Abstract

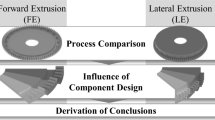

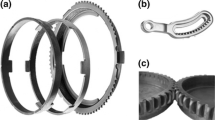

The rising demands on forming processes regarding the functional integration of components and lightweight construction pose a challenge to conventional processes. In that context, the application of bulk forming operations on sheet metal semi-finished products - also referred to as sheet-bulk metal forming (SBMF) - is a suitable approach to meet these challenges. One of the most relevant industrial forming processes is the cold extrusion, which enables a high material and energy efficiency. Furthermore, extruded components show beneficial mechanical properties, a high surface quality and can be produced with a near net-shape geometry. However, the application of cold forming processes for SBMF is limited due to an insufficient die filling and high tool loads. In order to meet these challenges and overcome resulting limitations, it is necessary to enhance the process understanding. This is achieved by establishing two different reference processes (forward and lateral extrusion) for the manufacturing of functional integrated geared components and the basic analysis of the occurring material flow and tool load in sheet-bulk metal forming processes. Through a combination of numerical and experimental analysis, similarities and differences between both processes are investigated. It is shown that design parameters, tribological conditions, as well as process parameters, substantially influence the process result, regarding achievable accuracy and tool load. The gained process understanding is used to identify limitations and to derive measures to expand the process boundaries.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kleiner, M., Geiger, M., Klaus, A.: Manufacturing of lightweight components by metal forming. CIRP Ann. 2(52), 521–542 (2003)

Merklein, M.; Allwood, J.M.; Behrens, B.-A.: Bulk forming of sheet metal. CIRP Ann. Manuf. Technol. 2(61), 725–745 (2012)

Tekkaya, A.E., Khalifa, N.B., Grzancic, G.: Forming of lightweight metal components: need for new technologies. Procedia Eng. 81, 28–37 (2014)

Gruber, M., Lebaal, N., Roth, S., Harb, N., Sterionow, P., Peyraut, F.: Parameter identification of hardening laws for bulk metal forming using experimental and numerical approach. Int.J. Mater. Form. 9(1), 21–33 (2014)

Ingarao, G.;Di Lorenzo, R.: Design of Complex Sheet Metal Forming Processes: A New Computer Aided Progressive Approach. International Journal of Material Forming, S1(3), 21–24 (2010)

Schaper, M.; Lizunkova, Y.; Vucetic, M.: Sheet-bulk Metal Forming a New Process for the Production of Sheet Metal Parts with Functional Components. Metallurgical and Mining Industry, 3 (2011)

Lange, K., Kammerer, M., Pöhlandt, K.: Fließpressen: Wirtschaftliche Fertigung metallischer Präzisionswerkstücke. Springer, Heidelberg (2008)

Blesl, M., Kessler, A.: Energieeffizienz in der Industrie. Springer, Heidelberg (2017)

Klocke, F., König, W.: Fertigungsverfahren 4: Umformen. Springer, Berlin (2017)

Raedt, H.-W.: Leichtbau durch Massivumformung. Infostelle Industrieverband Massivumformung, Hagen (2004)

Schwager, A., Kammerer, M., Siegert, K.: Kaltumformen schräg innenverzahnter Hohlräder, pp. 517–531. Konferenzband Neuere Entwicklungen in der Massivumformung, Stuttgart (2003)

Marciniak, Z., Duncan, J.L., Hu, S.J.: 2 - Sheet deformation processes. In: Mechanics of Sheet Metal Forming (Second Edition). Marciniak, Z., Duncan, J.L., Hu, S.J. (eds.) Butterworth-Heinemann. pp. 14–29. Oxford (2002)

Locke, F., Raedt, H.-W.: Innovationen in der Feinschneidtechnik. Werkstattstechnik 6(92), 268–272 (2002)

Birzer, F.: Feinschneiden und Verfahrenskombinationen auf Feinschneid-pressen. in Internationale Konferenz “Neuere Entwicklungen in der Massivumformung. 2003. Fellbach: MATINFO Werkstoff-Informationsgesellschaft

Beisel, W., Oberste-Dommes, I., Precision embossing alternative method of forming flat parts. J. Mater. Process. Technol. 1(71), 18–24 (1997)

Kleiner, M., Chatti, S., Klaus, A.: Metal forming techniques for lightweight construction. J. Mater. Process. Technol. 1–3(177), 2–7 (2006)

