Abstract

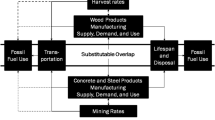

Forest-based products––often referred to as harvested-wood products (HWPs)––can influence the climate through two separate mechanisms. Firstly, when wood is harvested from forests, the carbon contained in the wood is stored in the HWP for months to decades. If the amount of wood entering the market exceeds the amount of wood being discarded annually, this can lead to a HWP sink impact. Secondly, HWPs typically have a lower fossil carbon footprint than alternative products, so, for example, using wood in construction can lower fossil emissions by reducing the production of cement and steel, resulting in a substitution impact. The international greenhouse gas (GHG) reporting conventions and the related Intergovernmental Panel on Climate Change guidance covers the HWP sink impact, but not the substitution impacts. The HWP sink impact is restricted to tracing biogenic carbon flows, whereas the substitution impact typically covers fossil carbon flows exclusively. Importantly, the substitution and HWP sink impacts do not represent the climate- change mitigation impact of wood use, as such. Instead, they are important pieces of the broader puzzle of GHG flows related to the forest sector. This chapter presents the state-of-the-art approaches for determining the HWP sink and substitution impacts, and concludes with the policy and research implications.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

- Carbon storage

- Climate-change mitigation

- Displacement factor

- Harvested wood products (HWPs)

- Life-cycle assessment

- Substitution impact

7.1 Contribution of Wood Products to Climate-Change Mitigation

In harvesting, woody biomass is transferred from the ecosystem to the technosphere. Wood is harvested to meet various needs, such as construction, energy, hygiene and communication.

Forests and forest-based products have a wide range of impacts across the economy and the environment, and can therefore contribute to the United Nations (UN) Sustainable Development Goals in several ways. The renewability of wood resources can aid in improving resource efficiency when substituting for plastics, for example. Favouring wood- based textiles in place of cotton-based textiles reduces the need for fresh water for irrigation and obviates the need for pesticides, while releasing land for afforestation or food production. Wood-based industrial prefabrication practices can reduce the noise and dust pollution associated with construction. Bio-based chemicals can reduce the eco-toxicity and human toxicity of commodities. Such impacts can be captured using standardised life-cycle assessment (LCA) methods. Besides a wider range of benefits, a more comprehensive analysis could also reveal possible trade-offs, such as between climate and biodiversity, or between greenhouse gas (GHG) emissions and the livelihoods of small-scale entrepreneurs, such as cotton farmers. However, to keep the scope manageable, in this chapter, we focus only on the climate-change mitigation aspect of forest-based products.

Forest-based products or energy may compete with products or energy carriers made from alternative materials. Substitute products can be defined as those products that provide interchangeable value or service in terms of economic utility or technical function. Printed newspaper, wood-based textiles or carton board packaging serve as examples of substitutes––they may be consumed in place of digital media, cotton or plastic, respectively. Some forest products have no apparent substitutes, such as toilet tissue, and thereby no competition, except for water.

Replacing products on the market can exert impacts on the climate due to the different emissions intensities of the substitute products. There is uncontested evidence that wood-based products are, on average, associated with lower fossil- based GHG emissions compared to non-wood products or energy carriers (Sathre and O’Connor 2010; Leskinen et al. 2018). In other words, by using wood products in place of more fossil-emission-intensive materials, greater production-.related fossil-based emissions can be avoided, thus avoiding the accumulation of additional atmospheric carbon from the use of fossil resources. Thus, in the context of forest-based climate-change mitigation, the term substitution impact refers to the amount of fossil emissions avoided when using wood-based products or energy in place of alternative products or energy carriers.

Besides the substitution impacts, wood products can contribute to climate-change mitigation by storing carbon in products for extended periods of time, which can lead to a sink effect, typically referred to as harvested-wood product (HWP) carbon storage. HWPsFootnote 1 act as temporary storage for the bio-based carbon sequestrated by trees from the atmosphere. The impact of this carbon flow on net emissions depends on the level of harvest and the products produced from wood. That is, the HWP pool acts as a carbon sink when input to the product pool exceeds outflow from the product pool (i.e. the product pool is increasing). In contrast, if the change in the overall HWP carbon stock is negative, the HWP pool acts as a source of emissions. In the GHG inventory reporting rules under the Paris Agreement, the HWP sink impact of all HWPs manufactured in the producer countries is attributed to producer countries, regardless of export destination (UN Framework Convention on Climate Change [UNFCCC] 2018).

Unlike the carbon sinks represented by forests and HWPs, the substitution impacts do not exist in the national inventory submissions for GHG reporting under the UNFCCC, and they are thereby not a part of the Intergovernmental Panel on Climate Change (IPCC) methodology for reporting emissions and removals. Although this makes the substitution impacts invisible (Holmgren 2019), one can argue that they are implicitly included in the form of reduced emissions in other sectors, such as construction. However, the producer countries cannot therefore directly benefit from the substitution impacts, as this would effectively lead to double counting. That is, the producer would gain substitution credits explicitly, even though these credits would already have been implicitly accounted for in the countries where the production of more emissions-intensive products were lowered as a consequence of substitution, either in the export destinations of the HWPs or in third-party countries that would have exported steel, for example. These substitution impacts can only be calculated and interpreted against a separately determined reference, and are therefore not necessarily directly comparable to the absolute reported emissions and sinks.

Substitution and HWP sinks can be a part of (national) climate policy, such as when promoting wood construction in a government programme (e.g. Finnish Government 2019), but should not be viewed in isolation from other climate- change mitigation strategies (see Chap. 8). Despite their abstract nature, the substitution and HWP sink impacts form an important part in the overall carbon flows associated with forests and wood use to and from the atmosphere.

Climate-change mitigation measures are always forward-looking. Regardless of the current situation, only additional measures compared to a baseline ought to be regarded as mitigation. Thus, it is necessary to distinguish between the substitution impacts and HWP carbon sinks originating from the current use of wood and the possible changes in the use of wood. The former gives an estimate of the amount of emissions that would occur if non -wood products were used in place of HWPs––that is, the already achieved mitigation. Only the latter (i.e. a marginal increase in the use of wood) can possibly be attributed to further efforts on climate-change mitigation. However, substitution can occur both ways. A reduction in the market share of wood from the baseline may increase fossil emissions if, for example, wood was replaced by coal in the energy sector or concrete in the construction sector.

Despite the fairly intuitive basic principles, quantifying the substitution and carbon-storage impacts is technically complex and demanding. The results are also highly dependent on the applied system boundaries and other assumptions. In this chapter, we first introduce the basic approaches for quantifying HWP substitution and sink impacts, and then draw attention to, and discuss, their potential pitfalls.

