Abstract

The textile industry is one of the oldest and largest industries in the world. The fields of application for textile products are diverse. Although the technologies for manufacturing textiles are extensively researched, the industry is still highly dependent on expert knowledge. To date, manual process- and machine adjustments and quality control are the norms rather than the exception. Heat setting is used in the process chain to dissolve or selectively introduce tensions from the weaving or knitting process and to prepare the products for digital printing. The correct setting of the machine depends on a large number of different materials-, processes- & environmental parameters. For each product, the machine has to be set up again by an experienced textile engineer. To ease the training for new workers and shorten the machine setting process, this study aims to use machine learning to facilitate and objectify the setting of the heat-setting process. Machine parameters are generated using an invertible neural network (INN) based on pre-defined target parameters. The results can be used to identify trends in machine settings and respond accordingly. Thus, a reduction of machine setting time could be realized.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The textile industry is one of the oldest industries in the world with a wide variety of product applications. These range from medical applications (e.g. stents) and technical textiles (e.g. protective equipment) to clothing and building materials (e.g. insulation) [1]. Similar to all manufacturing companies, the industry is exposed to new challenges due to global change. For example, batch sizes are becoming increasingly smaller due to individual customer requirements [2, 3], experts are retiring [4] and qualified employees are becoming increasingly difficult to find [5]. As the textile industry is characterized by manual labor and expert knowledge dependency, these challenges pose a threat to a large number of companies.

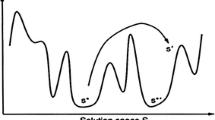

The advancement of production technologies as well as the introduction of digital sensing and networking technologies are opening up new opportunities for companies. Machine learning (ML), for example, can be used to record and analyze product/process data, as well as derive recommendations for action [6,7,8]. Expert knowledge can even be objectified to a certain extent using ML [9, 10]. This objectification could help support decisions in production environments. In the textile industry, finding appropriate process parameters is often done by varying the parameters in an empirically defined range. This results in a significant workload since theoretically, a full factorial experimental design needs to be conducted for every new material. Traditionally, a process can be modelled using ML techniques, then, said model can be used as a part of an optimization process (e.g. evolutionary algorithms [11]) to estimate the required parameters to produce a result of certain characteristics [11,12,13,14,15,16]. Yet, these approaches can not only be computationally expensive, but the used models are applied in non-bijective settings and are often not trivially invertible [12,13,14]. This setting limits severely the amount of knowledge that can be represented in the models. In contrast, the usage of deep invertible models allows an accurate modelling of a process, efficiency in its usage as well as a correct objectification of the parameter prediction problem, in a non-bijective setting.

In this paper, the use of invertible neural networks (INN) is suggested to generate the machine setting of a textile thermosetting machine to shorten setup time and reduce the complexity of the process. Implementing expert knowledge in the training and setup of the INN, machine settings are generated for specific product quality. This partial objectification of expert knowledge supports inexperienced personnel in process handling. For this purpose, experimental data is gathered, an INN is trained, an artificial dataset is generated, its consistency is reviewed for model evaluation, and the accuracy is validated in a set of experiments.

2 Background and State of the Art

2.1 Thermosetting

Thermosetting is a finishing process for textiles. It is used to relieve residual stresses resulting both from the spinning process and from subsequent deformation (knitting, warp knitting, etc.) [17, 18]. Mechanical properties and the crystallinity of the fibers are determined in the spinning process and vary for each production batch. Therefore, the thermosetting process needs to be adapted for every product.

During heat setting, the textile is pre-tensioned and heat is applied. As soon as the textile cools down, new intermolecular bonds are formed which hold the textile in the “deformed” structure [19]. Directional shrinkage occurs in the process [20]. In our application, a textile armband is clamped in a machine, fed to a padder via several deflection rollers, then dried with infrared, and finally fixed via two heated deflection rollers (Fig. 1).

The settings that an employee without expert knowledge can adjust on the machine are listed in Table 1. In addition, empirically recorded minimum and maximum values are given, which must not be exceeded to ensure an error-free process. In particular, the intensity of the heat input and the dwell time of the textile in a heating zone has a major influence on the test result.

