Abstract

The research investigated the influence of different collection bag types on the environmental and energy performances of the food waste management chain, comparing paper and bioplastic bags. First, the use of bags during the food waste household storage was examined. Subsequently, the behavior of bags when subjected to anaerobic digestion was evaluated, performing Biochemical Methane Potential tests and semi-continuous co-digestion tests with the food waste, to simulate the operating conditions of full-scale digesters. Finally, the performances of the food waste management chain were evaluated, with a Life Cycle Assessment (LCA). The experimental tests showed a more favorable behavior of paper bags, showing a very good compatibility with the anaerobic digestion. The LCA results revealed how paper bags lead to improvements in the impact associated to the food waste management.

Graphical Abstract

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

- Food waste

- Anaerobic digestion

- Life cycle assessment

- Affordable and clean energy

- Sustainable cities and communities

- Responsible consumption and production

1 Introduction

The organic fraction is generally the most relevant among all the separately collected materials in the municipal solid waste. In Italy, 6.4 million metric tons of organic waste were separately collected in the year 2019 [1]. In addition to the typical components of this fraction (food waste and green waste), the amount of compostable bioplastics conferred within the organic waste has grown to 3.9% of the organic waste in the period 2019/2020 compared to 1.5% in the period 2016/2017 [2].

Bioplastics show several issues when managed together with the food waste. Such criticalities are first associated with the mechanical pre-treatments that precede the biological process: when the waste is subjected to size-based separation, most of the bioplastic products are discarded as residues, similarly to conventional plastics [2, 3]. This is particularly relevant in anaerobic digestion (AD) plants, where pre-treatments are often very intense [3] to avoid further hydraulic and operational problems. The problems and costs associated with the management of discarded bioplastic items are amplified by the fact that, when removed, they drag a non-negligible amount of food waste that remains adhered to them and is not delivered to the AD process [2, 3].

Although the increasing amount of different bioplastic items, a relevant contribution is still constituted by the bags employed for the collection of food waste. In Italy, the current collection systems of food waste from households are mainly based on the use of bioplastic bags. In detail, the collection can be performed with bags specifically sold for this purpose (dedicated bags) or with bags used for the overall shop at the supermarkets (shopper bags) that can be reused for the food waste separate collection. Both types are typically manufactured with the Mater-Bi® polymer, a compostable bioplastic according to the UNI EN 13,432:2002 standard [4].

Alongside, a less widespread type of paper bag designed for the collection of food waste is available on the market. It is made of recycled fibers and composed by a main bag and a separate cartonboard bottom to be inserted inside the main bag before its use. As regards the compatibility with the AD, unlike bioplastic bags, the paper does not require prior removal since it quickly breaks down during pre-treatments.

Building up on the previous considerations, this research was carried out with the aim to analyze the environmental and energy performances of the overall treatment chain of the food waste collected from households, focusing on how it is influenced by the different types of collection bags. First, the use of different bag types during the food waste household storage was examined. Subsequently, the behavior of bags when subjected to AD was evaluated. Finally, the influence of the bag types on the environmental performances of the food waste management chain was evaluated, by means of the Life Cycle Assessment (LCA) methodology.

First, the aim at evaluating the collection bag type that optimizes the household management and the subsequent collection of food waste agrees with the SDG 11, promoting the development of more sustainable cities and communities. In parallel, the goal to reduce the potential impacts of the overall food waste management chain, promoting the production and the use of more sustainable collection bags, addresses the SDG 12, supporting more sustainable productions and consumptions. Finally, the aim at identifying the management option allowing to increase the energy valorization of food waste through the AD process agrees with the SDG 7, promoting the production of energy both sustainable and widely available wherever food waste is produced.

2 Materials and Methods

2.1 Household Storage Tests

Firstly, the behavior of the food waste during the household storage when collected inside the different types of bag was examined. In detail, the food waste weight loss during the household storage (i.e. time occurring between the delivery in the bag by the user and its collection) was analyzed by adopting a dynamic, progressive bag filling. This approach aimed at investigating the progressive bag filling due to the daily food consumption, differently from the typical methodology applied in tests reported in the literature, where the bag is completely filled at the beginning.