7.1.1 Product-Level Substitution Impacts

The estimation of substitution impacts caused by an HWP replacing a specific product is the first step in estimating the total substitution impacts of wood utilisation. In practise, the substitution impacts of HWPs are calculated with the help of product-specific displacement factors (DFs). A DF measures how many units of fossil GHG emissions are avoided when using one unit of HWP in place of a specific alternative product. For example, if the DF for a product were 1 tCO2eq/m3, this would mean that using 1 m3 of a wood-based product in a certain end use would avoid 1 t of carbon-dioxide-equivalent emissions.

The estimation of DFs is based on GHG data obtained from LCAs of HWPs and their non-wood-product counterparts. The methodology for LCAs has been standardised (Finkbeiner et al. 2006), and there are guidelines for calculating LCAs (Joint Research Centre 2010; PAS 2050:2011 2011; EN 15804:2012 2012). A necessary requirement for the comparison of items is that pairs of wood-based and non-wood-based products must have the same functional units, such as 1 m2 of a building with the same functionality in terms of energy efficiency, for example. The functional unit provides a reference against which the inputs (raw materials and land use) and outputs (emissions) are calculated. The results of such calculations vary depending on the data quality, system boundaries and assumptions used in the life-cycle analyses that quantify the fossil GHG emissions of the compared products using the same functional unit. Therefore, the resulting DF estimates are often product specific.

Formally, the DF for product i is typically defined as:

where GHGalternative and GHGwood are the fossil GHG emissions resulting from the use of the non-wood and wood alternatives, expressed in mass units of carbon derived from CO2 equivalents in a timeframe of 100 years, and WUwood. and WUalternative are the amounts of wood used in the wood and non-wood alternatives, expressed in mass units of carbon contained in the wood (Sathre and O’Connor 2010). Using standardised carbon units results in a unitless ratio (tonne C/tonne C), which makes the DFs comparable across widely varying cases. A positive DF value represents reduced emissions, where an alternative product is replaced by a wood-based product, while a negative value stands for the opposite.

The DF ought to be disaggregated to separately assess the impacts of different life-cycle stages––the production, use, cascading (reuse or recycle) and disposal stages (Leskinen et al. 2018). It may be possible to attribute several life-cycle stages to one DF, but doing so should be made explicit to avoid double counting.

Regarding the divisor in Eq. (7.1), the DFs can be estimated for either the amount of wood (carbon) required to produce a wood-based product or the amount of wood (carbon) contained in the final product. When upscaling the product -level substitution impacts to a region or a market, the latter approach is more straightforward to apply, as this allows allocating the correct DF to the correct feedstock flow while avoiding double counting (see Sect. 7.1.2).

Calculating DFs requires making a number of assumptions. For example, for textiles, it is more straightforward than for a construction product, as one can assume 1 t of viscose to provide roughly the same function as 1 t of cotton or polyphenols, while for construction products, one needs to consider at least the widely varying densities of the materials and the design of the functions they provide in terms of load-bearing capacity, service life, energy efficiency, fire load, etc.

Although DFs are specified for single-product pairs, their values can still range significantly from one estimate to another. Also, there is large variation in DFs between products and product categories (Table 7.1). Perhaps the most reliable average DF values are for construction and energy, due to the relatively large number of cases assessed having relatively converging estimates. For example, for chemicals, the DFs can vary significantly due to a very large number of possible combinations of feedstock, pretreatment options, sugars, conversion technologies, downstream processes, as well as end uses (Taylor et al. 2015).

Around half of all harvested wood is used for energy, including wood harvested directly from forests or as sidestreams from and byproducts of wood harvesting and industrial operations. When looking at emissions factors per unit of energy created, the emissions from biomass burning are higher than those from burning fossil fuels (e.g. Zanchi et al. 2012). As Table 7.1 suggests, bioenergy nevertheless results in positive substitution impacts due to the DF capturing only fossil emissions, while the biogenic emissions are accounted for in the land use, land-use change and forestry (LULUCF) sector (see Chap. 8 and Sect. 7.1.2). For the same reason, the climate impact of different bioenergy fractions may differ substantially, even if not reflected in the DF. That is, while the DF will be different depending on which energy source the woody biomass is assumed to be substituting for, the release of biogenic emissions in a counterfactual situation depends on, for example, whether the biomass fraction is solid wood or byproducts and residues that would decay more quickly if left in forests and not used for energy (e.g. Repo et al. 2012).

Based on a comprehensive review of studies that have estimated DFs for wood-based products, the average DF for all included life-cycle stages has been estimated to be 1.2 tC/tC across a wide range of wood products and substitute products (Leskinen et al. 2018). This compares to an average of 2.1 tC/tC, determined previously by Sathre and O’Connor (2010). Although there can indeed be systematic changes through time in the average DFs, the apparent difference between these two average estimates may be partly incidental, but may also reflect differing scopes for determining the DFs, such as in terms of separating biogenic and fossil carbon flows.

Importantly, the average substitution impact found in the literature (1.2–2.1 tC/tC) should not be used as such, as it does not have a meaningful interpretation, for at least two reasons. Firstly, the value is an arithmetic average of all those cases that have been assessed in the literature so far, but ignores those wood uses that have not been assigned a DF. Assessing an average DF for an entire market is more complicated than defining a DF for a single pair of products. To estimate a weighted DF for the overall wood use, it would be necessary to determine all wood flows related to forest- based products and all of the alternative products that the forest-based products are substituting for. Taking the average DF reported in the literature and multiplying it by the total wood use to estimate the overall substitution impacts of wood use would ignore the wood flows and those wood uses that have no substitution impacts, therefore yielding a flawed result. Secondly, these DFs capture only the difference in fossil-based emissions, while the biogenic carbon emissions are counted as changes in the carbon stocks in forests and HWPs, which adds an important aspect of time dynamics due to the circulation of carbon in ecosystems versus permanent fossil emissions. The static product-level DFs therefore do not capture the full impact of using wood on the climate over time, but do provide an important piece of the overall calculation framework (see Chap. 8). In the following, we examine the process of upscaling substitution impacts from the product level to the market level.

7.1.2 Market-Level Substitution Impacts

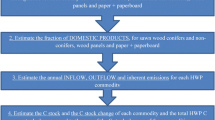

There is no single, established way of deriving market-level substitution impact estimates. Besides assumptions, the approaches can differ in terms of the scope of the upscaling exercise. Similarly to the different approaches used for calculating the HWP sink impact (Rüter et al. 2019), the substitution impacts can be defined using production data, consumption data or value-chain data (Knauf 2015). However, the differences, in terms of calculation routines, are minor.

