Abstract

Digital twins in manufacturing plays a key factor for the digital transformation. A necessary component of any digital twin in manufacturing is a geometric model of a workpiece as it is processed through steps. DT requires solid 3d models, machining features, and information regarding machines, tools, and its constraints such as initial setup, machining direction, etc. The objective of this paper is to generate alternate feature interpretations to identify geometric constraints, machine and tool requirements, and stock materials to generate flexible manufacturing plans that fit a defined criterion. In this study we propose using the IMPlanner system to retrieve a 3d model from a CAD software, read its geometric features and convert them into possible machining features. This information along with information from the database of stock materials, tools, machines, and tolerances, the system generates several feature interpretations, thus offering a more flexible manufacturing plan.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Manufacturing companies strive to streamline their processes to reduce operational costs and minimize lead times. The constant pursues to integrate computer aided design CAD and computer aided process planning CAPP resulted in several feature-based solutions. However, this integration proved challenging due to the complexity of the features for each part, and different interpretations of features in each step. Several solutions have been presented to overcome such challenges, which will be explained in the following section. The goal of this paper is to propose a new methodology to generate alternate feature interpretations using a digital twin model which creates intermediate solid models. This way the design and planning processes use the same data types, and the system has the ability to exchange information bidirectionally between the two. We use the IMPlanner systems that connects to a Siemens NX™ CAD software’s API and retrieves the geometric model information which is used to generate a digital twin of the desired part and the features included. The different solutions proposed in the literature are outlined in Sect. 2. Section 3 will explain the procedure to generate the alternate features, a machining process sequence and intermediate workpiece model. An example using a complex part is presented in Sect. 4, and finally the conclusion along with prospect future work to complement this research is presented in Sect. 5.

2 Literature Review

Computer aided process planning CAPP and its integration with computer aided design CAD has received significant attention since the 1980s [1]. CAD and CAPP integration became the main focus area due to the versatility of options provided by feature-based integration [1]. Yang et al. [2] reviewed the different types of product modeling explaining the advantages of feature-based product modeling over solid product modeling. Their reasoning states that feature-based modeling maintains data integrity across several domains and it’s easier to transfer. Additionally, they explain the role of those modeling types in newer modelling techniques such as object-oriented product modeling. Ma et al. [3] explain how features can be used as information units to avoid incompatible data structures amongst different design stages. Their unified modeling scheme combines both geometric and non-geometric attributes to determine the inter or intra-relation between features. Kritzinger et al. [4] define digital twin as mirroring an asset with advanced technology to reproduce them in a virtual setting. This practice allows for further product development and more efficiency. Goopert et al. [5] emphasize the benefits of digital twins in modern manufacturing practices. As they explain, the connection between physical and digital assets enables smooth data transfer and easier adaptations. Liu and Wang [6] presented a feature sequencing method using knowledge-based rules and geometric reasoning to generate feature sequencing rules considering setups on tool-approaching directions. To expand on this study, Mokhtar et al. [1] discuss the machining precedence of STEP-NC features. Their approach is to detect interacting features considering their geometric constraints and machining constraints. Using both they determined the precedence of the features and generated several machining plans. Adding to this work, Dipper et al. [7] propose a set of algorithms to generate a feature interaction detection system for STEP-NC data models. Their algorithms, written in the programming language C++, calculate the volumes of all the features and faces that are interconnected in a part. However, this method is limited to simple faces. Further efforts considered more complex features. Zheng and Mohd Taib [8] developed an algorithm for feature recognition of inner loops. This methodology focuses on the Solidworks models and converts shapes such as islands, through pockets and pockets into machining features. Ma et al. [3] explained the importance of collaborative feature-based engineering systems to improve the product development process. The authors outline the issues related to this approach, including different definitions of features and their data structures. Therefore, they proposed a feature-based unification to integrate all the features into suitable applications. Different approaches with more unconventional algorithms were taken. Houshmand et al. [9] proposed a flower pollinating with artificial bees (FPAB) technique to generate machinable features. Their approach is to develop elementary volumes and then merge them to generate machinable volumes which are considered as candidates and their tool evaluates them to generate possible sequences of machining operations. Liu et al. [10] proposed a semantic feature language that is compatible across multiple domains in concurrent engineering. Their approach to ease integration between CAD and CAM systems separates features hierarchically. Different hierarchies are required for different domains. Therefore, this approach simplifies the communication and exchange of machining features across different platforms. Mokhtar and Xu [1] complemented this work with a proposed a rule-based system for machining precedence relations and make it compatible with STEP-NC models. Their system considers the interaction between all the features and includes more complex faces such as pockets, and through holes. To include sequence considerations, Khoshnevis et al. [11] proposed a planning system using feature reasoning and space search-based optimization. Their approach is to upstream integration with design systems and downstream integration with scheduling considering dynamic constraints such as machine and tool availability to produce more efficient process plans. Applying this methodology to manufacturing, Šormaz et al. [12] designed and proposed the IMPlanner system. A set of algorithms and rules that use XML data representation to generate process plans considering all the mentioned constraints. Expanding upon the previous work, Sormaz et al. [13] proposed a rule based process selection of milling processes considering GD&T requirements. This approach considers different requirements which outputs new manufacturing routes for more optimality in the entire process. Guo et al. [14] proposed a hybrid feature recognition method using graph and rule based methods. Their approach uses traditional graph techniques such as boundary representation, and a set of algorithms to recognize individual features. It then loads the information into a matrix to find the relationships and extract the required information for the following process. Throughout the years there has been extensive work done in the area of feature recognition and interpretation for manufacturing planning. Earlier work focused on simpler faces and pockets, and later work expanded to more complex shapes. The industry 4.0 movement increased the digitalization of the manufacturing processes using data driven methods. Our work expands on a systematic approach to generate alternate feature interpretations. The previous research considers feature recognition is several ways, however, this methodology uses a novel approach of creating a digital twin model for a more extensive feature interpretation to generate intermediate solid models for further analysis and application in manufacturing planning and processing.