In two years, 112 domestic tests were performed in parallel to compare paper and bioplastic bags behavior: 59 paper vs. bioplastic dedicated bags and 53 paper vs. bioplastic shopper bags. In each comparative test, one paper bag and one bioplastic bag were placed inside aerated bins. Before each bag filling (twice a day, after lunch and dinner) the food waste was homogenized and split into two portions with the same weight discharged respectively in the paper bag and in the bioplastic bag. Each test lasted 5 days. At the end of the test, the two bags were removed and weighed. The weight loss with respect to the total inserted waste was then calculated for both bags. Subsequently, the differences in terms of weight loss between the two materials were statistically tested (Mann-Whitney U test). In addition, empirical observations on the resistance of the bags were performed during the tests.

Six bags (three dedicated and three shopper bags) manufactured by different companies were tested. The analyses were performed during the different seasons, with the aim to consider the variations of both the environmental conditions (temperature and humidity) and the composition and characteristics of the food waste. The tests were conducted by different households in order to consider various eating habits and therefore different amounts and characteristics of the generated food waste.

2.2 Evaluation of the Anaerobic Degradation of Food Waste Collection Bags

In the second part of the study, the treatment stage of the food waste management chain was examined. Assuming that the operational problems associated to the management of bioplastics in biological plants (see Sect. 1) could be solved in the future, bioplastic collection bags must be compatible with biological processes. According to the UNI EN 13,432: 2002 technical standard, only aerobic degradability tests must be performed, while it is generally not necessary to test the anaerobic biodegradability [4]. However, in Italy there is an increasing tendency to manage food waste in AD plants; therefore, it is essential to verify the behavior of bags even under such conditions.

Accordingly, preliminary biochemical methane potential (BMP) tests were performed to evaluate the anaerobic degradability and the corresponding biomethane yield of the three bag types (paper bag—PB, one bioplastic dedicated bag—BDB, and one bioplastic shopper bag—BSB). For the tests, bags were manually cut in square pieces of 1 cm side. Tests, performed both under mesophilic (35 ± 0.5 °C) and thermophilic conditions (50 ± 0.5 °C), were carried out with digestates, serving as inoculum, sampled from full-scale AD plants processing food waste. An inoculum to substrate ratio equal to 2 VSinoculum/VSsubstrate was adopted. A mineral medium with macro and micro-nutrients was also dosed before the tests.

According to the results of preliminary BMP tests (see Sect. 3.2), a deeper investigation on bags anaerobic degradability under thermophilic conditions was performed with new lab-scale tests. Four bioplastic bags were selected, including two dedicated bags (bioplastic dedicated bag 1—BDB1 and bioplastic dedicated bag 2—BDB2), and two shopper bags (bioplastic shopper bag 1—BSB1 and bioplastic shopper bag 2—BSB2). Bags manufactured by different companies with different thickness (two shoppers and two dedicated bags) and colors (red, yellow, not colored, and green) were selected. Moreover, the type of paper bag (PB) examined in household storage tests (see Sect. 2.1) and in preliminary BMP assays was tested.

The experimental plan first included BMP tests, performed on all five bags, and on a synthetic food waste (its composition was defined based on 90 composition analysis of the organic fraction received in composting plants) at 50 ± 0.5 °C.

Subsequently, to better simulate the real operating conditions of full-scale digesters, collection bags were subjected to semi-continuous co-digestion tests with the food waste. To the authors’ knowledge, similar tests are reported only in one literature study, though performed only under mesophilic conditions.

Tests were performed on two out of the four bioplastic bags and on the paper bag (co-digestions of food waste—BSB1, food waste—BDB1, and food waste—PB), in 2.4 L stirred reactors, under thermophilic conditions (50 ± 0.5 °C). Semi-continuous conditions were obtained by removing part of the digestate and by adding the new substrates and water twice a week, to maintain a hydraulic retention time (HRT) of 21 days and an organic loading rate (OLR) of 2.20 kg COD/(m3 × d) (COD, Chemical Oxygen Demand). Mineral mediums with macro and micro-nutrients were prepared and periodically dosed in the reactors.

Tests were performed in four reactors; in the first period (phase 1, 20 feed cycles corresponding to more than three HRTs) all the bottles were fed with only food waste to reach inoculum acclimation and stationary conditions. In the second period (phase 2, 19 feed cycles), three reactors were also fed with bioplastics (11.5% of the OLR on COD basis), the fourth serving as blank. The selected proportion corresponds to about 1 kg of food waste inserted into a collection bag.