Deriving product-level substitution impact estimates requires having data on: (i) the volume of demand (in mass units of carbon, tC) for a product or energy carrier; (ii) the end-use distribution of the product (share of all end uses, %); (iii) the mix of substitute products in the end market (market share, %); and (iv) a DF (tC/tC) for all substitution cases (a product replacing another product in a specific end use). Taking dissolving pulp, primarily used for textile fibres, as an example, Table 7.2 shows which data are needed to derive a volume-weighted DF for an intermediate product. These assumptions are very streamlined, as the case ignores other fibres in the market, such as traditional wool and, more importantly, the emerging recycled fibres of various origins. The case also assumes that all viscose and lyocell products perform the exact same function as the fibre they are substituting for, which is unlikely to be the case in reality. The products may have different qualities, such as moisture-wicking properties, proneness to wrinkles, ability to be washed at different temperatures, etc. Moreover, the average energy mix and production structure differs between regions, which means different DFs for different regions; that is, the DFs are not only product specific, but also region specific. Lastly, defining a weighted DF for the end uses of dissolving pulp other than textiles would require an extensive survey, as there are dozens of end uses, with dissolving pulp displacing possibly more than one other material in each end use. Probably, the overall weighted DF for dissolving pulp could therefore be higher than the case suggests, as a quarter of the volume, with dozens of end uses, is ignored.

If the products were more complex than in the case of textile fibres, extensive background analysis would be required to define all possible substitution cases and their respective DFs. For example, different structural solutions in construction (light frame versus massive frame) can produce a tenfold difference in the relative wood-use intensity (cubic metres of wood used per square metre of a building) to gain the same functionality, which ought to be mirrored in the respective DF estimates to avoid large errors. There are also differences, for example, between the end-use distributions of different wood species (Poljatschenko and Valsta 2021). Moreover, there are opposite points of view––whether wood-based energy ought to be assumed to substitute for an average energy mix or for fossil fuels only. Again, the assumptions in such cases ought to be made case by case, as the marginal energy sources may differ, for example, in heat production and power production, and may vary between regions.

Once the data (i–iv) have been gathered and the necessary assumptions made, the production-stage substitution impact (PSI) for a single product or energy carrier, i, can be calculated as:

where DFi is the volume-weighted DF for the avoided fossil-based GHG emissions (expressed as tC) per carbon contained in product i (tC), Si is the annual volume of a wood product produced (MtC year−1) and t is year. For example, taking the annual production of dissolving pulp in the world in 2018 (8.4 Mt) and multiplying it by the weighted DF from the example in Table 7.2 (1.11 tC/tC), an estimate of avoided emissions of 9.3 MtCO2eq/year is derived.

A similar exercise could be performed for all relevant life-cycle stages. For example, the energy recovery of wood- based products at their end-of-life can yield substitution impacts. The end-of-life substitution impact (ESI) for product i are determined as:

where DF_EoLi is the avoided fossil-based carbon emissions (tC) per carbon contained in product i (tC) for the end-of-life stage (incineration), and OF is the outflow from the HWP pool (MtC year−1); that is, the volume of wood products accumulated over decades of historical wood harvesting exiting the HWP pool as the wood products in use are gradually discarded. For example, assuming that the annual outflow of products based on dissolving pulp from the HWP pool was the same as the annual production in 2018 (8.4 Mt) (i.e. assuming a steady state HWP pool), and multiplying this volume by a DF for energy (0.7 tC/tC), avoided emissions of 5.9 MtCO2eq/year would be estimated. Together, the avoided fossil emissions from the production and end-of-life stages would, in this hypothetical case, amount to 15.2 MtCO2eq/year.

Note that, without a separately defined reference for the interpretation, this overall estimate refers to the amount of avoided fossil emissions compared to a hypothetical situation in which no wood would be used, and cannot therefore be directly compared, for example, to the absolute HWP sink impacts that portray the changes in carbon stocks in a distinct time period. To make the substitution impact comparable, it is necessary to calculate the impact of a marginal change in the system compared to a counterfactual scenario (see Chap. 8); that is, to focus on the additional substitution impacts.

To derive the substitution impacts for the total wood use in a given region and time period, data (i–iv) should be gathered for each current or emerging wood-based product and the product they are substituting for. If the different biomass streams for the production and end-of-life stage substitution impacts are disregarded, the average DF of overall wood use can be calculated by summing up the substitution impacts of all products and dividing the sum by the amount of carbon contained in the total harvested biomass delivered to the technosphere. Detailed data on wood flows is required for this task, in order to, for example, estimate the material losses in harvesting and wood processing, and the share of wood-based energy used in the production of wood-based products.

Importantly, the resulting substitution impact should not, as such, be considered to be the climate-change mitigation potential of wood-based products due to the separation of biogenic and fossil emissions. That is, the relative benefit of wood-based products compared to alternative products (a positive DF value) is mostly a consequence of tracking only fossil emissions and not biogenic emissions (Rüter et al. 2016). The energy used in the production of HWPs originates, to a great extent, from wood residues. Following the IPCC methodology, bioenergy is calculated as carbon neutral (zero emissions) in energy production because biogenic emissions are considered in full in the LULUCF sector. In effect, harvesting wood reduces forest carbon sinks for a certain amount of time, which depends on regional circumstances, such as the forest growth rate and management regime. Even though, under sustainable forest management, biogenic carbon can be assumed to circulate between the ecosystem, the technosystem and the atmosphere, the carbon payback time can be so long––up to a century––that it needs to be considered in climate policy (see Chap. 8). While there can be other analytical approaches for dealing with the separation of biogenic and fossil emissions, excluding biogenic emissions from the DFs avoids double counting when assessing the net emissions of the forest-based sector. On the other hand, this highlights the role of tracing the exact wood flows for the entire wood-use system. To avoid double counting, substitution impacts should not be allocated to the sidestream flows going into the internal bioenergy use of forest-based product mills. However, energy production that is not consumed in the production process of wood-based products causes substitution impacts similar to those of the product use. Despite the importance of understanding the implications of the assumption concerning carbon-neutral bioenergy, the positive DF values can also partly be explained by the lower embodied energy of HWPs (less energy needed in their production) and the end-of-life energy recovery of wood-based products (substituting fossil energy when a HWP is incinerated at its end-of-life).

Clearly, deriving the substitution impacts for the total wood use is a daunting task. Consequently, substitution analyses have so far typically focused only on well-known, large-volume markets and have made several simplifying assumptions to keep the analysis manageable (Holmgren 2019). Moreover, as market-level substitution analyses tend to be forward- looking, one should consider how the wood-products markets, as well as the markets of the competing products, evolve over time. As demonstrated in Chap. 4, there are several plausible pathways for the evolving uses of wood. However, in practical terms, it can be impossible to reliably determine some of the DFs for future markets, as it is not possible to trace the evolving emissions profiles of novel wood-based products, nor those of the competing products. Clearly, the accuracy of the estimates is limited by the complexity of the market and the consequent lack of data, which calls for careful documentation and sensitivity analysis.

