Abstract

Purpose Construct and investigate a method for optimizing the processes of forming thin-walled structures. A criterion for the optimization of deformation processes is introduced, which ensures minimal damage. Under the condition of a given tooling, the optimal control problem is posed to find the best path for deformation of the workpiece. In the space of solutions to optimal control problems developed by the methods, non-monotonic deformation trajectories should be included, taking into account partial unloading.

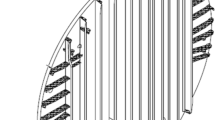

Design/methodology/approach. Modeling of technologies for forming double-curvature shells using CAE systems is considered. As devices for forming products from sheets and panels, equipment with numerical control is used, in particular, a reconfigurable rod punch and stretch forming equipment. Calculation of the optimal forming path of the workpiece is performed by modeling and analyzing the nonlinear deformation of the panel with contact constraints using the finite element method. A discrete optimal control problem is formulated, which is solved by the dynamic programming. The numerical method algorithms implemented in the MSC system Marc allow us to calculate the optimal parameters of the process equipment.

Findings. Calculations using the developed method of optimal trajectory for technological processes of forming are presented. The results of solving these problems are compared with known analytical and practical data.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ribeiro, F., Marinho, E., Inforzato, D., Costa, P., Batalha, G.: Creep age forming: a short review of fundaments and applications. J. Achiev. Mater. Manuf. Eng. 43(1), 353–361 (2010)

Yan, Y., Wan, M., Wang, H., Huang, L.: Design and optimization of press bend forming path for producing aircraft integral panels with compound curvatures. Chin. J. Aeronaut. 23(2), 274–282 (2010)

Verichev, S., Gorev, B., Banshchikova, I.: The shaping by bending of elements aircraft structures at plasticity conditions. Obrabotka Metallov 4(65), 85–93 (2014)

Annin, B., Oleynikov, A., Bormotin, K.: Modeling of forming the wing panels the SSJ-100 aircraft. J. Appl. Mech. Tech. Phys. 51(4), 579–589 (2010)

Wang, W., Jia, B., Yu, J.: A new flexible sheet metal forming method and its stamping process. In: Proceedings of the 14th IFToMM World Congress (2015). https://doi.org/10.6567/IFToMM.14TH.WC.PS20.006

Feoktistov, S., Pogartseva, M.: Technique for the development of the technological process for the tightening of aircraft parts on CNC presses. In: Materials Science Forum, vol. 945 MSF, pp. 839–844 (2019)

Potianikhin, D., Maryn, B., Feoktistov, S., Soe, K.: Simulation of thin-walled workpieces ends expanding for pipelines making. In: IOP Conference Series: Materials Science and Engineering, vol. 510, p. 012015 (2019). https://doi.org/10.1088/1757-899X/510/1/012015

Simon, D., Kern, L., Wagner, J., Reinhart, G.: A reconfigurable tooling system for producing plastic shields. Procedia CIRP 17, 853–858 (2014)

Molod, M.: Managing the process of forming linings for CNC equipment. Bull. Voronezh State Tech. Univ. 7(12–2), 62–64 (2011)

Huang, L., Wan, M., Chi, C., Ji, X.: FEM analysis of spring-backs in age forming of aluminum alloy plates. Chin. J. Aeronaut. 20, 564–569 (2007)

Lihua, Z., Jianguo, L., Minghui, H.: Study on springback behavior in creep age forming of aluminium sheets. Adv. Sci. Lett. 19(1), 75–79 (2013)

Miheev, V., Klochkov, Y., Kuzina, A., Grechnikova, A., Savin, D.: The choice of the kinematic diagram of the formation of the skin-tight contour-forming shells of complex spatial form. Vestnik Samarskogo gosudarstvennogo aerokosmicheskogo universiteta 5(36), 239–245 (2012)

Miheev, V., Grechnikova, A., Kuzina, A.: Improvement of the processes of forming by the stretch wrap forming of the shells of the dual curvature. Izvestia of Samara Sci. Center Russian Acad. Sci. 13(4), 217–224 (2011)

Bormotin, K.: An iterative method for solving geometrically nonlinear inverse problems of forming structural components in creep. Comput. Math. Math. Phys. 53(12), 1908–1915 (2013)

Wriggers, P. (ed.): Computational Contact Mechanics. Springer, Heidelberg (2006)

Vasil’ev F. (ed.): Optimization Methods. Faktorial Press, Moscow (2002)

Moiseev, N. (ed.): Elements of the Theory of Optimal Systems. Nauka, Moscow (1974)

Tsvelodub, I.: On optimal ways of deformation under creep conditions. Some applications to the problems of processing materials by pressure. Izv. USSR Acad. Sci. Mech. Solids 6, 128–136 (1987)

Acknowledgments

This research was financially supported from the Ministry of Education and Science of the Khabarovsk Territory of the Russian Federation (No. 74C/2020 from 24.08.2020).

The study was carried out using the equipment of the Center for Collective Use “New Materials and Technologies” on the basis of KnASU.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bormotin, K.S. (2021). Modeling and Optimization of Forming Processes of Aircraft Engineering Thin-Wall Structures. In: Shakirova, O.G., Bashkov, O.V., Khusainov, A.A. (eds) Current Problems and Ways of Industry Development: Equipment and Technologies. Lecture Notes in Networks and Systems, vol 200. Springer, Cham. https://doi.org/10.1007/978-3-030-69421-0_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-69421-0_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69420-3

Online ISBN: 978-3-030-69421-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)