Statistical tests (Kruskal-Wallis and Mann-Whitney U tests) were applied for the evaluation of differences among reactors in terms of methane production. First, reactors were compared in the last part of phase 1 to verify the absence of statistically significant differences before the phase 2. Moreover, the differences in phase 2 were evaluated.

In phase 2, the extracted digestates were sieved (2 mm) to recover undigested pieces of bags. All the residual bioplastic pieces were washed with water, dried at 35 °C, and weighed to evaluate their mass losses during the digestion. Moreover, undigested pieces with a surface equal to at least ¾ of that of the input were recovered and counted.

2.3 Life Cycle Assessment

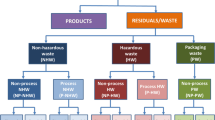

The environmental performances of the management chain of the food waste collected from households were evaluated, by means of the LCA methodology, comparing two systems in which the employed collection bags are respectively made of bioplastic and paper. Differently from the LCAs reported in the literature for the evaluation of the potential impacts of the food waste management chain, this analysis included stages such as the collection bag production (and its influence on the management system) and the food waste household storage. The management of 1 kg of food waste generated (i.e., inserted into the collection bag) at the household was assumed as functional unit. Non-compostable materials mistakenly discarded along with food waste were excluded because their quantity was assumed not to be affected by the different bags. The system boundary included the overall food waste management chain (Fig. 1).

Potential impacts were calculated by examining 16 midpoint impact categories with the indicators and assessment models of the Environmental Footprint 2.0 method [5]. Normalization and weighing were applied with the factors considered in this method.

The investigated systems were mainly modeled with primary inventory data for the Italian context as regards the paper bag manufacturing, the bags distribution, the bags use (modeled according to results of the household storage tests, see Sect. 3.1), and the food waste treatment by means of the AD process.

The ecoinvent database (version 3.5 allocation, cut-off by classification system model) was used to support the modeling [6]. The SimaPro software (9.0 version) supported the analysis. For the modeling of the life cycle stages of products included in the systems (collection bags and packaging), two different approaches were considered: the approach applied in the International EPD system [7] and the one applied in the Product Environmental Footprint (PEF) methodology [8, 9].

Firstly, a Baseline scenario was modeled, representing the average situation of the current Italian food waste management system, strongly based on bioplastic bags, in terms of bag filling level and frequency of food waste collection. These conditions were assumed to be identical with the alternative use of paper bags (Table 1).

A Sensitivity scenario was then examined (Table 1), considering the worst conditions for the system based on bioplastic bags, to evaluate the maximum benefits achievable with the use of paper bags. In particular, the bioplastic bag system shows the worst performances when:

-

bioplastic bags are filled with only 1 kg of food waste (e.g., waste generated by one single person) and therefore collected, not completely filled, twice a week;

-

bioplastic bags discarded during pre-treatments of the AD drag an amount of food waste higher than the average plant performances, and residues are sent to landfill.

The worst performances of the current system were assumed to be improved with the use of paper bags. As detailed in Sect. 3.1, the use of paper bags allows for a higher weight loss and a lower generation of leachate and odor during the household storage. Accordingly, when the amount of generated waste is low, paper bags could be employed for a longer time increasing the bag filling level (from 1 to 2 kg), which allows to decrease the collection frequency (from bi-weekly to weekly).

3 Results and Discussion

3.1 Household Storage Tests

Bioplastic and paper collection bags showed a different behavior during the household storage tests, with the paper allowing for higher weight losses: +29% and +44% on average, compared respectively to bioplastic dedicated and shopper bags (Fig. 2).

The higher weight losses of the food waste collected inside paper bags are favored by the breathable fabric of paper that allows for a relevant evaporation of moisture. According to the results, the weight losses of the food waste collected inside paper and bioplastic bags are statistically different.

In addition, paper bags allow for a lower odor and leachate release during their use at the household, paving the way to a potential decrease of the frequency of food waste collection, thus reducing costs and environmental impacts.

3.2 Evaluation of the Anaerobic Degradation of Food Waste Collection Bags

The preliminary BMP assays showed a very limited anaerobic degradability of bioplastic bags (9–15%) under mesophilic conditions, with residues of the substrates at the end of tests showing only slight changes in color brilliance, without any appreciable size reduction compared to the input samples (Fig. 3). In the thermophilic tests, the bioplastic bags showed a degradability in the range 22–57%. On the contrary, paper bags showed a good anaerobic degradability under both temperature conditions (58–66%) without residues of substrate remaining after the tests.