Given the challenges in the implementation and interpretation of overall substitution impact estimates, it may be more fruitful to assess mitigation scenarios with varying wood-use structures, and compare these scenarios against a reference (see, e.g., Brunet-Navarro et al. 2021), rather than focus on perfecting a single-point estimate. While this is more relevant for decision-making, it adds another layer of complexity due to the necessity to address various dynamic, and partly indirect, market responses (e.g. Howard et al. 2021).

7.1.3 Carbon Sinks of Harvested-Wood Products

Besides substitution, HWPs can contribute to climate-change mitigation by storing carbon in biomass for a certain time period, from months to centuries. The reason why the carbon stocks of HWPs are taken into account in the GHG calculations is related to the rules of the national GHG emissions inventory, determined by the UNFCCC process. According to that process, the carbon associated with wood biomass harvested and delivered to the technosphere is considered as emissions, as it decreases the carbon stock in forests. To fine-tune this streamlined assumption, by considering the extended lifetime of biogenic carbon in the technosphere, the carbon flows in products should be monitored in the annual carbon balance calculations.

An increase in the HWP carbon storage is assigned a negative value when reporting the net emissions of the forest- based sector, which refers to a sink effect. However, this is only true in terms of notation and should not be confused with the net ecosystem production (see Chap. 6). The carbon that has been sequestered by living trees in the biomass is transferred to the HWPs and stored there for a certain time. Thus, the carbon storage itself does not imply mitigation. A mitigation impact is achieved when there is an increase in the HWP carbon stock in the technosphere (i.e. when the input to the product pool is greater than the outflow from the product pool). If there is no change in the volume of the harvest, nor in the product portfolios, there is no change in the HWP carbon stock, in which case the stock change (sink impact) remains zero. As with substitution, the HWP stock change can occur both ways––if the HWP carbon stock is reduced, the HWP pool turns into a source of carbon. Whether this results in net benefits or losses for the climate over a certain time period is determined by simultaneously assessing the entire scope of carbon pools and flows in the forest sector through time (see Chap. 8).

If the initial carbon pool of HWPs is zero, or already saturated, the mitigation impact of HWP carbon storage can be increased either by increasing the level of harvesting or by increasing the relative share of wood-based products with long life-spans, such as wood construction products, in the total harvest. The net emissions balances of these two strategies are not necessarily equal in terms of climate-change mitigation over the next few decades. That is, depending on the forest growth conditions and the product portfolio, an increase in the level of harvesting can reduce the carbon sink of forests for a longer time period than the carbon can remain stored in HWPs, on average (Heinonen et al. 2017). However, any such conclusions ought to be assessed by comparing the impacts against a holistic counterfactual scenario (see Chap. 8) due to various indirect and cascade impacts.

Compared to substitution, the HWP sink is more straightforward to estimate. This is partly because it is included in the international GHG reporting guidance by the IPCC (Rüter et al. 2019). However, it should be noted that the four approaches detailed in the GHG reporting guidance (stock change, production, atmospheric flow, simple decay) have differences in terms of their conceptual frameworks and system boundaries (Rüter et al. 2019). The system boundary may cross national borders, such as when applying the ‘production’ approach, in which the producing country reports carbon stock changes from HWPs produced by that country, regardless of where the HWPs are consumed and used (Rüter et al. 2019). Thus, the policy processes have been aimed at agreeing on the use of a common method for all parties to avoid double counting across national GHG inventories in order to facilitate the global stocktake of climate-change mitigation measures.

Despite there being more peer reviewed literature on the HWP sink impact than on the substitution impact, there are still considerable uncertainties in the assumptions related to HWP sink estimates. Notably, the product half-lives are generally assumed to vary between 0 (e.g. bioenergy) and 35 (e.g. sawnwood), but they remain very difficult to assess reliably (e.g. Iordan et al. 2018). While the HWP sink impact is currently marginal compared to the substitution impact, this could change in the future due to the expected average decline in the substitution impacts and the simultaneously expected increase in the cascade use of wood (i.e. the reuse or recycling of wood), which would extend the lifetime of the carbon in the technosphere before it being released back to the atmosphere.

7.2 Scale and Future Outlook of Substitution Impacts and Harvested-Wood Product Sinks

7.2.1 Scale of Substitution Impacts and Sinks of Wood-Based Products

Before jumping to the estimates of overall substitution and HWP sink impacts, some caveats must be re-emphasised. Importantly, the absolute substitution impact values alone should not be interpreted as the climate benefits of wood use or as the climate-change mitigation potential. Instead, they are components of the overall carbon flow; they do not necessarily provide a meaningful interpretation in isolation from other parts of the studied system and without comparison to a common reference. To guide managerial or policy decision-making, it is necessary to calculate the overall substitution impacts of wood use and use this information in calculating the net GHG emissions of the forest-based sector under different forest management regimes and market structures (see Chap. 8).

There are very few systematic analyses of the overall substitution impacts at the global or European levels that depict the scale of fossil emissions avoided compared to no wood use. At the global level, Roe et al. (2019) estimated that the avoided emissions potential from increasing the demand of wood products to replace construction materials ranged from 0.25 to 1 GtCO2eq/year. At the European level, Holmgren (2020) estimated that the currently avoided emissions from the industrial and energy uses of wood account for −410 MtCO2eq/year (not considering the fossil emissions of the forest-based value chains of 51 MtCO2eq/year). In Finland, the current annual substitution impacts of forest-based-sector activities have been estimated as accounting for between 16.6 and 35 MtCO2eq, with a domestic harvest level of 65–70 Mm3 (Soimakallio et al. 2016; Alarotu et al. 2020; Hurmekoski et al. 2020). According to the National Inventory Report submissions under the UNFCCC, the HWP sink impact in the EU was −40.6 MtCO2eq/year in 2017, whilst in Finland, it has varied between −6.6 and 1.6 MtCO2eq/year since 1990. Future research may be able to provide more detailed estimates and a more comprehensive geographical context.

The absolute carbon pools related to forests are highly sensitive to the level of harvesting, which can mean large annual fluctuations. One option to alleviate this issue, in the context of substitution impacts, is to focus on the average values across total wood use (tC/tC). Mirroring the overall shortage of substitution estimates, there are also not many studies globally that have approximated the weighted DF for overall wood use on a national level. These estimates range between 0.3 and 1.2 tC/tC in different scenarios and with varying geographical and product scopes, with an average of around 0.5 tC/tC (e.g. Werner et al. 2010; Braun et al. 2016; Suter et al. 2017; Kayo et al. 2018; Hurmekoski et al. 2020). It can be seen that the national-level average substitution impact can be smaller than the average DF reported from meta- analyses (1.2–2.1 tC/tC) (Sathre and O’Connor 2010; Leskinen et al. 2018), which makes it all the more important to keep these values separate and to understand the reason behind the difference––the scope of the wood flows and product portfolios considered.