2.2 Invertible Neural Networks

The task of process parameter prediction has traditionally been modeled as an optimization process [11, 15, 16]. This approach requires the approximation of the process dynamics through a function, which later is wrapped in an optimization process, changing the input parameters to minimize the difference against the desired quality and the prediction of the process model. Invertible neural networks (INN) allow an approximation of a process that can be evaluated as a forward or inverse function [21]. This replaces the optimization loop of the traditional parameter prediction with an inverse evaluation of the estimated function describing the process.

INNs base layers were introduced by Dinh et al. [22] as ‘inverse coupling layers’, which in contrast with other neural networks can be inverted trivially. Inverse coupling layers require an equal dimensionality of input and output vectors, which is obtained by adding the input and output, as well as adding an extra latent space (bootstrapped to a normal distribution) to the output of the network [21]. During training, the minimized loss is composed of four terms. First is the maximum mean discrepancy (MMD) norm between the input batches and the inverse predictions of the network. Second, the MMD norm between the extra latent space and a normal distribution with mean 0 and variance 1. Finally, the mean square errors (MSE) between the predictions of the network, and the labeled dataset inputs and outputs. In addition, one term was added as a conditional MSE, to ensure forward and inverse predictions stay within a range. Similarly, the gradient of the forward prediction was added to the loss, to increase the smoothness of the approximated INN.

3 Machine Setting Generation in Textile Processing

3.1 Data Acquisition

The data for this approach was acquired in two steps. First, data was gathered in a production environment at the Digital Capability Center (DCC), Aachen, Germany over four days. For that, probes of a woven armband were prepared. Each probe had an initial length of 20 cm and a mean weight of 3.5 g. After thermosetting, the deviance in length, weight, and residual moisture was measured for each probe. An experimental plan with a total of 43 different machine settings was prepared and conducted. For each setting 5 probes were produced, resulting in 215 probes (i.e., data points) in total. Figure 2 shows the deviation of the length of the armband before and after heating.

Second, an INN was trained with the data and created an enlarged artificial dataset. This set was used to validate the INN performance. Textile experts reviewed the dataset to ensure the reflection of physical phenomenons within the model (see Sect. 3.2 for detailed information).

All experiments were conducted on a coating machine MFR2 2C from Jakob Mueller AG, Frick, Switzerland. Pressure was monitored using an SV-Advanced-Box-Mobile, WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany. The residual moisture after processing was measured using an HE53 Moisture Analyzer Scale, Mettler-Toledo GmbH, Greifensee, Switzerland. The length before after processing was measured with a steel rule by Bayerische Maßindustrie A. Keller GmbH, Hersbruck, Germany. All data were collected in the middleware Kepware provided by PTC Inc., Boston, USA.

3.2 Parameter Generation

Since the acquired data for training the neural network was limited, the model had to be improved in another way. Therefore, different measures were taken to train the model to fit the limited acquired data.

First, extra thresholds and the derivative terms were added to the loss for training the model. By limiting the range of values, only values that empirically allow a correct process flow can be specified.

After that, a hypercube with 5 values per variable was created. The values ranged between −2.5 and 2.5 times the previous variable limits. This is to show not only how the predictions behaved for the known regions of the variables, but also how they behaved for extreme values outside of training.

Finally, the trained model was used to compute forward predictions of every data point on the created hypercube, obtaining a representative dataset of the behavior of the model with 16,000 data points. In the first run, the range of the data was not constrained. To enhance the performance, the range of values was narrowed, excluding unrealistic high or low values.

4 Results and Discussion

The generated data were analyzed, revealing several values that could not be produced by the production process under consideration. Furthermore, values were identified, which did not exactly reflect the physical relationships between the influencing parameters (e.g., increasing weight despite lower moisture and higher heat input). Constraints for the data set were therefore developed together with data scientists to increase the data quality.