3 Methodology

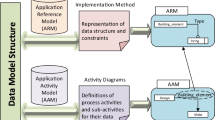

This section expands the process to generate intermediate workpiece from a CAD model via an interface with a CAD system. After a brief overview, previously built modules are briefly described and modules for intermediate workpiece generation explained.

3.1 Overview

Figure 1 shows a complete map of the process to retrieve CAD model and use its information to develop a machining processing plan. This task is accomplished using the IMPlanner system and the CAD software Siemens NX. The IMPlanner system is a software tool developed at Ohio University comprised of several algorithms for the purpose of CAPP. It connects to the CAD system’s API and retrieves the desired model. Next, the system completes feature mapping and feature solid creation operations. Then, a feature interaction analysis is performed to check the interaction between features, this analysis considers face neighborhood, feature neighborhood, feature interaction and feature precedence. It considers geometric factors concerned with tolerance, technological factors concerned with machine feasibility, and economic factors concerned with cost. This information helps separate required features from optional features, then generate a precedence network which then is used for the process sequencing stage. All the information is uploaded to the feature-based CAPP. This system then generates optimal machining operation sequences for all the volumes and processes them into the manufacturing assembly model.

The major steps of the procedure are feature mapping and feature interaction analysis, process selection and process sequencing, feature volume generation, intermediate workpiece model (digital twin) generation. Some of the steps were reported in the earlier work and they will be just briefly explained. The steps for feature volume generation and intermediate workpiece are subject of this paper and they are explained in more details.

3.2 Feature Mapping and Interaction Analysis

A manufacturing feature is a collection of related geometric elements, which can be associated to a manufacturing process. Features of mechanical components have been selected as the communication medium for the integration of CAD/CAM systems [15]. The features are usually viewed differently in different stages of the product design and manufacturing process. Design features differ from manufacturing features. Figure 2 shows the different interpretation for a hole as a design feature and a manufacturing feature. A CAD software shows a simple hole with a specified radius and depth inside a block, whereas a cylinder removed from a block showing an approach axis and depth is considered a machining feature. Feature mapping considers all the faces and generates a coordinates index array which contains the axis points, reference points and the attributes of the feature such as radius, length, distance among others. Figure 3 outlines the approach for feature mapping of a general slot. The design features and their parameters are retrieved from the CAD model. The program converts the model features into appropriate machining features by finding its outline location and setting it as a reference position, then projects a normal vector from it and uses the placement outline to create profiles for the new volume. Finally, the floor offset sets the bottom distance. This approach changed the design features into machining features that satisfy approachability criteria. After the machining features are mapped, their interactions are analyzed using geometric and neighborhood information from the CAD model. This results in the Feature Precedence Network (FPN) which is a set of constraints on the order of manufacturing individual features. The details of the procedure are outside the scope of this paper, but its details can be found in [16].