Merklein, M., Opel, S., Chinesta, F.: Investigation of tailored blank production by the process class sheet-bulk metal formin, pp. 395–400 ( (2011))

Koch, J.: Grundlegende Untersuchungen zur Herstellung zyklisch-symmetrischer Bauteile mit Nebenformelementen durch Blechmassivumformung, J. Franke, M. Merklein, and M. Schmidt, Editors. 2016, Meisenbach: Bamberg

Gröbel, D.: Manufacturing of functional elements of varying shapes on blanks using extrusion as a Sheet-Bulk Metal Forming process. FAU University Press, Erlangen (2019)

Pilz, F.: Fließpressen von Verzahnungselementen an Blechen: Friedrich-Alexander-Universität Erlangen-Nürnberg (2019, submitted)

Pilz, F., Merklein, M.: Comparison of extrusion processes in sheet-bulk metal forming for production of filigree functional elements. CIRP J. Manuf. Sci. Technol. 26, 41–49 (2019)

Gröbel, D., Koch, J., Vierzigmann, H.U.: Investigations and approaches on material flow of non-uniform arranged cavities in sheet bulk metal forming processes. Procedia Eng. 81, 401–406 (2014)

Groche, P., Fritsche, D., Tekkaya, E.A.: Incremental Bulk Metal Forming. CIRP Ann. 2(56), 635–656 (2007)

Schafstall, H.: Verbesserung der Simulationsgenauigkeit ausgewählter Massivumformverfahren durch eine adaptive Reibwertvorgabe. Universität der Bundeswehr Hamburg, Aachen (1998)

Bambach, M.: Fast simulation of incremental sheet metal forming by adaptive remeshing and subcycling. Int. J. Mater. Forming, 3(9), 353–360 (2014)

Löffler, M., Engel, U., Willner, K.: Investigation of the tribolgocal behaviour of microstructures for controlling the material flow in sheet-bulk metal forming. CIRP J. Manuf. Sci. Technol. 22, 66–75 (2018)

DIN-Norm: Prüfung metallischer Werkstoffe - Druckversuch bei Raumtemperatur. Deutsches Institut für Normen (DIN), DIN 50106, Berlin: Beuth-Verlag (2016)

Groenbaek, J.;Birker, T.: Innovations in cold forging die design. J. Mater. Process. Technol. 2(98), 155–161 (2000)

Tekkaya, A.E.: A guide for validation of FE-simulations in bulk metal forming. Arabian J. Sci. Eng. 1(30), 113–136 (2005)

Pilz, F., Merklein, M.: Influence of component design on extrusion processes in sheet-bulk metal forming. Int. J. Mater. Forming (2019)

Pilz, F., Henneberg, J., Merklein, M.: Extension of the forming limits of extrusion processes in sheet-bulk metal forming for production of minute functional elements. Manuf. Rev. 7, 9 (2020)

Brinksmeier, E., Riemer, O., Twardy, S.: Tribological behavior of micro structured surfaces for micro forming tools. Int. J. Mach. Tools Manuf. 4(50), 425–430 (2010)

Esche, S.K., Khamitkar, S., Kinzel, G.L.: Process and die design for multi-step forming of round parts from sheet metal. J. Mater. Process. Technol. 1–2(59), 24–33 (1996)

Merklein, M., Hagenah, H., Schneider, T.: Sheet-bulk metal forming processes - state of the art and its perspectives. In: TTP 2013 - Tools and Technologies for Processing Ultra High Strength Materials, R. Kolleck, Editor. Verlag der TU Graz. 197–204 (2015)

Acknowledgment

This project was supported by the German Research Foundation (DFG) within the scope of the Transregional Collaborative Research Centre 73 for sheet-bulk metal forming (TCRC 73, Subproject A2) under grant number TRR73/3 68237143. The authors are also grateful to all laboratory assistants and students who supported the execution of this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Reck, M., Rohrmoser, A., Jobst, A., Pilz, F., Merklein, M. (2021). Forming of Complex Functional Elements on Sheet Metal. In: Merklein, M., Tekkaya, A.E., Behrens, BA. (eds) Sheet Bulk Metal Forming . TCRC73 2020. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-61902-2_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-61902-2_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-61901-5

Online ISBN: 978-3-030-61902-2

eBook Packages: EngineeringEngineering (R0)