The real data was plotted with the artificial data to identify correlations between machine parameters and measured quality parameters (Fig. 3). It was possible to show trends between the measured data and the generated set. The green dots indicate the original data, the blue dots represent the artificial data. The generated data traces the relationship between feed rate and weight well, for example. With increasing speed, a higher weight was measured. At the same time, a higher infrared intensity reduces the weight. Based on these findings, it is reasonable to assume that the model reflects a large part of the physiological phenomena in thermosetting. In some experiments, armbands were stretched rather than shrunk (bottom left, green dots over the yellow and red line). This is not displayed by the artificial data, indicating that our model is still to be improved. The deviance in length after processing is significant between measured and generated data sets (see the deviation in the “Length” row). There are two theories for that problem.

The first one is, that there is no data available regarding the material used nor from previous processing. Therefore, errors already worked into the material (e.g., from fiber production or weaving) are not considered.

The second thought is missing information on at least one significant variable in the process. It can be assumed, that the gathering of environmental data such as room temperature and humidity, enhances the accuracy significantly. Despite the inaccuracies, the model at hand is still suitable to limit the range of machine settings to a certain degree.

For validation, a total of 5 different values of the quality parameters weight and length of the wristband were determined. These values were fed into the INN and the resulting machine parameters were used for the process. The accuracy for predicted and measured length and weight varied between 63.4%–88.12% (length) and 71.63%–91.8% (weight). These results show, that the model can predict a trend and limit the options for machine settings to a specific interval. At the same time, the accuracy varies significantly, which needs to be addressed in further research.

5 Summary and Outlook

In this paper, a study to generate machine settings based on desired product properties using an invertible neural network (INN) was presented. To do so, a small data set from the production environment was acquired and used to train an INN. A larger artificial dataset was generated to evaluate the model, and finally, the accuracy of the generated process parameters was validated in an experiment.

Although it was not possible to compile accurate machine settings due to the very complex process and unavailable data regarding material properties from previous production steps as well as environmental data, results are still promising. The model showed clear trends and correlations between the different parameters that were expected by textile experts. For example, the increasing weight of the wristband corresponds with a higher feed rate. Additionally, the influence of heat treatment was detectable. The accuracy for predicted quality parameters varied between 63% and 91%. Though the gap between values is considerable, the results significantly minimize the number of adjustment possibilities for the process and therefore the number of iterations needed for machine setup.

Further research lies in the possibility of transferring the approach to other industries. On top of that, further tests taking into account additional factors such as environmental data, the chemical composition of the coating material, or process data from previous process steps could increase the accuracy of the prediction.

References

Gries, T., Veit, D., Wulfhorst, B.: Textile Fertigungsverfahren: Eine Einführung, Zweite überarbeitete und erweiterte Auflage, Hanser, München (2015)

Klocke, F., et al.: Self-optimizing production technologies. In: Brecher, C., Özdemir, D. (eds.) Integrative Production Technology, pp. 745–875. Springer, Cham (2017). https://doi.org/10.1007/978-3-319-47452-6_9

Piller, F.T.: Kundenindividuelle Massenproduktion (Mass Customization). In: Piller, F.T. (Ed.), Mass Customization, pp. 200–266. Deutscher Universitätsverlag, Wiesbaden (2001). https://doi.org/10.1007/978-3-663-08187-6_7

Krüger, K.: Herausforderung Fachkräftemangel. Springer Fachmedien Wiesbaden, Wiesbaden (2018). https://doi.org/10.1007/978-3-658-20421-1

Pultarova, T., Onita, L.: A problem we can’t afford to ignore [labour resources]. Eng. Technol. 10, 30–33 (2015). https://doi.org/10.1049/et.2015.0317

Colosimo, B.M., Huang, Q., Dasgupta, T., Tsung, F.: Opportunities and challenges of quality engineering for additive manufacturing. J. Qual. Technol. 50, 233–252 (2018). https://doi.org/10.1080/00224065.2018.1487726

