Abstract

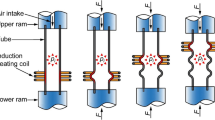

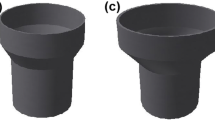

The environmental concerns to save energy are currently driving the attention toward alternative ways to produce lightweight components, matching the most promising light alloys (as in the case of aluminium alloys) with new and innovative manufacturing trends. To address these new requirements the use of tubular structures has increased as a solution to reduce weight. Parallel to the need to increase the material formability local heat treatment of metal sheets has gained some relevance in the last years. The present work is focused on the evaluation of the formability at room temperature of thin-walled aluminium alloy tubes previously overaged in specific zones by laser. The formability limits of the thin-walled tube material in the ‘as-received’ condition were preliminarily determined by means of tensile tests and tube expansion with elastomer. An initial numerical analysis was performed in order to define laser heating parameters to effectively overage the material. The experimental work (tensile and tube expansion tests) was assisted by the Digital Image Correlation (DIC). On the other hand, the laser treatment to obtain Locally Overaged Tubes (LOTs) was investigated according to the results of the preliminary numerical simulations and such LOTs were subjected to experimental tensile and tube expansion tests. The strain paths and failure strains obtained on LOTs were assessed and compared to the formability limits of the ‘as-received’ tube, thus allowing to evaluate the effect of the local modification of the material properties on the formability of the tube.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Tekkaya AE (2018) Energy saving by manufacturing technology. Proc Manuf 21:392–396

Jeswiet J, Geiger M, Engel U, Kleiner M, Schikorra M, Duflou J, Neugebauer R, Bariani P, Bruschi S (2008) Metal forming progress since 2000. CIRP J Manuf Sci Technol 1:2–17

Geiger M, Merklein M, Vogt U (2009) Aluminum tailored heat treated blanks. Prod Eng 3:401–410

Kahrimanidis A, Lechner M, Degner J, Wortberg D, Merklein M (2015) Process design of aluminum tailor heat treated blanks. Materials (Basel) 8:8524–8538

Peixinho N, Soares D, Vilarinho C, Pereira P, Dimas D (2012) Experimental study of impact energy absorption in aluminium square tubes with thermal triggers. Mater Res 15:323–332

Merklein M, Böhm W, Lechner M (2012) Tailoring material properties of aluminum by local laser heat treatment. Phys Proc 39:232–239

Merklein M, Nguyen H (2011) Adjusting optimized material properties for tailored heat treated blanks. Key Eng Mater 473:420–427

Hung N, Marion M (2012) Improved formability of aluminum alloys using laser induced hardening of tailored heat treated blanks. Phys Proc 39:318–326

Magrinho JP, Silva MB, Centeno G, Moedas F, Vallellano C, Martins PAF (2019) On the determination of forming limits in thin-walled tubes. Int J Mech Sci 155:381–391

12004–2 ISO (2008) Metallic materials - sheet and strip - determination of forming-limit curves - part 2: determination of forming-limit curves in the laboratory

Martins PAF, Bay N, Tekkaya AE, Atkins AG (2014) Characterization of fracture loci in metal forming. Int J Mech Sci 83:112–123

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Piccininni, A., Magrinho, J.P., Silva, M.B., Palumbo, G. (2021). Formability Analysis of a Local Heat-Treated Aluminium Alloy Thin-Walled Tube. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_230

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_230

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)