7.2.2 Future Trends for Substitution Impacts and Harvested-Wood Product Sinks

Future estimates of substitution impacts are uncertain, not only because of the long time frames, per se, but more because of the ongoing structural changes in the forest-based industries and their possibly evolving competitive positions. Some of the new wood-based products may have superior environmental performance compared to the current state, such as alternative solvent processes for regenerated cellulose fibres for textiles (Rüter et al. 2016). This could increase the average substitution impact of wood use if produced in place of the declining communication-paper market, to which no significant substitution impact can be attributed (Achachlouei and Moberg 2015).

At the same time, we should expect an opposite trend that will diminish the average substitution impacts of wood use, such as emissions reductions in the energy and industrial sectors to comply with the Paris Agreement target (e.g. Harmon 2019). That is, these alternative products tend to be more energy intensive than wood-based products, as indicated by positive DF values. When the average emissions from energy production are lowered, the emissions reductions of the competing products will be relatively greater than for wood-based products, thereby diminishing the relative benefit of wood use. Besides the emissions from energy production, there may be large reductions in the energy intensity of production processes, as well as process-related emissions. For example, in the construction sector, the emissions from calcination in the cement production process, which currently produces around half the total emissions in cement production, could eventually be diminished (e.g. Licht et al. 2012). In the chemicals and biofuels sector, CO2 could be captured and used as a feedstock (e.g. Kruus and Hakala 2017), which could entirely change the logic of substitution impact estimates, if applied on a large scale. Thus, when fossil emissions are eventually phased out, there will be no fossil emissions to be avoided, leading to a zero substitution impact potential, regardless of wood use.

In addition to direct emissions, the importance of recycling has been recognised in the European Union Circular Economy action plan, which aims to improve resource efficiency by keeping the value of materials, products and resources in the technological ‘closed loop’ system for as long as possible by, for example, reuse, recycling and product design (European Commission 2015). Technological solutions may contribute to this target by: (i) minimising the virgin feedstock demand; and (ii) improving the reuse and recycling possibilities of materials. The expected increase in the recycling rates of non-wood products may further diminish the substitution impacts of forest-based products, such as in the case of replacing recycled plastic compared to primary plastic. The impact of wood cascading on the substitution impacts remains unclear, depending on whether, for example, the recycled wood products create additional demand, or if they substitute for existing wood products. Production technologies that improve the durability, recyclability or resource efficiency of wood-based products, such as laser scanning, improved sawing techniques, waste separation technologies and recycling technologies, would increase the HWP sink.

Thus, without investments in new wood-based products with superior environmental profiles, the average substitution impacts of wood use can be expected to diminish (e.g. Keith et al. 2015). This interplay of hypothetical developments and innovations in the wood-based products sector and in competing sectors makes the outlook very uncertain. Moreover, where the wood products and competing products are produced can make a difference, as the average energy profile and the pace of emissions reductions may be different from one region to another. However, from the environmental and societal perspectives, the competition between forest-based products and alternative products is welcome, as it strengthens the incentives for developing products and processes that cause less harm for ecosystems.

While there are still huge barriers to the large-scale uptake of novel negative emissions technologies, they will be necessary in the long-term, due to the sluggish rate of global emissions reductions (IPCC 2018). Introducing negative emissions technologies, such as bioenergy with carbon capture and storage (BECCS) or biochar, in the forest value chain, could also influence the relative benefits of wood-based products. However, this dynamic would not necessarily be captured by the DFs, if they only track fossil emissions, and should therefore be reflected elsewhere in GHG inventories. This could have implications both for research and policy. Research should consider whether the use of DFs is the most appropriate approach in such cases, and international agreements should determine who would benefit from the uptake of such technologies. These decisions could possibly influence the rate of BECCS market uptake.

7.3 Role of Harvested Wood Products in Climate-Change Mitigation

Seppälä et al. (2019) introduced the concept of a required DF, which depicts the required scale of substitution impacts that would exceed the temporary loss of ecosystem carbon when wood is being harvested. In other words, it depicts the minimum value for the average substitution impacts that would result in an immediate net reduction of emissions, despite an increased level of harvesting. The level of the required DF that would satisfy this condition has been estimated to be between 1.9 and 2.5 tC/tC (Seppälä et al. 2019; Köhl et al. 2020). This compares to an estimated current weighted overall substitution impact of around 0.5 tC/tC in Finland (Soimakallio et al. 2016; Hurmekoski et al. 2020), suggesting that the substitution impacts alone would not be large enough to compensate for the loss of the forest carbon sink , even in the medium- and long-term. In other words, in the Finnish context, a marginal increase in the use of wood is unlikely to reduce the net carbon emissions of wood use within the timespan of a century (see also Heinonen et al. 2017). The Finnish forest sector is characterised by long rotation periods (60–120 years), an intensive forest management regime with a young-stand-dominated age class structure, a relatively low level of natural disturbances, and a pulp- and paper-dominated industry structure, which together help to explain this difference. In other regions, the circumstances may allow opposite conclusions within a reasonable time frame.

However, it is important to acknowledge that the scope of the analysis leading to these conclusions is limited. Added to the uncertainty of the substitution and carbon sink estimates of forests and their products, such analyses tend to disregard other possibly relevant determinants of net emissions, such as the possible risks and benefits associated with the impact of climate change on forests, including increased forest growth and the different abiotic and biotic damage caused to forests by windstorms, drought, insects, pathogens and forest fires. Such elements may have a decisive impact on the conclusions, although state-of-the-art research faces difficulties in capturing them all under a single framework. Moreover, mitigation strategies are naturally influenced by a holistic assessment of efficiency and feasibility, which broadens the scope from physical carbon flows to, for example, the incentives created by harvesting income to finance further mitigation measures.