The subsequent BMP tests under thermophilic conditions on four commercial types of bioplastic bags indicate a good degradability (>71%) of all these substrates, without residues after the tests, although obtained after a very long time (Table 2). On the contrary, the degradation of paper is much faster, with 90% of the final BMP reached in six days. Similarly, for the food waste, two and six days are enough to reach 50% and 90% of the final BMP, respectively.

As regards the semi-continuous co-digestion tests, the following reductions in terms of methane production were observed in reactors fed with bags pieces, compared to the reactor fed with only food waste:Footnote 1 −9.9% (BSB1 + food waste), −8.0% (BDB1 + food waste), and −1.2% (PB + food waste). According to statistical tests, the differences in methane productions resulted statistically significant between each of the two reactors fed with bioplastic bags and the reactor fed with only food waste and between each of the two reactors fed with bioplastic bags and the reactor fed with the paper bag.

The reduced methane production of bioplastics corresponds to a low anaerobic degradability (<27%; Table 2). On the contrary, very interesting perspectives are offered by the tested paper bag, since its anaerobic degradability in the semi-continuous tests (82%) resulted even higher than that observed in the BMP tests (74%; Table 2). This indicates a very good compatibility with the AD process, suggesting effects of biomass acclimation or synergic effects given by the co-digestion of PB and food waste.

As regards the physical status of undigested substrates, several undigested pieces of BSB1 and BDB1, similar in shape and color to the fed pieces, were observed (Fig. 4).

The overall mass of undigested pieces resulted equal to 93% and 69% of the weight inserted for BSB1 and BDB1, respectively. The corresponding weight losses agree with the different anaerobic degradability observed for the two bioplastics (Table 2). The similarity in shape between fed and undigested bioplastics is confirmed by the very high number of residual pieces with a surface equal to at least ¾ of that of fed substrate, corresponding to 96% and 98% for BSB1 and BDB1, respectively.

As regards PB, only very small amounts of residues were retained during sieving, in which single pieces were not detectable (Fig. 4).

3.3 Life Cycle Assessment

The LCA results show a relevant influence of the collection bag on the potential impacts of the food waste management chain. The comparison highlighted a beneficial influence associated with the use of recycled paper bags instead of bioplastic bags, in particular the dedicated ones; shopper bags are less impacting because they are used, as the first purpose, for carrying the grocery shopping. Accordingly, only 50% of impacts related to the production and the treatment at the end of life of the bioplastic shopper bag are included in the analyzed system. The benefits of the use of paper bags are associated to both the bag manufacturing (less impacting, especially thanks to the use of recycled fibers) and the benefits in the AD treatment, since they are not discarded during pre-treatments, differently from bioplastic bags. Anyway, the methodological approach used in the LCA modeling has an important influence on the comparison. In particular, the paper bag system achieves the highest environmental advantages with the EPD approach (Fig. 5a), while using the PEF entails a significant increase of the impacts because of the effect of partially considering the virgin paper production, in place of the use of recycled fibers, with an important influence on the comparison between paper and bioplastic bags, as shown in Fig. 5b.

Life Cycle Assessment results: comparison of potential impacts of the paper bag and the bioplastic bag systems, with the EPD (a) and the PEF (b) approaches. Impact categories: CC Climate change; OD Ozone depletion; IR Ionizing radiation, human health; POF Photochemical ozone formation; RI Respiratory inorganics; HTNC Human toxicity, non-cancer effects; HTC Human toxicity, cancer effects; A Acidification; EAF Eutrophication, aquatic freshwater; EAM Eutrophication, aquatic marine; ET Eutrophication, terrestrial; EF Ecotoxicity freshwater; LU Land use; WU Water use; RUE Resource use, energy carriers; RUM Resource use, mineral, and metals

Table 3 shows the potential impacts of both the food waste management systems after the normalization and the weighing stages.

Examining the Baseline scenario, with the EPD approach, the paper bag system allows for a decrease of the potential impacts compared to the bioplastic system, both considering dedicated and shopper bags. Moreover, it is important to underline that the paper bag system is characterized by a result negative in sign (i.e., the management of food waste collected inside paper bags as modeled allows for environmental benefits).

With the PEF approach, the paper bag system still allows for a decrease of potential impacts compared to the bioplastic dedicated bag system (−57%). On the contrary, the bioplastic shopper bag system is better (−34%) than the system based on paper bags.

