Abstract

Carbon fiber composite materials are intensively used in many manufacturing domains such as aerospace, aviation, marine, automation and civil industries due to their excellent strength, corrosion resistance, and lightweight properties. However, their increased use requires a conscious awareness of their entire life cycle and not only of their manufacturing. Therefore, to reduce waste and increase sustainability, reparation, reuse, or recycling are recommended in case of defects and wear. This can be largely improved with reliable and efficient non-destructive defect detection techniques; those are able to identify damages automatically for quality control inspection, supporting the definition of the best circular economy options. Hyperspectral imaging techniques provide unique features for detecting physical and chemical alterations of any material and, in this study, it is proposed to identify the constitutive material and classify local defects of composite specimens. A Middle Wave Infrared Hyperspectral Imaging (MWIR-HSI) system, able to capture spectral signatures of the specimen surfaces in a range of wavelengths between 2.6757 and 5.5056 µm, has been used. The resulting signatures feed a deep neural network with three convolutional layers that filter the input and isolate data-driven features of high significance. A complete experimental case study is presented to validate the methodology, leading to an average classification accuracy of 93.72%. This opens new potential opportunities to enable sustainable life cycle strategies for carbon fiber composite materials.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Hyperspectral imaging

- Automatic defect detection

- Deep learning

- Convolutional neural network

- Composite materials

- Circular economy

1 Introduction

In the past few decades, carbon fiber composite materials have been largely used in many manufacturing domains such as aerospace, aviation, marine, automation, sports, and civil industries, due to their excellent strength, corrosion resistance, low thermal expansion, and lightweight properties.

It is estimated that by 2025, the annual global CFRP (Carbon fiber reinforced polymers) waste will reach 20 kt; at this year the cumulative amount of CFRC (Carbon fiber reinforced composites) waste which is ready to be recycled in Europe is estimated to reach 144,724 t [1]. This poses great challenges, due to the current environmentally unfriendly CFRC waste management, yet in disagreement with the European Composites Industry Association (EuCIA) directives, which in 2011 has set strict recycling and reuse practices based on the European Union directives on End-of-Life (EOL) vehicles 2000/53/EC and waste 2008/98/EC [2].

1.1 Hyperspectral Imaging (HSI)

The defect detection techniques assist the life cycle assessment, structural performance maintenance, value chain integration, reverse logistic strategy, ecological benefits, and transition into a circular economy model. Several non-destructive techniques (NDTs) are often used for defect detection; however, they cannot usually identify the material and have several disadvantages. Visual inspection and RGB machine vision system methods are extensively affected by the surrounding conditions and unsuitable for hazardous material [3]. Due to the radiation hazard, safety protection tools are required for X-ray imaging and neutron imaging methods [4, 5]. Eddy current tests detect surface and subsurface cracks, but only for conductive materials [6]. The active infrared (IR) thermography is safe and quick with respect to other NDTs [7], but the automatic data processing is challenging despite the recent methodologies such as machine-learning [8], deterministic-differential analyses [9], and deep learning [10]. The resonant inspection method detects the resonant frequency shifts resulting from changes in mass or stiffness of defected areas [11], but the accuracy is highly sensitive to the surrounding noise. Ultrasonic testing is not suitable for the intricate shape of material surfaces [12]. The shearography testing results are difficult to interpret and require a good light source [13].

Along with defect detection, precise material identification is also necessary to address remanufacturing, repair, reuse, and recycling processes in a circular economy perspective. X-ray imaging [14], x-ray computed tomography (XCT) [15], optical microscopy-based imaging [16], and scanning electron microscopy [17] can be utilized for both defect and material identification. However, they require sample extraction, preparation and measurement steps, which are very time-consuming and usually carried out offline; while the online or inline identification of material is essential to set the parameters of manufacturing, repair, remanufacturing, and recycling. This is particularly relevant in the case of composite materials, since the material compositions and, thus, process specifications vary according to different types, designs, manufacturers, and applications.

HSI measures the continuous spectrum of the light for each pixel of the sample with fine wavelength resolution and it can work online or inline directly on parts with no sample preparation nor causing any damage. Therefore, it can perform a very powerful quality control task, playing a vital role in EOL management.

HSI is able to extract a large variety of information on any kind of surface and provides a promising solution to identify the material along with defect classifications. In compare to other HSI applications [18, 19], very few research studies are reported to identify defects in carbon fiber composite material and still in their infancy [20]. Carbon fiber composites are used in many high precision applications where, in addition to visual and geometric quality control, other quality parameters of performance related defects must be identified in order to comply with the safety of end-users. Therefore, the quality control should be intelligent and robust, to handle the complexities, uncertainties, and variability of the operations.