3.3 Process Selection and Process Sequencing

The interaction analysis determines required and optional features. Features which volumes can only be removed by machining processes associated with it are considered required. On the other hand, optional features can be removed while machining another feature. This aspect is crucial for process and sequence selection. In this step the system verifies GD&T requirements, process capability, and tools and machine availability. Then implements a process selection procedure based on specific and generic rules. Specific rules include cutting operation and quality while generic rules include compatible machines, process capability, and feature relations. The optimization algorithm generates process instances, then checks for process capabilities. If a match is complete, then the process is accepted for the feature, then tools and machine is specified and finally the machining time and cost are considered guarantee optimality (see Fig. 4). Process sequencing uses a space search-based optimization to generate alternate sequences. All those decisions are made based on knowledge in rules and facts inferred from the CAD model. Details of these steps have been reported in earlier work and, therefore, are out of the scope for this paper.

3.4 Feature Volume Generation

Feature volume generation is based on a stock volume and parameters of each feature. Using process information which may have several access directions thus can be approached from several different positions, we can generate volume for each possible feature. Considering each non-floor face of a feature as the floor face for a possible alternative feature allows to project the face on the stock for the part, then the generated volume is a new possible feature. Features are presented in a parametric way, and it is necessary to convert those parameters into solid volumes. These volumes depend on the size and shape of the stock. Figure 5 shows the parameters used to map out the slot and how they are derived to generate a solid volume which is minimal for material removal.

3.5 Intermediate Workpiece Generation

Upon the completion of process planning procedure, an intermediate workpiece of the manufacturing process is created. The IMPlanner system takes the manufacturing part model and the stock material as input, both of them in the form of CAD models. Based on recommendation from Siemens NX [17] an assembly file that contains all components of the digital twin is created. The components of that assembly file are (see Fig. 6): the part model, the stock model, delta volume, and incremental manufacturing model. The part model and stock model are input for a given design, the delta volume is a CAD model of all machining features (or set difference between stock and part). An incremental manufacturing model corresponds to removal of individual features from stock. Based on the process sequence, as individual feature is machined, its volume is subtracted from the stock volume and intermediate model is created. Those intermediate models can be saved in order to explore forces and stress during machining. An example of this procedure will be shown later in Sect. 4. All these steps are performed from IMPlanner’s digital twin module, but they generate and modify CAD models using Siemens NX Java API.

4 Case Study

In order to illustrate the intermediate workpiece generation procedure, we will use an example of a mechanical part called slider. Figure 7 shows the drawing from a CAD model of the part with all its specifications.

The IMPlanner system loads the part from Siemens NX and reads all its geometric features, Fig. 8 shows the results of feature mapping process with a 3D view for verification. Process selection and process sequencing procedures are executed within IMPlanner with generation of alternate processes and their sequencing according to the FPN. The results of those steps are shown earlier in Fig. 4. The complete process plan is loaded into the Digital twin module to finalize the CAD Models creation steps. The individual feature volumes and the whole delta volume are created first as shown in Fig. 9. Incremental volume can be created in two modes: individually by selecting features in the feature tree, or automatically using the process sequence. The result after completing some features is shown in Fig. 10 in NX (three features) and in Fig. 11 in IMPlanner (nine features).

This case study demonstrates the capability to generate the workpiece solid on demand. Any alternate process and feature sequence can be used to generate intermediate workpiece solid for that sequence, which can be used for validation and selection of optimal alternative and sequence. Intermediate solid brings additional validation (in addition to time/cost done in sequence optimization), which is, for example, collision detection for tool, fixture, and machine elements.

5 Conclusion

The proposed methodology developed a novel procedure for generation of manufacturing digital twin. Intermediate solid models can be used to generate more machining features. The main advantages of this approach are extensive analysis of features and feature interactions which lead to more machining sequences thus offering more flexible manufacturing plans. To expand upon this work, integration of feature modeling with CAD manufacturing assembly model generation can be considered. The same approach can be used to generate assembly features and develop optimal assembly sequence plans. Combining machining processes with assembly processes will lead to a more efficient and cost-effective manufacturing plan which can benefit the manufacturing industry.