Regardless of the harvest level, the net emissions of the forest-based sector can, at least in principle, be reduced by changing the process and production structure to increase resource efficiency and the share of products with very high DFs and long life-spans, in addition to increasing the carbon sequestration with the help of forestry practices. More specifically, in terms of climate-change mitigation, improvements in the wood utilisation patterns from the perspective of the climate can be divided into two general actions: (i) reducing the share of energy involved in overall wood use, and satisfying the operational energy demand of the pulp mills and sawmills through alternative, low-emissions energy sources or by increasing the energy efficiency of such mills; or (ii) improving resource efficiency in the manufacturing of products and/or applying more cascade loops to increase the length of HWP carbon storage. In general, the use of wood for energy, in most cases, produces a lower DF compared to its material uses, while new wood-based products, such as chemicals, textiles and mixed-material composites, exhibit the highest potential (Soimakallio et al. 2016; Leskinen et al. 2018). Therefore, wood-material flows, including secondary flows, such as sidestreams and waste wood, should primarily be used for those high DF applications before being used as combustion for energy. In wood construction, the substitution potential is, on average, estimated to be slightly lower, but the HWP sink is considerably higher compared to many of the new wood-based products. Thus, the assumed carbon-storage time of up to 70 years compensates for the smaller substitution impact.

A big question mark in this context concerns the extent to which the production structure could change. The market structure is simultaneously influenced by consumer demand, the competitive advantage of a firm, industry, region or country to produce a certain product, and the strategies of the industries. For example, it is unrealistic to assume that the production of short life-span products with no substitution impacts, such as hygiene papers, would come to a halt. Even if this was the case in one region, the production would likely shift elsewhere, at least in part (see Box 7.1). Nonetheless, besides reducing the direct energy use of industrial sidestreams, one clear opportunity relates to the declining demand for communication papers, and the resulting increased availability of pulpwood for alternative uses, such as packaging (Hurmekoski et al. 2018).

It is necessary to remember that, ultimately, the primary focus of any climate-change mitigation strategy ought to be on minimising overall emissions to the atmosphere rather than, for example, maximising the substitution impacts of wood use, whether this means favouring certain products or, for example, changing forest management practices for improved ecosystem resilience. Due to established industries being required to find several complementary emissions-reduction pathways to meet the obligations of the Paris Agreement, the increased use of wood becomes all the more relevant for climate-change mitigation, especially the more pessimistic the overall climate policy outlook. However, as lignocellulosic resources will, in any case, be insufficient for replacing the entire fossil-based economy, the uses of wood will need to be prioritised in those markets where significant emissions reductions seem the most difficult to obtain, or where co-benefits on, for example, the water footprint could be gained, markets allowing.

7.4 Research Implications

Estimating substitution impacts and HWP carbon storage is a technically complex task and, in practical terms, limited by data availability. Unlike for HWP sinks, there is no IPCC guidance, or other established guidance, for deriving market- level substitution estimates, although the LCA used to derive product-specific DFs is based on international standards. The complexity of the markets and carbon flows causes variation in the scope of assumptions, whilst the abstract nature of substitution and the lack of precise data cause significant uncertainty in substitution estimates. Even though the few available estimates indicate a reasonably similar scale, this may be the result of using, at least partly, the same few data sources and similar market assumptions.

The GHG data produced by LCA is a key data source for assessing the DFs of wood-based products. However, the current practise of LCA does not include GHG emissions caused by LULUCF. In order to assess the total climate impacts of wood utilisation, including changes in the carbon stocks in forests, and their products and substitution effects, the impacts of LULUCF on GHG emissions caused by alternative non-wood products should also be taken into account. For example, the production of cotton causes land-use change, releasing CO2 emissions from soils.

DF data on the use and end-of-life stages of products remains scarce. In particular, the impact of recycling on the overall DFs is unclear for many products. More research is needed to avoid false conclusions.

Product substitution is an abstract and essentially unobservable phenomenon. Thus, a satisfactory understanding of substitution impacts cannot be gained by looking at carbon pools and flows alone––market dynamics also require consideration. While substitution can, to some extent, be traced using market shares (e.g. Batten and Johansson 1987), our overall understanding of the occurrence and nature of substitution in the wood-based products markets remains incomplete, if not fragile. For example, consider the case of deriving an end-use-weighted DF for dissolving pulp (Sect. 7.1.2). Measuring the market share may not fully capture the substitution dynamics in the market. If the production of cotton remains stable, having reached a limit (e.g. due to no more land or water being available for its production), and at the same time man-made cellulosic fibre (MMCF) consumption increases, is it then a logical interpretation that MMCFs substitute for cotton? If the production of MMCFs were not increased to meet the increased demand for textile fibres, perhaps the remainder of the demand would have been met by synthetic fibres. Thus, it is not clear whether we should assume that MMCFs will substitute for synthetic fibres or cotton. More importantly, we cannot be sure if we can assume substitution to have occurred in the first place. That is, in the absence of perfect substitutes, the overall demand for textile fibres may have remained lower due to the markets adjusting to increased prices as a consequence of constrained supply.

Even if we accept the premise of substitution between wood-based and alternative textile fibres, can we be certain that this prevents the extra fossil feedstocks from being used? Due to carbon leakage (Box 7.1), an additional unit of wood products consumed does not necessarily lead to a unit reduction in other consumption, as the consumption of the alternative product may shift elsewhere in the economy (e.g. Sathre and O’Connor 2010), or the use of fossil feedstocks may be delayed for a certain period (Harmon 2019). Thus, the (non-)permanence of avoided emissions can end up being an issue equally as complex as the (non-)permanence of forest carbon sinks.

Box 7.1. Carbon Leakage

The term ‘carbon leakage’ refers to a shift in emissions-intensive production from one region to another, for example, if a carbon tax is operationalised in one region only. This issue is not specific to any sector, but is a generic result of supply shifting to unregulated areas to meet the global demand, when the supply is restricted either directly or through pricing. Besides shifting the production capacity, leakage can also occur in the supply side, such as in forestry, for example, when forest land is set aside (e.g. for enhancing carbon sinks through a compensation scheme for forest owners or to conserve forests through the UN’s Reducing Emissions from Deforestation and forest Degradation [REDD+]) schemes. In this case, the reduced supply of wood in one region may result in an increased level of harvesting elsewhere, thus watering down the initial aim. According to Pan et al. (2020), carbon leakage is estimated to be higher in the forest sector than in energy-intensive industries.

In the forest sector, the term has mostly been used in the context of limiting the level of wood harvesting and the resulting international carbon leakage. Kallio and Solberg (2018) suggested that a change in harvest level in one country may lead to up to a 60–100% opposite change in the rest of the world. In addition to international leakage in a sector, there may also be intersectoral or intertemporal carbon leakage. This relates to the assumptions about substitution, in that an additional unit of wood products consumed does not necessarily lead to a unit reduction in other consumption, as the consumption of the alternative product may shift from one use to another (Sathre and O’Connor 2010). That is, if wood replaces concrete in the construction sector, the avoided use of fossil feedstocks may end up being used in another sector. Similarly, substitution may delay the use of fossil feedstocks for a certain period, but not necessarily avoid its use altogether (Harmon 2019). In other words, the substitution impact would be slowing down the fossil depletion rate, but not necessarily preventing it from happening.