In this context, the traditional vision systems normally fail, while hyperspectral acquisition system goes far beyond the RGB imaging; it captures the high-resolution spectra at every pixel providing not only physical but also chemical information of the specimen. The large amount of information provided by HSI system comes at the cost of complex data acquisition and a huge volume of data. Indeed, HSI acquires two spatial and one spectral dimension, requiring a complex image analysis for image preprocessing (i.e. calibration, noise removal, data reduction), feature extraction, and classification. The use of HSI integrated with remanufacturing processes will improve the ability of industries to retrieve re-usable CFRC materials from composite components. Consequently, this will reduce the usage of virgin materials, the energy required during manufacturing and logistics operations and, ultimately, the CO2 footprint along the whole product lifecycle, maintain the waste management legislation, and product emissions regulations.

In this work, a case study shows the possibility of using HSI method to identify material and defects of CFRC. A defect apparatus has been developed to create different defects on carbon fiber composites. A hyperspectral imaging system has been used for acquiring the images and an image processing technique, based on a deep neural network, has been designed to classify the types of defects and identify the different materials.

2 Material and Method

A material and defect identification method is proposed using the middle wave infrared hyperspectral imaging system. Two different types of thermosetting carbon fiber reinforced composites have been studied and two types of defects have been generated on the specimens. The specimens were scanned by the middle wave infrared hyperspectral imaging system, and the spectra have been analyzed with a convolutional neural network (CNN) to identify the unique response from the specimen material and defects.

Two types of thermosetting carbon fiber reinforced composites, FDCA 0.6 (5% CAT 4 layer) and AFD 60 (4 layers) [21], developed by Politecnico di Milano [22], have been investigated. The used samples have square shapes with dimensions of about 10 cm x 10 cm and thickness between 1 and 1.5 mm. Since CFRC material appears black, it has a very limited reflectance in the visible near-infrared and near-infrared spectral region, thus, a MWIR-HSI has been used in this study: a SPECIM broom type camera with spectral range from 2.6757 μm to 5.5056 μm.

The apparatus for defect creation, based on the drop weight impact test procedure, consists of a hollow pipe, a falling body, an impactor holder, and two types of impactors. The two cylindrical shape falling bodies with 0.995 kg and 2.046 kg of mass are used to pass through a hollow pipe at the height of 1 m. The two main defects (conical and hemispherical) (Fig. 1) have been created using a conical impactor generating an impact energy of 10 J and a pressure of 1.6 bar and a hemispherical impactor generating an impact energy of 20 J and a pressure of 1.8 bar.

The approximate diameters of conical and hemispherical defects are 2.9 mm and 5.5 mm, respectively. For each specimen, before acquiring the specimen image (Iraw), the dark (Idark) and white references (Iwhite) were captured with the camera cover and a frosted aluminum alloy tile, respectively, and used for the calibration procedure to obtain the reflectance values (Eq. 1).

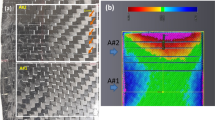

Hyperspectral images of three specimens of each material were acquired before and after the creation of the defects. Figure 2a represents the hypercube of a CFRC-AFD 60 specimen and Fig. 2b three reference spectra, one for each defect type and one for the material of that specimen. Each spectrum was preprocessed to feed a convolutional neural network and used either for the training, the validation or the test. Each spectrum is made of N samples representing the reflection contribution of the specimen at a specific wavelength. Each point of the specimen surface produces a response labeled in one of four classes: one for each material type and one for each defect type.

The network architecture is shown in Fig. 3. The convolutional layer (Conv 1D) consists of a bank of 35 convolutional filters having 35-entries-length kernels and the classification layer is made of three sublayers: fully connected layer - a neural network receives the input features, processed by the previous convolution-based layers, a softmax layer - the four outputs of the fully connected layer are arguments of a softmax function and a classification layer - the probabilities are compared to select the class with the maximum score (probability).

It is worth noting that the network processes each spectral signature alone, without considering further contributions from adjacent pixels. In this way, the defect detection is independent of the shape of the training defects. The classification only depends on the current response of the material for the specific pixel under analysis.

3 Results and Discussions

The acquisition parameters have been optimized to improve the quality of the images, detect small features, and reduce the computational load. A high exposure time value is desirable to increase the signal-to-noise ratio and thus, provide better spectra. However, a trade-off has to be selected to avoid image saturation, in particular for the white reference. Therefore, several tests have been carried out to identify the best exposure time. Moreover, in order to acquire not distorted images of the samples, the correct aspect ratio has to be found varying the frame rate and the scanning speed. Figure 4a and 4b show the effect of an incorrect setting. A proper aspect ratio (Fig. 4c) has been found with a frame rate 21.5 times bigger than the scanning speed. Furthermore, the larger the specimen the better the analysis. Accordingly, the field of view has been reduced as much as possible, taking into account the depth of focus of the camera and the physical constraints of the HSI system.