Dai, H.-N., Wang, H., Xu, G., Wan, J., Imran, M.: Big data analytics for manufacturing internet of things: opportunities, challenges and enabling technologies. Enterp. Inf. Syst. 14, 1279–1303 (2020). https://doi.org/10.1080/17517575.2019.1633689

Dekhtiar, J., Durupt, A., Bricogne, M., Eynard, B., Rowson, H., Kiritsis, D.: Deep learning for big data applications in CAD and PLM – Research review, opportunities and case study. Comput. Ind. 100, 227–243 (2018). https://doi.org/10.1016/j.compind.2018.04.005

MacInnes, J., Santosa, S., Wright, W.: Visual classification: expert knowledge guides machine learning. IEEE Comput. Grap. Appl. 30, 8–14 (2010). https://doi.org/10.1109/MCG.2010.18

Holzinger, A.: From machine learning to explainable AI. In: 2018 World Symposium on Digital Intelligence for Systems and Machines (DISA), Kosice, vol. 82018, pp. 55–66. IEEE (2018)

Mia, M., Królczyk, G., Maruda, R, Wojciechowski, S.: Intelligent optimization of hard-turning parameters using evolutionary algorithms for smart manufacturing. Materials 12, 879 (2019). https://doi.org/10.3390/ma12060879

Nassef, A.M., Sayed, E.T., Rezk, H., Abdelkareem, M.A., Rodriguez, C., Olabi, A.G.: Fuzzy-modeling with particle swarm optimization for enhancing the production of biodiesel from microalga. Energy Sour. Part A Recov. Utiliz. Environ. Effects 41, 2094–2103 (2019). https://doi.org/10.1080/15567036.2018.1549171

Ronowicz, J., Thommes, M., Kleinebudde, P., Krysiński, J.: A data mining approach to optimize pellets manufacturing process based on a decision tree algorithm. Eur. J. Pharm. Sci. 73, 44–48 (2015). https://doi.org/10.1016/j.ejps.2015.03.013

Chuang, K.-C., Lan, T.-S., Zhang, L.-P., Chen, Y.-M., Dai, X.-J.: Parameter optimization for computer numerical controlled machining using fuzzy and game theory. Symmetry 11, 1450 (2019). https://doi.org/10.3390/sym11121450

Gurrala, P.K., Regalla, S.P.: Multi-objective optimisation of strength and volumetric shrinkage of FDM parts. Virtual Phys. Prototyp. 9, 127–138 (2014). https://doi.org/10.1080/17452759.2014.898851

Dey, A., Yodo, N.: A systematic survey of FDM process parameter optimization and their influence on part characteristics. JMMP 3, 64 (2019). https://doi.org/10.3390/jmmp3030064

Mittal, K.L., Bahners, T.: Textile Finishing. John Wiley & Sons Inc., Hoboken (2017)

A. Kumar, R. Choudhury, Principles of Textile Finishing, Woodhead Publishing, Cambridge (2017)

Choi, Y.J., Kim, I., Kim, S.H.: Effect of heat-setting on the physical properties of chemically recycled polyester nonwoven fabrics. Text. Res. J. 89, 498–509 (2019). https://doi.org/10.1177/0040517517750643

Horrocks, A.R. Anand, S.C.: Handbook of Technical Textiles. Woodhead Publishing (2016)

Ardizzone, L., et al.: Analyzing inverse problems with invertible neural networks. In: ICLR 2019 (2019)

Dinh, L., Sohl-Dickstein, J., Bengio, S.: Density estimation using Real NVP (2016)

Acknowledgement

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany’s Excellence Strategy – EXC-2023 Internet of Production – 390621612.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Müller, K., Posada-Moreno, A., Pelzer, L., Gries, T. (2023). Objectifying Machine Setup and Parameter Selection in Expert Knowledge Dependent Industries Using Invertible Neural Networks. In: Kim, KY., Monplaisir, L., Rickli, J. (eds) Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus . FAIM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-18326-3_29

Download citation

DOI: https://doi.org/10.1007/978-3-031-18326-3_29

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18325-6

Online ISBN: 978-3-031-18326-3

eBook Packages: EngineeringEngineering (R0)