Unless a policy has perfect coverage over the entire world economy, it may be impossible to avoid leakages. Although the exact rate of leakage is somewhat uncertain, it should nevertheless be considered when designing climate policies, not to encourage measures that lead to suboptimal or controversial impacts. This calls for long-term and integrated land-use planning (Pan et al. 2020).

A few practical implications arise from the identified uncertainties. There is a need to balance between expected developments in the forest-products markets and the availability of data for the determination of DFs. While there can be alternative ways for addressing the structural changes in forest-sector modelling to gain market scenarios, we simply do not have data for accurately determining the DF for novel wood-based products, or their counterparts that are not yet in production. We can, however, make assumptions about the factors that will influence the outcome, and can rely on sensitivity analysis to test their impact. Indeed, in future endeavours to estimate the scale of the overall substitution impacts, a range of estimates based on minimum and maximum assumptions should be considered, rather than a single value, together with extensive sensitivity analysis on the critical uncertainties. Focusing on marginal substitution, and using optimisation techniques to define optimal substitution cases, allows for the formulation of tangible and policy- relevant strategies (Smyth et al. 2017).

Importantly, there is a need for integrated modelling frameworks to capture the various market dynamics, such as rebound effects. For example, Antikainen et al. (2017) found that using textiles for longer before disposal, or substituting synthetic fibres for MMCFs, increases the overall material consumption of the economy, as this drives the consumption from textiles towards other commodities, which are often more material-intensive than textiles, and because synthetic fibres are produced from the sidestreams of the oil industry. Such impacts cannot be captured by focusing on the forest- product markets alone, but require a broader understanding of the end-use markets and value chains, as well as consumer behaviour.

A further layer of complexity is added when the fossil carbon flows are compared against the biogenic carbon flows. While GHG molecules and their impact on the climate obviously cannot be told apart based on their origin, this distinction is necessary when defining long-term mitigation strategies. In the next chapter of this book, we combine the insights of Chaps. 6 and 7, highlighting the possible trade-offs, and searching for no-regret mitigation strategies in light of these carbon flows.

7.5 Key Messages

-

HWPs can influence the climate through two separate mechanisms. Firstly, when wood is harvested from a forest, the carbon contained in the wood is stored in wood-based products for months to decades. If the amount of wood products entering the market exceeds the amount of wood products being discarded annually, this can lead to a HWP sink impact. Secondly, as wood-based products have, on average, a lower fossil carbon footprint than alternative products, using wood in construction, for example, can avoid larger fossil emissions by reducing the production of cement and steel. This is a substitution impact. The international GHG reporting conventions and the related IPCC guidance only cover the HWP sink impact, but not the substitution impacts.

-

Substitution impacts are measured by tracking market developments (material flows, end uses, consumer demands) and the emissions profiles of wood-based products versus products they substitute for. So far, there is no established framework for upscaling the substitution impacts to the market level. While there are rough estimates of substitution impacts, it is unclear what percentage of current or future wood-based products may ultimately substitute for fossil feedstocks. Even some of the principles remain uncertain, such as the extent to which substitution can be assumed to occur in individual cases. Despite these uncertainties, HWPs can, at least in principle, further contribute to climate-change mitigation by changing the production structure of forest industries by, for example, shifting from communication-paper manufacturing to textile manufacturing, or by shifting the use of by-products from energy to material uses.

-

Importantly, the substitution and HWP sink impacts do not represent the climate-change mitigation impact of wood use, as such. Instead, they are important pieces of the broader puzzle of GHG flows related to the forest sector, and need to be considered in decision-making accordingly. This is because substitution impacts only depict changes in fossil emissions, while changes in biogenic emissions are accounted for in the LULUCF sector, indicating a possible short-term trade-off between substitution impacts and HWP sink impacts on one hand, and forest carbon sinks on the other. These fossil and biogenic carbon flows need to be tracked across time and across markets in alternative scenarios compared to a common reference in order to yield relevant policy implications.

Notes

- 1.

HWPs are synonymous with forest-based products. The term HWP has been established in technical and policy nomenclature, despite it seeming somewhat illogical.

References

Achachlouei MA, Moberg Å (2015) Life cycle assessment of a magazine, part II: a comparison of print and tablet editions. J Ind Ecol 19:590–606

Alarotu M, Pajula T, Hakala J, Harlin A (2020) Metsäteollisuuden tuotteiden ilmastovaikutukset (Climate impacts of forest industry products). VTT-CR-00682-20

Batten DF, Johansson B (1987) Substitution and technological change. In: The global forest sector: an analytical perspective. Wiley, New York, pp 278–305

Braun M, Fritz D, Weiss P, Braschel N, Büchsenmeister R, Freudenschuß A, Gschwantner T, Jandl R, Ledermann T, Neumann M (2016) A holistic assessment of greenhouse gas dynamics from forests to the effects of wood products use in Austria. Carbon Manag 7:271–283

Brunet-Navarro P, Jochheim H, Cardellini G, Richter K, Muys B (2021) Climate mitigation by energy and material substitution of wood products has an expiry date. J Clean Prod 127026

EN: 15804:2012 (2012) Sustainability of construction works. Environmental product declarations. Core rules for the product category of construction products, British Standards Institute, London

European Commission (2015) Closing the loop – an EU action plan for the circular economy. European Commission, Communication COM (2015) 614/2

Finkbeiner M, Inaba A, Tan R (2006) The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int J Life Cycle Assess 11:80–85. https://doi.org/10.1065/lca2006.02.002

Finnish Government (2019) Programme of Prime Minister Sanna Marin’s Government 10 December 2019. Inclusive and competent Finland—a socially, economically and ecologically sustainable society. Publications of the Finnish Government 2019:33, Helsinki

Harmon ME (2019) Have product substitution carbon benefits been overestimated? A sensitivity analysis of key assumptions. Environ Res Lett 14:65008

Heinonen T, Pukkala T, Mehtätalo L, Asikainen A, Kangas J, Peltola H (2017) Scenario analyses for the effects of harvesting intensity on development of forest resources, timber supply, carbon balance and biodiversity of Finnish forestry. For Policy Econ 80:80–98

Holmgren P (2019) Contribution of the Swedish forestry sector to global climate efforts. Swedish Forest Industries Federation

Holmgren P (2020) Climate effects of the forest based sector in the European Union. Confederation of European Paper Industry

Howard C, Dymond CC, Griess VC, Tolkien-Spurr D, van Kooten GC (2021) Wood product carbon substitution benefits: a critical review of assumptions. Carbon Balance Manag 16:1–11

