Abstract

Purpose: capability check of removal the contact-precipitated iron from the samples surfaces of titanium alloy VT6ch after vibro-impact strengthening by steel balls using vibro-abrasive processing by ceramic granules.

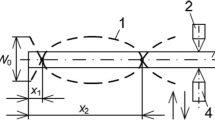

Design/methodology/approach: the theory of resiliency and plasticity, of contact destruction mechanics positions are used in the article. Experimental researches were based on experiment planning theory, the data statistical processing methods, facilities of the computing engineering and software. The iron tracks presence on the samples surface was controlled by visual examination of the imposed on it filtration paper, moistened in solution, containing potassium ferricyanide. The iron tracks removal from the strengthened samples surface was conducted by two methods: by etching in nitric acid solution and vibro-abrasive processing by ceramic granules. The samples surface layer was corrosion resistance tested using the climate chamber; the surfaces were visually inspected after the test. The samples surface quantitative chemical composition was determined. The samples surface roughness was contact measured.

Findings: surface dressing by ceramic granules RXX 15/15 using process equipment Rosler during 80 и 160 min, as well as etching in nitric acid allows almost complete removal of iron embedded after vibro-impact surface strengthening. Single iron inclusions remain during any type of processing. According to the results of climatic tests of samples (strengthened, strengthened and scraped, strengthened and etched), there were no obvious signs of iron corrosion products.

Originality/value: preliminary studies of the effect of scraping on fatigue resistance have shown that vibro-abrasive processing (scraping) of strengthened samples improves fatigue resistance.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bakhmatov, P., Murav’ev, V.: Manufacture of high-quality ribbed titanium panels. Steel Transl. 47(2), 91–98 (2017)

Murav’ev, V., Bakhmatov, P., Logvinov, O., Melkostupov, K.: Effect of activation of weld edges on the formation of pores in fusion welding of titanium components. Weld. Int. 27(7), 548–552 (2013)

Mouraviev, V., Shport, V., Krupskii, R.: Titanium alloys – a promising structural material. In: Mouraviev, V. (ed.) Ensuring the Reliability of Titanium Alloy Structures. Ekom, Moscow (2009)

Heilmann, P., Clark, W., Rigney, D.: Orientation determination of subsurface cells generated by sliding. Acta Metallugica 31(88), 1293–1305 (1983)

Zangwill, A.: Physics of surfaces. Cambrige University Press, Cambrige (1988)

Kopylov, Y.: The Dynamics of Vibrohardening Processes. Publishing and Printing Center Nauchnaya kniga Ltd., Voronezh (2011)

Zyk, E., Pleshakov, V.: Analytical assessment of the distribution of the diagram of residual stresses along the depth of the surface layer of parts made of high-strength steels during surface plastic deformation. University Proceedings. Volga Region. Technical Sciences. Engineering and Mechanical Engineering 38(2), 136–147 (2016)

Papshev, D.: Finishing and Hardening by Surface Plastic Deformation. Engineering, Moscow (1978)

Dyachenko, Y., Kollerov, V., Trifonov, O., Voron’ko, I., Garin, V.: Development of a mathematical model of the process of surface hardening by impacts of balls. Open Inf. Comput. Integr. Technol. 76, 39–51 (2017)

Kolesnikov, Y., Morozov, E.: Contact Fracture Mechanics. Publishing House LKI, Moscow (2007)

Krupskiy, R., Altukhova, V.: Removing traces of contact precipitated iron from the surface of titanium alloy preforms during vibration impact treatment. In: Advanced Innovative Developments. Prospects and Experience of Use, Problems of Implementation in Production: Collection of Scientific Articles of the Eighth International Scientific Conference. LLC Envelope, Kazan (2019)

PI 1.4.2188: Vibration Impact Processing. Moscow: JSC NIAT (2005)

OST 1 90013: Titanium alloys. Stamps, Moscow: FSUE VIAM (1981)

PI 1.4.2207: Determination of processing intensity during hardening by impact surface plastic deformation. Moscow: JSC NIAT (2008)

GOST 9.311: Metallic and non-metallic inorganic coatings. Corrosion Damage Assessment Method. Moscow: Gosstandart (1987)

Acknowledgments

The study was carried out using the equipment of the Center for Collective Use “New Materials and Technologies” on the basis of KnASU.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Altukhova, V.V., Krupskiy, R.F., Krivenok, A.A., Kravchenko, E.G. (2021). Vibro-Abrasive Engineering of the High-Resource Titanium Aircraft Parts Surface. In: Shakirova, O.G., Bashkov, O.V., Khusainov, A.A. (eds) Current Problems and Ways of Industry Development: Equipment and Technologies. Lecture Notes in Networks and Systems, vol 200. Springer, Cham. https://doi.org/10.1007/978-3-030-69421-0_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-69421-0_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69420-3

Online ISBN: 978-3-030-69421-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)