The classification performance of the proposed network has been proven through the analysis of a complete dataset made of several acquisitions. Six specimens have been used in this case study, which includes three specimens made of FDCA 0.6 and three specimens of AFD 60. All the specimens were scanned by HSI system before and after damaging them so that around 30 defects for each type (hemispherical and conical) have been selected as a train set. The network training minimizes the loss function, i.e. the mean distance between the expected and predicted class, with the Adam optimizer considering each class of the same weight. The stop criterion is computed through a validation procedure. The validation set is used to compute an accuracy value while learning a correct prediction ratio, helpful in stating whether the network is converging towards a correct solution.

Due to the reduced dimension of impact areas, in comparison with the area of the specimens, the populations of the classes are unbalanced. Therefore, since the loss optimization is performed considering equally-weighted classes, the most populated classes have been partially reduced but not matched to the least populated ones to induce an implicit bias to the predictions of non-defective regions. The tuning of the network has been completed in 34 epochs achieving an accuracy of 94.32% in label predictions, thus suggesting the exact convergence of the optimization, confirmed by the balanced accuracy, which scales the standard accuracy by the population of the reference class [23]. The testing process confirms the network’s capability to classify the input spectra, recognizing the specific constitutive material of the specimens and the defects. Specifically, the global accuracy, considering all correct detections, reaches 93.72%, with an average balanced accuracy of 85.55%. A prediction map of a test specimen is reported in Fig. 5. Conical defects are identified with low sensitivity since they are often confused with defects of the other classes, but not with homogeneous areas, which is very promising for manufacturing quality control. As shown in Fig. 6, the sensitivity can be easily improved, without inducing misclassifications of the hemispherical-shaped defects, whose probabilities are much higher and close to 1 (refer Fig. 6(a)), setting the threshold of classification scores of conical defects to 0.25.

In this work, HSI potential has been exploited with plastic composites with a very limited reflectance. In comparison with another study that used HSI to detect surface damage in carbon fiber reinforced polymer materials [20] no issues related to the background have been observed. Moreover, the low impact energy of the defects (11.9 J) and the complex surface texture, which has been assumed in [20] as the cause of a reduced detection accuracy, are very similar to the conditions of the present study, where good overall classification accuracy is achieved due to a robust computation algorithm. Finally, in this work not only the defects, but also the constituent materials have been detected at the same time as required in industrial product management.

4 Conclusions

In this paper, HSI method is proposed for accurate, fast, and reliable quality control of carbon fiber composite parts and demonstrated with a simple case study, in which it was combined with a deep neural network to identify material and defects of thermosetting CFRC samples. The results confirm that HSI is very suitable for non-destructive defect detection and allows not only an efficient classification of various types of defects, but also a reliable identification of material differences in CFRC.

As a practical and managerial implication, this study demonstrated that HSI is a very promising candidate as enabling technology for sustainable manufacturing and the circular economy of composite materials. By systematically adopting HSI as a reliable and accurate solution for in-line or online quality control of manufactured parts, companies will be able to early detect defects and repair parts in order to limit non-quality costs and customers’ complaints. In terms of circular economy, the precise identification and characterization of materials and defects through HSI will provide companies the necessary information to select the most appropriate strategies, including repair, reuse, and recycling. This will minimize the production of new parts and, at the same time, will maximize the value of products and materials with significant environmental benefits. This research presents some limitations. First, this methodology can be exploited to all types of materials and, thus, a large variety of product domains, but it is not applicable in the case of internal damage as HSI scans only external surfaces. Second, this research was limited to plain specimens of CFRP, investigating defects bigger than 2.9 mm. Third, from a business point of view, the economic and industrial sustainability of the introduction of HSI was not investigated due to the explorative nature of this research. Accordingly, further work, studies with a larger variety of materials, smaller dimensions of the defect and other geometrical profiles of defects such as wrinkles, cracks, and scratches have to be implemented to verify the sensitivity of the hyperspectral imaging system.

References

Oliveux, G., Dandy, L.O., Leeke, G.A.: Current status of recycling of fibre reinforced polymers: review of technologies, reuse and resulting properties. Prog. Mater. Sci. 72, 61–99 (2015)

Chang, C.-I.: Hyperspectral Imaging: Techniques for Spectral Detection and Classification, vol. 1. Springer Science & Business Media, Boston, MA (2003)

Shanmugamani, R., Sadique, M., Ramamoorthy, B.: Detection and classification of surface defects of gun barrels using computer vision and machine learning. Measurement 60, 222–230 (2015)

Garcea, S.C., Wang, Y., Withers, P.J.: X-ray computed tomography of polymer composites. Compos. Sci. Technol. 156, 305–319 (2018)

