Abstract

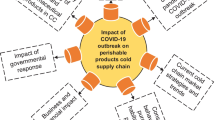

The COVID-19 pandemic impacted several services organizations such as hotels and restaurants. Some studies suggest that 50% of restaurants closed during quarantining days will not reopen in the future, producing a domino effect with their suppliers. Therefore, to survey in this crisis, organizations focused their efforts on reducing waste and/or repurposing their manufacturing operations by introducing new products. The purposes of this paper are (1) to mention an overall strategy followed by food equipment manufacturing plant to address the COVID-19 pandemic challenge; and (2) to describe one of the five Kaizen events conducted to address COVID-19 challenges. This Kaizen focused on increasing forklifts utilization rate from 44% to 80%. The authors followed three steps to achieve this aim: understanding company background, conducting a literature review, and elaborating on a Kaizen event. Practitioners in manufacturing and services organizations could extract several highlights to help them to sort operations problems during crisis time. However, future research still needs to understand the socio-economic impact that COVID-19 pandemic around the world.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kelp, R, Becker, H.: Managing costs in times of COVID-19: focus on transformation, rather than reactive cost cutting in manufacturing industries. OliverWyman (2020). https://www.oliverwyman.com/our-expertise/insights/2020/nov/manufacturing-industries-2030/by-function-new-sources-of-value/managing-costs-in-times-of-covid-19.html. Accessed 23 Aug 2021

Barlow, J., Vodenska, I.: Socio-economic impact of the COVID-19 pandemic in the U.S. Entropy 23(6), 673–695 (2021). https://doi.org/10.3390/e23060673

Buheji, M., et al.: The extent of COVID-19 pandemic socio-economic impact on global poverty. a global integrative multidisciplinary review. Am. J. Econ. 10(4), 213–224 (2020). https://doi.org/10.5923/j.economics.20201004.02

Euromonitor: Coronavirus pandemic to rewrite the future of businesses. Euromonitor International (2020). https://www.euromonitor.com/coronavirus-pandemic-to-rewrite-the-future-of-businesses/report. Accessed 23 Aug 2021

Simpkins, R.A.: How great leaders avoid disaster: the value of contingency planning. Bus. Strategy Ser. 10(2), 104–108 (2009). https://doi.org/10.1108/17515630910942241

Morrison, M.: Innovation: the lasting legacy of the COVID-19 crisis - industry analysis by Loyale Healthcare. Cision PRWeb (2020). https://www.prweb.com/releases/innovation_the_lasting_legacy_of_the_covid_19_crisis_industry_analysis_by_loyale_healthcare/prweb17051171.htm. Accessed 22 July 2020

Imai, M.: Kaizen: The Key to Japan’s Competitive Success. McGraw-Hill, New York (1986)

Suarez-Barraza, M.F., Ramis-Pujol, J., Kerbache, L.: Thoughts on kaizen and its evolution: three different perspectives and guiding principals. Int. J. Lean Six Sigma 2(4), 288–308 (2011)

Farris, J.A., Van Aken, E.M., Doolen, T.L., Worley, J.: Learning from less successful Kaizen events: a case study. Eng. Manag. J. 20(3), 10–20 (2008). https://doi.org/10.1080/10429247.2008.11431772

Natale, J., Uppal, R., Maggelet, N., Wang, S., Taylor, J., Ogrinc, M.: The impacts of Kaizen event duration on Kaizen success and logistics. In: IIE Annual Conference. Proceedings, pp. 971–979. Institute of Industrial and Systems Engineers (IISE), San Juan, Puerto Rico (2013)

Doolen, T.L., Van Aken, E.M., Farris, J.A., Worley, J.M., Huwe, J.: Kaizen events and organizational performance: a field study. Int. J. Product. Perform. Manag. 57(8), 637–658 (2008). https://doi.org/10.1108/17410400810916062

