Abstract

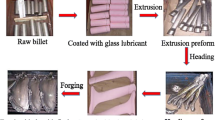

The connecting rod is one of the most important parts in the engine, which plays a key role in the normal operation of the engine. High strength aluminum alloy was selected as raw materials for production in this program, and multi-wedge cross wedge rolling was applied for forming an engine connecting rod by numerical simulation, to explore the deformation mechanism and defect generation mechanism and its influencing factors. It is will be beneficial for subsequent forging connecting rod to provide quality assurance and provide the reference for the production of aluminum alloy connecting rod.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Hong, S.Z., Zeng, Z.P.: Application and development of cross wedge rolling process. Die Mould Technol. 32(5), 97–99 (2000)

Lou, Y.Z., Zhang, K.S., Yang, C.P., et al.: Effect of process parameters on axial parts with super large area reduction during twice cross wedge rolling. J. Univ. Sci. Technol. Beijing 30(4), 432–435 (2008)

Lu, H.Y., Yan, H.J., Zhang, S.J., et al.: Reserch on optimization of rolling curve for multi-step shaft in cross wedge rolling. Foring Stamping Technol. 44(12), 41–48 (2019)

Zeng, J., Xu, C.G., Ren, W.W., et al.: Effect of process parameters on concavity depth of rolled piece by cross wedge rolling under defferent end shapes. J. Plast. Eng. 24(2), 111–117 (2017)

Hu, Z.H., Zhang, W.: Development of part rolling technology in China. J. Mech. Eng. 48(18), 7–12 (2012)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Zhang, KX. et al. (2021). Numerical Simulation of Aluminum Alloy Connecting Rod with Multi-wedge Cross Wedge Rolling. In: Zheng, L., Sun, C., Goh, KL. (eds) Proceedings of MEACM 2020. MEACM 2020. Mechanisms and Machine Science, vol 99. Springer, Cham. https://doi.org/10.1007/978-3-030-67958-3_16

Download citation

DOI: https://doi.org/10.1007/978-3-030-67958-3_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-67957-6

Online ISBN: 978-3-030-67958-3

eBook Packages: EngineeringEngineering (R0)