Finally, as regards the Sensitivity scenario, the differences between the systems are significantly more relevant. This is due to both the important increase of impacts of the bioplastic bag system under the worst operational conditions and the improvements introduced for the paper bag system. Thanks to the latter, the paper bag system is characterized by a result negative in sign with both modeling approaches.

4 Conclusions

According to the findings of the study, the use of paper bags for the food waste collection in the Italian system, currently widely based on bioplastic bags, should be encouraged. First, the reduction of the amount of waste to be collected and the lower odor and leachate release during the use of paper bags at the household could pave the way to a potential decrease of the food waste collection frequency, then reducing the environmental impacts. As regards the food waste treatment process, while bioplastic bags are discarded as residues, there is a very good compatibility of the paper bags with the AD process, leading to potential energy benefits: according to semi-continuous tests, the use of paper bags allows for an 8% increase in the methane production per mass unit of food waste in addition to that obtained from the sole food waste digestion. Finally, the use of paper bags allows for the reduction of the potential environmental impacts of the current food waste management based on bioplastic bags. Globally, paper bags can improve the current food waste management system allowing for a reduction of treatment residues and an improvement of the energy valorization leading to a reduction of the potential environmental impacts. Accordingly, the outcomes of the study can significantly contribute to the fulfillment of the selected SDGs.

Notes

- 1.

All the results of semi-continuous tests are related to the second part of phase 2 (starting 40 days after the first introduction of bag pieces into the reactors).

References

ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale: Rapporto rifiuti urbani edizione 2020—Urban waste report (2020). https://www.isprambiente.gov.it/files2020/pubblicazioni/rapporti/rapportorifiutiurbani_ed-2020_n-331-1.pdf. Accessed 14 Oct. 2021

CIC-COREPLA: Studio CIC-COREPLA, 2020: triplicano le bioplastiche compostabili nella raccolta dell’organico—Compostable bioplastics in the food waste collection tripled (2020). https://www.compost.it/wp-content/uploads/2020/07/CS-4-Studio-CIC-COREPLA-2020_-raddoppiano-le-bioplastiche-compostabili-nella-raccolta-dell%E2%80%99organico-5.pdf. Accessed 4 Apr. 2022

Utilitalia: managing and recovering bioplastics. Utilitalia Position Paper adopted on January 21 2020 by the Environmental Board (2020). http://www.utilitalia.it/dms/file/open/?8bf343a1-901d-4f99-890b-bbe422a324fd. Accessed 14 Oct. 2021

UNI EN: UNI EN 13432:2002 Packaging—Requirements for packaging recoverable through composting and biodegradation—Test scheme and evaluation criteria for the final acceptance of packaging (2002)

Fazio, S., Castellani, V., Sala, S., Schau, E.M., Secchi, M., Zampori L.: Supporting information to the characterisation factors of recommended EF life cycle impact assessment methods. EUR 28888 EN. European Commission, Ispra (2018). https://doi.org/10.2760/671368

Ecoinvent centre: ecoinvent version 3.5 database.: (2018). http://www.ecoinvent.org/. Accessed 14 Oct 2021

EPD International: General Programme Instructions for the International EPD System. Version 3.01 (2019). www.environdec.com. Accessed 14 Oct 2021

EC—European Commission: Product Environmental Footprint Category Rules (PEFCR) Guidance document, Guidance for the development of Product Environmental Footprint Category Rules (PEFCRs), version 6.3 (2018). https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_guidance_v6.3.pdf. Accessed 14 Oct. 2021

EC: Recommendation 2013/179/EU of 9 April 2013 on the use of common methods to measure and communicate the life cycle environmental performance of products and organisations. Official J. Euro. Union L 124, 4 (2013)

Acknowledgements

I would like to acknowledge my supervisor Prof. Mario Grosso for the help and the support in the development of this research project. Many thanks to the other Professors and colleagues that supported and made this work possible.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2022 The Author(s)

About this chapter

Cite this chapter

Dolci, G. (2022). Influence of the Collection Equipment on Organic Waste Treatment: Technical and Environmental Analyses. In: Antonelli, M., Della Vecchia, G. (eds) Civil and Environmental Engineering for the Sustainable Development Goals. SpringerBriefs in Applied Sciences and Technology(). Springer, Cham. https://doi.org/10.1007/978-3-030-99593-5_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-99593-5_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-99592-8

Online ISBN: 978-3-030-99593-5

eBook Packages: EngineeringEngineering (R0)