Aleu, G., Flores, F.F., Perez, J., Gonzalez, R., Garza-Reyes, J.A.: Assessing systematic literature review bias: Kaizen events in hospitals case study. In: Proceedings of the 10th International Conference on Industrial Engineering and Operations Management (IEOM), pp. 1–8. IEOM Society, Dubai (2020)

Baril, C., Gascon, V., Miller, J., Côté, N.: Use of a discrete-event simulation in a Kaizen event: a case study in healthcare. Eur. J. Oper. Res. 249(1), 327–339 (2016). https://doi.org/10.1016/j.ejor.2015.08.036

Martin, K., Osterling, M.: The Kaizen Event Planner: Achieving Rapid Improvement in Office, Service, and Technical Environments. CRC Press, Boca Raton (2017)

Garza-Reyes, J.A., et al.: Deploying Kaizen events in the manufacturing industry: an investigation into managerial factors. Prod. Plan. Control 33, 1–23 (2020). https://doi.org/10.1080/09537287.2020.1824282

Vo, B., Kongar, E., Barraza, M.F.S.: Kaizen event approach: a case study in the packaging industry. Int. J. Product. Perform. Manag. 68(7), 1343–1372 (2019). https://doi.org/10.1108/IJPPM-07-2018-0282

Hanna, S., Deines, T.: Experiences of implementing lean manufacturing through Kaizen events. In: IIE Annual Conference Proceedings, pp. 1–5. Institute of Industrial and Systems Engineers (IISE). Portland, Oregon (2003)

Melnyk, S.A., Calantone, R.J., Montabon, F.L., Smith, R.T.: Short-term action in pursuit of long-term improvements: introducing Kaizen events. Prod. Invent. Manag. J. 39(4), 69–76 (1998)

Fathi, M., Syberfeldt, A., Ghobakhloo, M., Eskandari, H.: An optimization model for material supply scheduling at mixed-model assembly lines. Proc. CIRP. 72, 1258–1263 (2018). https://doi.org/10.1016/j.procir.2018.03.274

Bauters, K., Govaert, T., Limère, V., Van Landeghem, H.: Forklift free factory: a simulation model to evaluate different transportation systems in the automotive industry. Int. J. Comput. Aid. Eng. Technol. 7(2), 238–259 (2015)

Wei, L., Zhang, Z., Zhang, D., Lim, A.: A variable neighborhood search for the capacitated vehicle routing problem with two-dimensional loading constraints. Eur. J. Oper. Res. 243(3), 798–814 (2015). https://doi.org/10.1016/j.ejor.2014.12.048

Veres, P., Bányai, T., Illés, B.: Optimization of in-plant production supply with black hole algorithm. Trans Tech Publ.. 261, 503–508 (2017). https://doi.org/10.4028/www.scientific.net/SSP.261.503

Farris, J.A., Van Aken, E.M., Doolen, T.L., Worley, J.: Critical success factors for human resource outcomes in Kaizen events: an empirical study. Int. J. Prod. Econ. 117(1), 42–65 (2009). https://doi.org/10.1016/j.ijpe.2008.08.051

Ohno, T.: Taiichi Ohno’s Workplace Management. McGraw Hill, New York (2012)

Tompkins, J.A., White, J.A., Bozer, Y.A., Tanchoco, J.M.A.: Facilities Planning. John Wiley & Sons Inc., Hoboken (2003)

Abbas, A., Mohamed, T., Hazem, M.: Optimization of warehouse material handling parameters to enhace the efficiency of automated sorting and storage systems. J. Manag. Eng. Integr. 11(1), 72–84 (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Gonzalez-Aleu, F., Garza-Gutierrez, D., Granda-Gutierrez, E.M.A., Vazquez-Hernandez, J. (2022). Increasing Forklift Time Utilization in a Food Equipment Manufacturing Plant with a Kaizen Event. In: Hamrol, A., Grabowska, M., Maletič, D. (eds) Advances in Manufacturing III. MANUFACTURING 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-00218-2_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-00218-2_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-00166-6

Online ISBN: 978-3-031-00218-2

eBook Packages: EngineeringEngineering (R0)