Hurmekoski E, Jonsson R, Korhonen J, Jänis J, Mäkinen M, Leskinen P, Hetemäki L (2018) Diversification of the forest-based sector: role of new products. Can J For Res 48:1417–1432. https://doi.org/10.1139/cjfr-2018-0116

Hurmekoski E, Myllyviita T, Seppälä J, Heinonen T, Kilpeläinen A, Pukkala T, Mattila T, Hetemäki L, Asikainen A, Peltola H (2020) Impact of structural changes in wood-using industries on net carbon emissions in Finland. J Ind Ecol 24:899–912

Iordan CM, Hu X, Arvesen A, Kauppi P, Cherubini F (2018) Contribution of forest wood products to negative emissions: historical comparative analysis from 1960 to 2015 in Norway, Sweden and Finland. Carbon Balance Manag 13:12

IPCC (2018). Global warming of 1.5°C. An IPCC special report on the impacts of global warming of 1.5°C above pre—industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change. Intergovernmental Panel on Climate Change

JRC (2010) ILCD handbook: general guide for life cycle assessment—detailed guidance. European Union, Luxembourg

Kallio AMI, Solberg B (2018) Leakage of forest harvest changes in a small open economy: case Norway. Scand J For Res 33:502–510

Kayo C, Dente SMR, Aoki-Suzuki C, Tanaka D, Murakami S, Hashimoto S (2018) Environmental impact assessment of wood use in Japan through 2050 using material flow analysis and life cycle assessment. J Ind Ecol 23:635–648

Keith H, Lindenmayer D, Macintosh A, Mackey B (2015) Under what circumstances do wood products from native forests benefit climate change mitigation? PLoS One 10:e0139640

Knauf M (2015) A multi-tiered approach for assessing the forestry and wood products industries’ impact on the carbon balance. Carbon Balance Manag 10:4

Köhl M, Ehrhart H-P, Knauf M, Neupane PR (2020) A viable indicator approach for assessing sustainable forest management in terms of carbon emissions and removals. Ecol Indic 111:106057

Kruus K, Hakala T (2017) The making of bioeconomy transformation. VTT Technical Research Centre of Finland

Leskinen P, Cardellini G, Gonzalez-Garcia S, Gustavsson L, Hurmekoski E, Sathre R, Seppälä J, Smyth C, Stern T, Verkerk H (2018) Substitution effects of wood-based products in climate change mitigation. From science to policy, no. 7. European Forest Institute. https://doi.org/10.36333/fs07

Licht S, Wu H, Hettige C, Wang B, Asercion J, Lau J, Stuart J (2012) STEP cement: solar thermal electrochemical production of CaO without CO2 emission. Chem Commun 48:6019–6021

Pan W, Kim M-K, Ning Z, Yang H (2020) Carbon leakage in energy/forest sectors and climate policy implications using meta-analysis. For Policy Econ 115:102161

PAS 2050:2011 (2011) Specification for the assessment of the life cycle greenhouse gas emissions of goods and services. British Standards Institute, London

Poljatschenko VAM, Valsta LT (2021) Carbon emissions displacement effect of Finnish mechanical wood products by dominant tree species in a set of wood use scenarios. Silva Fenn 55. https://doi.org/10.14214/sf.10391

Repo A, Känkänen R, Tuovinen J, Antikainen R, Tuomi M, Vanhala P, Liski J (2012) Forest bioenergy climate impact can be improved by allocating forest residue removal. GCB Bioenergy 4:202–212

Roe S, Streck C, Obersteiner M, Frank S, Griscom B, Drouet L, Fricko O, Gusti M, Harris N, Hasegawa (2019) Contribution of the land sector to a 1.5° C world. Nat Clim Chang:1–12

Rüter S, Werner F, Forsell N, Prins C, Vial E, Levet A-L (2016) ClimWood2030-Climate benefits of material substitution by forest biomass and harvested wood products: perspective 2030. Final report. Thünen report

Rüter S, Matthews RW, Lundblad M, Sato A, Hassan RA (2019) Chapter 12: harvested wood products. In: 2019 Refinement to the 2006 IPCC guidelines for National Greenhouse Gas Inventories. Intergovernmental Panel on Climate Change, pp 12.1–12.49

Sathre R, O’Connor J (2010) Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ Sci Pol 13:104–114

Seppälä J, Heinonen T, Pukkala T, Kilpeläinen A, Mattila T, Myllyviita T, Asikainen A, Peltola H (2019) Effect of increased wood harvesting and utilization on required greenhouse gas displacement factors of wood-based products and fuels. J Environ Manag 247:580–587

Smyth C, Rampley G, Lemprière TC, Schwab O, Kurz WA (2017) Estimating product and energy substitution benefits in national-scale mitigation analyses for Canada. GCB Bioenergy 9:1071–1084

Soimakallio S, Saikku L, Valsta L, Pingoud K (2016) Climate change mitigation challenge for wood utilization the case of Finland. Environ Sci Technol 50:5127–5134

Suter F, Steubing B, Hellweg S (2017) Life cycle impacts and benefits of wood along the value ch Ain: the case of Switzerland. J Ind Ecol 21:874–886

Taylor R, Nattrass L, Alberts G, Robson P, Chudziak C, Bauen A, Libelli IM, Lotti G, Prussi M, Nistri R. (2015) From the sugar platform to biofuels and biochemicals. Final report for the European Commission Directorate-General Energy N (ENER/C2/423–2012/SI2.673791)

UNFCCC (2018) Report of the conference of the parties serving as the meeting of the parties to the Paris agreement on the third part of its first session, held in Katowice from 2 to 15 December 2018. United Nations Framework Convention on Climate Change

Werner F, Taverna R, Hofer P, Thürig E, Kaufmann E (2010) National and global greenhouse gas dynamics of different forest management and wood use scenarios: a model-based assessment. Environ Sci Pol 13:72–85

Zanchi G, Pena N, Bird N (2012) Is woody bioenergy carbon neutral? A comparative assessment of emissions from consumption of woody bioenergy and fossil fuel. GCB Bioenergy 4:761–772

Acknowledgements

Elias Hurmekoski wishes to acknowledge financial support from the SubWood Project (No. 321627), funded by the Academy of Finland.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2022 The Author(s)

About this chapter

Cite this chapter

Hurmekoski, E., Seppälä, J., Kilpeläinen, A., Kunttu, J. (2022). Contribution of Wood-Based Products to Climate Change Mitigation. In: Hetemäki, L., Kangas, J., Peltola, H. (eds) Forest Bioeconomy and Climate Change . Managing Forest Ecosystems, vol 42. Springer, Cham. https://doi.org/10.1007/978-3-030-99206-4_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-99206-4_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-99205-7

Online ISBN: 978-3-030-99206-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)