Abstract

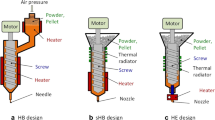

Nowadays, 3D printing technology is becoming more popular with various applications. 3D printing is also a potential process in tissue engineering applications for fabricating scaffold. The scaffold needs to have the proper structure and properties to initiate a favorable environment for cell growth and tissue generation. In this study, the customized direct powder extrusion based on screw extruder was developed and the influence of printing parameters including printing speed and temperature on characteristics of scaffolds from PCL powder was investigated. The result evaluation shows that the size of line width and pore size are significantly affected by printing parameters. The optimal printing conditions were obtained at print speed 6 mm/s, extrusion speed 50 rpm, and heating temperature of 100 ℃ to fabricate scaffolds from PCL powder materials. The results are the basis for further studies in optimizing the printing condition for PCL scaffolds based on direct powder extrusion.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Gleadall, A., et al.: Review of additive manufactured tissue engineering scaffolds: relationship between geometry and performance. Burns Trauma 6, 1–16 (2018)

Jahani, B., Wang, X., Brooks, A.: Additive manufacturing techniques for fabrication of bone scaffolds for tissue engineering applications. Recent Prog. Mater. 2(3), 1–41 (2020)

O’Brien, F.J.: Biomaterials & scaffolds for tissue engineering. Mater. Today 14(3), 88–95 (2011)

Paula, A., et al.: Advances in additive manufacturing for bone tissue engineering scaffolds. Mater. Sci. Eng., C 100, 631–644 (2019)

Acknowledgments

This research is funded by the Vingroup Innovation Foundation (VINIF) through project VINIF.2020.DA13.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Do, Q.D., Nguyen, D.K., Van Nguyen, T., Phung, L.X., Nguyen, T.K. (2023). Effect of Printing Parameters on Characteristics of PCL Scaffold Fabricated by Direct Powder Extrusion. In: Nguyen, D.C., Vu, N.P., Long, B.T., Puta, H., Sattler, KU. (eds) Advances in Engineering Research and Application. ICERA 2022. Lecture Notes in Networks and Systems, vol 602. Springer, Cham. https://doi.org/10.1007/978-3-031-22200-9_51

Download citation

DOI: https://doi.org/10.1007/978-3-031-22200-9_51

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22199-6

Online ISBN: 978-3-031-22200-9

eBook Packages: EngineeringEngineering (R0)