References

Mokhtar, A., Xu, X., Lazcanotegui, I.: Dealing with feature interactions for prismatic parts in STEP-NC. J. Intell. Manuf. 20, 431–445 (2008). https://doi.org/10.1007/s10845-008-0144-y

Yang, W., Xie, S., Ai, Q., Zhou, Z.: Recent development on product modelling: a review. Int. J. Prod. Res. 46, 6055–6085 (2008). https://doi.org/10.1080/00207540701343895

Ma, Y., Chen, G., Thimm, G.: Change propagation algorithm in a unified feature modeling scheme. Comput. Ind. 59, 110–118 (2008). https://doi.org/10.1016/j.compind.2007.06.006

Kritzinger, W., Karner, M., Traar, G., Henjes, J., Sihn, W.: Digital twin in manufacturing: a categorical literature review and classification. IFAC-Pap. 51(11), 1016–1022 (2018). https://doi.org/10.1016/j.ifacol.2018.08.474

Göppert, A., Grahn, L., Rachner, J., Grunert, D., Hort, S., Schmitt, R.H.: Pipeline for ontology-based modeling and automated deployment of digital twins for planning and control of manufacturing systems. J. Intell. Manuf., 1–20 (2021).https://doi.org/10.1007/s10845-021-01860-6

Liu, Z., Wang, L.: Sequencing of interacting prismatic machining features for process planning. Comput. Ind. 58(4), 295–303 (2007). https://doi.org/10.1016/j.compind.2006.07.003

Dipper, T., Xu, X., Klemm, P.: Defining, recognizing and representing feature interactions in a feature-based data model. Robot. Comput.-Integr. Manuf. 27(1), 101–114 (2011). https://doi.org/10.1016/j.rcim.2010.06.016

Zheng, Y., Mohd Taib, J.: Decomposition of interacting machining features based on the reasoning on the design features. Int. J. Adv. Manuf. Technol. 58, 359–377 (2012). https://doi.org/10.1007/s00170-011-3385-4

Houshmand, M., Imani, D., Niaki, S.: Using flower pollinating with artificial bees (FPAB) technique to determine machinable volumes in process planning for prismatic parts. Int. J. Adv. Manuf. Technol. 45, 944–957 (2009). https://doi.org/10.1007/s00170-009-2023-x

Liu, Y.-J., Lai, K.-L., Dai, G., Yuen, M.: A semantic feature model in concurrent engineering. IEEE Trans. Autom. Sci. Eng. 7, 659–665 (2010). https://doi.org/10.1109/TASE.2009.2039996

Khoshnevis, B., Sormaz, D.N., Park, J.Y.: An integrated process planning system using feature reasoning and space search-based optimization. IIE Trans. 31(7), 597–616 (1999). https://doi.org/10.1080/07408179908969862

Sormaz, D.N., Arumugam, J., Ramachandra, H., Patel, C., Neerukonda, N.: Integration of product design, process planning, scheduling, and FMS control using XML data representation | Elsevier Enhanced Reader. https://www.sciencedirect.com/science/article/abs/pii/S0736584510000931. Accessed 01 Feb 2022

Sormaz, D.N., Gouveia, R., Sarkar, A.: Rule based process selection of milling processes based on GD&T requirements. Prod. Eng. 21(2), 26 (2018)

Guo, L., Zhou, M., Lu, Y., Yang, T., Yang, F.: A hybrid 3D feature recognition method based on rule and graph. Int. J. Comput. Integr. Manuf. 34(3), 257–281 (2021). https://doi.org/10.1080/0951192X.2020.1858507

Gao, J., Zheng, D.T., Gindy, N.: Extraction of machining features for CAD/CAM integration. Int. J. Adv. Manuf. Technol. 24(7–8), 573–581 (2004). https://doi.org/10.1007/s00170-003-1882-9

Arumugam, J.: Analysis of feature interactions and generation of feature precedence network for automated process planning. Ohio University (2004). https://etd.ohiolink.edu/apexprod/rws_olink/r/1501/10?clear=10&p10_accession_num=ohiou1176142843. Accessed 02 Mar 2022

***: Mill Manufacturing Process, Student Guide, 6 vols. EDS Inc. (2003)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Šormaz, D., Campos, A.C., Arumugam, J. (2023). Generation of an Intermediate Workpiece for Planning of Machining Operations. In: Kim, KY., Monplaisir, L., Rickli, J. (eds) Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus . FAIM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-18326-3_37

Download citation

DOI: https://doi.org/10.1007/978-3-031-18326-3_37

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18325-6

Online ISBN: 978-3-031-18326-3

eBook Packages: EngineeringEngineering (R0)