Banhart, J., et al.: X-ray and neutron imaging – complementary techniques for materials science and engineering: dedicated to Professor Dr. H.-P. Degischer on the occasion of his 65th birthday. Int. J. Mater. Res. 101, 1069–1079 (2010)

García-Martín, J., Gomez-Gil, J., Vázquez-Sánchez, E.: Non-destructive techniques based on Eddy current testing. Sensors (Basel). 11, 2525–2565 (2011)

Balageas, D., et al.: Thermal (IR) and other NDT techniques for improved material inspection. J. Nondestr. Eval. 35(1), 1–17 (2016). https://doi.org/10.1007/s10921-015-0331-7

Marani, R., et al.: Automatic detection of subsurface defects in composite materials using thermography and unsupervised machine learning. In: Proceedings of the IEEE 8th International Conference on Intelligent Systems, p. 516 (2016)

Marani, R., et al.: Two-dimensional cross-correlation for defect detection in composite materials inspected by lock-in thermography. In: Proceedings of the 22nd International Conference on Digital Signal Processing, pp. 1–5 (2017)

Marani, R., Palumbo, D., Galietti, U., D’Orazio, T.: Deep learning for defect characterization in composite laminates inspected by step-heating thermography. Opt. Lasers Eng. 145, 106679 (2021)

Stultz, G., Bono, R., Schiefer, M.: Fundamentals of resonant acoustic method NDT. Adv. Powder. Metall. Part. Mater. 3, 11 (2005)

Felice, M.V., Fan, Z.: Sizing of flaws using ultrasonic bulk wave testing: a review. Ultrasonics 88, 26–42 (2018)

Hung, Y., Ho, H.P.: Shearography: an optical measurement technique and applications. Mater. Sci. Eng. R-Reports 49, 61–87 (2005)

Bunaciu, A.A., Udriştioiu, E.G., Aboul-Enein, H.Y.: X-Ray diffraction: instrumentation and applications. Crit. Rev. Anal. Chem. 45, 289–299 (2015)

Maire, E., Withers, P.J.: Quantitative X-ray tomography. Int. Mater. Rev. 59, 1–43 (2014)

Shen, Y., Wan, W., Zhang, L., Yong, L., Lu, H., Ding, W.: Multidirectional image sensing for microscopy based on a rotatable robot. Sensors (Basel). 15, 31566–31580 (2015)

Goldstein, J.I., Newbury, D.E., Michael, J.R., Ritchie, N.W.M., Scott, J.H.J., Joy, D.C.: Scanning electron microscope (SEM) instrumentation. In: Scanning Electron Microscopy and X-Ray Microanalysis, pp. 65–91. Springer, New York (2018). https://doi.org/10.1007/978-1-4939-6676-9_5

Wu, D., Sun, D.-W.: Advanced applications of hyperspectral imaging technology for food quality and safety analysis and assessment: a review — part I: fundamentals. Innov. Food Sci. Emerg. Technol. 19, 1–14 (2013)

Candiani, G., et al.: Characterization of fine metal particles derived from shredded WEEE using a hyperspectral image system: preliminary results. Sensors (Basel). 17, 1117 (2017)

Yan, Y., et al.: Nondestructive Testing of Composite Fibre Materials with Hyperspectral Imaging : Evaluative Studies in the {EU} {H2020} FibreEUse Project, CoRR. abs/2111.0 (2021)

Jin, Y., et al.: Recent advances in dynamic covalent chemistry. Chem. Soc. Rev. 42, 6634 (2013)

Fortunato, G., et al.: Simultaneous recovery of matrix and fiber in carbon reinforced composites through a diels-alder solvolysis process. Polymers (Basel) 11, 1007 (2019)

Marani, R., Palumbo, D., Galietti, U., Stella, E., D’Orazio, T.: Enhancing defects characterization in pulsed thermography by noise reduction. NDT E Int. 102, 226–233 (2019)

Acknowledgments

This work has been developed in the context of the COMPOSER (Carbon-fiber reinforced composites for Sustainable circular Economy models based on Repair and Remanufacturing for Reuse) project funded by “Fondazione Cariplo” and partially funded by the European Union under the DiManD project (H2020-MSCA-ITN, grant agreement No. 814078).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Patil, T., Pagano, C., Marani, R., D’Orazio, T., Copani, G., Fassi, I. (2023). Hyperspectral Imaging for Non-destructive Testing of Composite Materials and Defect Classification. In: Kim, KY., Monplaisir, L., Rickli, J. (eds) Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus . FAIM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-18326-3_39

Download citation

DOI: https://doi.org/10.1007/978-3-031-18326-3_39

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18325-6

Online ISBN: 978-3-031-18326-3

eBook Packages: EngineeringEngineering (R0)