to be designed. Second, an appropriate product lifespan has to be designed. When possible, designing a low-maintenance product is a recommended option.

Reparability and Modularity—Universal comprehensibility. Preferably use standardized connections and components. The product should be comprehensible for as many people as possible. At least experts should be able to perform repairs, extension, and disassembly.

The following criteria in reference to the Directive 2009/25/EC of the European Commission should be kept in mind:

Reparability: If necessary, the product can be opened without destroying it. The individual components are accessible and can be replaced.

Modularity: Components can be replaced, extended, or updated.

Disassembly: The use of different materials and connections is reduced; nondetachable connections are a taboo.

Open interfaces allow adaptation to technical innovations. Replacement parts should be available not only for the manufacturer but also for the user of the product. The manufacturer assumes a broader manufacturing responsibility, guarantees and warranties should be adjusted to the actual lifespan. The possibilities to repair and maintain are an incentive for a longer product use cycle. Attention should be paid to usability and product safety standards and regulations.

As first steps it is recommended to provide a usage and repair manual for the users. When the possibility to include reparability as criteria in the design process is given, all components and wear parts should be design exchangeable.

Energy Use—Increase efficiency per energy unit. Energy efficiency is the relationship between the energy output and input. Effective use of energy sources increases economy and reduces its environmental consumption. Energy from renewable energy sources is preferred. A distinction is made between thermal and electric energy. The EU energy label provides information about the energy consumed during usage; the cumulative energy expenditure (CEE) describes it over the entire life cycle. A longer lifespan has a positive effect on the CEE, as does the use of recycled materials. Intelligent and customizable control systems facilitate a more efficient use of energy. As first steps we recommend using renewable energy resources exclusively. It is advisable to reduce the energy consumption per service unit and to create incentives to reduce the energy consumption in general. One option is to enable feedback about the real energy consumption in order to include the user into the usage circle.

Material Use—Increase efficiency per material unit. Material efficiency refers to the relationship between the resulting product and the employed raw materials. The material use is optimized over the complete life cycle in terms of its impacts on health and the environment. Waste materials are avoided and fed back into the loop. The use of new, non-renewable resources is reduced. When selecting materials, attention should be paid to the origin, environmental impacts, and production conditions. Renewable resources are preferred. Materials should be able to be separated according to type and be marked as such. Reparability should be guaranteed [4]. Avoidance of problematic substances is preferred: Substances and materials should not have an adverse effect on health or the environment. Hazardous substances and materials should be reduced and marked as such in all cases. The first step is the replacement of resources with recyclates. In any case, it is reasonable to mark the materials used. This provides full transparency for manufactures as well as users and designers.

Design of Services—Offer product-service systems. Service units and business models should be conceived and organized, so that services and products can be made available to as many people as possible. In this way, on the one hand, resource efficiency increases (see: 4. Energy Use and 5. Material Use), and on the other, it facilitates products of a higher quality with improved serviceability. In this context the advantages of the digitalization (e.g. online networks, artificial intelligence, block chain technologies) can be applied expediently and strategically. Manufacturers and service providers work together closely in order to provide a closed natural or technical loop. Another option is to intensity the use of products. Products for sharing concepts are used considerably more intensively over the same time frame. When designing sharing concepts incentives for usage than property have to be thought of. Even more consistent would be the replacement of the product with a service, such as car sharing. First step here is comparing the actual use of the product in relation to the non-use.

Society and Circular Design—Make progress in society. Design decisions have a significant influence on who uses the product and how. In circular design the principles of reuse and social interaction are intrinsic to all product life cycles. Not only ecological but also socially sustainable and participative design strategies are important. Production processes are to be developed that take social values into account, create possibilities for further education, and facilitate social exchange.

3 Conclusions and Future Perspectives

Key target groups of generalized product design guidelines are practitioners experienced with circular economical systems and inexperienced people, as only a symbiosis of material providers, manufacturers, designers and consumers, respectively ‘recyclers’ can guarantee a successful transition to a circular economy.

All challenges and solutions experienced during production processes were integrated in these design guidelines, thus providing focal target groups of designers and manufacturers/investors with a practical guidance on how to potentially improve the product applications.

In the course of further steps business strategies will be determined, explored and developed with the aim to increase interest from European companies for an accelerated transition of their value chains towards a circular economical orientation. The inclusion of design guidelines for product re-use may provide (first) comprehensive information to stakeholders on the essential changes from linear to circular design in production.

In the long term, incessant development of product re-design guidelines by detailing information for industrial value chains needs to be established. Public dissemination and circulation of guidelines among pivotal stakeholders will support the crucial action of raising attention towards circular economically oriented product/industrial design.

References

Ellen MacArthur Foundation: Towards the circular economy. Opportunities for the consumer goods sector (2013)

Hora, M., Tischner, U.: Mit Ecodesign zu einer ressourcenschonenden Wirtschaft, p. 11. Hessen Trade & Invest GmbH, Wiesbaden (2015)

Social Design Lab, Hans Sauer Stiftung (eds.): Wege zu einer circular society. Potenziale des Social Design für gesellschaftliche Transformation. Munich (2020). https://www.hanssauerstiftung.de/inhalt/uploads/200420_HSS_Paper_CircularSociety_online.pdf. Last Accessed 29 June 2022

Club of Rome. https://clubofrome.org. Last Accessed 8 May 2020; Institute of Sustainable Economy. https://www.ioew.de/en/. Last Accessed 8 May 2020

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2022 The Author(s)

About this chapter

Cite this chapter

Filek, S., Gründl, H., Heinrich, V.L., Kellhammer, M., König, T. (2022). Product Re-Design Guidelines. In: Colledani, M., Turri, S. (eds) Systemic Circular Economy Solutions for Fiber Reinforced Composites. Digital Innovations in Architecture, Engineering and Construction. Springer, Cham. https://doi.org/10.1007/978-3-031-22352-5_13

Download citation

DOI: https://doi.org/10.1007/978-3-031-22352-5_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22351-8

Online ISBN: 978-3-031-22352-5

eBook Packages: EngineeringEngineering (R0)